- DL manuals

- Woods

- Cutter

- Batwing BW240Q

- Operator's Manual

Woods Batwing BW240Q Operator's Manual

Summary of Batwing BW240Q

Page 1

Op e r a t o r 's m a nu a l batwing ® man0725 ( r e v. 9 /1 1 /2 013 ) bw240, bw240q.

Page 2: 2 Introduction

2 introduction gen’l (rev. 3/28/2012) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 man0725 (10/3/2008) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general information . . . . . . ....

Page 4: 4 Introduction

4 introduction man0725 (10/3/2008) specifications bw240 / bw240q cutting height (varies with tire selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2" - 15" cutting width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 5: Safety 5

Safety 5 safety video order form (8/2/2005) free mower safety video fill out and return the order form and we will send you a free vhs or dvd video outlining industrial and agricultural mower safety practices. The 22 minute video, developed in cooperation with aem (association of equipment manufactu...

Page 6: 6 Safety

6 safety safety video order form (rev. 2/6/2006) free mower/cutter safety video order form (select one) vhs format - vhs01052 safety video dvd format - dvd01052 safety video please send me name: ________________________________________ phone: __________________ address: _____________________________...

Page 7: Safety 7

Safety 7 bw1800/bw1260 sr (rev. 11/13/2008) installation hydraulics must be connected as instructed in this manual. Do not substitute parts, modify, or connect in any other way. Training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and sa...

Page 8: 8 Safety

8 safety bw1800/bw1260 sr (rev. 11/13/2008) (safety rules continued from previous page) make sure driveline guard tether chains are attached to the tractor and equipment as shown in the pamphlet that accompanies the driveline. Replace if damaged or broken. Check that driveline guards rotate freely...

Page 9: Safety 9

Safety 9 bw1800/bw1260 sr (rev. 11/13/2008) never direct discharge toward people, animals, or property. do not operate or transport equipment while under the influence of alcohol or drugs. operate only in daylight or good artificial light. keep hands, feet, hair, and clothing away from equip...

Page 10: 10 Safety

10 safety bw1800/bw1260 sr (rev. 11/13/2008) (safety rules continued from previous page) never go underneath equipment (lowered to the ground or raised) unless it is properly blocked and secured. Never place any part of the body under- neath equipment or between moveable parts even when the engine...

Page 11: Safety 11

Safety 11 man0725 (10/3/2008) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! 1 - serial number plate 2 - front amber reflector (pn 1002940) 3 - rear red reflector (pn 57123) 4 - pn 18869 shield missing do not operate - put shield on 18...

Page 12: 12 Safety

12 safety man0725 (10/3/2008) 7 - pn 15503 falling off can result in being run over. Tractor must be equipped with rops (or rops cab) and seat belt. Keep foldable rops systems in “locked up” position at all times. Buckle up! Keep seat belt securely fastened. Allow no riders. Raised equipment can dro...

Page 13: Safety 13

Safety 13 man0725 (10/3/2008) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! 12 - pn 1004991 transport lock and cylinder requirements 1004991 transport lock warning raised cutter can drop and crush ers must be equipped with transport l...

Page 14: 14 Operation

14 operation man0725 (10/3/2008) operation the designed and tested safety of this machine depends on it being operated within the limitations as explained in this manual. Be familiar with and follow all safety rules in the manual, on the cutter and on the tractor. The safe operation of this cutter i...

Page 15: Operation 15

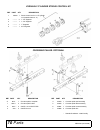

Operation 15 man0725 (10/3/2008) hydraulic connection 1. Inspect hydraulic hoses to ensure they are in good condition. 2. Clean the fittings before connecting them to the tractor hydraulic ports. 3. Route the hose through the hose holder at the hitch and be sure the hose can slide freely in the hold...

Page 16: 16 Operation

16 operation man0725 (10/3/2008) figure 1a. Attitude rod adjustment cutting height (normal mowing) - wings 1. Lower wings to normal mowing position. 2. Loosen the jam nut on the adjustable link (turn buckle). 3. Lengthening the link will raise the wing, shortening the link will lower the wing. The r...

