Woodbridge fireplace inc. Installation and operating instructions direct vent gas fireplace with electronic ignition system report # 401-s-05-4 models: (b,h)dv2000(n,p)-e, (b,h)dv3000(n,p)-e – do not store or use gasoline or other fl ammable vapors and liquids in the vicinity of this or any other ap...

Contents important safety information .......................... 3 product features............................................ 5 code approval ................................................ 5 pre-installation information............................. 6 installing above 2000 feet .....................

4. Never install the fireplace • in a recreational vehicle • where curtains, furniture, clothing, or other flammable objects are less than 42" from the front, top, or sides of the fireplace • in high traffic areas • in windy or drafty areas 5. This fireplace reaches high temperatures. Keep children ...

Important safety information continued from page 3 12. Do not use this fireplace to cook food or burn paper or other objects. 13. Never place anything on top of fireplace. 14. Do not use any solid fuels (wood, coal, paper, cardboard, etc.) in this fireplace. Use only the gas type indicated on rating...

Product features and code approval • this appliance has been certified for use with either natural or propane gas. See appropriate data plates. • this appliance is not for use with solid fuels. • the appliance is approved for bed- room or bedsitting room installa- tions. • this appliance is mobile h...

Pre-installation information installing above 2000 feet • in the usa, the appliance must be derated 4% for every 1,000 ft above 2,000 ft elevations. • in canada, these appliances are certified for altitudes of 0 – 4,500 ft. Orifice sizes, pressures and btus natural gas propane gas manifold press: (w...

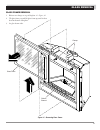

fireplace framing firebox framing can be built before or after the appliance is set in place. Construct firebox framing following figure 2 and the chart below for your specific installation requirements. See figure 3 on page 8 for firebox dimensions. The framing headers...

pre-installation information figure 3 - fireplace dimensions a b c d e f model front rear height glass number width width height standoff depth area 8 9 bdv3000 ne 37" 22" 33-5/16" 36-5/16" 18-1/4" 580 sq. In. Bdv3000p e 37" 22" 33-5/16" 36-5/16" 18-1/4" 580 sq. In. Bdv2000ne 33" 20-1/2"...

pre-installation information fireplace location plan for the installation of your appliance. This includes determining where the unit is to be installed, the vent configuration to be used, framing and finishing details, and whether any optional accessories (i.E. Blower, wall switch...

The fireplace must be secured to the floor and/or to framing studs as shown in figure 5. Use two (2) wood screws or masonry/ concrete screws to secure fireplace to the floor. Use four (4) screws to attach fireplace to framing. The side brackets are adjustable from 1/2" to 5/8" to accommodate differe...

12" maximum depth 11"minimum 72" minimum minimum 7" from both side walls clearances clearances to combustibles mantel clearances note: the combustible area above the facing must not protrude more than 3 / 4 " from the facing. If it does, it is considered a mantel and must meet the mantel requirement...

Installation precautions consult local building codes before beginning the installation. The installer must make sure to select the proper vent system for installation. Before installing vent kit, the installer must read this fireplace manual and vent kit instructions. Only a qualified installer/ser...

vent installation figure 7 - combustible clearances for vent pipe a minimum of 3" clearance to the top is required along horizontal length of pipe until flue pipe goes through nearest wall. Warning this fireplace must be vented to the outside. The venting system must never be attached to...

Vent installation installation planning there are two basic types of direct-vent installation: • horizontal termination • vertical termination it is important to select the proper length of vent pipe for the type of termination you choose. It is also important to note the wall thickness. For horizon...

vent installation figure 8 - horizontal vent termination location vent terminal air supply inlet area where terminals not permitted inside corner detail for horizontal termination minimum di...

...

16 l100001 17 figure 12 - vent opening requirements note: horizontal runs of vent must be supported every three feet (914mm). Use wall straps for this purpose. Figure 13 - rigid vent pipe connections female locking lugs male slots rear wall vent installation when installed as a rear vent...

Hot hot vent installation 4. Apply a bead of non-hardening mastic around the outside edge of vent cap. Position the vent cap in the center of hole on the exterior wall with the word “up” on the vent cap facing up. Insure proper clearance of 1" to combustibles is maintained. Attach the vent cap with ...

