- DL manuals

- Wonderfire

- Indoor Fireplace

- AC 16 NV

- Installer And Owner Manual

Wonderfire AC 16 NV Installer And Owner Manual

5134830/03

AIRFLAME

©

Baxi Heating U.K. Limited 2009.

MODEL

PRODUCT CODE

AF 16 NV

9500298 (coal)

0505411 (log)

AC 16 NV

9500296 (coal)

0505511 (log)

0503611 (pebble)

AF 18 XL

9500360 (coal)

AC 18 XL

9500361 (coal)

MODEL

PRODUCT CODE

AF 16 NV RC

0505601 (coal)

0505611 (log)

AC 16 NV RC

0505701 (coal)

0505711 (log)

AF 18 XL RC

0505301 (coal)

AC 18 XL RC

0505901 (coal)

MODEL

PRODUCT CODE

AC 16 NV TC

05036T1 (coal)

0505811 (log)

MODEL

PRODUCT CODE

AF 16 NV 5” Leg

9505298 (coal)

We trust that this guide gives

sufficient details to enable this

appliance to be installed, operated

and maintained satisfactorily.

However, if further information is

required, our

Wonderfire Premier Technical

Helpline will be pleased to help.

Telephone 0844 8711 554. (National

call rates apply in the United

Kingdom).

In the Republic of Ireland

Telephone 0044 844 8711 554.

INSTALLER: Please leave this guide with the owner

INSTALLER AND OWNER GUIDE

Summary of AC 16 NV

Page 1

5134830/03 airflame © baxi heating u.K. Limited 2009. Model product code af 16 nv 9500298 (coal) 0505411 (log) ac 16 nv 9500296 (coal) 0505511 (log) 0503611 (pebble) af 18 xl 9500360 (coal) ac 18 xl 9500361 (coal) model product code af 16 nv rc 0505601 (coal) 0505611 (log) ac 16 nv rc 0505701 (coal)...

Page 2

© baxi heating u.K. Limited 2009. All rights reserved. No part of this publication may be reproduced in any material form (including photocopying), stored in any medium by electronic means (including in any retrieval system or database) or transmitted, in any form or by any means, whether electronic...

Page 3

Safety first. Wonderfire premier fires are ce approved and designed to meet the appropriate british standards and safety marks. Quality and excellence. Wonderfire premier fires are manufactured to the highest standards of quality and excellence and are manufactured under a bs en iso 9001 quality sys...

Page 4

Page 4 © baxi heating u.K. Limited 2009. Installer guide for owner guide see pages 40 to 59 installer guide.

Page 5: Contents

Contents section page installer guide 4 - 39 owner guide 40 - 59 1. Safety 7 2. Lpg conversion 8 3. Appliance data and efficiency 9 3.1 general information. 9 3.2 efficiency. 10 4. General installation requirements 11 4.1 regulations, standards and law. 11 4.2 ventilation requirements. 12 4.3 the at...

Page 6: Contents (Continued)

7. Burner and supply pipe installation 26 8. Fitting the ceramic fuel effect 27 9. Full operational checks 27 9.1 general information. 27 9.2 checking the operation of the manual control burner. 27 9.2.1 to light the pilot. 27 9.2.2 lighting the main burner. 27 9.2.3 controlling the heat setting. 28...

Page 7: 1. Safety

1. Safety this product uses fuel effect pieces and burner (ac models also include a burner compartment rear wall) containing refractory ceramic fibres (rcf), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause irritation to eyes, skin and respiratory tract. C...

Page 8: 2. Lpg Conversion

Always grip with the palm of the hand. Do not use the tips of fingers for support. Always keep the fire as close to the body as possible. This will minimise the cantilever action. Use gloves to provide additional grip. Always use assistance if required. 2. Lpg conversion the following conversion kit...

Page 9

3. Appliance data and efficiency 3.1 general information. Page 9 © baxi heating u.K. Limited 2009. Model gross heat input (kw) inlet pressure (to be taken on max. Setting with the fire cold). Injector size min. Max. Af16nv (coal or log) ac16nv (coal or log) ac16nv tc (coal or log) af16nv 5” leg (coa...

Page 10

3.2 efficiency. The efficiency of this appliance has been measured as specified in bs 7977 - 1 and the result is as below: model efficiency %(gross) model efficiency %(gross) ac 16 nv rc 53 ac 16 nv 53 ac 18 xl rc 55 ac 18 xl 55 ac 16 nv tc 53 af models are not included above as they have a default ...

