- DL manuals

- Worcester

- Boiler

- 550CDi

- Instruction Manual

Worcester 550CDi Instruction Manual

UK/IE

INSTRUCTION MANUAL

INSTALLATION COMMISSIONING & SERVICING

8 716 115 219b (09.2008)

THE APPLIANCE IS FOR USE WITH

NATURAL GAS OR L.P.G. (Cat II 2H3P TYPE C13, C33 & C93)

NATURAL GAS:

GREENSTAR HIGHFLOW 440CDi GC NUMBER 47-406-24

GREENSTAR HIGHFLOW 550CDi GC NUMBER 47-406-25

LIQUID PETROLEUM GAS:

GREENSTAR HIGHFLOW 440CDi GC NUMBER 47-406-26

GREENSTAR HIGHFLOW 550CDi GC NUMBER 47-406-27

GREENSTAR

HIGHFLOW 440CDi & 550CDi

FOR SEALED CENTRAL HEATING SYSTEMS AND MAINS FED DOMESTIC HOT WATER

FLOOR STANDING RSF GAS-FIRED CONDENSING COMBINATION

BOILER

Summary of 550CDi

Page 1

Uk/ie instruction manual installation commissioning & servicing 8 716 115 219b (09.2008) the appliance is for use with natural gas or l.P.G. (cat ii 2h3p type c13, c33 & c93) natural gas: greenstar highflow 440cdi gc number 47-406-24 greenstar highflow 550cdi gc number 47-406-25 liquid petroleum gas...

Page 2

Installation & servicing instructions contact information installation & servicing instructions contact information installation & servicing instructions 8 716 115 219b (09.2008) please read these instructions carefully before starting installation. These instructions are applicable to the product m...

Page 3

Installation & servicing instructions contents s afet y & regul a tions f a ul t finding & dia grams appliance inf orma tion pre- ins t all a tion ins t all a tion c ommis sioning ser vicing & sp ares c onversion kit s contents 1 8 716 115 219b (09.2008) safety & regulations safety precautions 2 ins...

Page 4

Safety precautions installation regulations if you smell gas: don't smoke or strike matches. Don't turn electrical switches on or off. Do put out naked flames. Do open doors and windows. Do keep people away from the area affected. Do turn off the control valve at the meter. Do call your gas company....

Page 5

Appliance inf orma tion installation & servicing instructions 3 general information general information 8 716 115 219b (09.2008) standard package: a - floor standing gas fired combination boiler for central heating and domestic hot water. B - mounting frame complete with pre- plumbing manifold assem...

Page 6

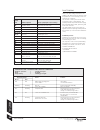

Appliance inf orma tion installation & servicing instructions 4 technical data technical data 8 716 115 219b (09.2008) central heating max. Rated heat output net 40/30°c kw 31.2 32.8 31.2 32.8 max. Rated heat output net 50/30°c kw 30.9 32.5 30.9 32.5 max. Rated heat output net 80/60°c kw 29.2 30.6 2...

Page 7

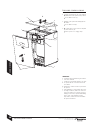

Appliance inf orma tion installation & servicing instructions 5 layout & components layout & components 8 716 115 219b (09.2008) a b c d e f 2 3 4 5 14 10 11 13 7 8 9 12 6 the diagram opposite shows the controls in the servicing position and excludes the outer case, inner covers and wiring. 1 contro...

Page 8

Pre- ins t all a tion installation & servicing instructions 6 cleaning primary systems cleaning primary systems caution: isolate the mains supplies before starting any work and observe all relevant safety precautions. Important: all the following pre-installation sections must be read and requiremen...

Page 9

Pre- ins t all a tion installation & servicing instructions 8 716 115 219b (09.2008) 7 mains supplies mains supplies electrical supply: • supply: 230v - 50hz. • cable: pvc insulated 0.75mm (24 x 0.2mm) temperature rated to 90°c. • external 3a fuse to bs1362. • the appliance must be earthed. • it mus...

Page 10

Pre- ins t all a tion installation & servicing instructions 8 716 115 219b (09.2008) 8 716 115 219b (09.2008) 8 mains supplies mains supplies gas supply: • boilers using ng must be connected to a governed meter. • lpg boilers must be connected to a regulator. • installation and connection of the gas...

Page 11

Pre- ins t all a tion installation & servicing instructions 8 716 115 219b (09.2008) 9 water systems & pipework primary system plastic pipework: • any plastic pipework must have a polymeric barrier with 600mm (minimum) length of copper connected to the boiler. • plastic pipework used for underfloor ...

