- DL manuals

- Worcester

- Boiler

- CDi Combi L.P.G

- Service Booklet

Worcester CDi Combi L.P.G Service Booklet

Supplied By www.heating spares.co Tel. 0161 620 6677

UK/IE

ENGINEER‘S SERVICE BOOKLET

FLOOR MOUNTED & WALL HUNG RSF GAS FIRED CONDENSING BOILERS

GREENSTAR CDi RANGE

87161

15748-00.1W

o

FOR CENTRAL HEATING SYSTEMS AND INDIRECT FED DOMESTIC HOT WATER

8 716

115

748 (

2009

/09)

This Service booklet covers the following

boiler ranges:

CDi Combi N.G.

CDi Combi L.P.G.

CDi System N.G.

CDi System L.P.G.

CDi Regular N.G.

CDi Regular L.P.G.

Highflow CDi N.G.

Highflow CDi L.P.G.

FS CDi Regular N.G.

FS CDi Regular L.P.G.

Summary of CDi Combi L.P.G

Page 1

Supplied by www.Heating spares.Co tel. 0161 620 6677 uk/ie engineer‘s service booklet floor mounted & wall hung rsf gas fired condensing boilers greenstar cdi range 87161 15748-00.1w o for central heating systems and indirect fed domestic hot water 8 716 115 748 ( 2009 /09) this service booklet cove...

Page 2: Table of Contents

Supplied by www.Heating spares.Co tel. 0161 620 6677 table of contents 8 716 115 748 (2009/09) 2 table of contents 1 explanation of symbols and safety precautions 3 1.1 explanation of symbols . . . . . . . . . . . . . . . 3 1.2 safety precautions . . . . . . . . . . . . . . . . . . 3 2 layout of boi...

Page 3

Supplied by www.Heating spares.Co tel. 0161 620 6677 explanation of symbols and safety precautions 8 716 115 748 (2009/09) 3 1 explanation of symbols and safety precautions 1.1 explanation of symbols warning symbols signal words indicate the seriousness of the hazard in terms of the consequences of ...

Page 4: Layout of Boiler

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 4 2 layout of boiler 2.1 cdi combi boilers fig. 1 cdi combi layout 1 flame viewing window 2 ignition electrode and flame sense electrode 3 heat exchanger 4 overheat thermostat 5 access point for cleaning he...

Page 5

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 5 fig. 2 this diagram shows the compact hydraulics and controls with the mantel and fascia panel removed 6 plate to plate dhw heat exchanger 9 drain point 32 pump, modulating 36 flow turbine 37 unused port ...

Page 6

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 6 2.2 cdi system boilers fig. 3 cdi system layout 1 flame viewing window 2 ignition electrode and flame sensing electrode 3 heat exchanger 4 overheat thermostat 5 access point for cleaning heat exchanger 6 ...

Page 7

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 7 fig. 4 this diagram shows the compact hydraulics and controls with the mantel and fascia panel removed 25 compact hydraulic mounting screw (2) to boiler 26 flow unit 27 auto air vent 28 return connection ...

Page 8

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 8 2.3 cdi regular boilers fig. 5 the diagram shows the controls in the service position with the mantle and fascia panel removed 1 5 6 7 11 12 13 14 16 18 19 20 21 15 17 22 23 10 8 9 2 3 4 8716115748-05.1wo.

Page 9

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 9 fig. 6 front of the control panel 1 flame viewing window 2 ignition electrode and flame sense electrode 3 heat exchanger 4 overheat thermostat 5 access point for cleaning heat exchanger 6 condensate hose ...

Page 10

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 10 2.4 highflow cdi combi boiler fig. 7 highflow cdi boiler, controls in service position fig. 8 highflow cdi control panel 1 cover - installer module 2 heat store 3 pressure relief valve 4 auto air vent 5 ...

Page 11

Supplied by www.Heating spares.Co tel. 0161 620 6677 layout of boiler 8 716 115 748 (2009/09) 11 2.5 fs cdi regular boilers fig. 9 fs cdi regular boiler layout 1 control panel 2 display 3 reset button 4 service function only 5 service function only 6 mains on/off indicator & fault diagnostic light (...

Page 12: Operation - Cdi

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - cdi 8 716 115 748 (2009/09) 12 3 operation - cdi 3.1 initialisation when it is switched on, the appliance performs a self- test which takes about 10 seconds. While the test is in progress, the display shows for the first two seconds . ...