Page 11

4. General installation requirements 4.1 regulations, standards and law. The installation must be in accordance with these instructions. For the user’s protection, in the united kingdom it is the law that all gas appliances are installed by competent persons in accordance with the current edition of...

Page 12

Improper installation of this gas fire could be hazardous to health. This gas fire is to be used only in a properly flued, incombustible, masonry fireplace with the chimney or flue free from obstruction. 4.2 ventilation requirements. Ie only: this appliance must be installed in accordance with the c...

Page 13

Should the a.S.D be altered or bypassed in any way. Only a genuine manufacturer’s replacement part should be fitted. The individual a.S.D components are not replaceable. 4.4 fireguard requirements. A fireguard complying with bs 8423 should be fitted for the protection of young children, the elderly,...

Page 14

4.7.5 the appliance must not stand on combustible materials or carpets. 4.8 fireplace clearances. The minimum height from the base of the fireplace opening to the underside of any shelf made from wood or other combustible materials is as follows: - • for a shelf up to 150mm deep minimum height = 818...

Page 15

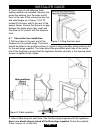

Page 15 © baxi heating u.K. Limited 2009. Installer guide figure 2. Hearth sizes..

Page 16

4.10 installation options. In the united kingdom, as supplied, the appliance can be installed in to a fireplace complete with a hearth complying with bs1251. The required hearth and clearance dimensions are shown in figure 2. (remove any existing heating appliance - when using a convection box it ma...

Page 17

Separator. For 16” fires - if this is not used then a 700mm long fender, kerb, horizontal bar, or other barrier, being fixed not less than 50mm above floor level and positioned 300mm in front of the fixing plane of the fire will meet the requirement. For 18” fires - if this is not used then a 760mm ...

Page 18: 5. Unpacking The Appliance

5. Unpacking the appliance carefully remove the contents. Check that all the listed parts are present and in good condition. Contents: 1 burner assembly. 1 ceramic fuel effect. 1 guarantee card. 1 smoke match tube. Af models only 1 loose parts pack (1 x fixing screw and fibre wall plug). Ac models o...

Page 19: Large Convection Boxes.

6. Sizes and installation of standard / large convection boxes. 6.1 general convection box information. The standard wonderfire premier convection box is designed to fit into fireplace openings between 16" and 18" and constructed in accordance with the requirements of bs1251. Any chairbrick / fireba...

Page 20

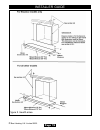

Page 20 © baxi heating u.K. Limited 2009. Installer guide figure 3. Convection box dimensions (the convection box may differ in design from that shown) key standard large a 530mm 590mm b 605mm 605mm c 410mm 470mm d 545mm 545mm e 405mm 475mm f 350mm 415mm g 255mm 225mm h 550mm 550mm j 395mm 395mm k 2...

Page 21

6.4 fireplace requirements. 6.4.1 fireplace opening and hearth dimensions. The fireplace opening should be as shown in figure 4. 6.4.2 fireplace size. The fireplace must comply with the requirements described in section 4. This will probably entail removing the fireback and infill material behind th...

Page 22

6.4.3 fireplace general condition. The fireplace floor should be reasonably flat to ensure that the convection box can be installed without it rocking and so that a good seal can be made at the bottom front of the box. The front face of the fireplace should be reasonably flat over the area covered b...

Page 23

Need remedial work - do not fit the appliance until there is a definite flow through the flue. 6.5 gas supply connection. A nut and olive are provided for an 8mm pipe inlet connection to the 't' connector at the bottom front of the appliance. The 't' connector includes a valve for isolating the gas ...

Page 24

4. Three strips of self adhesive foam sealing material are supplied. Remove the protective backing from the seals and fit them to the rear of the convection box top and side flanges as in figure 7 (on tc models fit the foam seal to the rear of the spacer frame). Ensure that there is no gap between t...

Page 25

Into the plugs. Make sure that the bolts are secure. 3. Place the convection box unit close to the fireplace but allow sufficient access into the fireplace opening so that the cables can be threaded through the eyebolts and returned through the back of the convection box. Insert the convection box i...

