- DL manuals

- Worcester

- Boiler

- 24I RSF

- Installation And Servicing Instructions

Worcester 24I RSF Installation And Servicing Instructions

Bosch Group

24i RSF

WALL MOUNTED COMBINATION BOILER FOR CENTRAL HEATING

AND MAINS FED DOMESTIC HOT WATER

INSTALLATION AND

SERVICING INSTRUCTIONS

GC NUMBERS

N.G. 47 311 37

L.P.G. 47 311 38

BOILER OUTPUT

To Domestic Hot Water – Modulated Control

Minimum 7.5 kW (25,600 Btu/h)

Maximum 23.4 kW (80,000 Btu/h)

To Central Heating – Modulated Control\

Auto Range Rated

Minimum 7.5 kW (25,600 Btu/h)

Maximum 23.4 kW (80,000 Btu/h)

THESE INSTRUCTIONS APPLY IN THE UK ONLY

THESE INSTRUCTIONS ARE TO BE LEFT WITH THE USER OR AT THE GAS METER

This appliance must be installed by a competent person in accordance

with the Gas Safety (Installation and Use) Regulations 1994

Summary of 24I RSF

Page 1

Bosch group 24i rsf wall mounted combination boiler for central heating and mains fed domestic hot water installation and servicing instructions gc numbers n.G. 47 311 37 l.P.G. 47 311 38 boiler output to domestic hot water – modulated control minimum 7.5 kw (25,600 btu/h) maximum 23.4 kw (80,000 bt...

Page 2

1.1 gas safety (installation and use) regulations, october 1994 all gas appliances must be installed by a competent person in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution. 1.2 the manufacturers notes must not be taken, in any way, as overri...

Page 3

2.5 electrical supply mains supply: 230v ~, 50 hz, 180 watts. External fuse: 3a., internal fuses: 2at hrc(f1), and 1 af (f2). 2.6 gas supply the boiler requires 2.76 m 3 /h (97.5 ft 3 /hr) of natural gas with a calorific value of 37.78 mj/m 3 (1014 btu/ft 3 ) or 1.07 m 3 /h (37.8 ft 3 /hr) of propan...

Page 4

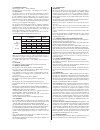

The data plate is fixed to the inner casing cover. 3. Data tables 4 nominal boiler ratings output input (net). Burner setting gas rate pressure kw btu/h kw btu/h m bar. In. Wg. M 3 /h ft 3 /h natural gas 7.5 (25,600) 9.60 (32,750) 1.0 0.4 1.01 35.7 23.4 (80,000) 26.05 (88,890) 13.6 5.4 2.76 97.5 pro...

Page 5

4.1 the appliance may be installed in any room although particular attention is drawn to the requirements of the current iee wiring regulations bs 7671 and, in scotland, the electrical provisions of the building regulations applicable in scotland, with respect to the installation of appliances in ro...

Page 6

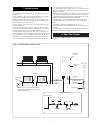

See fig. 3. 5.1 the flue must be installed as specified in bs 5440:part 1. 5.2 the terminal must not cause an obstruction nor the discharge cause a nuisance. 5.3 if the terminal is fitted within 850mm of a plastic or painted gutter or within 450mm of painted eaves then an aluminium shield at least 7...

Page 7

See figs. 4. 7.1 the system must comply with the requirements of bs 6798 and bs 5449. 7.2 the appliance must not be operated without the system being full of water, properly vented and pressurised. 7.3 the pressure relief valve operates at 3 bar (45lb/in 2 ). The discharge must be directed away from...

Page 8

9.1 the following are general requirements and, if necessary, reference should be made to the local water company before fitting the appliance. 9.2 mains cold water inlet. Devices capable of preventing the flow of expansion water must not be fitted unless separate arrangements have been made. A mini...

Page 9

10.1 mains supply. 230 v ~, 50 hz, 180 watts. External fuse: 3a. Internal fuses: 2at hrc(f1), and 1.Af (f2). 10.2 it must be possible to completely isolate the appliance. 10.3 the following connection alternatives must be used: a 3 amp fused three-pin plug and unswitched shuttered socket outlet (bot...

