- DL manuals

- Woods

- Paper Shredder

- S15CD

- Operator's manual

Woods S15CD Operator's manual

Summary of S15CD

Page 1

Op e r a t o r 's m a nu a l flail shredder man0506 (rev . 1 0 /1 /20 13) center drive s15cd s20cd s22cd s25cd s27cd.

Page 2: 2 Introduction

2 introduction gen’l (rev. 12/5/2011) to the dealer: assembly and proper installation of this product is the responsibility of the woods ® dealer. Read manual instructions and safety rules. Make sure all items on the dealer’s pre-delivery and delivery check lists in the operator’s manual are complet...

Page 3: Introduction 3

Introduction 3 man0506 (rev. 9/5/2008) table of contents introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 balance statement . . . . . ...

Page 4: 4 Introduction

4 introduction man0506 (rev. 9/5/2008 specifications maximum outside body width: 15 ′ . . . . . . . . . . . . . . . . . . 189 in. (4.9 m) 20 ′ . . . . . . . . . . . . . . . . . . 253 in. (6.4 m) 22 ′ . . . . . . . . . . . . . . . . . . 277 in. (7.0 m) 25 ′ . . . . . . . . . . . . . . . . . . 309 in....

Page 5: Introduction 5

Introduction 5 man0506 (rev. 9/5/2008) important! Balance statement both of the woods center drive shredder flail tubes are balanced as rotor assemblies to meet or exceed factory standards before installation. After installation, the shredders are statistically inspected to check bal- ance. These fa...

Page 6: 6 Safety

6 safety cd flail shredder man0506 (4/15/2006) training safety instructions are important! Read all attachment and power unit manuals; follow all safety rules and safety decal information. (replace- ment manuals and safety decals are available from your dealer. To locate your nearest dealer, check...

Page 7: Safety 7

Safety 7 cd flail shredder man0506 (4/15/2006) connect pto driveline directly to power unit pto shaft. Never use adapter sleeves or adapter shafts. Adapters can cause driveline failures due to incorrect spline or incorrect operating length and can result in personal injury or death. inspect rubb...

Page 8: 8 Safety

8 safety cd flail shredder man0506 (4/15/2006) (safety rules continued from previous page) look down and to the rear and make sure area is clear before operating in reverse. do not operate or transport on steep slopes. do not stop, start, or change directions sud- denly on slopes. use extrem...

Page 9: Safety 9

Safety 9 cd flail shredder man0506 (4/15/2006) make sure shields and guards are properly installed and in good condition. Replace if dam- aged. do not disconnect hydraulic lines until engine is stopped, power unit is properly secured, equip- ment and all components are lowered to the ground, and...

Page 10: 10 Safety

10 safety man0506 (rev. 9/5/2008) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! 3 - serial number plate model no. Serial no. Woods equipment company oregon, illinois, u.S.A. Caution precaucion 1. Read operator's manual before starting...

Page 11: Safety 11

Safety 11 man0506 (rev. 9/5/2008) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! (safety decals continued on next page) 6 - pn 50030978 rotating driveline hazard to prevent serious injury or death from rotating driveline: 1. Keep all g...

Page 12: 12 Safety

12 safety man0506 (rev. 9/5/2008) safety & instructional decals attention! Become alert! Your safety is involved! Replace immediately if damaged! 14 - pn 50530315 warning high-pressure fluid hazard to prevent serious injury or death: 1. Relieve pressure on system before repairing, adjusting, or disc...

Page 13: Operator Record 13

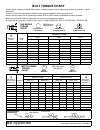

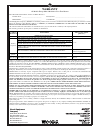

Operator record 13 man0506 (rev. 9/5/2008) operator sign-off record . Woods equipment company follows the general safety standards specified by the american society of agri- cultural and biological engineers (asabe) and the occupational safety and health administration (osha) for agricultural equipm...

Page 14: 14 Operation

14 operation man0506 (rev. 9/5/2008) operation the woods flail shredder is designed to pick up and shred crop and plant residue left in the field. Rotational power to the flails is provided by the tractor pto. Be familiar with the flail shredder before starting. The owner is responsible for training...

Page 15: Operation 15

Operation 15 man0506 (rev. 9/5/2008) figure 1. Flail shredder principal components pre-operation check list (owner's responsibility) notice ■ this pre-operation check list is provided for the operator. It is important to follow for both per- sonal safety and maintenance of the flail shredder. ___ ch...

