- DL manuals

- Weider

- Home Gym

- PRO 4950

- User Manual

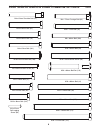

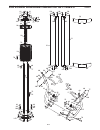

Weider PRO 4950 User Manual - Cable Assembly

16

24. Apply grease to an M10 x 110mm Bolt (93) and

a 90mm Spacer (59). Attach the Left Press Arm

(15) to the Right Press Arm (16) with the Bolt,

the Spacer, and an M10 Nylon Locknut (77).

Finish attaching the Press Arms (15, 16) with

two M10 x 63mm Bolts (79), two M10 Washers

(80), and two M10 Nylon Locknuts (77).

Do not

tighten the Nylon Locknuts yet.

Apply grease to an M10 x 110mm Bolt (93) and

a 90mm Spacer (59). Attach the Left and Right

Press Arms (15, 16) to the Right Base (1) with

the Bolt, the Spacer, and an M10 Nylon Locknut

(77).

Do not over tighten the Nylon Locknut;

the Press Arms must pivot freely.

Tighten the Nylon Locknuts (77) used in

this step.

25.

See the CABLE DIAGRAMS on page 32 and

33 to identify the cables as you assemble

them.

Identify the Butterfly Cable (50). Grease an

M8 x 22mm Shoulder Bolt (90). Attach the

Cable to the Left Butterfly Bracket (28) with the

Shoulder Bolt and an M8 Nylon Locknut (78).

Make sure the flat edge of the Cable is

against the Left Butterfly Bracket. Do not

overtighten the Shoulder Bolt; the Cable

must be able to pivot freely.

26. Wrap the Butterfly Cable (50) over a “V”-pulley

(47). Attach the “V”-pulley, a Long Cable Trap

(57), an M10 Washer (80), and two Guards (54)

to the Right Upright (2) with an M10 x 63mm

Bolt (79) and an M10 Nylon Locknut (77).

24

25

28

59

Grease

Grease

Grease

59

1

77

80

93

15

93

79

77

77

16

78

90

50

26

50

2

77 54

54

79

47 57

80

Cable Assembly

Flat Edge

Grease

Summary of PRO 4950

Page 1

Caution read all precautions and instruc- tions in this manual before using this equipment. Save this manual for future reference. • assembly • adjustments • troubleshooting • part list and drawing model no. 831.14623.0 serial no. Write the serial number in the space above for future reference. Weig...

Page 2: Table of Contents

Important precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 before you begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3: Warning:

1. Read all instructions in this manual and all warnings on the weight system before using the weight system. Use the weight system only as described in this manual. 2. It is the responsibility of the owner to ensure that all users of the weight system are ade- quately informed of all precautions. 3...

Page 4: Before You Begin

4 backrest curl pad shroud weight backrest adjustment knob military press arm seat adjustment knob curl adjustment knob butterfly arm seat right side left side note: the terms “right side” and “left side” are determined relative to a person facing away from the weight system; they do not correspond ...

Page 5: Part Identification Chart—

M10 nylon locknut (77) m8 washer (103) m8 nylon locknut (78) m6 washer (114) m4 washer (104) m4 x 12mm self-tapping screw (102) m4 x 16mm self-tapping screw (110) m6 x 16mm screw (88) m8 x 22mm shoulder bolt (90) m10 x 75mm button screw (118) m10 washer (80) m10 large washer (105) m12 large washer (...

Page 6: Part Identification Chart—

M6 x 60mm button screw (91) m8 x 75mm carriage bolt (83) m8 x 80mm bolt (100) m8 x 65mm bolt (101) m10 x 141mm bolt (141) m10 x 120mm bolt (115) m10 x 82mm button screw (92) m10 x 60mm bolt set (116) m4 x 25mm self-tapping screw (96) m10 x 90mm bolt (81) m10 x 75mm bolt (82) m10 x 82mm bolt (84) m10...

Page 7: Assembly

7 make sure you have the following tools: • two adjustable wrenches • one standard screwdriver • one phillips screwdriver • one rubber mallet • you will also need grease or petroleum jelly, a small amount of soapy water, and clear tape or masking tape. Note: assembly will be more convenient if you h...