Page 13

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - cdi 8 716 115 748 (2009/09) 13 3.3 operating elements cdi (wall hung) fig. 10 cdi control panel a on/off button b burner indicator (green) c service button (orange) d central heating boost button (orange) (in service mode for displayin...

Page 14

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - cdi 8 716 115 748 (2009/09) 14 3.6 resetting service functions to factory settings to reset all settings on service levels 1 and 2 to the factory settings: b display the value of the service function 8.E (second service level, value = ...

Page 15

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - highflow cdi and fs cdi regular 8 716 115 748 (2009/09) 15 4 operation - highflow cdi and fs cdi regular 4.1 initialisation when it is switched on, the appliance performs a self- test which takes about 10 seconds. While the test is in ...

Page 16

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - highflow cdi and fs cdi regular 8 716 115 748 (2009/09) 16 4.3 operating elements fig. 11 highflow cdi control panel a on/off button b burner indicator (green) c service mode button (orange) d central heating boost button (orange) (in ...

Page 17

Supplied by www.Heating spares.Co tel. 0161 620 6677 operation - highflow cdi and fs cdi regular 8 716 115 748 (2009/09) 17 4.5.3 exit service function/service level without storing b press the button to exit the service function without storing. After releasing the button goes out. First service le...

Page 18

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions - cdi combi & system boiler 8 716 115 748 (2009/09) 18 5 boiler service functions - cdi combi & system boiler 5.1 first service level (pressing the button for approx. 10 seconds) description display range adjustable from -...

Page 19

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions - cdi combi & system boiler 8 716 115 748 (2009/09) 19 5.2 second service level (enter at the first service level and press the eco button and simultaneously for 3 seconds) 5.3 explanation of service functions 5.3.1 first ...

Page 20

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions - cdi combi & system boiler 8 716 115 748 (2009/09) 20 the pump map can be selected within: • 0 (pump step adjustable), see service function 1.D (map pump step (heating)) • 1 (constant pressure high) • 2 (constant pressure...

Page 21

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions - cdi combi & system boiler 8 716 115 748 (2009/09) 21 1.E pump switch mode the choice of settings is as follows: • control mode 1 for heating equipment without a control unit. The pump is controlled by the central heating...

Page 22

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions - cdi combi & system boiler 8 716 115 748 (2009/09) 22 4.F syphon-fill programme the syphon filling function ensures that the syphon trap is filled when the appliance is first installed or shut down for a long period. Flue...

Page 23: & Fs Cdi Regular

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions cdi, highflow cdi & fs cdi regular 8 716 115 748 (2009/09) 23 6 boiler service functions cdi, highflow cdi & fs cdi regular 6.1 first service level (pressing the button for approx. 10 seconds) description display range adj...

Page 24

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions cdi, highflow cdi & fs cdi regular 8 716 115 748 (2009/09) 24 6.2 second service level (enter at the first service level and press the eco button and simultaneously for 3 seconds) description display range adjustable from ...

Page 25

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions cdi, highflow cdi & fs cdi regular 8 716 115 748 (2009/09) 25 6.3 explanation of service functions 6.3.1 first service level 1.A max. Output (heating) the heating output can be set to any level between minimum rated heat o...

Page 26

Supplied by www.Heating spares.Co tel. 0161 620 6677 boiler service functions cdi, highflow cdi & fs cdi regular 8 716 115 748 (2009/09) 26 the next time the heating or hot water system calls for heat, the appliance is held at minimum output for 15 minutes. The syphon filling programme remains activ...

Page 27: Rectifying Faults

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 27 7 rectifying faults 7.1 indication of faults faults are indicated simultaneously by a letter code in the display and by flashing of the fault indicator led. This helps to identify and eliminate the caus...

Page 28

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 28 7.3 notes on using the fault code tables the procedure is best described with the aid of an example: • work through the table from top to bottom and from left to right. • first make a note of the presen...

Page 29

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 29 7.4 error codes on the display a1 and fault indicator led are flashing controlled characteristic pump has run dry check action 1. System pressure below 1.2 bar yes: b power off the appliance b check app...

Page 30

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 30 a5 and fault indicator led are flashing. Appliance still available for heating demands. Tank (heat bank) ntc sensor defective. Check action 1. Is the tank ntc sensor connection corroded, damaged or dirt...