Page 16: 16 Operation

16 operation man0506 (rev. 9/5/2008) figure 2. Tractor front weight 3. 3-point hitch the 3-point hitch models require that the tractor be equipped with a category ii or category iii 3-point hitch. If the hitch can be converted from one to the other, use a category iii to provide a wider stance and m...

Page 17: Operation 17

Operation 17 man0506 (rev. 9/5/2008) keep bystanders away from equipment. 1. Clear the area of all bystanders. 2. Attach the 3-point hitch to the unit but not the pto driveline. 3. Raise the unit until the tractor pto and gearbox shafts are the same height. 4. Measure the dimension between the sha...

Page 18: 18 Operation

18 operation man0506 (rev. 9/5/2008) without quick hitch attachment: 1. Back tractor lower 3-point arms between lower mast plates and align with lower 3-point hole. 2. Place 1-3/4 od spacer through 3-point arm pivot (both sides). 3. Push tractor’s 3-point arm to the inside and slide a 1-7/16 od spac...

Page 19: Operation 19

Operation 19 man0506 (rev. 9/5/2008) raise stands 1. Use hitch ratchets or 3-point hitch to raise the front of the machine. 2. Unpin front frame stands. Raise and pin in their upper position. See figure 10. Removing shredder from tractor reverse the above procedure (steps 1-17) when removing unit fr...

Page 20: 20 Operation

20 operation man0506 (rev. 9/5/2008) the flails under all operating conditions. (see balance statement, page 5.) note: to avoid unnecessary wear on knives and related parts, never set the unit lower than the recom- mended setting. (see balance statement, page 5.) figure 11. 3-point hitch models set ...

Page 21: Operation 21

Operation 21 man0506 (rev. 9/5/2008) . Figure 14. Optional flail contour figure 15. “l” flails figure 16. Cup flails setting flail height 1. Be sure wheels are set to follow in the center of furrow row. Set flails 3 to 6 inches (75 to 150 mm) above the ground. (see balance statement, page 5.) 2. Ali...

Page 22: 22 Operation

22 operation man0506 (rev. 9/5/2008) hazard area make certain all movement of equipment com- ponents has stopped before approaching for ser- vice. Stay away from front, side, and rear of unit while it is running. Flails can pick up stones, sticks, wire, and other debris and throw it out with enoug...

Page 23: Operation 23

Operation 23 man0506 (rev. 9/5/2008) ● replace any safety decals that are missing or not readable (supplied free by your woods dealer). See safety decals section for location drawing. Storage block equipment securely for storage. keep children and bystanders away from stor- age area. At the end ...

Page 24: 24 Service & Maintenance

24 service & maintenance man0506 (rev. 9/5/2008) service & maintenance before dismounting power unit or performing any service or maintenance, follow these steps: disengage power to equipment, lower the 3-point hitch and all raised components to the ground, operate valve levers to release any hydr...

Page 25: Service & Maintenance 25

Service & maintenance 25 man0506 (rev. 9/5/2008) figure 22. Pto driveline lubrication points figure 23. Lubrication points a. Daily or 8 hours b. 25 hours c. 40 hours d. Check daily/change annually (rev. 1/24/2011).

Page 26: 26 Service & Maintenance

26 service & maintenance man0506 (rev. 9/5/2008) daily or every 8 hours of operation 1. Lubricate pto u-joints and over-running clutch. 2. Check gearbox daily or every 8 hours of operation. See figure 24 for gearbox oil fill location. Figure 24. Gearbox oil fill location every 25 hours of operation ...

Page 27: Service & Maintenance 27

Service & maintenance 27 man0506 (rev. 9/5/2008) gearbox oil leakage notice ■ major oil leakage from the gearbox shaft seal area is not acceptable and could cause the gearbox to fail due to lack of lubrication and cooling. It is the operator’s responsibility to check the gearbox oil level per the lu...

Page 28: 28 Service & Maintenance

28 service & maintenance man0506 (rev. 9/5/2008) gearbox leakage & troubleshooting some gearbox oil leakage may be acceptable if: 1. Oil covers less than a 3-inch diameter circle around the shaft seal area (see figure 30). 2. Oil covers less than a 4-inch diameter circle around the dipstick tube (se...

