- DL manuals

- Woods

- Surge Protector

- BACKHOE 1050

- Operator's Manual

Woods BACKHOE 1050 Operator's Manual

Summary of BACKHOE 1050

Page 1

Op e r a t o r 's m a nu a l backhoe 51861 r e v. 7 /7/2 006 tested. Proven. Unbeatable. 1050

Page 2: 2 Introduction

2 introduction gen’l (rev. 6/6/2005) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complete...

Page 3: Introduction 3

Introduction 3 51861 (rev. 6/16/2006) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general information . . . . . ...

Page 4: 4 Introduction

4 introduction 51861 (rev. 6/16/2006) bh1050 specifications reach below grade (standard bucket) maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127" (3225.8 mm) with two foot flat bottom trench* . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 5: Introduction 5

Introduction 5 51861 (rev. 6/16/2006) bh1050 specifications.

Page 6: 6 Introduction

6 introduction 51861 (rev. 6/16/2006) general information the purpose of this manual is to assist in setting up, operating and maintaining your backhoe. Read it care- fully. It furnishes information and instructions that will help you achieve years of dependable performance. These instructions have ...

Page 7: Safety 7

Safety 7 bh1050_sr (rev. 1/30/2004) installation hydraulics must be connected as instructed in this manual. Do not substitute parts, modify, or connect in any other way. after connecting hoses, check that all control lever positions function as instructed in the opera- tor's manual. Do not put i...

Page 8: 8 Safety

8 safety bh1050_sr (rev. 1/30/2004) only mount this backhoe on 50 hp or greater, category 2 or 3 tractors with 2000 lb. Lift capacity and with oem high-strength top link pin of at least 1” diameter or approved top link brackets and pins. Brackets and pins are available from your woods dealer for s...

Page 9: Safety 9

Safety 9 bh1050_sr (rev. 1/30/2004) being trapped should the boom swing control be accidentally activated. do not exceed these pto speeds: • 540 rpm on 6-tooth spline pto • 1000 rpm on 21-tooth spline pto. always dump spoil at least two feet away from opening. use extreme care when working clo...

Page 10: 10 Safety

10 safety 51861 (rev. 6/16/2006) lock 33437-e 4 - 33437 1 - 34994 5 - serial number plate model no. Serial no. Woods equipment company oregon, illinois, u.S.A. Be careful! Use a clean, damp cloth to clean safety decals. Avoid spraying too close to decals when using a pressure washer; high-pressure w...

Page 11: Safety 11

Safety 11 51861 (rev. 6/16/2006) 2 - 34296 3 - 34244 safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged!.

Page 12: 12 Operation

12 operation 51861 (rev. 6/16/2006) operation the operator is responsible for the safe operation of the backhoe. The operator must be properly trained. Operators should be familiar with the backhoe, the tractor, and all safety practices before starting opera- tion. Read the safety rules and safety d...

Page 13: Operation 13

Operation 13 51861 (rev. 6/16/2006) figure 3. Backhoe swing area. Position the machine before operating in an unfamiliar area, walk around the full length of the proposed site and check for hidden holes, drop-off or obstacles that could cause an acci- dent. Lower stabilizers until they carry the wei...

Page 14: 14 Operation

14 operation 51861 (rev. 6/16/2006) figure 4. Operator’s controls (typical view) after becoming familiar with the backhoe operation, practice coordinated use of the controls in a safe open area at reduced engine speed. Gradually increase engine speed as the technique is mastered. Operate backhoe gen...

Page 15: Operation 15

Operation 15 51861 (rev. 6/16/2006) figure 6. Fill bucket dump and return cycle keep the swing-dump-return cycle as brief as possible. Keep dipper moving outward and start boom swing as soon as the bucket clears the excavation. Continue extending dipper and, as you approach the spoil pile, start to ...

Page 16: 16 Operation

16 operation 51861 (rev. 6/16/2006) from being run over or crushed. Keep foldable rops system in “locked up” position at all times. never leave equipment unattended with engine running or with bucket in raised position. Always engage swing and boom transport locks, relieve system pr essure by oper...

Page 17: Operation 17

Operation 17 51861 (rev. 6/16/2006) ● inspect machine and replace worn or damaged parts. ● replace any safety decals that are missing or not readable. Periodically or before extended storage ● clean large debris such as clumps of dirt, grass, crop residue, etc. From machine. ● remove the remainder u...