Page 12

Pre- ins t all a tion installation & servicing instructions 8 716 115 219b (09.2008) 10 water systems & pipework filling primary systems: • the ch sealed system must be filled using a wras approved filling loop or comply with the diagram opposite for system fill. • the filling point must be at low l...

Page 13

Soil & vent stack 22mmØ minimum 450mm and up to 3 storeys invert condensate drainage pipe can be run above or below ground 25mm bottom of tube sealed limestone chippings hole depth 400mm min. By 300 Ø drainage holes 22mmØ condensate drainage pipe, max external length 3 metres diameter 100mm min. Pla...

Page 14

Pre- ins t all a tion installation & servicing instructions 12 8 716 115 219b (09.2008) pressure relief pipework a b a • the pressure relief drain pipe (a) should be at least 15mm diameter copper pipe and run downwards away from the boiler and discharge away from any electrics or other hazard, prefe...

Page 15

Pre- ins t all a tion installation & servicing instructions boiler location & clearances 8 716 115 219b (09.2008) 13 • this boiler is only suitable for installing internally within a property at a suitable location onto a fixed rigid non-combustible surface at least the same size as the boiler and c...

Page 16

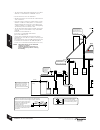

Pre- ins t all a tion installation & servicing instructions boiler location & clearances 8 716 115 219b (09.2008) 14 boiler location & clearances 600mm 2250mm 600mm 2250mm 600mm 600mm radius 750mm 750mm 2250mm m 2250m 1 1 2 2 1 1 2 2 6: bathrooms: important: any switch or appliance control using mai...

Page 17

Pre- ins t all a tion installation & servicing instructions 8 716 115 219b (09.2008) 15 mounting frame connections connections: water: 22mm compression fittings gas: 22mm compression fitting. Pre-plumbing: • with the mounting frame (a) installed, pipework can be connected to the valves on the plumbi...

Page 18

Pre- ins t all a tion installation & servicing instructions 16 terminal outlet positions 8 716 115 219b (09.2008) deduct one metre off the total flue length for every 45° bend used deduct two metres off the total flue length for every 90° bend used the flue turret has a built-in angle of 3° to ensur...

Page 19

Pre- ins t all a tion installation & servicing instructions 17 terminal outlet positions 8 716 115 219b (09.2008) terminal outlet positions flue clearances must be at least 300mm from the ground. Terminal guards must be fitted if the flue is less than 2 metres from the ground or if a person could co...

Page 20

The diagrams (opposite) show the components used and the maximum flue length for each configuration of Ø100mm and Ø125mm flues. • only straight flue sections can be reduced in length by cutting. • the Ø100mm horizontal flue terminal can be fitted from inside or outside the building. Important: all h...

Page 21

Ins t all a tion installation & servicing instructions 19 unpacking the boiler 8 716 115 219b (09.2008) important: all the previous pre-installation sections must be read and requirements met before starting boiler or flue installation. Take care not to damage the boiler panels or the floor and note...

Page 22

Ins t all a tion installation & servicing instructions 20 mounting frame fixing & flue opening 8 716 115 219b (09.2008) mounting frame fixing & flue opening 2 1 3 4 38mm z x y 123 343 123 743* +13 x y z all dimensions in mm 112 65 98.5 65 65 81 c b a a d e 267 b b 20 f d d caution: ensure there are ...

Page 23

Ins t all a tion installation & servicing instructions 21 mounting frame connections 8 716 115 219b (09.2008) caution: isolate the mains gas supply before starting any work and observe all relevant safety precautions. Gas and water connections: ensure all pipework is clean and each pipe is in the co...

Page 24

Ins t all a tion installation & servicing instructions 22 flue lengths flue measuring & cutting 8 716 115 219b (09.2008) horizontal flue: (60/100mm diameter) for vertical flues and 80/125mmØ horizontal flues, please refer to separate flue manuals. Ø60/100mm horizontal telescopic flue lengths: the ma...

Page 25

Ins t all a tion installation & servicing instructions 23 flue measuring & cutting 8 716 115 219b (09.2008) flue bends: 1 connecting flue bends increases the effective pipe length and an allowance must be made for the different connectors. The example opposite shows dimensions for two 90° bends conn...

Page 26

Ins t all a tion installation & servicing instructions 24 flue measuring & cutting 8 716 115 219b (09.2008) flue measuring & cutting flue outlets (l or p): 1 remove seal (b) from flue adaptor (a). 2 cut square to mark, as shown, deburr and clean. 3 replace seal (b). L p l l p a b a b b 1 2 3 1 3 2.