Page 29: Service & Maintenance 29

Service & maintenance 29 man0506 (rev. 9/5/2008) figure 31. Drain plug (underside of unit) 7. Re-install and tighten drain plug. 8. Dispose of used oil in an approved container. 9. Add sae 85w90 gear oil through the dipstick cover. Use the dipstick to check the oil level (figure 32) and add oil acco...

Page 30: 30 Service & Maintenance

30 service & maintenance man0506 (rev. 9/5/2008) 3. Disconnect driveline and hydraulic lines from the tractor. 4. Place safety stands or large blocks under the frame. 5. Loosen and remove the worn flail and its opposite on the other side of the rotor. Discard worn flails and their mounting hardware....

Page 31: Service & Maintenance 31

Service & maintenance 31 man0506 (rev. 9/5/2008) technical service for re-balance options or further details. Follow the procedure below if rotor removal or replace- ment is required. use a suitable lifting device of sufficient capac- ity. Use adequate personnel to handle heavy com- ponents. 1. Cl...

Page 32: 32 Service & Maintenance

32 service & maintenance man0506 (rev. 9/5/2008) figure 37. Rotor direction of rotation replacing stub shaft 1. Remove rotor (see servicing rotors (flail tubes), page 30). 2. Remove three 1/2 x 2-1/2 hex bolts in taper lock hub and re-install bolts in three threaded holes (see figure 38). 3. Tighten...

Page 33: Service & Maintenance 33

Service & maintenance 33 man0506 (rev. 9/5/2008) note: the shaft is heavy. Grasp the clutch firmly with both hands and slide off the input shaft. Rebuilding friction pack disassembly 1. Position clutch and universal joint assembly on a bench so that end is accessible. 2. Remove the long bolts on the...

Page 34: 34 Service & Maintenance

34 service & maintenance man0506 (rev. 9/5/2008) notes.

Page 35: Troubleshooting 35

Troubleshooting 35 man0506 (rev. 9/5/2008) troubleshooting the woods flail shredder uses swinging flails to pick up and shred crop residue left in the field. It is a simple and reli- able system that requires minimal maintenance. The following table lists problems, causes, and solutions that you may...

Page 36: 36 Contour Flail Patterns

36 contour flail patterns man0506 (rev. 9/5/2008) worksheet for contour flail patterns.

Page 37: Contour Flail Patterns 37

Contour flail patterns 37 man0506 (rev. 9/5/2008) worksheet for contour flail patterns 24’.

Page 38: 38 Assembly

38 assembly man0506 (rev. 9/5/2008) assembly dealer set-up instructions do not allow bystanders in the area when oper- ating, attaching, removing, assembling, or servic- ing equipment. do not handle blades with bare hands. Careless or improper handling may result in serious injury. keep hands ...

Page 39: Assembly 39

Assembly 39 man0506 (rev. 9/5/2008) 7. Attach front top link spacer, bolts, and lock nuts to front of upper mast assembly. Note: for quick hitch cat ii, use spacer in front lower hole of upper mast assembly. For quick hitch cat iii, use spacer in front upper hole of upper mast assembly. Without quic...

Page 40: 40 Assembly

40 assembly man0506 (rev. 9/5/2008) manual storage tube installation the manual storage tube may be supplied in either of the following styles. For one-piece style manual tube: mount the manual tube to the inside of the shredder side sheet, using three 3/8 x 1-1/4" hex bolts, washers, and 3/8" nuts....

Page 41: Assembly 41

Assembly 41 man0506 (rev. 9/5/2008) provided. Make sure that light lenses are in the correct position in relation to direction of equipment travel: amber lenses on the outside, red lenses on the inside facing rear of shredder. 3. Install light bracket on end of shredder using 1/2 nc x 1-1/2" hex bol...

Page 42: 42 Assembly

42 assembly man0506 (rev. 9/5/2008) center cut kit installation block shredded never go underneath equipment (lowered to the ground or raised) unless it is properly blocked and secured. Never place any part of the body under- neath equipment or between moveable parts even when the engine has been ...

Page 43: Assembly 43

Assembly 43 man0506 (rev. 9/5/2008) install motor housing 1. Slide motor assembly between shredder center channel and secure to the left side using two 1/2 nc x 1-1/4 carriage bolts (29) and flange lock nuts (30). 2. Install 1/2 nc x 1 cap screw (31) and flat washer (32) to the right rear hole of th...

