- DL manuals

- Woods

- Lawn Mower

- RD990X

- Operator's Manual

Woods RD990X Operator's Manual

Summary of RD990X

Page 1

Op e r a t o r 's m a nu a l rearmount mowers man0845 (r e v. 1 0 /1/ 201 3) tested. Proven. Unbeatable. Rd990x.

Page 2: 2 Introduction

2 introduction gen’l (rev. 12/5/2011) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 man0845 (1/12/2010) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 general information . . . . . . . ...

Page 4: 4 Introduction

4 introduction man0845 (1/12/2011) specifications rd990x 3-point hitch category 1 and 2 cutting width 90" cutting height range 1-1/2" - 7" operating weight with chain shielding 1200 lbs blade speed (feet per minute) 17,000 blade speed (rpm) 2,074 blade spindles 3 number of blades 6 universal drive s...

Page 5: Safety 5

Safety 5 prd mower (9/13/2005) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check the dealer loca...

Page 6: 6 Safety

6 safety prd mower (9/13/2005) of thrown objects. The mower deck and protec- tive devices cannot prevent all objects from escaping the blade enclosure in every mowing condition. It is possible for objects to ricochet and escape, traveling as much as 300 feet (92 m). inspect and clear area of stone...

Page 7: Safety 7

Safety 7 prd mower (9/13/2005) and blocking requirements or have work done by a qualified dealer. frequently check blades. They should be sharp, free of nicks and cracks, and securely fastened. do not handle blades with bare hands. Careless or improper handling may result in serious injury. yo...

Page 8: 8 Safety

8 safety man0845 (1/12/2011) 9 - 57123 9" red rear reflector shield missing do not operate put shield on danger 18867--b 6 - 15503 5 - 18867 1 - serial number plate model no. Serial no. Woods equipment company oregon, illinois, u.S.A. Be careful! Use a clean, damp cloth to clean safety decals. Avoid...

Page 9: Safety 9

Safety 9 man0845 (1/12/2011) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! Guard missing. Do not operate. Danger 33347e danger danger guard missing. Do not operate. Falling off can result in being run over. Tractor must be equipped wi...

Page 10: 10 Operation

10 operation man0845 (1/12/2011) operation the operator is responsible for the safe operation of the mower. The operator must be properly trained. Operators should be familiar with the mower, the trac- tor, and all safety practices before starting operation. Read the safety rules and safety decals o...

Page 11: Operation 11

Operation 11 man0845 (1/12/2011) refer to figure 2 1. For category 1 hitch, position mower hitch arms (e) with offset toward center of mower. For category 2 hitch, position mower hitch arms (e) with offset toward outside of mower. 2. Attach the mower hitch pins (b) to lower tractor lift arms and sec...

Page 12: 12 Operation

12 operation man0845 (1/12/2011) 9. To raise front of mower, move spacers under front caster wheel arms. Figure 4. Cutting height adjustment remember, measurement at location a (figure 4) should not be less than location b and should not be over 1/2" greater than location b. Figure 5. Cutting height...

Page 13: Operation 13

Operation 13 man0845 (1/12/2011) front caster wheel interference check notice ■ do not operate tractor and mower until this interference check has been performed. If you change tractors, you must perform the check for that mounting. Figure 8. Front caster wheel interference check perform this check ...

Page 14: 14 Operation

14 operation man0845 (1/12/2011) plan your mowing pattern to travel straight forward whenever possible. Mow with uncut grass to the right. This will distribute the clippings over the cut area. Uneven terrain do not operate or transport on steep slopes. do not stop, start, or change directions su...

Page 15: Owner Service 15

Owner service 15 man0845 (1/12/2011) owner service the information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual. ne...

Page 16: 16 Owner Service

16 owner service man0845 (1/12/2011) figure 10. Lubrication points & chart ref description frequency 1 driveline u-joints 8 hours 2 gearbox (fill to center of horizontal shaft with sae 90w gear lube) check for leaks daily 3 caster wheel (four wheels) 8 hours 4 caster pivot (four yokes) 8 hours 5 sli...

Page 17: Owner Service 17

Owner service 17 man0845 (1/12/2011) figure 11. Belt routing belt service belt replacement one of the major causes of belt failure is improper installation. Before installing a new belt, check the fol- lowing: 1. Check pulley shafts and bearings for wear. 2. Check pulley grooves for cleanliness. 3. ...

Page 18: 18 Owner Service

18 owner service man0845 (1/12/2011) blade installation your dealer can supply genuine replacement blades. Substitute blades may not meet original equipment specifications and may be dangerous. Figure 13. Blade assembly 1. Install blade pin (3) thru blade (2) and blade spindle (1). 2. Make sure bl...

