- DL manuals

- Woods

- Cutter

- DS10.50

- Operator's Manual

Woods DS10.50 Operator's Manual

Summary of DS10.50

Page 1

Op e r a t o r 's m a nu a l rotary cutter man1 168 ( r e v. 7 /12/ 201 6) ds8.50/ds8.50q ds10.50/ds10.50q dso8.50/dso8.50q dso10.50/dso10.50q.

Page 2: 2 Introduction

2 introduction gen’l (rev. 2/25/2016) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 man1168 (5/27/2016) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general information . . . . . . ....

Page 4: 4 Introduction

4 introduction man1168 (rev. 5/27/2016) specifications general information some illustrations in this manual show the equipment with safety shields removed to provide a better view. This equipment should never be operated with any necessary safety shielding removed. The purpose of this manual is t...

Page 5: Safety 5

Safety 5 safety video order form (8/2/2005) free mower safety video fill out and return the order form and we will send you a free vhs or dvd video outlining industrial and agricultural mower safety practices . The 22 minute video, developed in cooperation with aem (association of equipment manufact...

Page 6: 6 Safety

6 safety safety video order form (rev. 2/6/2006) free mower/cutter safety video order form (select one) vhs format - vhs01052 safety video dvd format - dvd01052 safety video please send me name: ________________________________________ phone: __________________ address: _____________________________...

Page 7: Safety 7

Safety 7 ds/dso.50 safety rules (5/19/2016) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check th...

Page 8: 8 Safety

8 safety ds/dso.50 safety rules (5/19/2016) (safety rules continued from previous page) remove accumulated debris from this equip- ment, power unit, and engine to avoid fire hazard. make sure all safety decals are installed. Replace if damaged. (see safety decals section for location.) make su...

Page 9: Safety 9

Safety 9 ds/dso.50 safety rules (5/19/2016) (safety rules continued from previous page) transportation the maximum transport speed for towed and semi-mounted machines is 20 mph (32 km/h). Regardless of the maximum speed capability of the towing tractor, do not exceed the implement’s max- imum tran...

Page 10: 10 Safety

10 safety ds/dso.50 safety rules (5/19/2016) (safety rules continued from previous page) do not disconnect hydraulic lines until machine is securely blocked or placed in lowest position and system pressure is released by operating valve levers. leak down or failure of mechanical or hydraulic sys...

Page 11: Safety 11

Safety 11 man1168 (5/27/2016) 1 - serial number plate 2 - pn 5669 3 - pn 12777 4 - pn 18877 be careful! Use a clean, damp cloth to clean safety decals. Avoid spraying too close to decals when using a pressure washer; high-pressure water can enter through very small scratches or under edges of decals...

Page 12: 12 Safety

12 safety man1168 (5/27/2016) 6 - pn 15503 7 - pn 18865 5 - pn 1003751 8 - pn 18864 9a - pn 18866 540 rpm -or- 9b - pn 15922 1000 rpm 10 - pn 1004114 11 - pn 57123 red rear reflector 9" 12 - pn 1002940 amber front reflector 9" safety & instructional decals attention! Become alert! Your safety is inv...

Page 13: Safety 13

Safety 13 man1168 (5/27/2016) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! 14 - pn 19924 15 - pn 1004991 17 - pn 33347 18a - pn 57840 540 rpm -or- 18b - pn 57841 1000 rpm 13 - pn 15502 16 - pn 1006348 (located on wheel rims).

Page 14: 14 Operation

14 operation man1168 (5/27/2016) operation the operator is responsible for the safe operation of the cutter. The operator must be properly trained. Operators should be familiar with the cutter, the tractor, and all safety practices before starting operation. Read the safety rules and safety decals o...

Page 15: Operation 15

Operation 15 man1168 (5/27/2016) 5. Connect cutter driveline to tractor pto shaft, making sure the spring-activated lock pin slides freely and is seated in tractor pto splined groove. 6. Remove parking jack from the tongue and attach it to the storage post on the front of the cutter. Hydraulic conne...