Page 31

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 31 a6 and fault indicator led are flashing. Appliance not available for demands. External under floor heating thermostat defective. Check action 1. B power off the appliance. B disconnect the appliance ele...

Page 32

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 32 a7 and fault indicator led are flashing. (boiler still produces hot water but at a lesser degree of accuracy over the temperature.) water ntc sensor defective. Check action 1. B check if the water ntc c...

Page 33

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 33 a8 and fault indicator led are flashing. Bus communication to the programmer interrupted (set value not received) check action 1. B switch off the appliance. B disconnect the appliance power. B remove t...

Page 34

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 34 5 has the bus module been replaced yes: a8? Go to 6 no: b switch off appliance b disconnect electrical power b replace bus module b reconnect appliance power b switch on appliance a8? Go to 5 6 the pcb ...

Page 35

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 35 b1 and fault indicator led are flashing code plug not detected. Check action 1. B select in the second service level the service function 8.B (code plug). B compare number displayed with that shown in a...

Page 36

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 36 c6 and fault indicator led are flashing. Fan speed too low check action 1. Fan cable connector correctly connected on fan? Yes: go to 2 no: b switch off the appliance. B reconnect connector. B switch on...

Page 37

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 37 cc and fault indicator led are flashing. Outside temperature sensor fault (open or short circuit) check action 1. B power off the appliance. B disconnect the boiler mains connection. Are the outside tem...

Page 38

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 38 d5 and fault indicator led are flashing. (boiler not available for demands) condensate float switch in condensate pump defective check action 1. B power off the appliance. B disconnect the boiler mains ...

Page 39

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 39 d6 and fault indicator led are flashing. (boiler not available for demands) tank overheat thermostat defective check action 1. B power off the appliance. B disconnect the boiler mains connection. Check ...

Page 40

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 40 e2 and fault indicator led are flashing. Flow temperature ntc sensor defective. Check action 1. B check if the flow temperature ntc sensor connector is corroded, damaged or dirty. Yes: b change relative...

Page 41

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 41 e9 and button reset and fault indicator led are flashing. Safety temperature circuit has tripped. Check action 1. Type of ch system: is the appliance installed in a fully pumped sealed system? Yes: go t...

Page 42

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 42 6. B switch off the appliance. B un-plug the connector from the flue safety temperature limiter. B measure the flue safety tempera- ture limiter for continuity. Resistance small? Yes: connect flue gas s...

Page 43

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 43 10. The pcb is damaged. B make a note of the altered service settings. B switch off the appliance. B disconnect the boiler power connection. B change pcb control board. B reconnect the appliance power c...

Page 44

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 44 ea and reset button and fault indicator led are flashing. During operation: flame not detected. Check action 1. Is a burner flame visible? Yes: go to 5 no: go to 2 2. Is the gas cock turned on? Yes: go ...

Page 45

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 45 5. B switch off the appliance. B disconnect the boiler power connection. Is the earth connection correct? Yes: b reconnect the appliance power connection. B switch on the appliance. Ea? Go to 6 no: b co...

Page 46

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 46 9. Problem with flue? B check co 2 level in combustion air in the flue (with outer casing fitted). Is the co 2 level above 0.2%? B perform a fan pressure test (as described in the installation manual). ...

Page 47

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 47 15. Electrode assembly defective? B switch off the appliance. B remove electrode assembly. Electrode assembly burnt out or cracked? Yes: b replace electrode assembly. B switch on the appliance. B press ...

Page 48

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 48 f0 and fault indicator led (and possibly reset button) are flashing. Internal failure check action 1. Button reset flashing? Yes: b press the reset button for 3 seconds and release it. After releasing t...

Page 49

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 49 f7 and reset button and fault indicator led are flashing. Although appliance switches off, flame still detected check action 1. Electrode(s) dirty or defective? B switch off the appliance. B remove elec...

Page 50

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 50 fa and reset button and fault indicator led are flashing. After appliance switches off flame is detected check action 1. Is the condensate trap blocked? Yes: b switch off the appliance. B clean out cond...

Page 51

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 51 6. The pcb is damaged. B make a note of the altered service settings. B switch off the appliance. B disconnect the boiler power connection. B change pcb control board. B reconnect the appliance power co...

Page 52

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 52 7.5 faults that are not displayed 7.5.1 appliance faults excessive burner noise, rumbling noises check action 1. Does the gas supply type match the specifications on the appliance type plate? Yes: go to...