Page 17: Operation 17

Operation 17 man0725 (10/3/2008) use extreme care and reduce ground speed on slopes and rough terrain. watch for hidden hazards on the terrain during operation. stop power unit and equipment immediately upon striking an obstruction. Turn off engine, remove key, inspect, and repair any damage b...

Page 18: 18 Operation

18 operation man0725 (10/3/2008) center section lock-up figure 3. Transport lock in operation position 1. Raise cutter with hydraulic cylinder to maximum height. 2. Rotate transport lock into position over cylinder rod (figure 2). 3. Lower cutter against transport lock. 4. To lower cutter for operat...

Page 19: Owner Service 19

Owner service 19 man0725 (10/3/2008) owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. ke...

Page 20: 20 Owner Service

20 owner service man0725 (10/3/2008) figure 4. Jackstand placement and lubrication points lubrication do not let excess grease collect on or around parts, particularly when operating in sandy areas. See figure 4 for lubrication points and frequency or lubrication based on normal operating conditions...

Page 21: Owner Service 21

Owner service 21 man0725 (10/3/2008) seasonal lubrication in addition to the daily recommended lubrication, a more extensive application is recommended season- ally. 1. Fill cv double yokes with 20 pumps of grease with the joints in a straight line. 2. Articulate cv body to maximum angle several tim...

Page 22: 22 Owner Service

22 owner service man0725 (10/3/2008) blade sharpening notice ■ when sharpening blades, grind the same amount on each blade to maintain balance. Replace blades in pairs. Unbalanced blades will cause excessive vibration, which can damage gearbox bearings. Vibration may also cause struc- tural cracks t...

Page 23: Owner Service 23

Owner service 23 man0725 (10/3/2008) shielding repair full chain or rubber shielding must be installed when operating in populated areas or other areas where thrown objects could injure people or dam- age property. • if this machine is not equipped with full chain or rubber shielding, operation mu...

Page 24: 24 Troubleshooting

24 troubleshooting man0725 (10/3/2008) troubleshooting problem possible cause solution does not cut dull blades sharpen blades. Worn or broken blades replace blades. (replace in pairs only.) incorrect pto speed set at rated pto speed. Ground speed too fast reduce ground speed. Drive not functioning ...

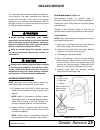

Page 25: Dealer Service 25

Dealer service 25 man0725 (10/3/2008) dealer service the information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you ma...

Page 26: 26 Dealer Service

26 dealer service man0725 (10/3/2008) vertical shaft seal replacement (figure 13) 1. Disconnect and remove the rear driveline from the gearbox. 2. Remove vent plug (24) and siphon gear lube from housing through this opening. 3. Remove crossbar (see page 30). 4. Remove protective seal (8) and vertica...

Page 27: Dealer Service 27

Dealer service 27 man0725 (10/3/2008) correct diameter. Be sure not to damage the seal lip. 8. Press in housing so that seal is recessed. Press protective seal (8) until seated flush with housing. Verify that the seal (8) is seated correctly. 9. Press bearing (7) into the housing, using a round tube...

Page 28: 28 Dealer Service

28 dealer service man0725 (10/3/2008) splitter gearbox repair (figure 14) removal from cutter 1. Disconnect and remove all drivelines from gearbox. 2. Remove the four cap screw and lock washers that secure gearbox to cutter, and remove gearbox. Note: gearbox is heavy: do not attempt to move it witho...

Page 29: Dealer Service 29

Dealer service 29 man0725 (10/3/2008) gearbox inspection 1. Check gearbox for leaks by: plugging all holes except one, applying 4 psi of compressed air, and immersing gearbox in water. Verify gearbox does not leak. Note: excessive air pressure will damage seals. 2. Remove gearbox from water and dry ...