Page 10

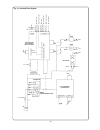

10 fig. 9. Functional flow diagram. F1 2athrc f2 1.25at optional links spark flame sense outputs inputs mains indicator modulating valve overheat stat x6 pins 8 & 9 x6 pins 15 & 16 x6 pins 5,6 & 7 x6 pins 1 & 2 x6 pins 19 & 20 x6 pins 3 & 4 flow signal ch temp. Sensor dhw temp. Sensor ch control pot...

Page 11

Technical helpline. The appliance is only suitable for fitting to a sealed system. 11.1 flue options. The standard flue length is from 127mm to 350mm measured from the appliance casing to the outer wall. Extension flue kits, a vertical take-off adapter, 45° and 90° flue bends are available to increa...

Page 12

Connect the gas, water and pressure relief valve connections to the appliance. The primary system should be flushed and treated in accordance with the recommendations of bs7593:1992. If the air and flue duct assembly is to be fitted from inside the room then the ducts must be adjusted to length, ass...

Page 13

2. If l is within the range 127mm to 350mm then the flue can be telescopically adjusted to the correct length (l+184mm for side flues or l+181mm for rear flues). The ducts are then fixed by drilling a pilot hole through the hole in the air duct and screwing the self tapping screw provided into the t...

Page 14

11.5 internal fitting of the duct assembly the rubber sealing gasket and the clamping ring are available from worcester heat systems. Measure and cut the ducts as previously described for external fitting (section 11.4). Fix the ducts to the terminal and fit the rubber sealing gasket and clamp to th...

Page 15

11.7 vertical adapter measure and fit the flue as in section 11.6 flue bends except the first section length is measured from the case top and the ducts are cut to x – 168mm. The minimum length for x is 190mm. See fig. 22. 11.8 final installation check that all the water and gas connections have bee...

Page 16

12.1 summary the appliance is dispatched with the controls set to provide a maximum output for domestic hot water and central heating of 23.4 kw (80,000 btu/h). The appliance automatically modulates to satisfy lower heat loads. Domestic hot water and central heating systems. Check that both the main...

Page 17

12.3 programmer any programmer fitted on the appliance should be set up at this stage following the instructions sent with the programmer. 12.4 appliance operation turn off the gas and electricity supplies to the appliance. Undo the two screws and hinge down the facia. Loosen the burner pressure tes...

Page 18

13.1 tell the user how to operate the appliance and hand over the users instructions leaflet. 13.2 tell the user what to do if the heating system is not to be used in frosty weather. 13.3 tell the user the sealed system set pressure. 13.4 tell the user of the importance of regular servicing. Worcest...

Page 19

14.3 dismantle the appliance to carry out a full and comprehensive service of the appliance remove the following parts to gain access to the components which need to be checked or serviced. (a) cabinet front panel. Remove by lifting off the supports. (b) inner casing cover. Check that the electricit...

Page 20

15.1 important switch off the electricity and gas supplies before replacing any components. After the replacement of any components, check for gas soundness where relevant and carry out functional checks as described in section 12 - commissioning 15.2 component access to replace components it is nec...

Page 21

6. Combustion chamber insulation. Check that the electricity supply to the appliance is turned off. Drain the central heating circuit as described in section 15.3(a). Remove the inner casing cover, fan, flue hood assembly, burner, and gas to water heat exchanger as described in sections 14.3 (b, e a...

Page 22

13. Domestic hot water sensor. Check that the electricity supply to the appliance is turned off. Hinge the facia assembly in the servicing position as described in section 14.3(c and d). Carefully pull off the two leads from the sensor. Undo and remove the clamping screw. Pull off the sensor and spr...

Page 23

20. Control board. Check that the electricity supply to the appliance is turned off. Undo the 3 screws and remove the facia bottom panel. Remove the two upper screws and hinge down the facia assembly. Carefully pull off all the connectors. Disconnect the mains supply lead at terminal x1 and the eart...