Vent installation horizontal termination configurations — rigid venting since it is very important that the venting system maintain its balance between the combustion air intake and the flue gas exhaust, certain limitations as to vent configurations apply and must be strictly adhered to. The vent gr...

7'6" a b • if a 90° elbow is used in the horizontal vent run (level height maintained) the horizontal vent length is reduced by 36" (914 mm) (fig. 21 a and b) this does not apply if the 90° elbows are used to increase or redirect a vertical rise. See figure 19. Example: according to the vent graph (...

Vent installation below grade installations — rigid venting when it is not possible to meet the required vent terminal clearances of 12" above grade level, a snorkel kit is recommended. It allows installation depth down to 7" (178mm) below grade level. The 7" (178mm) is measured from the center of t...

Restrictor disk vertical through-the-roof applications — rigid venting only this gas fireplace has been approved for, • vertical installations up to 40' (12m) in height. Up to a 10' (3m) horizontal vent run can be installed within the vent system using a maximum of two 90° elbows. See figure 25. Fig...

22 l100001 l100001 23 9” 9” vent installation installation for vertical termination 1. Determine the route your vertical venting will take. If ceiling joist, roof rafters or other framing will obstruct the venting system, consider an offset. See figure 27 to avoid cutting load bearing members. Note:...

Vent installation 4. Connect a section of pipe and extend up through the hole. Note: if an offset is needed to avoid obstructions, you must support the vent pipe every three (3) feet. Use wall straps for this purpose. See figure 25, page 22. Whenever possible, use 45° elbows instead of 90° elbows. T...

• • • do not crimp or rupture liner when bending it into chimney offsets. W arning • vent must meet all vent manufacturer’s requirements when installed. • make sure you have the following before installing unit: exhaust inlet maximum height 40' (12.9 m) minimum height 10' (3 m) maximum 1' (305mm) of...

Chimney flex vent extra 3" (914mm) flex vent chimney chimney excess flex vent slack in flex vent excess slack taken out of flex vent 3. Route flex vent through chimney figure 33a - placing figure 33b - attaching flex vent installation 2 . Have the fireplace and all parts required for installation re...

(propane/lp only) fireplace installation check gas type use proper gas type for the fireplace you are installing. If you have conflicting gas type, do not install fireplace. See dealer where you purchased the fireplace for proper fireplace for your gas type or conversion kit. Installing gas piping t...

fireplace installation a listed manual shutoff valve must be installed upstream of the appliance. Union tee and plugged 1 / 8 " npt pressure tapping important: install main gas valve (equipment shutoff valve) in an accessible location. The main gas valve is for turning on or shutting off...

Checking gas pressure 1. Check gas type. The gas supply must be the same as stated on the appliance’s rating decal. If the gas supply is different from the fireplace, stop! Do not install the appliance. Contact your dealer immediately. 2. To ease installation, a 30" (mm) flex line with manual shut-o...

Electrical installation electrical wiring electrical connections should only be performed by a qualified, licensed electrician. Main power must be off when connecting to main electrical power supply or performing service. All wiring shall be in compliance with all local, city, and state codes. The a...

Glass removal glass frame removal 1. Release two clamps on top of fireplace. See figure 36. 2. Tilt glass frame out and lift glass frame up until it clears bottom channel of fireplace. 3. Set glass frame aside. Figure 36 - removing glass frame glass frame bottom channel clamps 28 31.

Final installation rock wool placement 1. Place rock wool on burner to provide glowing embers. For best results, pull the rock wool apart into pieces the size of a nickel or smaller. 2. Distribute one layer of rock wool to cover the entire burner. Fill front gap between grate and burner. See figure ...

Final installation 4. Place bottom right log (#4) in front of rear log. Line up the holes in the bottom right log with the pins on the log support bracket. See figure 41. 5. Place back end of bottom center log (#5) on right notch of rear log. Rest front “y” shape on burner as shown in figure 42. Imp...

Top right log #6 final installation figure 44 - placing top center log (#7) 6. Place top right log (#6) across bottom center log and right bottom log as shown in figure 43. Logs should now look like figure 45. Figure 45 - all logs in place figure 43 - placing top right log (#6) figure 46 - log place...

Safety screen installation warning: a barrier (safety screen) designed to reduce the risk of burns from the hot viewing glass is provided with this appliance and shall be installed for the protection of children and other at-risk individuals. Important:safety screen must be in place when the firepla...