Page 27

Ins t all a tion installation & servicing instructions 25 flue installation 8 716 115 219b (09.2008) flue installation 1 remove retaining screw (a) to swing control panel assembly (b) outwards to its full extent. 2 remove screws (c) from inside of casing. Lift front of top panel (d) to release. Pull...

Page 28

Ins t all a tion installation & servicing instructions 26 standard flue installation 8 716 115 219b (09.2008) standard flue installation top 110mm 3 b k g f h e e g h j c 4 5 6 a clip c b a 2 b 1 a top top note: to ease assembly of the flue components, grease seals lightly with the solvent-free grea...

Page 29

Ins t all a tion installation & servicing instructions 27 extended flue installation 8 716 115 219b (09.2008) extended flue installation top m 110mm 10 n 8 6 9 m k c b b l k b k b e g h j a d d f b e 1 2 3 c b 1m 2m 52mm 104mm 5 7 a c top top g h 4 clip note: to ease assembly of the flue components,...

Page 30

Ins t all a tion installation & servicing instructions 28 flue terminal plume management 8 716 115 219b (09.2008) flue terminal plume management the flue discharge can be redirected allowing some plume management control, alternatively, a complete plume management system can be fitted to the flue te...

Page 31

Ins t all a tion installation & servicing instructions condensate, gas & water connections 29 condensate, gas & water connections 8 716 115 219b (09.2008) h j k max. 4500mm h min. 200mm g e d c b a f m f h l condensate connection: the condensate pump (g) fills up and periodically discharges through ...

Page 32

Ins t all a tion installation & servicing instructions 30 pressure relief valve outlet 8 716 115 219b (09.2008) pressure relief valve outlet fitting the pressure relief valve drain pipe: connect a length of 15mm copper pipe (a) to the p.R.V drain pipe (b). The p.R.V drain pipe (b) should be at least...

Page 33

Note: mains supply to the boiler and system wiring centre must be through a common fused double pole isolator situated next to the boiler. The isolator must have a contact separation of 3mm minimum between all poles. Any system connected to the boiler must not have a separate electrical supply. Exte...

Page 34

C ommis sioning installation & servicing instructions 32 pre-commisioning checks 8 716 115 219b (09.2008) pre-commisioning checks caution: isolate the mains supplies before starting any work and observe all relevant safety precautions. 1 check that the service and water pipes are connected to the co...

Page 35

C ommis sioning installation & servicing instructions 33 filling the system 8 716 115 219b (09.2008) filling the system 1 turn on the water main and open the system valves (align slot vertically). 2 open all radiator valves. 3 unscrew the tank drain cap and connect the integral filling loop. Open th...

Page 36

C ommis sioning installation & servicing instructions 34 water treatment 8 716 115 219b (09.2008) important: debris from the system can damage the boiler and reduce efficiency. Failure to comply with the guidelines for the use of water treatment with the appliance will invalidate the appliance warra...

Page 37

C ommis sioning installation & servicing instructions 35 starting the appliance 8 716 115 219b (09.2008) starting the appliance 1 2 3 a b c d 4 b e a d f l j c b i e h m g k a - master switch for on/off b - mains on/off indicator + fault diagnostic light c - central heating temperature control d - b...

Page 38

C ommis sioning installation & servicing instructions 36 finishing commissioning 8 716 115 219b (09.2008) finishing commissioning 1 engage top panel (a) onto rear retainers (b) and lower front of panel into position. Secure with screws (c). 2 swing control panel assembly (d) into the boiler. Secure ...

Page 39

Ser vicing & sp ares installation & servicing instructions 37 inspection & service 8 716 115 219b (09.2008) inspection & service important: any service work must be carried out by competent registered engineers, such as british gas or other corgi registered personnel. Note: a service must not be att...

Page 40

Ser vicing & sp ares installation & servicing instructions 38 inspection & service 8 716 115 219b (09.2008) inspection & service component access: 1 grip the outer sides of the front panel (a) pull and lift away from retaining lugs (b). 2 remove retaining screw (c) to swing control panel assembly (d...

Page 41

Ser vicing & sp ares installation & servicing instructions 39 inspection & service 8 716 115 219b (09.2008) inspection & service primary heat exchanger: there is a special accessory kit available (no. 840) specifically designed for cleaning the heat exchanger. If required order 7 719 001 996. 1 pull...

Page 42

Ser vicing & sp ares installation & servicing instructions 40 8 716 115 219b (09.2008) inspection & service inspection and service burner: check that the boiler is completely isolated from the gas supply. 1 remove the clips (a) and unscrew the castellated nuts (b). Remove springs. Unscrew and remove...