Page 26

6.8 sealing floor front - all installations. Using the floor sealing tape supplied, seal the bottom of the convection box to the base of the fireplace opening (and hearth where applicable) (see figure 9). Make sure that the whole length of the front edge of the convection box is fully sealed. On ele...

Page 27: 9. Full Operational Checks

8. Fitting the ceramic fuel effect the installer and owner guide for the ceramic fuel effect is supplied with the ceramic fuel effect. It is important that the fitting guide for the ceramic fuel effect be placed inside or attached to this guide and handed to the customer following completion of the ...

Page 28

9.2.3 controlling the heat setting. In order to change from one setting to another depress the control knob slightly and turn the knob to the required position. Alternatively, if a setting between low and high is required, then the control knob may be turned to this position. 9.2.4 to turn the fire ...

Page 29

(2) acoustic signals. After the second, longer acoustic signal, release the reset button. the subsequent 20 seconds press the (small flame) button on the handset until you hear an additional long signal confirming the code is set (please inform the customer that this is a one time setting as i...

Page 30

9.4 checking the operation of the top control (tc) burner. This fire may be controlled manually, by use of the controls mounted on the appliance. The flame settings may also be controlled by means of the touch button control on the upper right hand side of the fire. 9.4.1 preliminaries. 1. Remove th...

Page 31: 9.5 Inlet Pressure Check.

9.4.3 checking the heat settings. 1. Once the pilot light is established, light the main burner by turning the pilot burner control knob anti-clockwise to the "main burner on" position (number 3 in figure 12), and by then turning the main burner control knob to the high position (number 5 in figure ...

Page 32

The pressure gauge and replace the test point sealing screw. 5. Relight the appliance. Turn to the maximum output position and test around the sealing screw for gas soundness with a suitable leak detection fluid. When the above checks have been completed close the isolating valve on the inlet 't' co...

Page 33

Convection box / fireplace opening 30mm from either end of the convection box opening / fireplace opening as shown in figure 16. The installation is satisfactory if smoke is drawn into the convection box opening / fireplace opening. If smoke is not drawn into the convection box opening / fireplace o...

Page 34

In the room. Keep all doors and windows that open to the outside of the window closed. Recheck for spillage as above. If an extractor fan is installed in the same room as the appliance or a connecting room check that spillage does not occur with the fan operating and all doors and other openings bet...

Page 35: 11. Decorative Firefronts

11. Decorative firefronts if the appliance is not supplied with a decorative firefront a slotted firefront with a minimum free area as shown in figure 17 must always be used. For models supplied with a firefront, the open area may differ slightly from that stated in figure 17. In these cases the fir...

Page 36: 12. Final Review

Page 36 12. Final review 1. Complete the information in the warranty and service section of the owner guide (see last pages of the owner guide). 2. Visually inspect the appliance. Clean off any marks incurred during installation. 3. Advise the customer how to operate the appliance. Explain to the cu...

Page 37

13. Servicing & parts replacement this product uses fuel effect pieces and burner (ac models also include a burner compartment rear wall) containing refractory ceramic fibres (rcf), which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause irritation to eyes, skin ...

Page 38

13.2 to remove the injector. 1. Remove the decorative firefront. 2. Remove the ceramic ceramic fuel effect pieces. 3. Shut off the gas supply and disconnect the fire at the inlet "t" connector. 4. Detach the burner unit by removing the fixing nut / screw from the front leg of the burner. On top cont...

Page 39

13.5 to remove the convection box from the fireplace (for models fitted into a convection box). 1. Detach any decorative fascia from the convection box. 2. Remove the bottom decorative firefront. 3. Remove the ceramic ceramic fuel effect pieces. 4. Shut off the gas supply and disconnect the fire at ...

Page 40

Page 40 © baxi heating u.K. Limited 2009. Owner guide owner guide for warranty and service information see pages 53 to 59 this gas fire is designed to meet the most stringent quality, performance and safety requirements to provide you with many years’ trouble-free service. This guide aims to improve...

Page 41: List of Contents

List of contents section page safety 42 gas consumption 43 operating the fire 44 the oxysafe flame sensing & flue blockage safety system. 44 operating the manual control burner. 44 to light the pilot. 44 lighting the main burner. 45 controlling the heat setting. 45 to turn the fire back to pilot set...

