- DL manuals

- Worcester

- Boiler

- 28CDi RSF

- Installation and servicing instructions

Worcester 28CDi RSF Installation and servicing instructions

28CDi RSF

WALL MOUNTED COMBINATION BOILER FOR CENTRAL HEATING

AND MAINS FED DOMESTIC HOT WATER

INSTALLATION AND

SERVICING INSTRUCTIONS

GC NUMBER 47 311 34 (N.G.)

GC NUMBER 47 311 35 (L.P.G.)

BOILER OUTPUT

Automatic Modulating Control

To Domestic Hot Water

To Central Heating

Minimum

9.0 kW

9.0 kW

Maximum

28.0 kW

24.0 kW

IMPORTANT: THESE INSTRUCTIONS APPLY IN THE UK ONLY

THESE INSTRUCTIONS ARE TO BE LEFT WITH THE USER OR AT THE GAS METER

This appliance must be installed by a competent person in accordance

with the Gas Safety (Installation and Use) Regulations 1994

Bosch Group

Summary of 28CDi RSF

Page 1

28cdi rsf wall mounted combination boiler for central heating and mains fed domestic hot water installation and servicing instructions gc number 47 311 34 (n.G.) gc number 47 311 35 (l.P.G.) boiler output automatic modulating control to domestic hot water to central heating minimum 9.0 kw 9.0 kw max...

Page 2

1.1 gas safety (installation and use) regulations, october 1994 all gas appliances must be installed by a competent person in accordance with the above regulations. Failure to install appliances correctly could lead to prosecution. 1.2 the manufacturers notes must not be taken, in any way, as overri...

Page 3

The boiler requires 3.35 m 3 /h (115 ft 3 /hr) of natural (g20) or 1.29 m 3 /hr (46 ft 3 /hr or propane gas (g31). The gas meter and supply pipes must be capable of supplying this quantity of gas in addition to the demands of any other appliances being served. The meter governor should deliver a dyn...

Page 4

The data plate is fixed to the inner casing cover. Check data plate to ensure appliance has been adjusted for supply gas. 3. Technical data 4 available pump head boiler output head min. Flow rate temperature rise across heating kw btu/h metres feet l/min. Gal/min. Flow and return 9.0 (30,700) 4.2 13...

Page 5

4.1 the appliance may be installed in any room although particular attention is drawn to the requirements of the current i.E.E. Wiring regulations bs 7671 and, in scotland, the electrical provisions of the building regulations applicable in scotland, with respect to the installation of appliances in...

Page 6

See fig. 4 5.1 the flue must be installed as specified in bs 5440:part 1. 5.2 the terminal must not cause an obstruction nor the discharge cause a nuisance. 5.3 if the terminal is fitted within 1000mm of a plastic or painted gutter or within 500mm of painted eaves then an aluminium shield at least 1...

Page 7

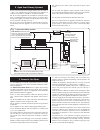

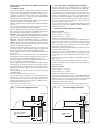

See figs. 5, 6 and 6a. 7.1 the system must comply with the requirements of bs 6798 and bs 5449. 7.2 the appliance must not be operated without the system being full of water, properly vented and pressurised. 7.3 the pressure relief valve operates at 3 bar (45lb/in 2 ). The discharge must be directed...

Page 8

8.1 the size of the flow and return pipework is given in section 3 – table 4. The components required to connect the appliance to an open vent system are available as an optional extra kit. 8.2 the feed and expansion cistern should be arranged so that there is a minimum static head of 0.3 metres (12...

Page 9

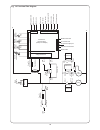

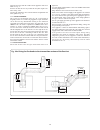

See figs. 8, 9, 10, 11, 12 and 13. 10.1 mains supply. 230 v ~, 50 hz, 180 watts. External fuse: 3a. Internal fuses: t 2a (f1), and t 1.25a (f2). Spare internal fuses are supplied at the rear of the facia, next to the pressure gauge. 10.2 it must be possible to completely isolate the appliance. 10.3 ...

Page 10

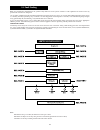

10 fig. 10. Functional flow diagram. Mains indicator on/of f switch st8 (l s ) st8 (l r ) st8 (n s ) st1 centre pin st15 pin l st1 pin l rel 1 rel 3 high low rel 4 pump fan (2 speed) st12 pin n optional link room thermostat t ransformer fuse f2 (1.25a slow) fuse f1 (2a slow) n n st12 pin l live in g...