Page 16: 16 Operation

16 operation man1168 (5/27/2016) category 3 standard hitch 1. Position tractor lower lift arms between hitch mast plates. 2. Insert lower hitch pins to position a, figure 2, through mast plates and tractor lower lift arms. 3. Secure with lynch pins. 4. Attach top link for mounted units in the top ho...

Page 17: Operation 17

Operation 17 man1168 (5/27/2016) 4. Cut the shield to the overall dimension (figure 6). Figure 6. Cut shield 5. Place the cutoff portion of the shield against the end of the shaft and use it as a guide. Mark and cut the shaft. See figure 7. 6. Repeat step 5 for other half of drive. 7. File and clean...

Page 18: 18 Operation

18 operation man1168 (5/27/2016) attitude adjustment (pull-type) normal mowing for the most economical power use and best cutting results, the cutter should be from 1/2" to 3/4" higher at the rear than at the front. For grass and weed mowing, adjust cutter to run level or with the front slightly low...

Page 19: Operation 19

Operation 19 man1168 (5/27/2016) cutter operation when beginning operation of the cutter, make sure that all persons are in a safe location. Slowly move into the material with the tractor pto set at 540 rpm (1000 rpm on "q" models). Mowing tips look down and to the rear and make sure area is clear...

Page 20: 20 Operation

20 operation man1168 (5/27/2016) pre-operation check list (owner's responsibility) ___ review and follow all safety rules and safety decal instructions on pages 7 through 13. ___ check that all safety decals are installed and in good condition. Replace if damaged. ___ check that equipment is properl...

Page 21: Owner Service 21

Owner service 21 man1168 (5/27/2016) owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. ke...

Page 22: 22 Owner Service

22 owner service man1168 (5/27/2016) figure 10. Jackstand placement and lubrication points ref description frequency 1. Driveline u-joint 10 hrs. 2. Telescoping shaft 10 hrs. 3. Cv body assembly 10 hrs. (10 pumps minimum) 4. Driveline shield 10 hrs. 5. Carrier bearing 40 hrs. 6. Side drive yoke 40 h...

Page 23: Owner Service 23

Owner service 23 man1168 (5/27/2016) blade servicing removing blades (figure 11) notice ■ if blade pin (12) is seized in crossbar and extreme force will be needed to remove it, support crossbar from below to prevent gearbox damage. 1. Disconnect driveline from tractor pto. 2. Open blade access cover...

Page 24: 24 Owner Service

24 owner service man1168 (5/27/2016) figure 13. Slip clutch assembly slip clutch adjustment the slip clutch is designed to slip so that the gearbox and drive are protected if the cutter strikes an obstruc- tion. A new slip clutch or one that has been in storage over the winter may seize. Before oper...

Page 25: Owner Service 25

Owner service 25 man1168 (5/27/2016) belleville spring clutch (ds8.50 pull-type and ds8.50 3-point mounted models) 1. Turn off tractor engine and remove key. 2. Remove driveline from tractor pto. 3. Loosen six 12 mm cap screws (6) to remove all tension from belleville spring plate (7). 4. Hold clutc...

Page 26: 26 Owner Service

26 owner service man1168 (5/27/2016) servicing tires safely used aircraft tires (figure 15) do not attempt to mount a tire unless you have the proper equipment and experience to perform the job. Always maintain the correct tire pressure. Do not inflate tires above the recommended pressure. Never wel...

Page 27: Troubleshooting 27

Troubleshooting 27 man1168 (5/27/2016) troubleshooting problem possible cause solution does not cut dull blades sharpen blades. Worn or broken blades replace blades. (replace in pairs only.) incorrect pto speed set at rated pto speed. Ground speed too fast reduce ground speed. Drive not functioning ...

Page 28: 28 Troubleshooting

28 troubleshooting man1168 (5/27/2016) notes.

Page 29: Dealer Service 29

Dealer service 29 man1168 (5/27/2016) dealer service the information in this section is written for dealer service personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you may ...

Page 30: 30 Dealer Service

30 dealer service man1168 (5/27/2016) vertical seal should be recessed in housing. Horizontal seal (19) should be pressed flush with outside of housing. Note: distortion to seal cage or damage to seal lip will cause seal to leak. 5. Fill gearbox with sae 80w or 90w gear lube until it runs out the le...

