- DL manuals

- Wonderfire

- Indoor Fireplace

- 961

- Installer And Owner Manual

Wonderfire 961 Installer And Owner Manual

5137994/03

©

GDC Group Ltd. 2011

Model 961

Inset live fuel effect gas fire

Incorporating the Wonderfire Premier

Control.

Fitted with one of the following fascia:

Bauhaus, Bloomsbury

or

Ebony.

(G.C. Number 32-032-88)

INSTALLER AND OWNER GUIDE

Please keep me in a safe place for future use.

We trust that this guide gives sufficient details to enable this appliance to be

installed, operated and maintained satisfactorily. However, if further information is

required, our Wonderfire premier Technical Helpline will be pleased to help.

Telephone 0844 8711 565 (National call rates apply in the United Kingdom).

In the Republic of Ireland Telephone 0044 844 8711 565.

Summary of 961

Page 1

5137994/03 © gdc group ltd. 2011 model 961 inset live fuel effect gas fire incorporating the wonderfire premier control. Fitted with one of the following fascia: bauhaus, bloomsbury or ebony. (g.C. Number 32-032-88) installer and owner guide please keep me in a safe place for future use. We trust th...

Page 2

© gdc group ltd. 2011. All rights reserved. No part of this publication may be reproduced in any material form (including photocopying), stored in any medium by electronic means (including in any retrieval system or database) or transmitted, in any form or by any means, whether electronic, mechanica...

Page 3

Safety first. Wonderfire premier fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. All wonderfire premier fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso 9001 quality...

Page 4

© gdc group ltd. 2011 page 4 installer guide for owner guide see pages 48 to 67 installer guide.

Page 5

Contents section heading page installer guide 4 - 47 owner guide 48 - 67 1. Images 7 2. Safety and unpacking 8 3. Appliance data, efficiency and nox 9 3.1 general information. 9 3.2 efficiency. 10 3.3 nox 10 4. General installation requirements 11 4.1 regulations, standards and law. 11 4.2 ventilati...

Page 6

Contents (continued) section heading page 12. Fitting the ceramic fuel effect 32 13. Fitting the window frame assembly 33 14. Operating and spillage checks 33 14.1 fitting the control knob extension on the bloomsbury model. 33 14.2 checking the control settings. 33 14.3 check for spillage. 34 14.4 f...

Page 7

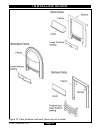

1. Image © gdc group ltd. 2011 page 7 ebony fascia bauhaus fascia bloomsbury fascia installer guide.

Page 8: Installer

2. Safety and unpacking installer before continuing any further with the installation of this appliance please read the following guide to manual handling. The approximate lifting weight (kg) of this appliance is as below: model heat engine firefront combined weight bauhaus 8.64 12.00 20.64 bloomsbu...

Page 9

3. Appliance data, efficiency and nox 3.1 general information. Under no circumstances is this fire to be converted to lpg. An lpg conversion kit does not exist for this gas fire. The appliance information label is located on a chained plate at the base of the fire. This can be seen by removing fire ...

Page 10

3.2 efficiency. The efficiency of this appliance has been measured as specified in bs 7977 - 1 and the result is as below: model efficiency % (gross) efficiency % (net) 961 80 89 the gross calorific value of the fuel has been used for this efficiency calculation. The test data from which it has been...

Page 11

4. General installation requirements 4.1 regulations, standards and law. The installation must be in accordance with these instructions. For the user’s protection, in the united kingdom it is the law that all gas appliances are installed by competent persons in accordance with the current edition of...

Page 12

4.2 ventilation requirements. Normal adventitious ventilation is usually sufficient to satisfy the ventilation requirements of this appliance. In gb reference should be made to bs 5871 part 2 and in ie reference should be made to the current edition of is 813 “domestic gas installations” which makes...

Page 13

4.7 fireplace preparation. 4.7.1 if the fireplace opening is an underfloor draught type, it must be sealed to stop any draughts. 4.7.2 the fireplace floor should be reasonably flat to ensure that the convection box can be installed without it rocking and so that a good seal can be made at the bottom...

Page 14

4.9 fireplace clearances. 4.9.1 the minimum height from the base of the fireplace opening to the underside of any shelf made from wood or other combustible materials is detailed below. For bauhaus and ebony models:- • for a shelf up to 150mm deep: minimum height = 700mm. • for a shelf deeper than 15...

