- DL manuals

- Woodstock

- Nail Gun

- W1782

- Owner's Manual

Woodstock W1782 Owner's Manual

Phone: (360) 734-3482 • Online Technical Support: tech-support@shopfox.biz

COPYRIGHT © JUNE, 2007 BY WOODSTOCK INTERNATIONAL, INC., REVISED DECEMBER, 2007 (JM)

WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUT

THE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.

#9571BL Printed in China

MODEL W1782

34˚ ANGLE

FINISH NAILER

OWNER'S MANUAL

Find and replace list

Find Examples to Replace With

W1782

W1736

34˚ Framing Nailer

18 Gauge Stapler Kit

Nailer

Stapler

Summary of W1782

Page 1

Phone: (360) 734-3482 • online technical support: tech-support@shopfox.Biz copyright © june, 2007 by woodstock international, inc., revised december, 2007 (jm) warning: no portion of this manual may be reproduced in any shape or form without the written approval of woodstock international, inc. #957...

Page 2

...

Page 3: Safety

Model w1782 34˚ angle finish nailer -1- safety instructions for pneumatic tools 1. Keep all safety devices in place and in working order. 2. Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches are removed from tool before operation. 3. Keep work area cl...

Page 4

Model w1782 34˚ angle finish nailer -2- 10. Use proper air hose for the tool. Make sure your air hose is in good condition and is long enough to reach your work without stretching. 11. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get...

Page 5

Model w1782 34˚ angle finish nailer -3- 1. Hand injuries: do not place your hands near the nail point of entry. A nail can deflect and tear through the surface of the workpiece, puncturing your hand or fingers. 2. Combustible gases: never connect the nailer to pressurized oxygen or other combustible...

Page 6: Introduction

Model w1782 34˚ angle finish nailer -4- no list of safety guidelines can be complete. Every shop environment is different. Always consider safety first, as it applies to your individual working conditions. Use this and other tools with caution and respect. Failure to do so could result in serious pe...

Page 7: Compressed Air System

Model w1782 34˚ angle finish nailer -5- the model w1782 is designed to be operated at 60-100 psi using clean, dry, regulated, compressed air. Do not exceed the 120 psi maximum operating pressure for your model. Before using your new nailer, regulate the air pressure to find the optimum setting withi...

Page 8: Setup

Model w1782 34˚ angle finish nailer -6- setup inventory this tool has been carefully packaged for safe transportation. If you notice the tool has been damaged during shipping, please contact your authorized shop fox dealer immediately. Unpacking the following is a description of the main components ...

Page 9: Safety Nose Mechanism

Model w1782 34˚ angle finish nailer -7- a safety mechanism on the nose of the nailer protects against accidental firing. When the trigger is pressed, the nailer will not fire until the safety nose mechanism is depressed. Before you use your nailer for the first time, check the safety nose mechanism ...

Page 10: Operations

Model w1782 34˚ angle finish nailer -8- operations loading when replacing nails in your model w1782, follow these guidelines: gauge: ........................................15 length: ............................. 1 1 ⁄ 4 " -2 1 ⁄ 2 " capacity: .............................. 40 nails angle: ...........

Page 11: Adjusting Depth

Model w1782 34˚ angle finish nailer -9- 5. Pull the trigger. — if the nail drove into the wood far enough, continue with your intended operations. — if the nail either went too far or not far enough, then go to the adjusting depth section on this page. Figure 4. Example of nail deflection. A depth a...

Page 12: Clearing Jammed Nails

Model w1782 34˚ angle finish nailer -10- a jammed nail must be cleared before using the nailer again. To clear a jammed nail from the dis- charge area, do these steps: 1. Disconnect nailer from the air supply! 2. Push the finger tab (figure 6) inside the magazine pusher, pull the pusher back slightl...

Page 13: Replacing Piston And

Model w1782 34˚ angle finish nailer -11- replacing piston and o-rings under heavy use, a piston or piston shaft may wear out. Replacement is quick and easy. Contact your authorized shop fox dealer to obtain the piston repair kit (part number x1782001). To replace a piston and o-rings, do these steps...

Page 14: Cleaning & Lubrication

Model w1782 34˚ angle finish nailer -12- cleaning & lubrication cleaning use a good solvent to clean the nose assembly of the nailer. Always be sure that the nailer is dry before using it again. Do not allow dust, chips, sand, etc. Into the air connectors or into the body of the nailer; this may res...

Page 15: Parts Breakdown

Model w1782 34˚ angle finish nailer -13- parts breakdown ...

Page 16: Parts List

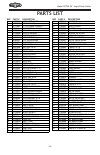

Model w1782 34˚ angle finish nailer -14- parts list ref part # description ref part # description 1 x1782001 piston repair kit 49 x1782049 joint seat 2 x1782002 air plug case 50 x1782050 roll pin 3 x 28 3 x1775007 1/4" npt male connect 51 x1782051 safety spacer 4 xpsb53m cap screw m5-.8 x 18 52 x17...

Page 17: Troubleshooting

Troubleshooting symptom possible cause cause possible solution air leaking at trigger valve area. 1. O-rings in trigger valve housing are damaged. 1. O-rings must be replaced & operation of safety nose must be checked. Air leaking between housing and hose. 1. Loose screws in housing. 2. Damaged o-ri...

Page 18

...

Page 19: Warranty Registration

Cut along dotted line name ___________________________________________________________________________________ street __________________________________________________________________________________ city _________________________ state ___________________________zip ________________________ phone ...

Page 20

Tape along edges--please do not staple fold along dotted line woodstock international inc. P.O. Box 2309 bellingham, wa 98227-2309 place stamp here fold along dotted line.