Page 19: Troubleshooting 19

Troubleshooting 19 man0845 (1/12/2011) trouble shooting mowing conditions problem possible cause solution grass cut higher in center of swath than at edge height of mower higher at rear than at front adjust mower height and attitude so that mower rear and front are within 1/2 inch of same height. Se...

Page 20: 20 Troubleshooting

20 troubleshooting man0845 (1/12/2011) trouble shooting belt conditions * check belt for damage by laying it flat on the floor. A belt that does not lie flat (has humps or twists, indicating broken or stretched cords) must be replaced. Problem possible cause solution belt slippage mower overloading;...

Page 21: Troubleshooting 21

Troubleshooting 21 man0845 (1/12/2011) notes.

Page 22: 22 Dealer Service

22 dealer service man0845 (1/12/2011) dealer service the information in this section is written for dealer ser- vice personnel. The repair described here requires special skills and tools. If your shop is not properly equipped or your mechanics are not properly trained in this type of repair, you ma...

Page 23: Dealer Service 23

Dealer service 23 man0845 (1/12/2011) figure 16. Spindle disassembly spindle assembly refer to figure 17. Bearing cones and cups are designed to work together. It is important to position them so bearing cone taper mates with cup taper. 1. Lubricate new cups (6) with a light oil. Place them in spind...

Page 24: 24 Dealer Service

24 dealer service man0845 (1/12/2011) 2. Install pulley (12) and split taper bushing (13) with integral key (14) on spindle shaft. Make sure bushing is in contact with sleeve on spindle shaft. 3. Alternately tighten split taper bushing cap screws to 20 lbs-ft. 4. Install lock washer and nut on spind...

Page 25: Dealer Service 25

Dealer service 25 man0845 (1/12/2011) 1. Clean area in housing where seal outer diameter (od) seats. Apply a thin coat of permatex. 2. Inspect area of shaft where seal seats. Remove any burrs or nicks with an emery cloth. 3. Lubricate gear shaft and seal lips. 4. Place seal squarely on housing, spri...

Page 26: 26 Dealer Service

26 dealer service man0845 (1/12/2011) 4. Remove four cap screws (9), flat washer (11), and remove shield (5) from gearbox. 5. Remove castle nut (14) and hardware from output shaft of gearbox. 6. Remove sheave (4) from gearbox. 7. Remove four bolts (9) that attach gearbox to gearbox stand and remove ...

Page 27: Dealer Service 27

Dealer service 27 man0845 (1/12/2011) 16. Check that the gear backlash is between 0.006” and 0.016”. You should not have to adjust the backlash. 17. Press in input oil seal (19), using tube of correct diameter. Be careful not to damage seal lip. 18. Press oil cap (20) on to cover the rear of housing...

Page 28: 28 Dealer Service

28 dealer service man0845 (1/12/2011) 3. Clamp cup in vise as shown in figure 25 and tap on yoke to completely remove cup from yoke. Repeat step 2 and step 3 for opposite cup. Figure 25 figure 26 4. Place universal cross in vise as shown in figure 26 and tap on yoke to remove cup. Repeat step 3 for ...

Page 29: Assembly 29

Assembly 29 man0845 (1/12/2011) assembly instructions dealer set-up instructions assembly of this mower is the responsibility of the woods dealer. If should be delivered to the owner com- pletely assembled, lubricated, and adjusted for normal cutting conditions. Complete dealer check lists on page 3...

Page 30: 30 Assembly

30 assembly man0845 (1/12/2011) install front casters ( figure 28 & 29) 1. Remove cap screws (12 & 13) and lock nuts (15) from outer caster arms (10). 2. Place arms inside of pockets in front corners of deck. Replace hardware. Figure 29. Caster arm assembly torque caster arms 1. Place mower on a har...

Page 31: Assembly 31

Assembly 31 man0845 (1/12/2011) install driveshaft 1. Pull locking collar (b) back and, at the same time, push driveline onto gearbox shaft until locking device engages. 2. Rotate pto hanger forward. Rest driveline on pto hanger. 3. If so equipped, hook anti-rotation chain (c) on shield (2). Figure ...

Page 32: 32 Assembly

32 assembly man0845 (1/12/2011) figure 32. Chain shield installation install chain shielding full chain shielding must be installed when operating in populated areas or other areas where thrown objects could injure people or damage property. • if this machine is not equipped with full chain shield...