Page 43

Ser vicing & sp ares installation & servicing instructions 41 replacement parts 8 716 115 219b (09.2008) replacement parts important: any service work must be carried out by competent registered engineers, such as british gas or other corgi registered personnel. Important: after re-assembly the comb...

Page 44

Ser vicing & sp ares installation & servicing instructions 42 replacement parts 8 716 115 219b (09.2008) fan assembly: undo lower pipe union on gas pipe (e). Remove fan lead and earth connector. The earth connector has a positive clip fixing. Remove fixing screws attaching fan (a) to the burner cove...

Page 45

Ser vicing & sp ares installation & servicing instructions 43 replacement parts 8 716 115 219b (09.2008) replacement parts sensors: check that the appliance is electrically isolated. Central heating flow temperature sensor (a): remove the connector. Release the sensor clip and withdraw the sensor. A...

Page 46

Ser vicing & sp ares installation & servicing instructions 44 replacement parts 8 716 115 219b (09.2008) replacement parts domestic hot water heat exchanger: before removing the heat exchanger shut the inlet valves, drain the hot water circuits and tank. The pipe (a) may be removed between the flow ...

Page 47

Ser vicing & sp ares installation & servicing instructions 8 716 115 219b (09.2008) 45 replacement parts replacement parts electrode assembly: switch off the master switch. Isolate appliance from the power supply. Move control panel into service position. Release 4 screws to remove inner case door. ...

Page 48

Setting the air/gas ratio ser vicing & sp ares installation & servicing instructions 46 setting the gas/air ratio 8 716 115 219b (09.2008) gas type co 2 setting maximum. Natural gas type h (g20) lpg (propane) (g31) 9.4 ±0.5% 8.6 ±0.5% 10.8 ±0.5% 10.4 ±0.5% e a b d c 1 2 3 4 5 c greenstar highflow 44...

Page 49

Ser vicing & sp ares installation & servicing instructions 47 short parts list 8 716 115 219b (09.2008) short parts list 1a burner skin seal: part no. 8 711 004 168 0 (gc no. E27 201) 1b burner: part no. 8 718 006 658 0 (gc no. E27 200) 2 fan assembly: 440cdi: part no. 8 717 204 410 0 (gc no. H66 91...

Page 50

C onversion kit s installation & servicing instructions 48 l.P.G. Conversion 8 716 115 219b (09.2008) change code plug: 1 release three screws (a) to remove cover (b). 2 remove and dispose of the existing code plug (c). Replace with new conversion code plug. N.G. Code plug number: 440cdi 1700 550cdi...

Page 51

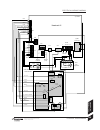

St8 9 8 7 a f 1 2 4 b b heatronic iii st10 st6 safety isolation st25 ls ns st9 st17 st4 st5 pump div-v ch dhw l n 230v in l n ns ls lr ignition transformer 230v twin programmer 230v hw interface ‘installer module’ external frost stat external pump ems bus external stat fan gas valve flame sense spar...

Page 52

F a ul t finding & dia grams installation & servicing instructions 50 central heating function 8 716 115 219b (09.2008) central heating function o n e ys i a mn w st i h c n o e cl a r t n ha ei tg n e dn a md ft r at s ot n a . D e e ps evl av s a g . N e p o r eli o b s et ar e p o ct a m ot h d n...

Page 53

F a ul t finding & dia grams installation & servicing instructions 51 8 716 115 219b (09.2008) dhw function dhw function i a mn w st i h c n o green lg it h n o o n e ys t d n a m e d k n a l art n ec s e dir r ev o( .) d n a m e d g nit a e h d n a m e d r et a w t o h r e ht o ll a s e dir r ev o(...

Page 54

F a ul t finding & dia grams installation & servicing instructions 52 fault finding 8 716 115 219b (09.2008) note ; this fault finding information is for guidance only. Worcester bosch cannot be held responsible for costs incurred by persons not deemed to be competent. The electronic control system ...

Page 55

Controls tick the appropriate boxes time and temperature control to heating room thermostat and programmable load/weather optimum start programmer/timer room thermostat compensation control time and temperature control to hot water cylinder thermostat and programmer/timer combination boiler heating ...

Page 56

Service record it is recommended that your heating system is serviced regularly and that the appropriate service record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufacturer’s instruction...

Page 60

Dedicated to heating comfort worcester, bosch group cotswold way, warndon, worcester wr4 9sw tel. 01905 754624 fax. 01905 754619 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 8 716 115 219b (09.2008).