Page 15

4.9.2 the minimum allowable distance from the outside of the appliance fascia to a corner wall having combustible material or any other combustible surface which projects beyond the front of the appliance is shown in figure 5. A 10mm access clearance from a non-combustible surface is necessary at th...

Page 16

4.10 installation options. In the united kingdom, as supplied, the appliance can be installed in the following situations: - 4.10.1 conventional fireplace and hearth. To a fireplace complete with surround and hearth as shown in figure 6 and complying with bs1251 after removal of the fireback and suf...

Page 17

4.10.1.1 ‘hole-in-the-wall’ installations. It is recommended that a hearth should be installed as in section 4.8. If a reduced depth hearth is fitted, the fire must be installed so that the distance from the base of the fireplace opening in the wall to the finished floor level is at least 100mm. It ...

Page 18

4.10.3 precast concrete or clay flue block system and hearth. The appliance can be installed to a precast concrete or clay flue block system conforming to bs en 1858 with dimensions as in figure 9. Bs 1289 part 1 recommends there should be an air space or insulation between the flue blocks and the p...

Page 19

4.11 flues. 1. Suitable flues and minimum flue sizes are as follows: it should be noted that, as with many appliances, sharp bends or horizontal runs in metal flues at the top of the system can be a cause of problems in these types of installation. 225mm x 225mm conventional brick flue. 125mm or 175...

Page 20

5. Pack contents 1 burner and convection box unit. 1 burner tray trim. 1 outlet baffle for the convected air outlet. 2 tapping screws for outlet baffle. 1 nut and olive for 8mm inlet pipe. 1 ‘t’ connector and pressure test point. 1 flue restrictor. 3 tapping screws (for flue restrictor). 2 small “u”...

Page 21

© gdc group ltd. 2011 page 21 figure 10. Pack contents (items are not to scale- continued on next page) installer guide.

Page 22

© gdc group ltd. 2011 page 22 figure 10. Pack contents continued (items are not to scale) installer guide.

Page 23

6. Fireplace check 6.1 soundness for appliance attachment. Two primary methods of retaining the appliance are provided: - 1) by fixing to the fireplace front surround. 2) using concealed tension cables fixed to the rear of the fireplace opening together with secondary fixing to the fireplace floor. ...

Page 24

7. Ignition check before attempting to install, it is worth checking that the electronic ignition system performs satisfactorily. Fit the alkaline battery to the ignition block located below the burner tray at the left side (see figure 11). The positive terminal (+) is to the bottom as you insert. D...

Page 25

9. Preparing appliance for installation 1. Unscrew and remove the knurled screw connecting the slider control arm to the burner module. Lift the slider control knob, moving the control arm away from the burner module. 2. Unscrew and remove the six screws that secure the window mounting frame and win...

Page 26

4. Fit the two “u” section seals to the bottom edges of the convection box side flanges (see figure 15). 5. It is important that the grommet supplied in the loose parts pack is fitted to the hole in the rear of the convection box (see figure 18). For concealed connection only: pierce the grommet to ...

Page 27

8. There is a length of self adhesive foam seal supplied with the fire. This will need to be fitted to the outer rear edges of the side and top flanges of the convector box. Cut a 485mm length of foam seal. Be careful not to stretch the seal when measuring. Remove the protective backing from the foa...

Page 28

4. Remove the convection box. Drill four holes in the fireplace front surround at the marked positions using a suitably sized masonry drill for the fibre / wooden plugs supplied. 5. Insert a fibre / wooden plug into each hole. 6. Place the convection box back in position in the fireplace. 7. Fit a w...

Page 29

6. Thread the cables through the eyebolts. Return the cables through the holes near the bottom of the convection box back panel (see figure 22). 7. Place the convection box fully back into the fireplace opening so that it is sealed against the fireplace front surround. 8. Drill a hole into the firep...

Page 30

11. Pull each cable taut. Push the cable retainers hard up against the back panel. The end of the cable adjuster will pass into the hole. Tighten the screws in the retainers so that they clamp the cables in position. Apply tension to the cables by turning the hexagonal adjusters by hand (see figure ...

Page 31

11. Burner and supply pipe installation 11.1 burner and supply pipe installation. 1. Refit the burner unit to the convection box with the two screws removed previously. 2. Connect the supply line to the appliance. 3. If closed , open the isolating valve at the inlet ‘t’ connector. 4. Turn on the gas...

