- DL manuals

- Worcester

- Boiler

- 27Ri Compact

- Installation, Commissioning And Servicing Instructions

Worcester 27Ri Compact Installation, Commissioning And Servicing Instructions

UK/IE

INSTALLATION, COMMISSIONING AND SERVICING INSTRUCTIONS

WALL HUNG RSF GAS FIRED CONDENSING REGULAR BOILER

Greenstar Ri Compact

6720646610-00.1W

o

FOR OPEN VENTED AND SEALED CENTRAL HEATING SYSTEMS AND

INDIRECT MAINS FED DOMESTIC HOT WATER

6 72

0 646 610 (2013/12)

These appliances are for use with:

Natural Gas or L.P.G.

(Cat. II 2H 3P type C13, C33 & C53)

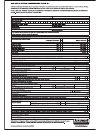

Model

GC Number

Natural Gas

27Ri Compact

41-406-17

30Ri Compact

41-406-19

L.P.G.

27Ri Compact

41-406-18

30Ri Compact

41-406-20

Summary of 27Ri Compact

Page 1

Uk/ie installation, commissioning and servicing instructions wall hung rsf gas fired condensing regular boiler greenstar ri compact 6720646610-00.1w o for open vented and sealed central heating systems and indirect mains fed domestic hot water 6 72 0 646 610 (2013/12) these appliances are for use wi...

Page 2

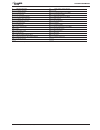

Contents greenstar ri compact 6 720 646 610 (2013/12) 2 contents 1 key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 safety precautions . . . . . . . . . . . . . . . . . . . . . . ...

Page 3

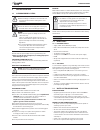

Key to symbols and safety instructions greenstar ri compact 6 720 646 610 (2013/12) 3 1 key to symbols and safety instructions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that could result in damage to property or eq...

Page 4

Key to symbols and safety instructions greenstar ri compact 6 720 646 610 (2013/12) 4 benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and servic...

Page 5

Appliance information greenstar ri compact 6 720 646 610 (2013/12) 5 2 appliance information 2.1 appliance fig. 1 ri compact standard package boiler features and checklist • pre-wired and pre-plumbed • aluminium coated steel inner frame • digital control system • memory retention after power cut • a...

Page 6

Appliance information greenstar ri compact 6 720 646 610 (2013/12) 6 2.2 layout fig. 2 ri compact main boiler components 1 3 2 18 31 30 29 4 5 11 12 10 21 20 19 22 23 25 27 28 26 9 8 7 6 13 14 15 17 16 6720646610-02.2w o 24.

Page 7

Appliance information greenstar ri compact 6 720 646 610 (2013/12) 7 1 wall mounting frame 17 temperature control and reset 2 primary return pipe 18 fan 3 primary flow pipe 19 flow temperature sensor (ntc) 4 flue connector 20 electrode assembly 5 flue overheat thermostat 21 maximum safety sensor (nt...

Page 8

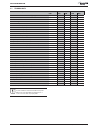

Appliance information greenstar ri compact 6 720 646 610 (2013/12) 8 2.3 technical data description ri compact natural gas l.P.G. Unit 27kw 30kw 27kw 30kw gas flow rate - max. 10 minutes from lighting natural gas g20 m³/h 2.92 3.24 gas flow l.P.G. Kg/h 2.1 2.33 central heating minimum heat input kw ...

Page 9

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 9 3 pre-installation 3.1 cleaning primary systems before cleaning the system: ▶ ensure that the system and pipe work is in good working order. ▶ where possible keep the existing boiler/circulating pump in place when flushing the system. F...

Page 10

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 10 sealed primary system: • if the system is sealed then the system must be filled using a wras approved filling loop or comply with figure 3 for system fill. • the expansion vessel (2) must be fitted as close as possible to the appliance...

Page 11

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 11 new installation 3.4 condensate pipe work 3.4.1 internal connections in order to minimise risk of freezing during prolonged cold spells, the following methods of installing condensate drainage pipe should be adopted, in order of priori...