Page 30: 30 Dealer Service

30 dealer service man0725 (10/3/2008) crossbar removal 1. It is necessary to gain access to bottom side of cutter for crossbar removal. See blocking method page 19. Note: you will need to use either the puller screw (item 6, figure 16) or a small hydraulic jack to remove the crossbar. 2. Remove blad...

Page 31: Dealer Service 31

Dealer service 31 man0725 (10/3/2008) crossbar installation 1. Using emery cloth (220 or finer), remove surface rust, loctite ® and foreign material from hub, splined gearbox vertical shaft, and crossbar assembly. 2. Slide crossbar assembly (8) onto splined shaft. Install washer (68) and nut (69) an...

Page 32: 32 Dealer Service

32 dealer service man0725 (10/3/2008) 4. Place universal cross in vise as shown in figure 22 and tap on yoke to remove cup. Repeat step 3 for final removal. Drive remaining cup out with a drift and hammer. Figure 22 u-joint assembly 1. Place seals securely on bearing cups. Insert cup into yoke from ...

Page 33: Assembly 33

Assembly 33 man0725 (10/3/2008) assembly instructions dealer set-up instructions assembly of this cutter is the responsibility of the woods dealer. It should be delivered to the owner completely assembled, lubricated and adjusted for nor- mal cutting conditions. The cutter is shipped partially assem...

Page 34: 34 Assembly

34 assembly man0725 (10/3/2008) 3. Tighten nuts until there is approximately 1 inches of thread exposed past the nuts. Further adjustment will be need once cutter is attached to tractor drawbar. See cutting height adjustment, page 15. Install height adjustment cylinder refer to figure 26. 1. Attach ...

Page 35: Assembly 35

Assembly 35 man0725 (10/3/2008) install spring wheel arms 1. Slide right spring wheel arm assembly (14) over center wheel yoke tube and secure into position using four cap screw (28) and flanged lock nut (37). Repeat step to install left spring wheel arm assembly. Keep spacing as wide as possible fo...

Page 36: 36 Assembly

36 assembly man0725 (10/3/2008) install 3-joint drive (540 rpm only) before installing cutter input driveline to gearbox, check the tag wired to the driveline and the tag wired to the input shaft of gearbox. Ensure the tag rpm speeds match the rpm speed decal on front of cutter. After con- firming a...

Page 37: Assembly 37

Assembly 37 man0725 (10/3/2008) install cv drive (optional) before installing cutter input driveline to gearbox, check the tag wired to the driveline and the tag wired to the input shaft of gearbox. Ensure the tag rpm speeds match the rpm speed decal on front of cutter. After con- firming all speeds...

Page 38: 38 Assembly

38 assembly man0725 (10/3/2008) figure 32. Wing cylinder & wing transport lock installation install wing wheel yoke 1. Attach wing wheel yoke (6) to the wing using pivot pins (31). Make sure pin flange is on the underside of the deck. See figure 33. 2. Secure pivot pins to deck using carriage bolts ...

Page 39: Assembly 39

Assembly 39 man0725 (10/3/2008) install wing wheel yoke adjustment link use a suitable lifting device of sufficient capac- ity. Use adequate personnel to handle heavy com- ponents. 1. With a lifting device raise right wing and lock in the up position using the wing lock-up bar. Leave lifting devic...

Page 40: 40 Assembly

40 assembly man0725 (10/3/2008) optional equipment install tandem wheel assembly (center) 1. Slide spring wheel arm assembly (1) over right side of center wheel yoke tube and secure into position using four cap screw (22) and flanged lock nut (23). Repeat step to install spring wheel arm assembly on...

Page 41: Assembly 41

Assembly 41 man0725 (10/3/2008) install chain or belt shielding full chain shielding must be installed when operating in populated areas or other areas where thrown objects could injure people or damage property. • if this machine is not equipped with full chain shielding, operation must be stoppe...

Page 42: 42 Assembly

42 assembly man0725 (10/3/2008) figure 38. Chain shielding installation - right wing shown figure 39. Belt shielding installation - center section 1. Front wing chain plate, inner 2. Front wing chain plate, center 3. Front wing chain plate, outer 4. Rear wing chain plate 13. 5/16 chain - 4-link 12. ...