Page 32

11.3 inlet pressure check. The appliance is pre-set to give the correct heat input at the inlet pressure shown in section 3 of this guide. No adjustment is necessary. 1. Ensure that the appliance is off, then fit a pressure gauge at the test point (see figure 27). 2. Check the pressure with the appl...

Page 33

13. Fitting the window frame assembly 1. Locate the window mounting frame and window assembly in place. 2. Secure in place using the six screws removed previously. 14. Operating and spillage checks 14.1 fitting the control knob extension bracket on the bloomsbury model. 1. Unscrew and remove the two...

Page 34

14.2 checking the control settings. Please note: when first turned on from cold, the flames will appear predominantly blue. It is normal for condensation to form on the rear of the window assembly. The condensation will disappear after a few minutes use. When operating the fire for the first time, s...

Page 35

Not drawn into the appliance inspect the sealing to the fireplace surround. If the sealing is satisfactory but the appliance is installed with the flue restrictor (see section 9 point 7) remove the restrictor, reseal the appliance and retest. If smoke is still not drawn into the appliance disconnect...

Page 36

15. Outlet baffle and fascia fitting 15.1 fitting the outlet baffle. Locate the outlet baffle and secure in place using two tapping screws supplied (see figure 32). Before fitting the fascia ensure that the information on the back pages of the owner guide have been completed. Please remove all prote...

Page 37

3. For bloomsbury and ebony models. Secure the bottom of the fascia using two knurled screws (see figure 34). Please note that on bloomsbury and ebony models that the casting is not expected to sit flat against the fixing bracket. Tighten the knurled screws sufficiently to retain the casting, over t...

Page 38

16. Final review 1. Complete the information in the warranty and service section of the owner guide (see last pages of the owner guide). 2. Visually inspect the appliance. Clean off any marks incurred during installation. 3. Advise the customer how to operate the appliance. Explain to the customer t...

Page 39

17. Servicing and parts replacement always turn off the gas supply before commencing any servicing and allow to cool completely. (the appliance inlet ‘t’ connector incorporates an isolating valve). It is recommended that, at least once a year, the appliance is disconnected and the fireplace opening ...

Page 40

17.1 checking the aeration setting of the burner. 1. The aeration shutter is factory set. It is important to ensure that the aeration setting is correct (see figure 35). 2. To adjust the aeration setting loosen the two aeration shutter screws, slide the aeration shutter to the desired position and t...

Page 41

17.4 to remove the fascia. For bloomsbury and ebony models. 1. Remove the bottom front cover and the fire front casting. 2. Remove the two knurled screws securing the bottom of the fascia to the sides of the convection box (see figure 38). 3. Carefully lift the fascia upward to clear the upper retai...

Page 42

17.5 to replace the control slide unit. 1. Remove the fascia (see section 17.4). 2. Remove the knurled screw securing the control linking arm to the burner (see figure 39). 3. Detach the slide unit by removing two screws securing it to the convection box flange (see figure 40). 4. Replace in the rev...

Page 43

17.7 to remove and fit the window mounting frame and window assembly. When servicing the appliance it will be necessary to remove all of the window mounting frame and the window assembly to enable the front coal, ceramic walls and burner to be removed. 1. Remove the fascia as in section 17.4. 2. Uns...

Page 44

17.9 to remove the fuel effect. All of the fuel effect components except the front coal and ceramic walls can be removed by simply removing the window assembly as in this section 17.8. If the front coal or ceramic walls are to be replaced it will be necessary to remove the window frame and window as...

Page 45

17.12 to remove the complete burner unit. 1. Remove the window frame and window assembly as in section 17.7. 2. Remove the ceramic fuel effect as in section 17.9 3. Close the isolating valve in the inlet ‘t’ connector. Support the inlet ‘t’ connector to avoid straining the pipework and disconnect th...

Page 46

17.15 to remove the shut-off tap. (see figure 47). 1. Remove the burner unit (see section 17.12). 2. If lying the burner on its back, ensure that the work surface is suitably protected this will avoid damage to the work surface. Turn the burner unit upside down. Detach the thermocouple and interrupt...

Page 47

4. Detach the burner pipe from the controller. Support the controller while detaching to prevent excessive strain. 5. Remove the nut and washer securing the control pivot bracket to the controller at the front. Support the pivot bracket while removing the nut to prevent possible damage to the micros...

Page 48

© gdc group ltd. 2011 page 48 owner guide for warranty and service information see pages 61 to 67 owner guide.