Page 18: 18 Owner Service

18 owner service 51861 (rev. 6/16/2006) owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. ...

Page 19: Owner Service 19

Owner service 19 51861 (rev. 6/16/2006) figure 12. Tooth replacement hydraulic hoses and fittings hydraulic hoses are severely worked on a backhoe. Examine them daily and replace if necessary. Hose routing is very important. Make certain hoses can move freely, without kinking, and cannot be damaged ...

Page 20: 20 Owner Service

20 owner service 51861 (rev. 6/16/2006) troubleshooting problem possible cause solution noisy pump caused by cavitation oil too heavy change to proper viscosity. Oil filter plugged replace filter. Suction line plugged or too small clean line and check for size. Suction line kinked replace line. Oil ...

Page 21: Dealer Service 21

Dealer service 21 51861 (rev. 6/16/2006) dealer service the information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, it ...

Page 22: 22 Dealer Service

22 dealer service 51861 (rev. 6/16/2006) assembly lubricate o-rings and seals with clean hydraulic fluid. Install back-up washer (3e) on rod guide (5), then install o-ring (3f) in exterior o-ring groove of rod guide. Install rod seal (3d) into inner groove of rod guide with open portion of v-groove ...

Page 23: Dealer Service 23

Dealer service 23 51861 (rev. 6/16/2006) system. The backhoe pump will separate or crack if system pressure exceeds the maximum. Relief valve adjustment requires a test bench and accurate gauges. Adjusting system relief valve pressure adjustment of system relief pressure must be done by a qualifie...

Page 24: 24 Dealer Service

24 dealer service 51861 (rev. 6/16/2006) figure 17. Hydraulic valve repair.

Page 25: Dealer Service 25

Dealer service 25 51861 (rev. 6/16/2006) swing cylinder cushion oil flow (figure 18 & figure 19) swing cylinder operational theory our swing cylinders are designed to cushion and soften swing action. Cross sections are shown in figure 19 to give you a view of the internal workings of the cylinder. C...

Page 26: 26 Dealer Service

26 dealer service 51861 (rev. 6/16/2006) figure 18. Swing cylinder oil flow - energy figure 19. Swing cylinder oil flow - prince.

Page 27: Assembly 27

Assembly 27 51861 (rev. 6/16/2006) assembly dealer set-up instruction backhoe assembly is the responsibility of the woods dealer. The backhoe should be delivered to the owner completely assembled, lubricated and adjusted for nor- mal operating conditions. Set up backhoe as received from the factory ...

Page 28: 28 Assembly

28 assembly 51861 (rev. 6/16/2006) figure 20. Dipperstick & bucket assembly plumbing installation keep hands and body away from pressurized lines. Use paper or cardboard, not hands or other body parts to check for leaks. Wear safety goggles. Hydraulic fluid under pressure can easily penetrate skin...

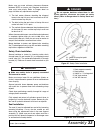

Page 29: Assembly 29

Assembly 29 51861 (rev. 6/16/2006) figure 21. Pump installation apply teflon tape to hose nipple (7) threads and install one into reservoir suction screen filter and one into 90° elbow (9). Important ■ fittings with o-rings must be installed properly. Loosen lock nut completely, install fitting all ...

Page 30: 30 Assembly

30 assembly 51861 (rev. 6/16/2006) contamination will shorten the life of hydraulic system components. Change oil and filter after first 20 hours of operation and then every 200 hours of operation. Engage pto and run at idle for 5 minutes, then check oil level. Add fluid as necessary. Position backh...

Page 31: Assembly 31

Assembly 31 51861 (rev. 6/16/2006) saf-t-lok ® installation insert hitch pin (4) through rear holes as shown in fig- ure 23 and place diagonal bars (3) on hitch pins. Install slotted hex nut (18) and snug up bit do not tighten at this time. Attach tractor lower lift arms to backhoe hitch pins (use s...

Page 32: 32 Assembly

32 assembly 51861 (rev. 6/16/2006) figure 25. Top link and saf-t-lok hitch installation important ■ there may be more than one hole provided in tractor top link attachment bracket; select the hole that most evenly distributes the load between top link bracket and its mounting bolts. See figure 25. N...

Page 33: Assembly 33

Assembly 33 51861 (rev. 6/16/2006) make sure you meet minimum clearance distances between rops or tractor cab. Required head clear- ance must take priority. Refer to danger decal on page 10. Make any adjustments required. 1. The bolt center distance attaching the diagonal brace to the top link must ...