Page 8: Frame Assembly

8 2. Insert six m8 x 75mm carriage bolts (83) up through the left base (119). Note: it may be helpful to place a piece of tape over each bolt head to hold it in place. 2 3 119 83 83 83 1 78 78 119 103 103 100 1 3. Attach the right base (1) to the left base (119) with two m8 x 80mm bolts (100), two m...

Page 9

9 5. Attach the right upright (2) to the right base (1) with two m8 nylon locknuts (78) and the two indicated m8 x 75mm carriage bolts (83). Do not tighten the nylon locknuts yet. 5 2 78 78 83 1 6. Orient the rear upright (121) so that the top bracket slopes toward the left upright (120). Attach the...

Page 10

10 7. Attach the right top frame (4) to the right upright (2) with two m8 x 80mm bolts (100), two m8 washers (103), and two m8 nylon locknuts (78). Do not tighten the nylon locknuts yet. 7 4 78 78 2 103 103 100 8. Attach the left top frame (126) to the rear upright (121), the left upright (120), and...

Page 11

11 10. Slide the two weight bumpers (71) onto the weight guides (18). Orient eleven weights (19) with the pin holes on the bottom as shown. Slide the weights onto the weight guides. Insert the weight tube cap (76) into the weight tube (20). Insert the weight tube into the eleven weights (19). Make s...

Page 12

12 12. Attach leg lever bumper (75) to the front leg (10) with an m4 x 16mm self-tapping screw (110) and an m4 washer (104). Attach the front leg (10) to the right base (1) with two m8 nylon locknuts (78) and the indi- cated m8 x 75mm carriage bolts (83). Do not tighten the nylon locknuts yet. 13. A...

Page 13: Arm Assembly

13 15. Attach the butterfly frame brace (6) to the right upright (2) with two m8 x 80mm bolts (100), two m8 washers (103), and two m8 nylon locknuts (78). Do not tighten the nylon locknuts yet. Attach the butterfly frame (5) to the right top frame (4) and the butterfly frame brace (6) with two m8 x ...

Page 14

14 18. Apply grease to the 44mm bushing (136) and an m10 x 68mm bolt (85). Then, insert the bushing into the military press frame (127). Attach the military press frame inside the left upright (120) with the bolt (85) and an m10 nylon locknut (77). Do not overtighten the nylon locknut; the military ...

Page 15

15 21. Apply grease to tw0 m10 x 82mm bolts (84) and to the indicated locations on the leg press frame (123) and the front leg press (132). Attach the leg press (124) to the leg press frame and the front leg press frame (123, 132) with the two bolts (84) and two m10 nylon locknuts (77). 22. Apply gr...

Page 16: Cable Assembly

16 24. Apply grease to an m10 x 110mm bolt (93) and a 90mm spacer (59). Attach the left press arm (15) to the right press arm (16) with the bolt, the spacer, and an m10 nylon locknut (77). Finish attaching the press arms (15, 16) with two m10 x 63mm bolts (79), two m10 washers (80), and two m10 nylo...

Page 17

17 27. Wrap the butterfly cable (50) under a 90mm pulley (48). Attach the pulley and two half guards (55) to the double “u”-bracket (61) with an m10 x 50mm bolt (97) and an m10 nylon locknut (77). Make sure the half guards are oriented as shown. 28. Wrap the butterfly cable (50) over a “v”-pulley (4...

Page 18

18 30. Identify the lat cable (49). Route the cable up through the left top frame (126) and over a 90mm pulley (48). Attach the pulley inside the left top frame with an m10 x 82mm bolt (84), two m10 washers (80), two 19mm spacers (67), and an m10 nylon locknut (77). 31. Route the lat cable (49) over...

Page 19

19 34. Wrap the lat cable (49) under a 90mm pulley (48). Attach the pulley and a cable trap (56) to the second hole in the “u”-bracket (151) with an m10 x 50mm bolt (97), two half guards (55), and an m10 nylon locknut (77). Make sure the cable trap and half guards are oriented as shown. 35. Wrap the...