Safety screen installation continued step 7: repeat previous step with the bottom louver. Notice will be permanent when heater is lit. Before installing the safety screen remove all fingerprints from the glass door with a 50/50 vinegar and water solution. Any fingerprints left on the glass or the sa...

Operating fireplace for your safety read before lighting a. This appliance is equipped with an ignition device which automatically lights the pilot. Do not try to light the pilot by hand. Use any phone in your building. • immediately call your gas supplier from a neigh- bor's phone. Follow the gas s...

26 if pilot does not stay lit, contact a qualified service person or gas supplier for repairs. Figure 9d - remote receiver switch in on position 1. Slide the remote receiver switch to the on position. This will allow the main burner to ignite. 1. Slide the remote receiver switch to the off position....

T turning on the appliance 1. Press the on/off button on the transmitter. The transmitter screen will display all active icons. The receiver will command the dfc board to start the ignition process, once the pilot flame is lit, the dfc 1. With the system on and the flame level at maximum height, pre...

26 48d0139 smart thermostat the smart thermostat function adjusts the flame height in accordance to the difference between the set point temperature and the actual room temperature. As the room temperature gets closer to the set point, the smart function will modulate the flame down. 2. To adjust th...

Figure 52 - pilot flame burner flame the flames from the burner should be visually checked as soon as the heater is installed and periodically during normal operation. In normal operation, at full rate, and after operat- ing for about 15 to 30 minutes, the flame should be yellow and slightly taller ...

Cleaning and maintenance vent system the fireplace and venting system should be inspected before initial use and at least annually by a qualified field service person. Inspect the external vent cap on a regular basis to make sure that no debris is interfering with the airflow. Inspect entire venting...

Replacement parts label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Caution note: unplug power cord before servicing. The blower is attached to the insert bottom and back ...

Rigid vent components 1 3 4 5 6 7 8 9 2 illustrated parts list direct vent pro item qty/box description or woodbridge part # simpson duravent 10 — 1 30° starter elbow for vertical from firebox 46dva-e30 — 1 60° starter elbow for horizontal from firebox 46dva-e60 1 1 simpson horizontal high wind ...

Illustrated parts lists 1 2 5 6 7 4 firebox components 8 3 standard features factory installed options 5 standard firebrick center 1 a100022 a100016 a100022 a100016 a100019 6 standard firebrick right 1 a100020 a100014 a100020 a100014 a100017 7 standard firebrick left 1 a100021 a100015 a100021 a10001...

Illustrated parts lists troubleshooting item description qty bdv/hdv2000 bdv/hdv3000 hdv4000 1 rear log 1 m100517 m100503 m100510 2 bottom left log 1 m1000518 m100504 m100511 3 top left log 1 n/a m100505 m100512 4 bottom right log 1 m100519 m100506 m100513 5 bottom center log 1 m100520...

Illustrated parts lists (continued) proflame wiring diagram receiver 14 pin connector pilot cpi / ipi mode 120 vac input 7 vdc stabilized supply output motor ipi/cpi receiver dc supply split flow on / off tpth th dfc supply dc supply ground 885 proflame orange green chassis connection 12 1 5 13 6 14...

Illustrated parts lists 40 4 3 8 5 7 11 4 6 10 2 7 4 9 12 3 1 48.

43 parts list illustrated parts lists (continued) part number key no. Description qty this list contains replaceable parts used in your fireplace. 1 h200010 h200010 remote control receiver 1 4 c100010 c100010 18" flex connector with shutoff valve 1 5 c200001 c200002 main gas valve 1 7 a100014 a10001...

43 parts list illustrated parts lists (continued) part number key no. Description qty this list contains replaceable parts used in your fireplace. 1 h200010 h200010 remote control receiver 1 4 c100010 c100010 18" flex connector with shutoff valve 1 5 c200001 c200002 main gas valve 1 7 a100010 a10001...

Troubleshooting 51 warning: turn off the unit and let cool before servicing. Only a qualified service person should service and repair this appliance. Note:all troubleshooting items are listed in order of operation. Symptom possible cause action light pilot after repeated triggering of piezo. After ...

Limited lifetime warranty policy lifetime warranty five year warranty the following components are warranted five (5) years to the original owner, subject of proof of purchase: ceramic fiber logs. Basic warranty woodbridge fireplace inc. Warrants the components and materials in your gas appliance to...