Page 34: 34 Dealer Check Lists

34 dealer check lists 51861 (rev. 6/16/2006) dealer check lists pre-delivery check list dealer’s responsibility inspect the backhoe (and sub-frame when applicable) thoroughly after assembly to be certain it is set up properly before delivering it to the customer. The check lists are a reminder of po...

Page 35: Parts 35

Parts 35 51861 (rev. 6/16/2006) parts index bh1050 main frame assembly................................................................................................. 36 bucket & dipperstick assembly............................................................................. 38 broom assembly .......

Page 36: 36 Parts

36 parts 51861 (rev. 6/16/2006) bh1050 main frame assembly.

Page 37: Parts 37

Parts 37 51861 (rev. 6/16/2006) bh1050 main frame assembly hardware ref part qty description 1 34060 1 main frame (includes item 63) 2 34041 1 swing frame (includes item 64) 3 34344 1 console assembly and decal 4 34100 2 stabilizer 5 34218 2 2-1/2 x 15 stabilizer cylinder (see page 50) 6 34219 2 2-1...

Page 38: 38 Parts

38 parts 51861 (rev. 6/16/2006) bh1050 dipperstick & bucket assembly.

Page 39: Parts 39

Parts 39 51861 (rev. 6/16/2006) bh1050 dipperstick & bucket assembly hardware ref part qty description 1 34011 1 dipperstick (includes items 2, 3, and 31) 2 34014 2 1-1/4 x 1-1/2 x 1-1/2 tension bushing 3 34017 6 1 x 1-1/4 x 1-1/2 tension bushing 4 34217 1 2-1/2 x 28 hydraulic bucket cylinder assemb...

Page 40: 40 Parts

40 parts 51861 (rev. 6/16/2006) bh1050 boom assembly hardware ref part qty description 1 34216 2 3 x 27 hydraulic cylinder assembly (see page 52) 2 34343 1 boom 3 34172 2 1-1/8 x 10-3/4 pin ht 4 34167 1 4-hose clamp 5 34169 1 hose clamp ref part qty description 10 3597 * - 1/8 x 1 cotter pin 11 1972...

Page 41: Parts 41

Parts 41 51861 (rev. 6/16/2006) valve controls & hardware hardware ref part qty description 1 34179 1 console valve (see page 42) 2 34141 1 left handle assembly 3 34140 1 right handle assembly 4 34144 2 linkage pivot assembly 5 34149 2 2.31 valve link, right and left 6 34147 2 2.75 valve link, right...

Page 42: 42 Parts

42 parts 51861 (rev. 6/16/2006) bh1050 console valve assembly.

Page 43: Parts 43

Parts 43 51861 (rev. 6/16/2006) bh1050 console valve assembly ref part qty description 1 34179 1 console valve 2 34368 1 relief valve assembly, 2100 psi 3 33339 6 check valve assembly 4 33343 1 spool position control assembly 5 33345 5 spool position control assembly 6 33346 6 spool repair kit 7 343...

Page 44: 44 Parts

44 parts 51861 (rev. 6/16/2006) bh1050 hoses & fittings.

Page 45: Parts 45

Parts 45 51861 (rev. 6/16/2006) bh1050 hoses & fittings ref part qty description 1 34234 1 3/8 npt x 1/2 npt nipple 2 34180 1 restrictor valve 3 10802 * 1 3/8 x 1/2 pipe reducer bushing, straight 4 31274 2 1/4 npt run tee 5 31275 8 9/16 - 18 x 3/8 o-ring union 6 14396 6 9/16 - 18 x 1/4 o-ring union ...

Page 46: 46 Parts

46 parts 51861 (rev. 6/16/2006) bh1050 pump assembly hardware ref part qty description 1 34231 1 540 rpm gear pump assembly (see page 47) -or- 1a 62437 1 1000 rpm gear pump assembly (see page 48) 2 34238 1 540 rpm pump adapter -or- 2a 34281 1 1000 rpm pump adapter 3 34285 1 pump mounting bracket 4 3...

Page 47: Parts 47

Parts 47 51861 (rev. 6/16/2006) bh1050 540 rpm hydraulic pump ref part qty description 1 ----- † 1 front seal 2 nss 1 retaining ring 3 ----- † 1 rear seal 4 nss 1 mounting flange 5 ----- † 2 outer o-ring 6 ----- † 2 nylon back-up strip 7 ----- † 2 o-ring 8 nss 4 plate o-ring 9 nss 1 key 10 nss 2 pre...