Page 44: 44 Assembly

44 assembly man0506 (rev. 9/5/2008) install hose clamps 1. Place hose clamps (36) around hoses (11) and center hoses between center plate. 2. Mark clamp holes in desired location on shedder body and drill two 11/32" holes. 3. Secure hose clamps to shredder using 5/16 nf x 1-1/4 cap screws (20), flat...

Page 45: Dealer Check Lists 45

Dealer check lists 45 man0506 (rev. 9/5/2008) dealer check lists pre-delivery check list (dealer’s responsibility) inspect the equipment thoroughly after assembly to make sure that it is set up properly before delivering it to the customer. The following check lists are a reminder of points to inspe...

Page 46: 46 Dealer Check Lists

46 dealer check lists man0506 (rev. 9/5/2008) notes.

Page 47: Parts Index

Parts 47 man0506 (rev. 9/7/2011) parts index flail shredder center drive frame assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-49 flail tube assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 wheel assembly . . . . . . . . . . . . . ....

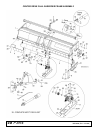

Page 48: 48 Parts

48 parts man0506 (rev. 9/5/2008) center drive flail shredder frame assembly.

Page 49

Parts 49 man0506 (rev. 9/7/2011) center drive flail shredder frame assembly parts list ref part qty description 1 nss 1 s15cd body weldment 1 nss 1 s20cd body weldment 1 nss 1 s22cd body weldment 1 nss 1 s25cd body weldment 1 nss 1 s27cd body weldment 2 ---------- - flail tube asy, right & left (see...

Page 50: 50 Parts

50 parts man0506 (rev. 9/5/2008) flail tube assembly ref left part # right part # qty description 1 1016199lk 1016198lk 1 15’ flail tube w/knives 1 1016199hd 1016198hd 1 15’ hd cotton tube w/knives 1 1016199cp 1016198cp 1 15’ cup knife tube w/knives 1 1013109lk 1013108lk 1 20’ flail tube w/knives 1 ...

Page 51

Parts 51 man0506 (rev. 9/7/2011) wheel assembly ref part no qty description 1 90509009 1 dust cap 2 90109002 1 seal 3 90101023 1 inner bearing cone 4 90101022 1 inner cup 5 90509011 5 1/2 nf wheel nut 6 90509003 1 hub, 5-bolt 7 90101016 1 outer bearing cup 8 90101015 1 outer bearing cone 9 90509067 ...

Page 52: 52 Parts

52 parts man0506 (rev. 9/5/2008) bed cone assembly (optional) 50510065 type a - weasler ® 24k pull-type pto shaft with torqmaster clutch ref part no qty description 1 20031440 1 u-bolt, 3/4 nc x 4 x 5.5 long 2 2377 6 3/4 nc x 6 hex bolt gr5 3 50520162 1 strut weldment 4 50520163 1 yoke weldment 5 50...

Page 53

Parts 53 man0506 (rev. 9/7/2011) type b - weasler ® 24k pull-type pto shaft with torqmaster clutch ref part no qty description a 1016108 1 pto complete 1-3/8 21 spline -or- a 1016109 1 pto complete 1-3/4 20 spline 1 19851 1 slide lock repair kit 1.38 id -or- 19837 1 slide lock repair kit 1.75 id 2 1...

Page 54: 54 Parts

54 parts man0506 (rev. 9/5/2008) weasler ® 24k 2-point & 3-point pto shaft with torqmaster clutch dual safety light kit (optional) cd6523 1 2 3 4 5 6 7 8 9 5 10 3 11 ref part qty description 1 19851 1 slide lock repair kit 1.38 id -or- 1 19837 1 slide lock repair kit 1.75 id 2 90317208 1 slide yoke ...

Page 55

Parts 55 man0506 (rev. 9/7/2011) weasler ® 24k torqmaster clutch assembly ref part no qty description 11 90318175 2 friction disk 12 90318174 1 separator plate 13 90003055 4 m10 x 1.50 x 25 serrated hex head cap screw 14 90003053 6 m8 x 1.25 x 60 hex bolt, cl 10.9 15 90011236 a/r washer, 8 mm x 1.6 ...