Page 42: Safety

Safety do have the fire installed by a competent person. In the united kingdom, installation must be in accordance with the latest edition of the gas safety (installation & use) regulations. In the republic of ireland, installation must be in accordance with all national and local regulations in for...

Page 43: Gas Consumption

Become hot). Do wait three minutes before attempting to relight if the fire is switched off or the flames are extinguished for any reason. (your fire is fitted with a safety device that will automatically shut off the gas supply to the fire if, for any reason, the flames go out). Do get advice about...

Page 44: Operating The Fire

Operating the fire the oxysafe flame sensing & flue blockage safety system. For your safety, this appliance is fitted with a flue blockage safety device that will shut down the appliance in the event of abnormal flue conditions. This device is not a substitute for an independently mounted carbon mon...

Page 45

Once the pilot is lit, keep the control knob depressed for ten seconds to allow the flame supervision device to establish. When the control knob is released, the pilot should remain lit. If the pilot fails to remain lit, repeat the ignition procedure, this time keeping the control knob depressed for...

Page 46

Adjusting the flame height. When the burner is operating press the (large flame) button to increase the flame height and press the (small flame) to decrease the flame height. For fine adjustment press the / button for approximately two seconds until an acoustic signal is given, then release the butt...

Page 47

Operating the fire without the remote control handset. Lighting the burner in the event of battery failure. 1. To gain access to the gas valve remove the firefront cover / casting 2. The ‘main valve knob’ is the knob on the right hand side (see figure 2). Turn this knob to the ‘off’, fully clockwise...

Page 48

10. If the appliance will not operate, follow the instructions “to turn off” below and call the valor fires technical helpline 0844 8711 554. To turn off. To turn the fire off press the ‘on/off’ switch to the ‘o’ (off position). Operating the top control (tc) burner. This fire may be controlled by u...

Page 49

Controlling the heat setting. 1. Once the pilot light is established, light the main burner by turning the pilot burner control knob anti-clockwise to the "main burner on" position (number 3 in figure 4), and by then turning the main burner control knob to the high position (number 5 in figure 4). 2...

Page 50: Cleaning Your Fire

Mode (control knob pushed in) at the beginning of each operation and if running at the minimum rate setting, or to burn off any carbon deposits which may have built up after prolonged use of the minimum aerated setting. Cleaning your fire turn the fire off and allow it to cool completely before atte...

Page 51: Maintenance

Dust back into the air. We suggest that you remove the ceramic fuel effect in the reverse order to that shown in the fuel bed installer and owner guide. Ceramic burner. Remove any deposits of soot or other foreign matter from the solid areas of the burner with a dry soft brush. Be careful not to bru...

Page 52

6. Replace the receiver top cover. Slide the receiver back into its housing. Changing the batteries in the top control battery holder. Please note: in order to ensure maximum battery life and optimal performance, we recommend that only 'long life' alkaline type replacement batteries are used. 1. Rem...

Page 53: Warranty And Service

Warranty and service standard warranty terms & conditions the warranty is for 12 months subject to contract. In the united kingdom servicing can be carried out either by a heateam service engineer or a gas safe register engineer. You must register your fire with heateam, the service division of baxi...

Page 54

When calling heateam, it would be helpful if you could have the following information to hand:- 1. Fire serial number and fascia code (located on the information label - see figure 8 on page 59)*. 2. Date of installation* 3. Your installer name and address details* 4. Fire make and model number* 5. ...

Page 55

Page 55 © baxi heating u.K. Limited 2009. Owner guide.

Page 56

© baxi heating u.K. Limited 2009. Page 56 owner guide.

Page 57

Page 57 © baxi heating u.K. Limited 2009. Owner guide.

Page 58

Page 58 © baxi heating u.K. Limited 2009. Owner guide model product code please tick af 16 nv 9500298 (coal) 0505411 (log) ac 16 nv 9500296 (coal) 0505511 (log) 0503611 (pebble) af 18 xl 9500360 (coal) ac 18 xl 9500361 (coal) af 16 nv rc 0505601 (coal) 0505611 (log) ac 16 nv rc 0505701 (coal) 050571...

Page 59

Page 59 © baxi heating u.K. Limited 2009. D d m m y y brand baxi valor wonderfire premier date of installation serial number (can be found on information label - see figure 8) fascia name (block capitals) fascia code - can be found on information label (block capitals) figure 8. Information label lo...

Page 60

© baxi heating u.K. Limited 2009..