Page 43: Assembly 43

Assembly 43 man0725 (10/3/2008) figure 40. Belt shielding installation - right wing winch kit installation figure 41. Roller assembly installation 1. Locate and drill one 9/16" hole in each wing using dimensions shown in figure 41. Assemble items 1, 2, 3 and 4. Use assembly to locate and drill remai...

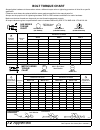

Page 44: 44 Dealer Check Lists

44 dealer check lists man0725 (10/3/2008) dealer check lists pre-delivery check list (dealer’s responsibility) inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspect. Check of...

Page 45: Parts 45

Parts 45 man0725 (10/3/2008) parts index batwing ® rotary cutter bw240, bw240q main frame assembly (front section) ...................................................... 46-47 (rear section) ......................................................... 48-49 wing assembly ..................................

Page 46: 46 Parts

46 parts man0725 (10/3/2008) main frame assembly (front section) (rev. 9/11/2013).

Page 47: Parts 47

Parts 47 man0725 (10/3/2008) main frame assembly (front section) ref part qty description 1 8825kt 1 blade kit, ccw 2 ----- 1 gearbox (see page 52) 3 1027297 1 driveline complete, 1340, 1.75-20 12.6 4 1027125 2 attitude rod 5 1027035 2 front skid 6 19407 1 safety chain 7 1008190 2 1-1/2 blade pin ki...

Page 48: 48 Parts

48 parts man0725 (10/3/2008) main frame assembly (rear section).

Page 49: Parts 49

Parts 49 man0725 (10/3/2008) main frame assembly (rear section) ref part qty description 1 1027070 1 center wheel yoke 2 57050 1 access hole cover 3 10475 1 hydraulic cylinder 3-1/2 (see page 69) 4 1027125 2 attitude rod 5 1004814 1 transport lock-up 6 24098 1 1-1/4 cylinder stroke control kit (opti...

Page 50: 50 Parts

50 parts man0725 (10/3/2008) wing assembly rev. (9/21/2009) right wing shown.

Page 51: Parts 51

Parts 51 man0725 (10/3/2008) wing assembly ref part qty description 1 8825kt 1 blade kit, ccw (right wing) - or - 1 8820kt 1 blade kit, cw (left wing) 2 ----- 1 gearbox (see page 52) 3 1027120 1 clutch shield with hinge 4 1027296 1 driveline complete 2400, 63.4 x 83.7 5 52234 1 hydraulic cylinder 3-...

Page 52: 52 Parts

52 parts man0725 (10/3/2008) wing & center gearbox assembly.

Page 53: Parts 53

Parts 53 man0725 (10/3/2008) wing & center gearbox assembly 540 rpm 1000 rpm ref qty left wing center right wing left wing center right wing description a 1 1029696 58806 1029695 1029696 1029697 1029695 complete gearbox 1 1 1025865 57316 1025865 1025865 57358 1025865 gear crown 2 1 ns ns ns ns ns ns...

Page 54: 54 Parts

54 parts man0725 (10/3/2008) splitter gearbox assembly ref part part qty description 540 rpm 1000 rpm 1 1029698 1029699 - complete splitter gearbox 2 21542 21542 24 10 mm lock washer 3 307201 307201 24 m10-1.5 x 30 hhcs 4 1019613 1019613 1 input cap 5 1019575 1019575 1 input shaft 6 1019589 1019589 ...

Page 55: Parts 55

Parts 55 man0725 (10/3/2008) center deck drive assembly ref part qty description a 1027297 1 complete center drive assembly 1 1004961 1 yoke, 1-3/4, 20 spline 2 110 2 cross & bearing kit 3 40576 1 inboard yoke 4 1005521 1 grease fitting 5 57416 1 friction clutch 1340 1-3/4, 20 spline 6 57438 1 flang...