Page 56: 56 Parts

56 parts man0506 (rev. 9/5/2008) weasler ® automatic clutch (optional) ref part no qty description a 1019811 - automatic clutch asy complete 1 1019813 1 yoke & hub, 30k auto 2 1019814 1 clutch pack, 30k auto 3 1010833 1 hub clamp assembly 1-3/4 4 1025874 6 hhcs, m12-1.75p x 20 mm cl10.9 flanged head...

Page 57

Parts 57 man0506 (rev. 9/7/2011) weasler ® 30k 3-point pto shaft with automatic clutch (optional) weasler ® 30k 3-point pto shaft with automatic clutch (optional) ref part qty description a 1019810 - pto shaft complete 1-3/4 20-spline 30k 3-point with automatic clutch 1 19837 1 slide lock repair kit...

Page 58: 58 Parts

58 parts man0506 (rev. 9/5/2008) type a - weasler ® 30k pull-type pto shaft with automatic clutch (optional) type b - weasler ® 30k pull-type pto shaft with automatic clutch (optional) ref part qty description a 1019820 - pto shaft complete 1-3/4 20-spline 30k pull-type with automatic clutch 1 19837...

Page 59

Parts 59 man0506 (rev. 9/7/2011) center drive gearbox note: to separate gearbox halves for servicing, seal guards (8) must be removed first otherwise damage to gearbox housings will occur. Seal guards can be removed by gently prying out of housing with a flat blade screwdriver using the cutout areas...

Page 60: 60 Parts

60 parts man0506 (rev. 9/5/2008) rubber belting ref part qty description 1 1012202 4 rubber belting (15 ft) 1 1012202 6 rubber belting (20 ft & 22 ft) 1 1012202 8 rubber belting (25 ft & 27 ft) 2 1022647 4 belt bar (15ft) 2 1022647 6 belt bar (20 ft & 22 ft) 2 1022647 8 belt bar (25 ft & 27 ft) 3 10...

Page 61

Parts 61 man0506 (rev. 9/7/2011) rubber flap ref part qty description 1 50531089 14 rubber flap (12" - 15 ft) 1 50531089 18 rubber flap (12" - 20 ft) 1 50531089 20 rubber flap (12" - 22 ft) 1 50531089 24 rubber flap (12" - 25 ft) 1 50531089 26 rubber flap (12" - 27 ft) 2 1022659 3 flap bracket, righ...

Page 62: 62 Parts

62 parts man0506 (rev. 9/5/2008) center cutter kit (optional) warning high-pressure fluid hazard to prevent serious injury or death: 1. Relieve pressure on system before repairing, adjusting, or disconnecting. 2. Wear proper hand and eye protection when searching for leaks. Use wood or cardboard ins...

Page 63

Parts 63 man0506 (rev. 9/7/2011) center cutter kit parts list center deflector (optional) ref part qty description 1 1024671 1 blade hub 2 1016161 1 motor housing 3 1024674 1 blade, .31 x 2.50 x 13.31 dbl edge 4 1017719 1 hydraulic motor 4a 1034644 1 kit, shaft & bearing (includes shaft, upper & low...

Page 64: 64 Appendix

64 appendix bolt torque & size charts (rev. 3/28/2007) bolt torque chart always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific application. Fasteners must always be replaced with the same grade as specified in the manual parts list. ...

Page 65: Appendix 65

Appendix 65 bolt torque & size charts (rev. 3/28/2007) bolt size chart note: chart shows bolt thread sizes and corresponding head (wrench) sizes for standard sae and metric bolts. Abbreviations ag .............................................................. Agriculture asabe.................... Am...

Page 66: 66 Index

66 index man0506 (rev. 9/5/2008) index assembly dealer set-up instructions 38 optional equipment center cut kit installation 42 rubber belting installation 40 rubber flap installation 40 safety light kit installation 40 dealer check lists delivery check list (dealer’s responsibility) 45 pre-delivery...

Page 67: Warranty

F-3079 (rev. 3/2/2012) woods equipment company 2606 south illinois route 2 post office box 1000 oregon, illinois 61061 usa 800-319-6637 tel 800-399-6637 fax www.Woodsequipment.Com warranty all models except mow’n machine tm zero-turn mowers please enter information below and save for future referenc...

Page 68: Warranty

F-8494 (rev. 10/3/2011) warranty (replacement parts for all models except mow’n machine tm zero-turn mowers) woods equipment company (“woods”) warrants this product to be free from defect in material and workmanship for a period of ninety (90) days from the date of delivery of the product to the ori...