Page 20

20 38. Wrap the lat cable (49) over a 90mm pulley (48). Attach the pulley to the top center frame (148) wtih an m10 x 45mm bolt (86) and an m10 nylon locknut (77). 38 77 48 49 86 148 39. Set an m12 large washer (98) on top of the weight tube (20). Thread the m12 nut (112) all the way onto the lat ca...

Page 21

21 42. Route the press cable (133) under a 90mm pulley (48). Attach the pulley and a cable trap (56) to the left frame (122) with an m10 x 116mm bolt (107), two half guards (55), an m10 washer (80), and an m10 nylon locknut (77). Make sure the cable trap and the half guards are oriented as shown. 43...

Page 22

22 46 47 85 80 109 109 10 80 77 48 55 51 55 bar 1 77 97 48 51 48 77 55 56 51 55 97 48 60 49. Wrap the leg lever cable (51) under a 90mm pulley (48). Attach the pulley to the right base (1) with an m10 x 50mm bolt (97), two half guards (55), and an m10 nylon locknut (77). Make sure the half guards ar...

Page 23

23 50 52 48 97 55 55 54 54 77 2 51 48 80 56 115 77 1 51 53 77 55 80 48 51 56 55 16 97 50. Wrap the leg lever cable (51) under a 90mm pulley (48). Attach the pulley to the right base (1) with an m10 x 50mm bolt (97), two half guards (55), and an m10 nylon locknut (77). Make sure the half guards are o...

Page 24: Seat Assembly

24 55 56 97 15 55 80 48 51 56 55 77 2 51 115 80 111 77 57 seat assembly 31 7 114 89 53 2 88 54. Wrap the leg lever cable (51) around a “v”- pulley (47). Attach the pulley to the right upright (2) with an m10 x 68mm bolt (85), two half guards (55), an m10 washer (80), a long cable trap (57), and an m...

Page 25

25 59 60 129 125 88 91 26 35 34 114 53 145 122 114 61 36 37 36 13 12 10 51 143 37 143 13 58. Attach the right seat (32) to the right seat frame (8) with two m6 x 16mm screws (88), an m6 x 32mm screw (89), and an m6 washer (114). Insert the right seat frame (8) into the right frame (9). Tighten the s...

Page 26

26 63 110 104 104 77 77 84 84 102 102 104 104 110 110 147 23 21 21 23 18 148 110 63. Attach a shroud (21) to the top center frame and bottom center base (148, 147) with four m4 x 12mm self-tapping screws (102). Note: it may be necessary to loosen the m10 nylon locknuts (77) and the two indicated m10...

Page 27

64. Attach the curl pad (33) to the curl post (11) with two m6 x 16mm screws (88). 65. Make sure that all parts have been properly tightened. The use of the remaining parts will be explained in adjustments, beginning on the following page. Before using the weight system, pull each cable a few times ...

Page 28: Adjustments

This section explains how to adjust the weight system. Refer to the accompanying exercise guide to see the cor- rect form for each exercise. Make sure that all parts are properly tightened each time the weight system is used. Replace any worn parts immediately. The weight system can be cleaned with ...

Page 29

Using the curl pad to use the curl pad (33), remove the indicated 50mm round inner cap (39) and insert the curl post (11) into the front leg (10). Tighten the curl adjustment knob (58) into the front leg. Make sure the curl adjustment knob passes through a hole in the curl post. When you are perform...

Page 30

30 locking the leg lever to lock or unlock the leg lever (12), remove the lock plate pin (95) from the lock plate (14). Move the lock plate to either the position shown on the front leg (10), or the indicated hole in the leg lever. Insert the lock pin back through the lock plate. 12 hole 95 14 10

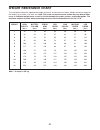

Page 31: Weight Resistance Chart

31 weight resistance chart the chart below shows the approximate weight resistance at each exercise station. Weight resistance shown for the butterfly arm station is for each arm. Note: the actual resistance at each station may vary due to differ- ences in individual weight plates as well as frictio...