Page 12

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 12 fig. 6 condensate pump disposal 3.4.2 external connections if no other discharge method is possible then the use of an externally run condensate drainage pipe terminating at a suitable foul water discharge point, or purpose-designed so...

Page 13

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 13 in situations where there are likely to be extremes of temperature or exposure, the use of a proprietary trace-heating system for external pipe work, incorporating an external frost thermostat, should be considered. If such a system is...

Page 14

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 14 3.6 plumbing manifold 3.6.1 connections use the fittings supplied in the hardware literature pack. Fig. 13 pipe dimensions fig. 14 plumbing manifold key to figures 13 & 14: [1] condensate 22mmØ - distance to left edge of case = 33mm [2...

Page 15

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 15 350 mm - 570 mm 130 mm min flat roof 300 mm 500 mm pitched roof 2 3 4 5 6 10 9 8 7 1 6720643895-12.1wo.

Page 16

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 16 3.8 flue terminal positions fig. 15 flue terminal positions key to illustration 1. 300mm adjacent to a boundary line. 2. The dimension below eaves, balconies and car ports can be reduced to 25mm, as long as the flue terminal is extende...

Page 17

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 17 3.9 plume management terminal positions fig. 16 plume terminal positions key to illustration 1. This feature allows some basic plume re-direction options on a standard telescopic horizontal flue terminal. 300mm minimum clearances to a ...

Page 18

Pre-installation greenstar ri compact 6 720 646 610 (2013/12) 18 3.9.1 determine the plume management system length minimum plume management length the minimum plume length is 500mm to ensure that the air inlet and exhaust have a minimum distance of 500mm between them. The plume management can be in...

Page 19

Installation greenstar ri compact 6 720 646 610 (2013/12) 19 4 installation 4.1 unpacking the wall frame & ancillary items 1. Open the top of the carton and remove the water pipes (1) and the wall mounting frame (2). 2. Remove all the other items to enable the boiler to be unpacked. Fig. 20 unpackin...

Page 20

Installation greenstar ri compact 6 720 646 610 (2013/12) 20 fig. 22 marking the flue position 4.3 unpacking the appliance 1. Remove outer carton (1) and place safely away from the working area. 2. With the outer packaging removed and the inner sleeve (2) can be removed. 3. Remove the protective wra...

Page 21

Installation greenstar ri compact 6 720 646 610 (2013/12) 21 fig. 25 releasing the control panel ▶ remove any packaging within the boiler and the packaging base (3). 4.4 boiler connection 4.4.1 wall mounting plate ▶ remove wall mounting template. ▶ mount the wall plate to the wall utilising at least...

Page 22

Installation greenstar ri compact 6 720 646 610 (2013/12) 22 4.4.3 hanging the boiler system pipes may be run vertically up behind the boiler or below it. The boiler mounting points on the wall frame are indicated in figure 28. Ensure the wall frame sides are not slightly splayed out after mounting;...

Page 23

Installation greenstar ri compact 6 720 646 610 (2013/12) 23 ▶ when the condensate connections are complete, pour approximately 200 to 250ml of clean water through the inner flue opening on top of the boiler to fill the siphon. Fig. 32 pipe work dimensions 4.5 flue installation horizontal flue (60/1...

Page 24

Installation greenstar ri compact 6 720 646 610 (2013/12) 24 to reduce the flue length further: fig. 36 further reduction ▶ mark the length required for the terminal as shown (min.130mm) and cut square, taking care not to damage the tubes. ▶ remove any burrs and chamfer the edges of the tubes to ass...

Page 25

Installation greenstar ri compact 6 720 646 610 (2013/12) 25 2. Refit to the terminal, ensuring that the clips (1 & 2) are engaged and secure. 3. Loosen screws (3) and rotate the entire outlet assembly to redirect the plume. Tighten screws (3) to secure in the required position. Fig. 41 plume redire...