Page 31: Dealer Service 31

Dealer service 31 man1168 (5/27/2016) 9. Press bearing (7) into the housing, using a round tube of the correct diameter and a hand press. Secure with shim (13) and snap ring (10). 10. Secure snap ring (11) on input shaft (3) if not already secure. 11. Place gear (1) through top of housing and align ...

Page 32: 32 Dealer Service

32 dealer service man1168 (5/27/2016) figure 15. Splitter gearbox assembly splitter gearbox repair (figure 15) note: replacing gears, shafts, bearings, and seals may not be cost effective. Purchasing a complete gearbox may be more economical. Remove gearbox from cutter 1. Disconnect driveline from t...

Page 33: Dealer Service 33

Dealer service 33 man1168 (5/27/2016) 13. Inspect vertical and horizontal shafts for grooves, nicks, or bumps in the areas where the seals seat. Resurface any damage with emery cloth. 14. Inspect housing and caps for cracks or other damage. Assemble gearbox (figure 15) 1. Clean housing, paying speci...

Page 34: 34 Dealer Service

34 dealer service man1168 (5/27/2016) the drives between the center and side gearboxes contain rubber shock-absorbing discs. To service or remove the side drives or remove a gearbox, the flexible coupling must be disassembled. See page 25 for rubber disk replacement. Remove end yokes by removing nut...

Page 35: Dealer Service 35

Dealer service 35 man1168 (5/27/2016) figure 18. Crossbar removal crossbar installation 1. Using emery cloth (220 or finer), remove surface rust, and foreign material from hub, splined gearbox vertical shaft, and crossbar. See figure 19. Figure 19. Typical crossbar and gearbox shaft 2. Install cross...

Page 36: 36 Dealer Service

36 dealer service man1168 (5/27/2016) crossbar timing crossbar must be re-timed anytime a crossbar or a side drive is disconnected. 1. To re-time crossbars, position bars as shown in figure 21. 2. The right crossbar will be at right angles to the front of the cutter. 3. Measure from the front of the...

Page 37: Dealer Service 37

Dealer service 37 man1168 (5/27/2016) figure 24. Remove cups 2. With snap rings removed, support drive in vise, hold yoke in hand and tap on yoke to drive cup up out of yoke. See figure 24. Figure 25. Remove cups 3. Clamp cup in vise as shown in figure 25 and tap on yoke to completely remove cup fro...

Page 38: 38 Assembly

38 assembly man1168 (5/27/2016) assembly instructions dealer set-up instructions these instructions are for the assembly of the ds8.50 and ds10.50 mounted and pull-type cutters as well as the dso8.50 and dso10.50 semi-mounted cutters. Many of the procedures apply to all units. When an instruction ap...

Page 39: Assembly 39

Assembly 39 man1168 (5/27/2016) figure 28. Ds8.50 & ds10.50 pull-type cutter assembly 1. Tongue 2. Lower hitch pin 3. Klik pin 4. Attitude rod 5. Tail wheel arm 6. Wheel and hub 7. H-frame 8. Drive shield 9. Rear drive 10. Cv drive 11. Smv bracket 12. Smv emblem 13. Parking jack 14. Hydraulic hose, ...

Page 40: 40 Assembly

40 assembly man1168 (5/27/2016) ds8.50 & ds10.50 3-point mounted cutter (see figure 29) place jackstands under cutter to raise it off the ground to provide clearance when assembling cutter. See “blocking method” on page 21 for jackstand placement. Install rear tailwheel 1. Attach tailwheel arms (11)...

Page 41: Assembly 41

Assembly 41 man1168 (5/27/2016) figure 29. Ds8.50 & ds10.50 3-point mounted cutter assembly 1. A-frame assembly 2. Break link 3. Lift arm 4. Sleeve, .781 x 1.38 x 2.40 5. Sleeve, 1-3/8 x 1-3/4 x 1-1/4 6. Sleeve 5/8 x 1 x 1-1/4 7. Sleeve, 5/8 x 1 x 13/16 8. Top link pin 9. Lower hitch pin 10. Driveli...

