- DL manuals

- Woods

- Lawn Mower

- RD6000-2, RD7200-2, RD8400-2

- Operator's Manual

Woods RD6000-2, RD7200-2, RD8400-2 Operator's Manual

Summary of RD6000-2, RD7200-2, RD8400-2

Page 1

Op e r a t o r 's m a nu a l rear discharge mowers man0180 r e v. 4 /28/ 200 6 tested. Proven. Unbeatable. Rd6000-2 rd7200-2 rd8400-2.

Page 2: Ii Introduction

Ii introduction gen’l (rev. 5/23/2005) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are comple...

Page 3: Introduction 1

Introduction 1 man0180 (rev. 1/7/2005) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Inside front cover specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 general information . . . . . . . . . ....

Page 4: 2 Introduction

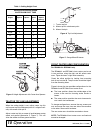

2 introduction man0180 (rev. 1/7/2005) specifications rd6000-2 rd7200-2 rd8400-2 3-point hitch category 1 category 1 category 1 cutting width 60" 72" 84" cutting height range 1" - 5-1/2" 1" - 5-1/2" 1" - 4-1/4" operating weight with chain shielding 605 lbs 671 lbs 770 lbs blade speed (feet per minut...

Page 5: Safety 3

Safety 3 rd mower (rev. 4/28/2006) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check the dealer ...

Page 6: 4 Safety

4 safety rd mower (rev. 4/28/2006) never direct discharge toward people, animals, or property. keep bystanders away from equipment. never go underneath equipment (lowered to the ground or raised) unless it is properly blocked and secured. Never place any part of the body under- neath equipment...

Page 7: Safety 5

Safety 5 rd mower (rev. 4/28/2006) always wear relatively tight and belted clothing to avoid getting caught in moving parts. Wear sturdy, rough-soled work shoes and protective equipment for eyes, hair, hands, hearing, and head; and respirator or filter mask where appropriate. make sure attachmen...

Page 8: 6 Safety

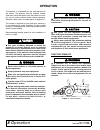

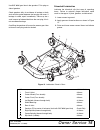

6 safety man0180 (rev. 1/7/2005) 12 1 1 9 10 6 2 2 8 3 5 6 7 cd4984a rotating blades and thrown objects do not put hands or feet under or into mower when engine is running. Before mowing, clear area of objects that may be thrown by blade. Keep bystanders away. Keep guards in place and in good condit...

Page 9: Safety 7

Safety 7 man0180 (rev. 1/7/2005) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! Guard missing. Do not operate. Danger 33347e danger danger guard missing. Do not operate. Falling off can result in being run over. Tractor must be equippe...

Page 10: 8 Operation

8 operation man0180 (rev. 1/7/2005) operation the operator is responsible for the safe operation of the mower. The operator must be properly trained. Operators should be familiar with the mower, the trac- tor, and all safety practices before starting operation. Read the safety rules and safety decal...

Page 11: Operation 9

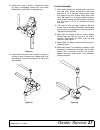

Operation 9 man0180 (rev. 1/7/2005) attaching mower to tractor make sure spring-activated locking pin or collar slides freely and is seated firmly in tractor pto spline groove. The standard 1-3/8" 6b-spline driveline with a qd yoke is used to connect the mower to the tractor. 1. Attach the mower h...

Page 12: 10 Operation

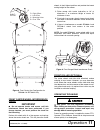

10 operation man0180 (rev. 1/7/2005) figure 5. Height adjustment with caster arm spacers tractor top link adjustment when the cutting height is set, adjust tractor top link until mower top link attachment point a is aligned verti- cally with mower hitch pin b. Adjust tractor top link so mower is lev...

Page 13: Operation 11

Operation 11 man0180 (rev. 1/7/2005) figure 8. Front caster arm configuration for rd6000-2 & rd7200-2 only front caster wheel interference check important ■ do not operate tractor and mower until this interference check has been performed. If you change tractors, you must perform the check for that ...

Page 14: 12 Operation

12 operation man0180 (rev. 1/7/2005) if mower becomes plugged causing belt to slip for over two seconds follow these steps: 1. Maneuver equipment into a previously cut area and allow mower to clear accumulated material. 2. Continue running at least two minutes, allowing pulleys to cool. Stopping the...

Page 15: Operation 13

Operation 13 man0180 (rev. 1/7/2005) owner pre-operation check list (owner's responsibility) ___ review and follow all safety rules and safety decal instructions on pages 3 through 7. ___ check that all safety decals are installed and in good condition. Replace if damaged. ___ check that all shields...

Page 16: 14 Owner Service

14 owner service man0180 (rev. 1/7/2005) owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. ...

Page 17: Owner Service 15

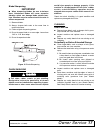

Owner service 15 man0180 (rev. 1/7/2005) use sae 90w gear lube in the gearbox. Fill to plug on side of gearbox. Check gearbox daily for evidence of leakage at both seals and the gasket between the housing and cover. If leakage is noted, repair immediately. There may be a small amount of lube emitted...