Page 33: Assembly 33

Assembly 33 man0845 (1/12/2011) figure 34. Quick hitch kit installation (optional) install quick hitch (optional) note: this kit allows mower to fit category 1 or category 2 standard quick hitches. 1. Lower hitch arms must be located in center attachment hole. See figure 34 for adjustment. 2. For us...

Page 34: 34 Notes

34 notes man0845 (1/12/2011) dealer check lists pre-delivery check list (dealer’s responsibility) inspect the equipment thoroughly after assembly to ensure it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspect. Check off each item a...

Page 35: Parts 35

Parts 35 man0845 (1/12/2011) parts index main frame assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 - 37 gearbox assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 driveshaft assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 36: 36 Parts

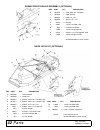

36 parts man0845 (1/12/2011) rd990x main frame assembly (rev. 10/1/2013).

Page 37: Parts 37

Parts 37 man0845 (1/12/2011) rd990x main frame assembly ref part qty description 1 ----- 1 deck (not sold separately) 2 1032786 2 lower hitch arm 3 56598 2 sleeve .885 x 1.125 x 2.62 4 19524 2 sleeve .64 x 1.00 x 2.09 ht 5 1032795 2 a-frame arm 6 1032798 1 sleeve .62 x .94 x 3.13 7 1032797 1 u-link ...

Page 38: 38 Parts

38 parts man0845 (1/12/2011) rd990x gearbox assembly ref part qty description a 1002499 1 gearbox assembly, complete 1 57458 1 gear, crown 25t m5.3 2 nss 1 gearbox housing 3 1005320 1 shaft, input 1-3/8 -6 4 1005321 1 shaft, output 1-1/4 5 57491 1 pinion gear 13t m5.3 6 57476 1 bearing cup & cone 7 ...

Page 39: Parts 39

Parts 39 man0845 (1/12/2011) rd990x drive shaft assembly ref part qty description a 1029937 1 drive assembly complete 1 40574 2 yoke, 1-3/8-6sp (complete with lock collar) 2 110 2 cross and bearing kit 3 40464 2 spring pin, 10 mm x 80 mm 4 40575 1 inboard youk (male drive tube) 5 40587 1 inner profi...

Page 40: 40 Parts

40 parts man0845 (1/12/2011) rd900x blade & spindle assembly ref part qty description 1 1032800 1 blade spindle, complete 2 18359 1 sleeve 1-3/8 x 1-3/4 x 5/8 3 2715 2 seal 1.75 x 2.56 x .5 4 2717 2 bearing cone 5 1032806 1 spindle housing w/ cups 6 2716 2 bearing cup 7 1032801 1 spindle shaft & cro...

Page 41: Parts 41

Parts 41 man0845 (1/12/2011) rd990x chain shielding assembly ref part qty description 1 1032821 2 front chain shield plate 2 1032832 1 right corner chain shield plate 3 1032833 1 left corner chain shield plate 4 1032822 1 right rear chain shield plate 5 1032823 1 left rear chain shield plate 6 4763 ...

Page 42: 42 Parts

42 parts man0845 (1/12/2011) rd990x front roller assembly (optional) quick hitch kit (optional) ref part qty description a 1032828 1 front roller kit - complete 1 1032829 1 roller bracket 2 1006418 1 roller, 4 x 7.38 3 1006420 1 spacer, .75 x 7.27 4 35193 2 bearing 5 38107 - 1/2 nc x 9 hhcs, gr5 6 3...

Page 43: Appendix 43

Appendix 43 bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 44: 44 Appendix

44 appendix bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe ....................Am...

Page 45: Index 45

Index 45 man0845 (1/12/2011) index assembly chain shielding 32 dealer set-up instructions 29 initial oil fill 31 optional equipment front roller 32 dealer check lists delivery (dealer’s responsibility) 34 pre-delivery (dealer’s responsibility) 34 dealer service blade spindle assembly 23 disassembly ...

Page 46: Warranty

F-3079 (rev. 5/10/2013) woods equipment a blount international company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 usa 800-319-6637 tel 800-399-6637 fax woodsequipment.Com warranty all models except mow’n machine tm zero-turn mowers please enter information below and save...

Page 47: Warranty

F-8494 (rev. 2/5/2013) woods equipment a blount international company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 800-319-6637 tel 800-399-6637 fax woodsequipment.Com ©2013 woods equipment company. All rights reserved. Woods ® and the woods logo are trademarks of woods eq...

Page 48: Man0845

Woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 815-732-2141 tel 815-732-7580 fax www.Woodsequipment.Com man0845 © 2011 woods equipment company. All rights reserved. Woods, the woods logo, and "tested. Proven. Unbeatable." are trademarks of woods equip...