Page 42: 42 Assembly

42 assembly man1168 (5/27/2016) dso8.50 & dso10.50 3-point mounted cutter (figure 30) place jackstands under cutter to raise it off the ground to provide clearance when assembling cutter. See “blocking method” on page 21 for jackstand placement. Install rear tailwheel 1. Attach tailwheel arms (9) to...

Page 43: Assembly 43

Assembly 43 man1168 (5/27/2016) figure 30. Dso8.50 & dso10.50 3-point mounted cutter assembly 1. Hitch assembly 2. Left hitch arm 3. Right hitch arm 4. 1.50 x 8.02 flag pin 5. Smv bracket 6. Smv emblem 7. Double acting cylinder 8. Driveline 9. Tailwheel assembly 10. Lower hitch pin 11. Sleeve, 1.56 ...

Page 44: 44 Assembly

44 assembly man1168 (5/27/2016) all models fill gearboxes notice ■ gearbox is not filled at the factory. Prior to delivery to customer, make sure gearbox is filled only half-full with 80w or 90w api gl-4 or gl-5 gear lube. Use side plug to remove any excess oil. 1. Make sure vent plug hole is clear ...

Page 45: Assembly 45

Assembly 45 man1168 (5/27/2016) optional chain shielding (see figure 32) the optional chain shielding assemblies are ready for installation when you receive them. 1. Install front chain shielding to the front of the frame using cap screws (6) and lock nuts (8). 2. Attach rear chain shielding to the ...

Page 46: 46 Dealer Check Lists

46 dealer check lists man1168 (5/27/2016) dealer check lists pre-delivery check list (dealer’s responsibility) inspect cutter thoroughly after assembly to make sure it is set up properly before delivering it to the customer. The following check list is a reminder of points to inspect. Check off each...

Page 47: Parts 47

Parts 47 man1168 (5/27/2016) parts index rotary cutters main frame assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 - 49 pull-type assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 ds8.50 / ds10.50 mounted cutter a...

Page 48: 48 Parts

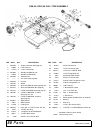

48 parts man1168 (5/27/2016) main frame assembly.

Page 49: Parts 49

Parts 49 man1168 (5/27/2016) main frame assembly ref part qty description 1 1043000 1 wheel yoke (ds8.50) -or- 1 1043001 1 wheel yoke (dso8.50) -or- 1 1043002 1 wheel yoke (ds10.50) -or- 1 1043003 1 wheel yoke (dso10.50) 2 58805 2 spindle gearbox (ds8.50, dso8.50) (see page 54) 2 58806 2 spindle gea...

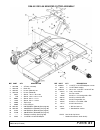

Page 50: 50 Parts

50 parts man1168 (5/27/2016) ds8.50 / ds10.50 pull-type assembly ref part qty description 1 1042250 1 tongue assembly (see page 62) 2 39064 2 lower hitch pin 3 27542 * 2 7/16 x 11/32 klik pin 4 1013388 1 attitude rod (ds8.50) -or- 4 39385 1 attitude rod (ds10.50) 5 1042240 2 tailwheel arm 6 ------- ...

Page 51: Parts 51

Parts 51 man1168 (5/27/2016) ds8.50 / ds10.50 mounted cutter assembly ref part qty description 1 1021350 1 a-frame assembly 2 1042244 2 break link 3 1042287 2 lift arm (ds8.50) -or- 3 1042243 2 lift arm (ds10.50) 4 39071 1 sleeve, .781 x 1.38 x 2.40 5 7176 1 sleeve, 1-3/8 x 1-3/4 x 1-1/4 6 66661 2 s...

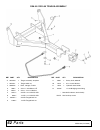

Page 52: 52 Parts

52 parts man1168 (5/27/2016) dso8.50 / dso10.50 assembly ref part qty description 1 1021775 1 hitch assembly 2 1042991 1 left hitch arm (dso8.50) -or- 2 1021783 1 left hitch arm (dso10.50) 3 1021784 1 right hitch arm 4 1021398 4 1.50 x 8.02 flag pin 5 1043012 1 smv bracket 6 24611 1 smv emblem 7 187...