Page 49

List of contents section page images 50 safety 51 gas consumption 53 appliance dimensions 54 operating your fire 55 the oxysafe flame sensing and flue blockage safety system. 55 to light the fire. 55 to turn the fire off. 56 lighting with a taper. 56 help and advice 57 ignition - lighting the fire. ...

Page 50

Images © gdc group ltd. 2011 page 50 ebony fascia bauhaus fascia bloomsbury fascia owner guide.

Page 51

Safety do have the fire installed by a competent person. In the united kingdom, installation must be in accordance with the latest edition of the gas safety (installation & use) regulations. In the republic of ireland, installation must be in accordance with all national and local regulations in for...

Page 52

Do provide a suitable guard that complies with bs 8423 for the protection of young children, the elderly and the infirm. Such a guard is also recommended for the protection of pet animals. (although this fire conforms to all the applicable standards, it is a heating appliance and certain parts of it...

Page 53

Gas consumtion gross figures model 961 has a maximum natural gas input of 5.0kw has a maximum natural gas output of 4.0kw has a minimum natural gas input of 2.5kw has a minimum natural gas output of 1.9kw net figures model 961 has a maximum natural gas input of 4.5kw has a maximum natural gas output...

Page 54

Appliance dimensions © gdc group ltd. 2011 page 54 figure 2. Appliance dimensions and clearances (the fascia may differ from that shown and dimensions are subject to manufacturing tolerances) key description model bauhaus bloomsbury ebony a height (mm) 616 741 616 b width (mm) 518 588 518 c depth in...

Page 55

Operating your fire the oxysafe flame sensing and flue blockage safety system. For your safety, this appliance is fitted with a flue blockage safety device which will shut down the appliance in the event of abnormal flue conditions. This device is not a substitute for an independently mounted carbon...

Page 56

3. If low heat is required, release the button. The button will automatically spring up to the low heat position shown in figure 3 (see note i below). If for any reason the slider control does not spring up, raise the slider to the off (o) position (topmost position) and contact your installer. Do n...

Page 57

Help and advice ignition - lighting the fire. When you depress the fireslide control you should hear a faint ticking sound from the bottom of the fire. This is the sound of the ignition spark that lights the gas. If there is no ticking sound it may be that the alkaline battery in the electronic spar...

Page 58

Cleaning your fire to maintain the high performance and quality finish of your fire please follow these guidelines: before attempting to clean the fire, please remember to turn off the fire and wait for the appliance to cool. The fire will retain heat for some time before cleaning can begin. If any ...

Page 59

1. The window assembly is held in place with two clamping brackets that rotate around a central pivot point. Push the brackets up and clear of the window assembly (see figure 5). Gently pull the top of the window frame forward and lift the window assembly clear of its support channels (see figure 6)...

Page 60

We suggest that you remove the ceramic fuel effect pieces in the reverse order to that shown in the ceramic fuel effect installer and owner guide. Once cleaned replace the fuel effect as in ceramic fuel effect installer and owner guide. Burner. To gain access to the burner the window assembly and ce...

Page 61

Regular maintenance. In order to achieve and maintain high levels of personal safety and performance efficiency, it is essential that the opening at the back of the fire and the flue are kept clear of any form of obstruction. It is possible that deposits of mortar or soot could fall and accumulate c...

Page 62

What you need to do if you experience a problem with the operation of the fire: 1. If the problem arises within 90 days of installation please contact your installer, because the cause of the fault may be related to the installation. 2. If your installer confirms that the installation has been under...

Page 63

11. Gas fires must have an annual service, commencing 12 months after date of purchase by a gas safe registered operative irrespective of use. 12. Proof of the completed services (if performed by third parties other than heateam) must be logged within the warranty booklet, along with the gas safe op...

Page 64

© gdc group ltd. 2011 page 64 owner guide.

Page 65

© gdc group ltd. 2011 page 65 owner guide.

Page 66

© gdc group ltd. 2011 page 66 where to find the information label. To be completed by the installer: installer details (block capitals) installer name gas safe register number. Company name. Company address company telephone number company fax number figure 8. Owner guide.

Page 67

© gdc group ltd. 2011 page 67 d d m m y y date of installation fascia code - can be found close to the information label (block capitals) model 9 6 1 fascia name (block capitals) owner guide serial number (a label containing this information may have been placed below or can be found on the serial n...

Page 68

© gdc group ltd. 2011.