Page 24

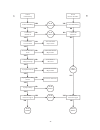

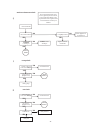

24 end of a domestic hot w ater o verrun escape pause b y resetting the mains electricity supply off-on anti-cy cle dela y m ain gas v alv e off 6 either aut oma tic st art -up sequence 1. Central heating mode no p ass present present absent absent f ail yes centr al heating temper atur e 5°c abo ve...

Page 25

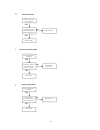

25 signal fr om the flow swit ch ho t w a ter demand (ov errides all other ov errun modes and functions) no demand and primary temper atur e below 6°c monit or ed b y the centr al heating sensor internal "a ut ofr ost at" demand run pump below 4°c abo ve 8°c 4°c t o 8°c m onit or centr al heating se...

Page 26

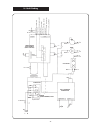

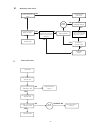

26 f1 2athrc f2 1.25at optional links spark flame sense outputs inputs mains indicator modulating valve overheat stat x6 pins 8 & 9 x6 pins 15 & 16 x6 pins 5,6 & 7 x6 pins 1 & 2 x6 pins 19 & 20 x6 pins 3 & 4 flow signal ch temp. Sensor dhw temp. Sensor ch control pot air pressure switch mains progra...

Page 27

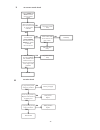

27 fault in central heating fault in domestic hot water is mains led flashing? Is mains led iluminated? Turn control knob fully clockwise set room stat to call for heat ensure link is fitted at x2 pins 2 & 3 set clock to call for heat has overheat thermostat tripped ensure link is fitted at x2 pins ...

Page 28

28 no mains led connect mains supply replace fuse is f1 (2athrc) ok? Is f2 (1.25at) ok? Faulty pcb replace flashing mains led remove x6 open circuit replace thermistor replace harness short circuit faulty pcb replace is resistance between pins 3 & 4 between 690ohms & 33k is resistance between pins 1...

Page 29

29 the overheat thermostat can be reset by pressing the reset button, but if it trips immediately or on a regular basis a serious problem has occurred therefore contact your installer reset thermostat overheat thermostat check pump check fan check does button hold in? Secure connector secure connect...

Page 30

30 thermistor check harness continuity check harness short check remove connectors from thermistor thermistor ok remove appropriate connectors is continuity observed between each end of wire in question? Faulty harness or connector harness ok remove appropriate connectors faulty harness harness ok i...

Page 31

31 ignition check is fan running? Is sparking present at the electrodes? Faulty pcb replace connect ignition leads securely are leads breaking down? Ignition coil faulty replace pcb replace leads does burner continue? Does gas pressure modulate? Ignition ok faulty pcb replace is flame sense electrod...

Page 32

32 remove brown and white terminals from air pressure switch air pressure switch faulty with no demand, is a short-circuit observed at exposed aps terminals? Reconnect the white & brown wire and remove the green wire. Initiate a demand. Does the fan run? Pcb faulty air pressure switch faulty aps ok ...

Page 33

With pressure above minimum, remove modureg lead. Does pressure drop to minimum? 33 is minimum pressure observed at burner at all times? Modulating valve check flow switch check go to check i yes yes go to check i yes yes no no harness ok yes yes no no no no is pressure at burner always the same? Is...

Page 34

34 key g.C. No. Part manufacturer’s reference qty whs no. Part no. 1 e01-579 burner assembly natural gas aeromatic ac23/053586 1 8 716 142 604 0 e01-580 burner assembly lpg aeromatic ac23/053587 1 8 716 142 611 0 2 e01-591 injector natural gas stereomatic o 4.3mm 1 8 716 140 224 0 e00-741 injector l...

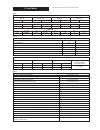

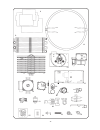

Page 35

35 9 8 14 3 21 1 15 13 4 22 11 7 12 10 23 20 6 25 24 2 19 18 16 23.

Page 36

This booklet is accurate at the date of printing but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued improvement. All goods sold are subject to our official conditions of sale, a copy of which may be obtained on application....