Page 53: Parts 53

Parts 53 man1168 (5/27/2016) ds8.50 / ds10.50 / dso8.50 / dso10.50 splitter gearbox assembly note: 1000 rpm gearbox shown; gear (8) and gear (19) are reversed on 540 rpm gearbox. Ref part qty description a 1002495 complete 540 rpm gearbox assembly ds8.50, dso8.50, ds10.50, dso10.50 -or- a 1002496 co...

Page 54: 54 Parts

54 parts man1168 (5/27/2016) ds8.50 / ds10.50 / dso8.50 / dso10.50 spindle gearbox assembly ref part qty description a 58805 gearbox, repair asy ds8.50/dso8.50 -or- a 58806 gearbox, repair asy ds10.50/dso10.50 1 57315 1 gear crown 25t m6.5 ds8.50/dso8.50 -or- 1 57316 1 gear crown 23t m6.7 ds10.50/ds...

Page 55: Parts 55

Parts 55 man1168 (5/27/2016) ds8.50 / ds10.50 / dso8.50 / dso10.50 flexible coupler ds8.50 ds10.50 dso8.50 right dso10.50 right dso8.50/dso10.50 left ref part qty qty qty qty qty description a 1040672 2 ------- ------- ------- ------- complete flex coupler drive (ds8.50) b 1040673 ------- 2 ------- ...

Page 56: 56 Parts

56 parts man1168 (5/27/2016) 540 rpm front cv drive assembly ref part qty description a 1024175 1 complete 540 rpm front cv drive 1 19851 1 slide lock repair kit, 1.38 id 2 1033103 1 yoke, qd cv 1.375-6 3 1033107 2 u-joint repair kit, cat 6 cv 55e 4 1033106 1 cv body with fitting 5 1033114 1 yoke & ...

Page 57: Parts 57

Parts 57 man1168 (5/27/2016) 1000 rpm front cv drive assembly 1000 rpm 1-3/8 21-splined 1000 rpm 1-3/4 20-spline ref part qty description a 1021102 1 1000 rpm cv drive assembly com- plete, 21-spline 1 19851 1 slide lock repair kit, 1.38 id 2 1033104 1 yoke, qd cv 1.375-21 3 1033107 2 u-joint repair ...

Page 58: 58 Parts

58 parts man1168 (5/27/2016) ds8.50 rear fixed-length drive ref part qty description a 1042288 1 drive assembly complete (ds8.50) 1 1041693 1 drive without shield 2 40566 1 cross & bearing kit 3 1041678 1 friction clutch 4 40766 1 bearing ring 5 40767 1 support bearing 6 18864 1 decal, danger, rotat...

Page 59: Parts 59

Parts 59 man1168 (5/27/2016) ds10.50 rear fixed-length drive ref part qty description a 1022221 1 drive assembly complete (ds10.50) 1 1024775 1 drive without shield 3 40566 1 cross & bearing kit 6 57421 1 friction clutch 9 40766 1 bearing ring 11 40767 1 support bearing 12 18864 1 danger decal - rot...

Page 60: 60 Parts

60 parts man1168 (5/27/2016) ds8.50 & ds8.50q slip clutch drive assembly - mounted ref part qty description a 1042761 1 complete 540 rpm drive assembly - ds8.50 -or- a 1042762 1 complete 1-3/8, 1000 rpm drive assembly - ds8.50q 1 40563 1 yoke, 1-3/8 - 6 spline asg, ds8.50 -or- 1 40757 1 yoke, 1-3/8 ...

Page 61: Parts 61

Parts 61 man1168 (5/27/2016) ds10.50 (q) / dso8.50 (q) / dso10.50 slip clutch drive assembly - mounted ref part qty description a 57419 1 complete 540 rpm drive assembly - ds10.50 -or- a 57290 1 complete 1-3/8, 1000 rpm drive assembly - ds10.50q -or- a 57422 1 complete 540 rpm drive assembly - dso8....

Page 62: 62 Parts

62 parts man1168 (5/27/2016) ds8.50 / ds10.50 tongue assembly ref part qty description a 1042250 1 tongue assembly, complete 1 1042251 1 tongue weld asy 2 1005595 1 hitch, category 2 clevis 3 13087 2 3/4 x 1 x 9/16 sleeve, ht 4 28873 2 3/4 x 1-1/2 x 1/4 washer 5 13759 * 3/4 nc x 2-1/4 hhcs, gr5 6 61...