Page 26

Installation greenstar ri compact 6 720 646 610 (2013/12) 26 fig. 43 removing the installer access cover 4. Mains in connections 5. Pump connections 6. Mains out connections connectors fig. 44 230v and 24v connections 4.6.1 mounting optional plug-in controls - only with greenstar wiring centre (opti...

Page 27

Installation greenstar ri compact 6 720 646 610 (2013/12) 27 new installations if a new complete heating system installation is in a new build property or is a first time installation in an existing property, heating systems must conform to current building regulations part l1a. All new heating syst...

Page 28

Commissioning greenstar ri compact 6 720 646 610 (2013/12) 28 5 commissioning 5.1 pre-commissioning checks ▶ check that the gas service pipe and water pipes are connected to the correct position on the manifold. 1. Gas inlet (22mm) 2. Flow (22mm) 3. Return (22mm) fig. 50 ▶ check the gas type specifi...

Page 29

Commissioning greenstar ri compact 6 720 646 610 (2013/12) 29 5.4 starting the appliance fig. 52 control panel switching the appliance on/off: ▶ turn on the mains power supply. ▶ turn on any external controls ▶ set the thermostatic radiator controls to maximum temperature ▶ set the clock/programmer ...

Page 30

Commissioning greenstar ri compact 6 720 646 610 (2013/12) 30 5.5 commissioning check the following points, and then continue with the commissioning: ▶ that the boiler has been installed in accordance with the installation instructions. ▶ the integrity of the flue system and flue seals. ▶ the integr...

Page 31

Commissioning greenstar ri compact 6 720 646 610 (2013/12) 31 5.6 co and combustion checks the following combustion and flue integrity checks will be mandatory from april 2014 and these values must be recorded on the benchmark check list, at the back of this manual. Once the gas rate and pressure ha...

Page 32

Commissioning greenstar ri compact 6 720 646 610 (2013/12) 32 5.7 finishing commissioning 5.7.1 replacing outer casing: 1. Replace outer casing. 2. Ensure that the securing clips on top of the case are properly located. 3. Tighten bottom two screws (2). 4. Raise the control panel and engage the lugs...

Page 33

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 33 5.7.5 handover ▶ complete the benchmark gas boiler commissioning checklist. ▶ open the fascia flap by hinging the flap downwards using the curved hand hold in the centre of the flap. ▶ set up the controls and show the customer how to...

Page 34

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 34 6.2 checking the gas inlet pressure ▶ check that the gas working pressures in the system conform to the figures shown in section 5.5.1: 6.3 checking flue integrity the integrity of the flue system and performance of the boiler can be...

Page 35

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 35 6.5 fan pressure test before setting the boiler to maximum output for the fan pressure test, refer to figure 66: ▶ switch the boiler off. ▶ remove the combustion air intake pipe (1). ▶ remove the fan pressure test point cover (2). ▶ ...

Page 36

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 36 6.6 flue gas analysis combustion test ▶ connect the flue gas analyser to the flue gas sampling point (1) as shown in the figure below. ▶ ensure that the probe reaches the centre of the flue gas exhaust, adjust the cone on the probe s...

Page 37

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 37 6.7 cleaning the heat exchanger the following items will have to be removed to gain access to the heat exchanger for cleaning: ▶ lower the control panel into the service position. ▶ remove the case. ▶ disconnect electrical wires to t...

Page 38

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 38 fig. 73 heat exchanger cleaning tool to clean the front channel of the heat exchanger 3. Orient the cleaning tool (2) as shown in figure 74 and insert the tool into the front channel for cleaning. 4. Move the cleaning tool handle in ...

Page 39

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 39 fig. 76 removing outer case 6.8.2 draining the boiler many of the tasks in this section require that the boiler be isolated and drained. 1. Connect a suitable hose firmly to the drain point and run the hose outside to a suitable poin...