Page 48: 48 Parts

48 parts 51861 (rev. 6/16/2006) bh1050 1000 rpm hydraulic pump ref part qty description 1 nss 1 back plate assembly 2 ----- † 2 o-ring 3 ----- † 1 thrust plate 4 nss 1 body 5 nss 2 dowel pin 6 nss 1 drive gear assembly 7 62536 * 1 1/4 x 1/4 x 15/16 key 8 ----- † 1 diaphragm 9 ----- † 1 back-up gaske...

Page 49: Parts 49

Parts 49 51861 (rev. 6/16/2006) bh1050 swing cylinder ref part qty description - 34219 1 complete cylinder assembly 1 34273 1 piston rod 2 1972 * 1 1/4-28 tapered threaded fitting 3 58822 1 seal kit (items 3a -3i) 3a ----- † 1 o-ring .75 x .875 3b ----- † 1 internal retaining ring 2.500 3c ----- † 1...

Page 50: 50 Parts

50 parts 51861 (rev. 6/16/2006) bh1050 stabilizer cylinder ref “e” part “p” part qty description 1 34218 34218 1 2-1/2 x 15 hydraulic cylinder assembly 2 1972 * 1972 * 2 1/4 - 28 tapered thread grease fitting 3 34330 n/a 1 retaining ring, internal 2-1/2 x 15 4 n/a n/a 1 wire retainer, 1/2 x 15 5 648...

Page 51: Parts 51

Parts 51 51861 (rev. 6/16/2006) bh1050 bucket cylinder ref part qty description 1 34217 1 2-1/2 x 28 hydraulic cylinder asy 2 1972 * 2 1/4 - 28 tapered thread grease fitting 3 34266 1 seal kit (contains items 3a-3g) (for lock collar style cylinders) -or- 3 58797 1 seal kit (contains items 3a-3g) (fo...

Page 52: 52 Parts

52 parts 51861 (rev. 6/16/2006) bh1050 boom & dipperstick cylinder ref part qty description 1 34216 1 3 x 27 hydraulic cylinder assembly 2 34259 1 collar 3 34260 1 seal kit (contains items 3a-3h) 3a ----- † 1 wear ring 3b ----- † 1 o-ring, 2-9/16 id x 2-3/4 od 3c ----- † 1 piston ring 3d ----- † 1 o...

Page 53: Parts 53

Parts 53 51861 (rev. 6/16/2006) bh1050 saf-t-lok ® assembly hardware ref part qty description 1 34129 1 double link assembly 2 34131 1 link assembly 3 34993 2 saf-t-bar assembly, only for s/n 3700 and above (includes item 8-11) -or- 3 34292 2 saf-t-bar assembly for s/n 3000- 3699 only (includes item...

Page 54: 54 Parts

54 parts 51861 (rev. 6/16/2006) bh1050 stabilizer pad kit (optional) ref part qty description 1 34107 2 stabilizer pad assembly (standard) 2 34093 2 rubber street pad (optional) 3 34106 2 stabilizer spike pad (optional) 10 29893 8 1/2 nc x 1-1/2 carriage bolt ht 11 855 * 8 1/2 extra-heavy lock washe...

Page 55: Appendix 55

Appendix 55 bolt torque & size charts (rev. 10/10/2005) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list....

Page 56: 56 Appendix

56 appendix bolt torque & size charts (rev. 10/10/2005) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag ............................................................ Agriculture atf ............................

Page 57: Index 57

Index 57 man0507 (3/20/2006) index assembly dealer set-up instructions 27 check lists delivery check list (dealer’s responsibility) 34 pre-delivery check list (dealer’s responsibility) 34 pre-operation check list owner’s responsibility) 17 dealer service hydraulic cylinder repair 21 boom, dipperstic...

Page 58: Warranty

F-3079 (rev. 5/2/2006) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com warranty (all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) please enter informati...

Page 59: Warranty

F-8494 (rev. 6/23/2005) warranty (replacement parts for all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) woods equipment company (“woods”) warrants this product to be free from defect in material and workmanship for a period of ninety (90) days from the dat...

Page 60: 51861

Woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 815-732-2141 tel 815-732-7580 fax www.Woodsequipment.Com 51861 © 1995 woods equipment company. All rights reserved. Woods, the woods logo, and "tested. Proven. Unbeatable." are trademarks of woods equipme...