Page 18: 16 Owner Service

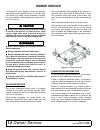

16 owner service man0180 (rev. 1/7/2005) belt service belt replacement one of the major causes of belt failure is improper installation. Before installing a new belt, check the fol- lowing: 1. Check pulley shafts and bearings for wear. 2. Check pulley grooves for cleanliness. 3. Make sure spindles t...

Page 19: Owner Service 17

Owner service 17 man0180 (rev. 1/7/2005) blade sharpening important ■ when sharpening blades, be sure to balance them. Unbalanced blades will cause excessive vibration which can damage blade spindle bear- ings. Vibration may also cause structural cracks in mower components. 1. Remove blades. 2. Alwa...

Page 20: 18 Owner Service

18 owner service man0180 (rev. 1/7/2005) trouble shooting mowing conditions problem possible cause solution grass cut higher in center of swath than at edge height of mower higher at front than at rear adjust mower height and attitude so that mower rear and front are within 1/2 inch of same height. ...

Page 21: Owner Service 19

Owner service 19 man0180 (rev. 1/7/2005) trouble shooting belt conditions * check belt for damage by laying it flat on the floor. A belt that does not lie flat (has humps or twists, indicating broken or stretched cords) must be replaced. Problem possible cause solution belt slippage mower overloadin...

Page 22: 20 Dealer Service

20 dealer service man0180 (rev. 1/7/2005) dealer service the information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, yo...

Page 23: Dealer Service 21

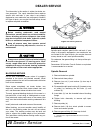

Dealer service 21 man0180 (rev. 1/7/2005) figure 17. Sheave and blade assembly spindle disassembly 1. Place spindle assembly in press and press shaft down through housing. 2. Remove seals from housing. Spindle assembly refer to figure 18. Bearing cones and cups are designed to work together. It is i...

Page 24: 22 Dealer Service

22 dealer service man0180 (rev. 1/7/2005) refer to figure 19. 12. Apply a thin coat of permatex to shaft area where sleeve will seat. 13. Install sleeve on shaft and press sleeve and bearing into housing until all free play is removed and there is a very light drag on bearings (similar to adjusting ...

Page 25: Dealer Service 23

Dealer service 23 man0180 (rev. 1/7/2005) figure 20. Seal installation vertical shaft seal replacement 1. Disconnect and remove the driveline from the gearbox. 2. Remove vent plug (24) and siphon gear lube from housing through this opening. 3. Remove gearbox stand from mower deck. 4. Remove gearbox ...

Page 26: 24 Dealer Service

24 dealer service man0180 (rev. 1/7/2005) remove gearbox from mower refer to figure 22. 1. Disconnect and remove the rear driveline from the gearbox. 2. Remove vent plug and siphon gear lube from housing through this opening. 3. Remove gearbox stand (20) from mower deck by removing four flanged lock...

Page 27: Dealer Service 25

Dealer service 25 man0180 (rev. 1/7/2005) figure 23. Gearbox assembly 6. Press gear (5) onto output shaft (4) and secure with washer (17), castle nut (14), and cotter pin (9). 7. Apply grease to lower seal lips (18) and press seal over output shaft (4), using a tube of the correct diameter. Be sure ...

Page 28: 26 Dealer Service

26 dealer service man0180 (rev. 1/7/2005) install gearbox note: gearbox is heavy: do not attempt to move with- out mechanical assistance. 1. Set gearbox on gearbox stand and fasten with bolts and nuts. Torque bolts to 175 lbs-ft. 2. Attach drive sheave to output shaft. Secure using castle nut and ha...

Page 29: Dealer Service 27

Dealer service 27 man0180 (rev. 1/7/2005) 3. Clamp cup in vise as shown in figure 28 and tap on yoke to completely remove cup from yoke. Repeat step 2 and step 3 for opposite cup. Figure 28 4. Place universal cross in vise as shown in figure 29 and tap on yoke to remove cup. Repeat step 3 for final ...

Page 30: 28 Assembly

28 assembly man0180 (rev. 1/7/2005) assembly instructions dealer set-up instructions assembly of this mower is the responsibility of the woods dealer. If should be delivered to the owner com- pletely assembled, lubricated, and adjusted for normal cutting conditions. Complete dealer check lists on pa...

Page 31: Assembly 29

Assembly 29 man0180 (rev. 1/7/2005) install rear offset links 1. Loosen nut (56) at rear frame lug and attach offset link (13) as shown in figure 33. 2. Repeat for opposite side. 3. Do not tighten at this time. Figure 33. Right rear offset link installed install top link figure 34. Top link assemble...

Page 32: 30 Assembly

30 assembly man0180 (rev. 1/7/2005) install driveline shield (rd8400-2) the counter-cone drive shield is factory installed on models rd6000-2 and rd7200-2. On the rd8400-2 model, attach counter-cone shield (22) to gearbox (21) with cap screws (43) and flat washers (42). Orient chain attachment lug a...

Page 33: Assembly 31

Assembly 31 man0180 (rev. 1/7/2005) install quick hitch kit (optional) note: figure 38 shows rm660, other models use the same assembly instructions. Note: this kit allows mower to fit only cat. 1 standard asae quick hitch. Figure 38. Quick hitch kit installation 1. Attach offset link (1) to mounting...