Page 40

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 40 6.8.5 “maximum safety sensor” ▶ disconnect the electrical connectors to the “maximum safety sensor”. 1. Remove the screw securing the sensor. 2. Remove the sensor from the heat exchanger. ▶ when replacing the sensor, ensure that the ...

Page 41

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 41 6.8.9 fan assembly to remove the fan the following components will have to be removed first: • flueway • combustion air inlet pipe and gas pipe flueway removal 1. Release the two screws securing the flueway to the sump. 2. Using a sc...

Page 42

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 42 combustion air inlet and gas pipe disconnection 1. Rotate the combustion air inlet pipe anti-clockwise to release from the fan assembly and pull away from the fan. 2. Undo the top gas pipe connector at the gas valve. Fig. 88 combusti...

Page 43

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 43 6.8.12 electrode assembly to remove the spark electrode assembly: 1. Undo and remove the two nuts securing the electrode assembly 2. Rotate the electrode assembly down and forward to remove from the heat exchanger. ▶ inspect the spar...

Page 44

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 44 6.8.14 heat exchanger heat exchanger disconnection 1. Undo the flow and return connections. 2. Pull both the flow and return pipes away from the heat exchanger. ▶ replace the fibre washers (1) when replacing the heat exchanger. Fig. ...

Page 45

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 45 6.8.16 access to boiler control components ▶ push in the catches and remove the bottom panel. 1. Release the two screws securing the control panel. 2. Pull down to release the two catches. 3. Pull the bottom of the control panel forw...

Page 46

Service and spares greenstar ri compact 6 720 646 610 (2013/12) 46 6.9 short parts list fan 7 746 009 09a 0 burner 8 718 600 23b 0 gas valve 8 718 600 04a 0 control panel 8 718 682 010 0 flue overheat thermostat (grommet type) 8 717 206 213 0 electrodes (including gasket) 8 718 600 28a 0 burner seal...

Page 47

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 47 7 fault finding and diagnosis 7.1 fault finding the electronic control system for this boiler incorporates a blue light on the front fascia. This light indicates normal operation, but by flashing at different rates during a ...

Page 48

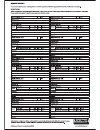

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 48 7.1.1 group 1 fault codes fig. 105 group 1 flash sequences flash sequence type of fault fault possible solutions/check light off no fault no boiler demand - boiler is ok light on heating demand on boiler- boiler is ok group ...

Page 49

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 49 7.1.2 group 2 fault codes fig. 106 group 2 flash sequences flash sequence type of fault fault possible solutions/check light off no boiler demand - boiler is ok light on heating demand on boiler- boiler is ok group 2 flashin...

Page 50

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 50 7.1.3 group 3 fault codes fig. 107 group 3 flash sequences flash sequence type of fault fault possible solutions/check light off no boiler demand - boiler is ok light on heating demand on boiler- boiler is ok group 3 flashin...

Page 51

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 51 7.2 wiring diagram hcm worcester 24v controls point fuse, slow f 5a h 230 v x7 x7 x3 x8 x12 x11 x10 l n lr l n l n 2 1 1 3 1 1 1 1 6 4 13 4 temperature control and reset ems 230v in l n 230v out l n lr l n flame sense electr...

Page 52

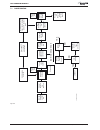

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 52 7.3 boiler function fig. 108 no ye s boiler de man d f an to start speed. P u mp o n . Mai n s po we r s u ppl y on ig n iti o n se qu e n ce (see detail) burner l it? Green fl a m e li g h t on stop spark and gas. Purge 30 ...

Page 53

Fault finding and diagnosis greenstar ri compact 6 720 646 610 (2013/12) 53 7.4 protection function fig. 109 internal boiler temperature between 8°c & 5°c boiler automatic frost function (monitors internal boiler primary temperature) internal boiler temperature rises above 9°c pump runs pump switche...

Page 56

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0330 123 9559 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk document no.6 720 646 610 (2013/12) worcester, bosch group: technical support: 0330 123 3366 appointments: 0330 123 9339 spa...