Page 32: Cable Diagram

32 cable diagram the cable diagram shows the proper routing of the cables (49, 50, 133, 51). Use the diagram to make sure that the cable and the cable traps have been assembled correctly. If the cable has not been correctly routed, the weight system will not function properly and damage may occur. T...

Page 33

33 6 2 7 8 9 10 11 leg lever cable (51) length 265" / 672cm 1 3 4 5.

Page 34: Maintenance

34 make sure all parts are properly tightened each time the weight system is used. Replace any worn parts imme- diately. The weight system can be cleaned with a damp cloth and a mild, non-abrasive detergent. Do not use solvents. Tightening the cables woven cable, the type of cable used on the weight...

Page 35: Exercise Guidelines

35 exercise guidelines the four basic types of workouts muscle building to increase the size and strength of your muscles, push them close to their maximum capacity. Your mus- cles will continually adapt and grow as you progres- sively increase the intensity of your exercise. You can adjust the inte...

Page 36

36 rest for a short period of time after each set. The ideal resting periods follow: • rest for three minutes after each set for a muscle building workout. • rest for one minute after each set for a toning work- out. • rest for 30 seconds after each set for a weight loss workout. Plan to spend the f...

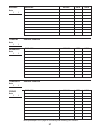

Page 37

Monday date: / / exercise weight sets reps exercise weight sets reps exercise weight sets reps aerobic exercise aerobic exercise tuesday date: / / wednesday date: / / thursday date: / / friday date: / / make photocopies of this page for scheduling and recording your workouts. 37.

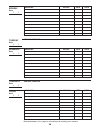

Page 38

Monday date: / / exercise weight sets reps exercise weight sets reps exercise weight sets reps aerobic exercise aerobic exercise tuesday date: / / wednesday date: / / thursday date: / / friday date: / / make photocopies of this page for scheduling and recording your workouts. 38.

Page 39

39 part list—model no. 831.14623.0 r0606a key no. Qty. Description key no. Qty. Description 1 1 right base 2 1 right upright 3 1 left backrest frame 4 1 right top frame 5 1 butterfly frame 6 1 butterfly frame brace 7 1 right backrest frame 8 1 right seat frame 9 1 right frame 10 1 front leg 11 1 cur...

Page 40

40 note: “#” indicates a non-illustrated part. Specifications are subject to change without notice. See the back cover of this manual for information about ordering replacement parts. Part list—model no. 831.14623.0 r0606a key no. Qty. Description key no. Qty. Description 107 1 m10 x 116mm bolt 108 ...

Page 41

41 15 16 17 17 23 40 40 48 48 55 55 55 55 56 56 59 77 77 106 77 80 80 80 80 80 80 80 93 93 77 97 97 77 77 79 80 77 99 99 99 99 99 80 80 106 106 23 21 21 110 104 110 104 110 104 110 104 110 104 81 80 77 77 80 77 80 77 18 72 73 112 98 20 76 71 71 19 81 49 84 80 77 84 77 80 80 108 108 108 108 80 78 78 ...

Page 42

63 64 64 60 48 48 55 55 56 56 60 77 97 55 55 49 67 80 77 86 77 38 38 67 80 77 78 78 78 78 97 77 83 83 83 78 78 78 78 53 3 42 41 41 31 88 89 114 103 100 100 103 100 103 80 67 84 84 67 48 97 55 55 77 56 48 48 80 48 97 48 56 80 77 55 55 53 80 55 80 55 88 56 74 74 114 77 77 54 80 48 48 56 54 38 74 74 77...

Page 43

62 1 2 4 6 7 8 9 10 11 12 13 13 14 25 27 28 31 32 33 34 36 36 37 37 39 39 38 113 113 41 41 42 43 44 46 46 45 45 47 47 47 48 48 48 48 48 48 48 50 51 51 52 58 53 54 54 54 55 55 55 55 55 55 55 55 55 54 54 56 57 57 57 59 61 65 66 109 109 68 68 109 68 68 74 74 75 78 78 77 78 78 78 78 78 77 74 77 77 77 77...

Page 44: 90 Day Full Warranty

Part no. 240547 r0606a printed in china © 2006 icon ip, inc. Your home for repair— in your home—of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories, and user’s manuals that you ...