- DL manuals

- Woods

- Lawn Mower

- 42C-6

- Operator's Manual

Woods 42C-6 Operator's Manual

Summary of 42C-6

Page 1

Op e r a t o r 's m a nu a l rotary mower 29900 r e v. 3 /14/ 200 8 tested. Proven. Unbeatable. 42c-6.

Page 2: 2 Introduction

2 introduction gen’l (rev. 2/19/2008) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 29900 (rev. 7/6/2007) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 safety rules . . . . . . . . . . . . . ....

Page 4: 4 Safety

4 safety 42c safety rules (rev. 7/9/2007) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check the ...

Page 5: Safety 5

Safety 5 42c safety rules (rev. 7/9/2007) do not stop, start, or change directions sud- denly on slopes. use extreme care and reduce ground speed on slopes and rough terrain. watch for hidden hazards on the terrain during operation. stop power unit and equipment immediately upon striking an ...

Page 6: 6 Safety

6 safety 29900 (rev. 7/6/2007) 4 - serial number plate 1 - 25505 rotating blades and thrown objects do not put hands or feet under or into mower when engine is running. Before mowing, clear area of objects that may be thrown by blade. Keep bystanders away. Keep discharge chute and guards in place an...

Page 7: Operation 7

Operation 7 29900 (rev. 7/6/2007) operation ■ do not allow children or unqualified persons to operate equipment. ■ keep bystanders away from equipment while it is in operation. ■ stop mower and tractor immediately upon striking an obstruction. Turn off engine, remove key, inspect and repair any dama...

Page 8: 8 Service

8 service 29900 (rev. 7/6/2007) service lubrication grease blade spindle shaft every 24 hours of operation until some grease is forced out around top of shaft. This is necessary to ensure that enough grease has been forced in to reach top bearing of spindle. V-belt idlers have sealed ball bearings a...

Page 9: Assembly 9

Assembly 9 29900 (rev. 7/6/2007) assembly ■ keep all persons away from operator control area while performing adjustments, service or maintenance. ■ always wear relatively tight and belted clothing to avoid entanglement in moving parts. Wear sturdy, rough-soled work shoes and protective equipment fo...

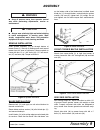

Page 10: 10 Assembly

10 assembly 29900 (rev. 7/6/2007) figure 5. Side skid and side shield side shield or discharge chute installation a side shield and discharge chute are provided for right side of mower. The side shield should be used for nor- mal operating conditions. The discharge chute may be used to replace side ...

Page 11: Assembly 11

Assembly 11 29900 (rev. 7/6/2007) mounting frame assembly push channel / push channel mounting angles and lift bars loosely assemble the following (see page 18): attach right push channel mounting angle (53) to right rear deck rail and rear mower deck with 1/2" x 1-1/2" carriage bolts (83) and flang...

Page 12: 12 Assembly

12 assembly 29900 (rev. 7/6/2007) figure 8. Mounting frame assembly photo.

Page 13: Assembly 13

Assembly 13 29900 (rev. 7/6/2007) figure 9. Mounting frame assembly photo with rear shield.

Page 14: 14 Assembly

14 assembly 29900 (rev. 7/6/2007) figure 10. Lift assembly photo.

Page 15: Dealer Check List 15

Dealer check list 15 29900 (rev. 3/14/2008) dealer check lists pre-delivery check list (dealer’s responsibility) inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspect. Check ...

Page 16: 16 Parts

16 parts 29900 (rev. 7/6/2007) 42-6 cw main frame assembly.

Page 17: Parts 17

Parts 17 29900 (rev. 7/6/2007) 42-6 cw main frame assembly ref part qty description 1 9874 1 frame 2 26403 1 front corner baffle 3 4141 1 right side skid 4 26396 1 right side shield 5 26402 1 side shield baffle 6 27663 1 blade spindle belt shield 7 ----- 1 overrunning clutch (see page 20) 8 3444 1 a...

Page 18: 18 Parts

18 parts 29900 (rev. 7/6/2007) 42c-6 mounting frame assembly drawing.

Page 19: Parts 19

Parts 19 29900 (rev. 7/6/2007) 42c-6 mounting frame assembly ref part qty description 40 27657 2 lift bar 41 1533 1 bottom lift arm 42 1441 1 upper lift arm 43 1500 1 center lift arm 44 484 1 5/8 x 1 x 7/16 heat-treated sleeve 45 1513 2 idler bracket clamp plate 46 1491 1 idler pipe 47 4072 2 7-5/16...

Page 20: 20 Parts

20 parts 29900 (rev. 7/6/2007) overrunning clutches important note: after installing clutch, rotate it back- wards to see that it ratchets freely. If it does not, add another washer (16) under cap (15) & rotate clutch again. Ref part qty description 1 ------ * 1 1/8 pipe plug (used on earlier models...

Page 21: Parts 21

Parts 21 29900 (rev. 7/6/2007) lift chain hook-up table special notes (refer to numbers in parentheses in above table) 1. Hook one 13-link chain between holes “c” & “d”. 2. Fasten one 10-link and one 7-link chain together. 3. Hook lower end of spring in crotch chain. 4. Hook spring into chain just a...

Page 22: 22 Parts

22 parts 29900 (rev. 7/6/2007) manual height adjustment.

Page 23: Parts 23

Parts 23 29900 (rev. 7/6/2007) manual height adjustment ref part qty description 1 ----- - chain (see chart for chain used on your mounting) 2 4155 2-3 1/4 cold shut repair link 3 10693 1 manual height adjustment lever assembly 4 484 1-2 5/8 x 1 x 7/16 ht sleeve 5 10706 1 3-3/8 long compression spri...

Page 24: 24 Parts

24 parts 29900 (rev. 7/6/2007) spindle assembly ref part qty description 1 18355 1 cw blade spindle 2 18359 1 1-3/8 x 1-3/4 x 5/8 sleeve 3 2718 2 1-3/4 x 2-3/8 x 13 ga flat washer 4 2715 2 seal for 1-3/4 shaft 5 2717 2 bearing cone 6 18361 1 spindle housing with cups 7 2716 2 bearing cup 8 195 * 1 s...

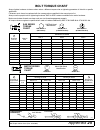

Page 25: Appendix 25

Appendix 25 bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 26: 26 Appendix

26 appendix bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe ....................Am...

Page 27: Warranty

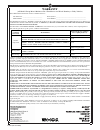

F-3079 (rev. 6/1/2007) warranty (all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) please enter information below and save for future reference. Date purchased: ____________________________ from (dealer): ___________________________________________ model num...

Page 28: Warranty

F-8494 (rev. 6/23/2005) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com ©2007 woods equipment company. All rights reserved. Woods, the woods logo, and "tested. Proven. Unbeatable." are trademarks...