Page 11

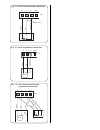

11 fig. 11. 230 v room thermostat connections. Fig. 13. 230 v room thermostat and programmer connections. Fig. 12. 230 v programmer connections. N s l s st8 st8 st8 remove link neutral live switched live neutral neutral switched live live live switched live l r spare n s l s l r spare spare motor ne...

Page 12

The appliance is supplied suitable for fitting to a sealed system. If it is to be fitted to an open vent system refer to section 8. 11.1 flue options. The standard flue length is from 100mm to 650mm measured from the appliance casing to the outer wall. Extension flue kits, a vertical take-off adapto...

Page 13

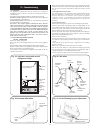

Note: read this section fully before commencing installation 11.2 general fitting. Check that the appliance carton contains: appliance, installers instruction pack, pre-plumbing manifold, wall plate cross member, user’s information pack and installer’s hardware pack. Assemble the wall plate cross me...

Page 14

Ducts into the flue outlet turret. Pull back the air duct slightly to allow access to the flue duct. Drill through the flue duct and fix with the screws provided. Push the air duct into the turret. Drill and fix the air duct to the turret with the screws provided. See fig. 19. Align the flue turret ...

Page 15

Align the flue turret with the 4 holes on the appliance and screw down. See fig. 16. Refit the fan. Do not use any sealant on the joint. Replace the inner casing cover. Seal the gap around the duct with the flexible seal provided and make good. See fig. 22. 11.6. Fitting flue bends flue bends are an...

Page 16

12.1 summary the appliance is dispatched with the controls set to provide a maximum output for domestic hot water of 28 kw and 24 kw for central heating. The appliance automatically modulates to satisfy lower heat loads. Domestic hot water system. Check that the mains water supply has been fully flu...

Page 17

Set the movable pointer on the pressure gauge to coincide with the indicating pointer giving a permanent record of the set system pressure. If the pressure indicated on the pressure gauge is greater than 2.6 bar when operating at the maximum central heating temperature, an extra expansion vessel mus...

Page 18

13.1 tell the user how to operate the appliance and hand over the users instructions leaflet. 13.2 tell the user what to do if the heating system is not to be used in frosty weather. 13.3 tell the user the sealed system set pressure. 13.4 tell the user of the importance of regular servicing. Worcest...

Page 19

Assembly from the appliance. See fig. 28. When refitting the hood ensure that the rear return edge passes under the lip at the rear of the combustion chamber. (g) combustion chamber front and sides. Remove the inner casing cover and flue hood assembly. Unscrew the two wing nuts securing the front an...

Page 20

Air pressure switch 2. Air flow pressure switch. See fig. 30. Check that the electricity supply to the appliance is turned off. Remove the cabinet front panel as described in section 14.3 (a). Carefully pull off the sensing tubes and the electrical connections from the switch. Unscrew the two screws...

Page 21

13. Central heating sensor. See fig. 31. Remove the inner casing cover as described in section 14.3(b). Check that the electricity supply to the appliance is turned off. Carefully pull off the two leads from the sensor. Pull off the sensor and spring retaining clip from the pipe. Fit the replacement...

Page 22

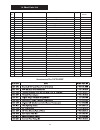

22 16. Short parts list accessories for 28cdi rsf 26 378 312 gas valve junkers bosch, type ce 426 1 8 747 003 366 0 78 e00-720 burner – natural gas aeromatic, ref. Ac 23/05 3584 1 8 716 142 603 0 78 e00-737 burner – propane aeromatic, ref. Ac 23/05 3585 1 8 716 142 605 0 80 e00-721 burner injector –...

Page 23

23 109.

Page 24

17 operational flow diagrams 24.

Page 25

25.

Page 26

26.

Page 27

18. Fault finding 27 note: this fault-finding information is for guidance only. Worcester heat systems cannot be held responsible for costs incurred by persons not deemed to be competent. The electronic control system for this boiler incorporates four lights on the facia. These are used to show norm...

Page 28

28.

Page 29

29.

Page 30

30

Page 31

31.

Page 32

32.

Page 33

33.

Page 34

34.

Page 35

35.

Page 36

This booklet is accurate at the date of printing but will be superseded and should be disregarded if specifications and/or appearances are changed in the interests of continued improvement. All goods sold are subject to our official conditions of sale, a copy of which may be obtained on application....