Page 56: 56 Parts

56 parts man0725 (10/3/2008) front 3-joint drive assembly (equal angle) 540 only ref part qty description a 57282 1 complete 540 rpm (6 spline) 1 40563 1 yoke 1-3/8 - 6 spline (540 rpm) 2 40566 2 cross & bearing 3 40751 2 inboard yoke 4 40753 1 outer profile 5 40765 2 spring pin 10 x 90 6 57299 1 yo...

Page 57: Parts 57

Parts 57 man0725 (10/3/2008) rear 3-joint drive assembly (equal angle) ref part qty description a 1004932 1 complete rear drive assembly 1 1004957 1 yoke, 1-3/4, 20 spline 2 40566 1 cross and bearing 3 1003471 1 inboard yoke 4 1004958 1 inner profile 5 40765 1 spring pin 10 x 90 6 1029936 1 stub sha...

Page 58: 58 Parts

58 parts man0725 (10/3/2008) type a - 540 rpm front cv drive ref part qty description a 1021103 1 complete cv drive (540 rpm) 1 19851 1 slide lock repair kit 2 58774 1 yoke qd cv 1.375 - 6 (540 rpm) 3 58759 2 cv u-joint repair kit cat 6 55e 4 58760 1 cv body with fitting 5 1021313 1 yoke and shaft c...

Page 59: Parts 59

Parts 59 man0725 (10/3/2008) type b - 540 rpm front cv drive ref part qty description a 1021103 1 complete cv drive (540 rpm) 1 19851 1 slide lock repair kit 2 1033103 1 yoke qd cv 1.375 - 6 (540 rpm) 3 1033107 2 cv u-joint repair kit cat 6 55e 4 1033106 1 cv body with fitting 5 1033113 1 yoke and s...

Page 60: 60 Parts

60 parts man0725 (10/3/2008) type a - 1000 rpm front cv drive 1000 rpm 1-3/8 21-splined 1000 rpm 1-3/4 20-splined ref part qty description a 1021104 1 complete cv drive assembly 1 19851 1 slide lock repair kit 2 58770 1 yoke qd cv 1.375 - 21 3 58759 2 cv u-joint repair kit, cat 6 55e 4 58760 1 cv bo...

Page 61: Parts 61

Parts 61 man0725 (10/3/2008) type b - 1000 rpm front cv drive 1000 rpm 1-3/8 21-splined 1000 rpm 1-3/4 20-splined ref part qty description a 1021104 1 complete cv drive assembly 1 19851 1 slide lock repair kit 2 1033104 1 yoke qd cv 1.375 - 21 3 1033107 2 cv u-joint repair kit, cat 6 55e 4 1033106 1...

Page 62: 62 Parts

62 parts man0725 (10/3/2008) wing drive assembly ref part qty description 1 1027296 complete wing drive assembly 2 1019111 1 yoke 1-3/4 20 special 3 38352 2 cross and bearing kit 2400 4 90317352 1 inboard yoke s4 5 40764 2 spring pin 10 x 80 6 1019112 1 inner profile s4l 7 1019115 1 outer shield 8 4...

Page 63: Parts 63

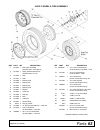

Parts 63 man0725 (10/3/2008) 5-bolt wheel & tire assembly ref part qty description 1 1017050 1 heavy hub assembly (includes items 1 through 15) 2 1017034 1 heavy wheel hub with cups (includes items 6,7,14) 3 1017033 1 axle 4 1017027 1 seal 5 1017028 1 bearing cone 6 1017036 1 bearing cup 7 1017037 1...

Page 64: 64 Parts

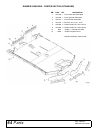

64 parts man0725 (10/3/2008) rubber shielding - center section (standard) ref part qty description 1 1027164 1 front center belt shield plate 2 1027166 1 front right belt shield plate 3 1027167 1 front left belt shield plate 4 1027176 4 bent link .25 x 1.61 x 12.00 5 1027284 2 rubber shield .25 x 8....