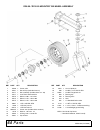

Page 63: Parts 63

Parts 63 man1168 (5/27/2016) wheel & tire assembly ref part qty description 1 1017050 1 heavy hub assembly (includes items 1 through 15) 2 1017034 1 heavy wheel hub with cups (includes items 6, 7, 14) 3 1017033 1 axle 4 1017027 1 seal 5 1017028 1 bearing cone 6 1017036 1 bearing cup 7 1017037 1 bear...

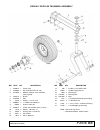

Page 64: 64 Parts

64 parts man1168 (5/27/2016) ds8.50 / ds10.50 mounted tailwheel assembly ref part qty description 1 15580 1 caster yoke 2 15591 1 hub w/cups (includes item 18) 3 15277 1 hub assembly (includes items 18 - 20) 4 12577 1 4 x 8 rim & laminated tire 5 15573 1 sleeve, 1.00 x 1.25 x 5.81 6 15574 1 sleeve, ...

Page 65: Parts 65

Parts 65 man1168 (5/27/2016) dso8.50 / dso10.50 tailwheel assembly ref part qty description 1 1043014 1 caster yoke 2 1041000 1 hub (includes items 16 - 20) 3 1017040 1 6.00 x 9 solid tire, rim & hardware (see page 63) 4 1042979 2 spacer 5 1042980 1 axle 6 11920 2 washer, 1 x 1-7/8 x 1/4 7 1006861 2...

Page 66: 66 Parts

66 parts man1168 (5/27/2016) ds8.50 / dso8.50 / ds10.50 / dso10.50 belt shielding (standard) ds8.50 / dso8.50 ds10.50 / dso10.50 ref part qty description 1 1042751 2 front rubber deflector 2 1043016 2 front belt bracket 3 1043017 1 rear band 4 14478 * 3/8 nc x 4 hhcs, gr5 5 6697 * 3/8 nc x 1 carriag...

Page 67: Parts 67

Parts 67 man1168 (5/27/2016) ds8.50 / dso8.50 / ds10.50 / dso10.50 chain shielding (optional) ds8.50 / dso8.50 ds10.50 / dso10.50 ref part qty description 1 1043020 2 front chain bracket 2 1043021 2 rear chain bracket 3 5496 a/r 5/16 - 7 link chain 4 1007853 2 pin, bent, .243 dia x 37 to 39 chains 5...

Page 68: 68 Parts

68 parts man1168 (5/27/2016) hydraulic cylinder stroke control kit crossbar puller (optional) ref part qty description 1 24098 1 stroke control set for 1-1/4" cylin- der rod (contains items 2 - 5) 2 – – – – 2 1-1/2" segment 3 – – – – 1 1-1/4" segment 4 – – – – 1 1" segment 5 – – – – 1 3/4" segment r...

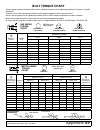

Page 69: Appendix 69

Appendix 69 bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 70: 70 Appendix

70 appendix bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe.................... Am...

Page 71: Index 71

Index 71 man1168 (5/27/2016) index assembly dealer set-up instructions ds8.50 & ds10.50 pull-type models 38 ds8.50 & ds10.50 3-point mounted cutter 40 dso8.50 & dso10.50 3-point mounted cutter 42 dealer check lists delivery (dealer’s responsibility) 46 pre-delivery (dealer’s responsibility) 46 deale...

Page 73: Warranty

F-8494 (rev. 2/25/2016) ©2016 woods equipment company. All rights reserved. Woods ® and the woods logo are trademarks of woods equipment company. All other trademarks, trade names, or service marks not owned by woods equipment company that appear in this manual are the property of their respective c...

Page 74: Part No.

Part no. Man1168 © 2016 woods equipment company. All rights reserved. Woods ® and the woods logo are trademarks of woods equipment company. All other trademarks, trade names, or service marks not owned by woods equipment company that appear in this manual are the property of their respec- tive compa...