Page 34: 32 Dealer Check Lists

32 dealer check lists man0180 (rev. 1/7/2005) dealer check lists dealer pre-delivery check list (dealer’s responsibility) inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspec...

Page 35: Parts 33

Parts 33 man0180 (rev. 1/7/2005) parts index main frame assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 - 35 gearbox assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 driveshaft assembly (walterscheid two-lobe) . . . . . . . . 37 blade & ...

Page 36: 34 Parts

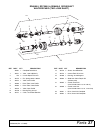

34 parts man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 main frame assembly 7 6 57 6 5 55 56 4 41 61 59 68 30 62 8 67 64 56 3 70 69 71 51 15 14 16 56 51 59 72 54 13 49 56 9 56 56 18 19 66 48 46 26 50 45 53 47 2 51 56 25 24 23 20 63 42 43 22 21 59 56 75 73 17b 17a 44 63 12 52 51 11 1 10 27 - c...

Page 37: Parts 35

Parts 35 man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 main frame assembly ref part qty ref 9 – – –– – cw spindle assembly (see page 38) 10 1001244 1 v-belt w99 (used on rd6000-2 only) or- 10 18879 1 v-belt w112 (used on rd7200-2 only) -or- 10 53418 1 v-belt w157 (used on rd8400-2 only) 11 5...

Page 38: 36 Parts

36 parts man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 gearbox assembly 13 10 19 1 3 12 7 10 20 14 17 5 16 6 9 4 26 18 8 22 24 13 2 23 11 25 15 21 cd6090 27 ref part qty description a 1002499 1 gearbox repair assembly 1 57458 1 gear crown z25 m5.3 2 ns 1 gearbox housing 3 1005320 1 shaft, in...

Page 39: Parts 37

Parts 37 man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 driveshaft walterscheid (two-lobe shaft) 23 24 22 13 18 12 14 20 1 2 4 3 5 21 14 12 17 6 7 3 2 1 13 cd5556 ref part qty description 40551 1 complete drive shaft 1 40571 2 yoke, 1-3/8-6 spline q 2 154 2 u-joint repair kit l14r 3 40775 2 p...

Page 40: 38 Parts

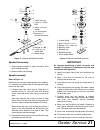

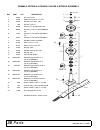

38 parts man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 blade & spindle assembly 22 16 23 seal lip 14 8 10 12 7 11 19 12 10 9 8 6 4 2 21 1 3 5 cd5055 seal lip ref part qty description 1 37009 nut, jam 7/8 nf 2 10378 * screw hhcs 1/4 nc x 1 gr5 3 52898 washer, lock .929 x 1.66 4 1985 * washer,...

Page 41: Parts 39

Parts 39 man0180 (rev. 1/7/2005) rd6000-2, rd7200-2 & rd8400-2 rear chain shielding assembly (optional) rd6000-2, rd7200-2 & rd8400-2 front roller assembly (optional) 1 2 3 15 14 ref part qty description 55348 chain shield assembly (rd6000-2) 53566 chain shield assembly (rd7200-2) 52856 chain shield...

Page 42: 40 Parts

40 parts man0180 (rev. 1/7/2005) quick hitch kit (optional) 10 2 3 1 5 6 5 7 5 5 5 8 9 5 a 4 1/2 x 4-3/4 hhcs cd6080a ref part qty description 1 1003692 2 link, offset .38 x 2.0 x 15 2 1005401 2 chain 3/8 proof coil 38 link 3 38214 2 sleeve, .91 x 1.44 x 1.25 4 13563 1 screw, hhcs 1/2 nc x 6 gr5 5 *...

Page 43: Appendix 41

Appendix 41 bolt torque & size charts (rev. 8/14/02) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. Al...

Page 44: 42 Appendix

42 appendix bolt torque & size charts (rev. 8/14/2002) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. 5/16 3/8 1/2 5/8 3/4 7/8 sae bolt thread sizes mm 25 50 75 100 125 150 175 in 1 7 metric bolt thread sizes 8mm 18mm 14mm...

Page 45: Index 43

Index 43 man0180 (rev. 1/7/2005) index assembly dealer set-up instructions 28 dealer check lists delivery (dealer’s responsibility) 32 pre-delivery (dealer’s responsibility) 32 dealer service blade spindle assembly 21 disassembly 21 installation 22 removal 20 service 20 blocking method 20 drive shea...

Page 46: Warranty

F-3079 (rev. 4/10/2006) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com warranty (all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) please enter informat...

Page 47: Warranty

F-8494 (rev. 6/23/2005) warranty (replacement parts for all models except mow’n machine tm zero-turn mowers and woods boundary tm utility vehicles) woods equipment company (“woods”) warrants this product to be free from defect in material and workmanship for a period of ninety (90) days from the dat...

Page 48: Part No.

Part no. Man0180 © 2002 woods equipment company. All rights reserved. Woods, the woods logo, and "tested. Proven. Unbeatable." are trademarks of woods equipment company. All other trademarks, trade names, or service marks not owned by woods equipment company that appear in this manual are the proper...