- DL manuals

- Woods

- Lawn Mower

- 59LB-1

- Operator's Manual

Woods 59LB-1 Operator's Manual

Summary of 59LB-1

Page 1

Op e r a t o r 's m a nu a l rotary mower 29932 r e v. 8 /10/ 200 7 tested. Proven. Unbeatable. 59lb-1 for use on ih154, ih185 cub loboy and ih184 (with or without 3-point lift). For tractors equipped with turf tires, also order wheel spacer kit 18240..

Page 2: 2 Introduction

2 introduction gen’l (rev. 7/20/2007) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 29932 (rev. 8/10/2007) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 general information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 safety rules . . . . . . . . . . . . . ...

Page 4: 4 Safety

4 safety 59lb-1 safety rules (rev. 7/9/2007) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check t...

Page 5: Safety 5

Safety 5 59lb-1 safety rules (rev. 7/9/2007) do not stop, start, or change directions sud- denly on slopes. use extreme care and reduce ground speed on slopes and rough terrain. watch for hidden hazards on the terrain during operation. stop power unit and equipment immediately upon striking ...

Page 6: 6 Safety

6 safety 29932 (rev. 8/10/2007) 3 - serial number plate 1 - 25505 rotating blades and thrown objects do not put hands or feet under or into mower when engine is running. Before mowing, clear area of objects that may be thrown by blade. Keep bystanders away. Keep discharge chute and guards in place a...

Page 7: Operation 7

Operation 7 29932 (rev. 8/10/2007) operation ■ do not allow children or unqualified persons to operate equipment. ■ keep bystanders away from equipment while it is in operation. ■ stop mower and tractor immediately upon striking an obstruction. Turn off engine, remove key, inspect and repair any dam...

Page 8: 8 Operation

8 operation 29932 (rev. 8/10/2007) figure 1. Attitude adjustment notice ■ improper belt alignment or tension can cause premature belt failure. Lubrication grease caster pivot and wheel every 8 hours of opera- tion. There are grease fittings on each of the three blade spindles, which are accessible w...

Page 9: Operation 9

Operation 9 29932 (rev. 8/10/2007) blade servicing keep blades sharp for a good mowing job. Sharpen both ends of the blade the same amount to maintain balance. Do not sharpen blade to a razor edge, but leave a 1/16" blunt edge. Do not sharpen back side of blade. When replacing blades, do not substit...

Page 10: 10 Assembly

10 assembly 29931 (rev. 8/10/2007) assembly mower frame assembly open box and lay parts out in an orderly manner. Side shield (see page 20) attach side shields (2 and 3) to mower with 3/8 x 1" bolts and flange nuts. A side discharge chute (5) may be installed on discharge end of mower in place of th...

Page 11: Assembly 11

Assembly 11 29931 (rev. 8/10/2007) first put belt on the bottom groove, right hand side of the center sheave. Then thread it to left, around the left hand sheave. Figure 6. Bring the belt back across the center sheave in the center groove over to the right outside sheave. Figure 7. Then thread it ba...

Page 12: 12 Assembly

12 assembly 29931 (rev. 8/10/2007) front hole of caster and deck rail; and secure with 3/8" lock washer and nut. In some cases it is necessary to open up the end link of the chain slightly so a 3/8" bolt will pass through it. On ih184, install 1/2 x 5/8 x 7/16 bushing (39) in tractor rockshaft arm. ...

Page 13: Assembly 13

Assembly 13 29931 (rev. 8/10/2007) figure 9. Mounting frame shown with 3-point lift mounting kit & 3-point lift installed figure 10. Mounting frame assembly.

Page 14: 14 Assembly

14 assembly 29931 (rev. 8/10/2007) figure 11. Lift assembly figure 12. Lift assembly.

Page 15: Assembly 15

Assembly 15 29931 (rev. 8/10/2007) notes.

Page 16: 16 Parts

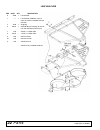

16 parts 29932 (rev. 8/10/2007) mounting frame assembly.

Page 17: Parts 17

Parts 17 29932 (rev. 8/10/2007) mounting frame assembly ref part qty description 1 6911 2 chain (7 link) 2 10772 2 lift angle 3 18314 2 1/2 x 5/8 x 5/16 sleeve 4 9814 † 1 idler and mounting frame assembly (standard) 5 2688 6 5/32 cotter pin 7 18440 1 belt (special w180) 8 4336 2 idler sheave with be...

Page 18: 18 Parts

18 parts 29932 (rev. 8/10/2007) spindle assembly note: repair items shaft (9) and sleeve (3) do not have a hole drilled in them for pin (4). After new parts have been assembled and proper bearing adjustment obtained, drill a 3/16 diameter hole through sleeve and shaft. Drive in sel-lock pin to hold ...

Page 19: Parts 19

Parts 19 29932 (rev. 8/10/2007) casters ref part qty description 1 29750 1 right and left caster bundle 2 12243 1 caster yoke (includes bolt, nut & sleeve) 3 29746 (a) 1 right caster arm asy, 13-5/32" long -or- 3 6761 (a) 1 right caster arm asy, 16-5/32" long 4 29747 (a) 1 left caster arm asy, 13-5/...

Page 20: 20 Parts

20 parts 29932 (rev. 8/10/2007) mower frame assembly.

Page 21: Parts 21

Parts 21 29932 (rev. 8/10/2007) mower frame assembly notes: (a) for all 59, l59 models except: gm2, lb, f10, f13, f15, h284, jd85, jd95, k17, k18, k210, k260, s, s55, s-bl, tb, ym. (b) for use on 59, l59 models: lb, k17, k18, k210, k260, s55, s-bl, tb, ym. (c) for f10, f13, f15, gm4, h284, jd85, jd9...

Page 22: 22 Parts

22 parts 29932 (rev. 8/10/2007) leaf mulcher ref part qty description a 7080 1 leaf mulcher 1 ----- 1 leaf mulcher weldment (if part is worn out, order a complete new leaf mulcher) 2 7076 1 angle lug 5 23218 1 3/8 scdl 40 pipe 5/8 long (for use on 59’s with bent down front frame) 7 839 * 3/8 nc x 1 ...

Page 23: Appendix 23

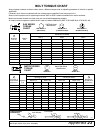

Appendix 23 bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 24: 24 Appendix

24 appendix bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe ....................Am...

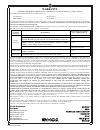

Page 25: Warranty

F-3079 (rev. 6/1/2007) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com warranty (all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) please enter informati...

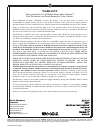

Page 26: Warranty

F-8494 (rev. 6/23/2005) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com ©2007 woods equipment company. All rights reserved. Woods, the woods logo, and "tested. Proven. Unbeatable." are trademarks...