Page 65: Parts 65

Parts 65 man0725 (10/3/2008) rubber shielding - wing (standard) ref part qty description 1 1027168 1 front right wing belt shield plate, outer - or - 1 1027169 1 front left wing belt shield plate, outer 2 1027171 1 front wing belt shield plate, inner 3 1027172 1 front wing belt shield plate, center ...

Page 66: 66 Parts

66 parts man0725 (10/3/2008) chain shielding - center section (optional) single row double row ref part qty description 1 1027131 1 front center chain plate 2 1027132 1 front right chain plate 3 1027133 1 front left chain plate 4 1027141 2 rear chain plate 8 1003644 4 pin, 22 to 24 chains 9 1003646 ...

Page 67: Parts 67

Parts 67 man0725 (10/3/2008) chain shielding - wing (optional) single row double row ref part qty description 1 1027134 1 front wing chain plate, inner 2 1027140 1 front wing chain plate, center 3 1027136 1 front right wing chain plate, outer - or - 3 1027137 1 front left wing chain plate, outer 4 1...

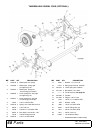

Page 68: 68 Parts

68 parts man0725 (10/3/2008) tandem axle wheel yoke (optional) ref part qty description 1 1024109 2 wheel yoke arm, spring 2 1027080 1 wheel yoke, spring right (for right wing) -or- 2 1027081 1 wheel yoke, spring left (for left wing) (not shown) 3 1029876 1 lower spring arm, wing right (for right wi...

Page 69: Parts 69

Parts 69 man0725 (10/3/2008) hydraulic cylinders 3-1/2 x 8 3-1/2 x 16 ref part part qty description 1 10475 52234 complete cylinder 2 23540 23540 1 seal repair kit (includes items 2a - 2g) 2a † † 1 wiper seal 2b † † 1 rod seal 2c † † 1 rod o-ring 2d † † 2 cap seal 2e † † 2 cap o-ring 2f † † 2 piston...

Page 70: 70 Parts

70 parts man0725 (10/3/2008) hydraulic cylinder stroke control kit crossbar puller (optional) ref part qty description 1 24098 1 stroke control set for 1-1/4" cylinder rod (contains items 2 - 5) 2 – – – – 2 1-1/2" segment 3 – – – – 1 1-1/4" segment 4 – – – – 1 1" segment 5 – – – – 1 3/4" segment ref...

Page 71: Parts 71

Parts 71 man0725 (10/3/2008) winch kit (optional) ref part qty description a 1019456 - winch kit, complete 1 52478 4 idler bracket 2 6696 2 chain idler casting 3 409 2 clevis pin, 1/2 x 2 4 22411 2 klik pin, 3/16 x 1 5 3379 * - hhcs, 1/2 nc x 1-1/2 gr5 6 11900 * - lock nut, 1/2 nc flanged 7 1863 * -...

Page 72: 72 Appendix

72 appendix bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 73: Appendix 73

Appendix 73 bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe.................... Am...

Page 74: 74 Index

74 index man0725 (10/3/2008) index adjustments cutting height 15 slip clutch 22 assembly dealer set-up instructions 33 fill gearboxes 39 optional equipment 40 dealer check list check lists delivery (dealer’s responsibility) 44 pre-delivery (dealer’s responsibility) 44 dealer service crossbar install...

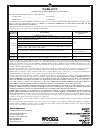

Page 75: Warranty

F-3079 (rev. 5/10/2013) woods equipment a blount international company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 usa 800-319-6637 tel 800-399-6637 fax woodsequipment.Com warranty all models except mow’n machine tm zero-turn mowers please enter information below and save...

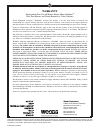

Page 76: Warranty

F-8494 (rev. 2/5/2013) woods equipment a blount international company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax woodsequipment.Com ©2013 woods equipment company. All rights reserved. Woods ® and the woods logo are trademarks of woods eq...