Page 53

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 53 heating up of last radiators in system too slow check action 1. Pump map/pump step incorrect? Wall hung combi and system appliances: b set appropriate pump map/pump step (service function 1.C/1.D). Conv...

Page 54

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 54 ignition too harsh, ignition poor check action 1. B select in the second service level the service function 8.F (permanent igni- tion). B select the value 1 and store. Check the permanent ignition at th...

Page 55

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 55 7. B test gas supply pressure - ok? Does pressure match figure specified in installation instructions? Yes: go to 8 no: b de-commission appliance. In case of natural gas: b notify gas utility. 8. Proble...

Page 56

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 56 7.5.2 programmer faults inadequate hot water outlet temperature (combi boiler) check action 1. Does pump run? B ensure the pump is not in eco mode (default after power on and after reset). B un-plug con...

Page 57

Supplied by www.Heating spares.Co tel. 0161 620 6677 rectifying faults 8 716 115 748 (2009/09) 57 5. Air in the heating system. B switch off the appliance. B check appliance and system for water leaks and repair as necessary. B top up system. B switch on the appliance. B select in the first service ...

Page 58: Troubleshooting - Fw 100

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fw 100 8 716 115 748 (2009/09) 58 8 troubleshooting - fw 100 bus device faults are indicated. If the controller shows fault 12, the cylinder temperature is so high that the cylinder high limit thermal cut-out has tripped. B reset...

Page 59

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fw 100 8 716 115 748 (2009/09) 59 fault 11 system configuration: new bus device new ism detected. Power up all isms simultaneously and start automatic system configuration. 131 132 new ism detected. Power up all isms simultaneous...

Page 60

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fw 100 8 716 115 748 (2009/09) 60 fault 50 solar pump jammed or air in system 121 126 140 solar pump (sp) sticking due to physical blockage. Unscrew and remove the slotted screw on the pump head and use a screwdriver to release t...

Page 61

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fw 100 8 716 115 748 (2009/09) 61 fault 59 mass flow rate in solar system too high/low. 201 mass flow rate in solar system for collector group 1 is too high. Set mass flow in solar system correctly (e.G. Increase/decrease pump sp...

Page 62

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fw 100 8 716 115 748 (2009/09) 62 8.2 troubleshooting without the display fault cause remedy required room temperature not achieved. Thermostatic valve(s) set too low. Set thermostatic valve(s) higher. Minimum outside temperature...

Page 63: Troubleshooting - Fr110

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fr110 8 716 115 748 (2009/09) 63 9 troubleshooting - fr110 bus device faults are indicated. If the controller shows fault 12, the cylinder temperature is so high that the cylinder high limit thermal cut-out has tripped. B reset t...

Page 64

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fr110 8 716 115 748 (2009/09) 64 fault 11 system configuration: new bus device new ism detected. Power up all isms simultaneously and start automatic system configuration. 131 132 new ism detected. Power up all isms simultaneousl...

Page 65

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fr110 8 716 115 748 (2009/09) 65 fault 50 solar pump jammed or air in system 121 solar pump (sp) sticking due to physical blockage. Unscrew and remove the slotted screw on the pump head and use a screwdriver to release the pump s...

Page 66

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fr110 8 716 115 748 (2009/09) 66 fault 59 mass flow rate in solar system too high/ low. 201 mass flow rate in solar system for collector group 1 is too high. Set mass flow in solar system correctly (e.G. Increase/ decrease pump s...

Page 67

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - fr110 8 716 115 748 (2009/09) 67 9.2 troubleshooting without the display fault cause remedy required room temperature not achieved. Thermostatic valve(s) set too low. Set thermostatic valve(s) higher. Flow temperature controller ...

Page 68: 10 Troubleshooting - Rt10

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - rt10 8 716 115 748 (2009/09) 68 10 troubleshooting - rt10 in the event of a fault in the heating appliance, the display will show e.G. A7 e. In the event of a fault in the fw 100, the display will show e.G. 1a4 e. Here the figure...

Page 69: 11 Troubleshooting - Td 200

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - td 200 8 716 115 748 (2009/09) 69 11 troubleshooting - td 200 faults in the devices using the bus are displayed. A fault in the heating appliance is shown in the display with corresponding help texts. Display cause remedy td 200 ...

Page 70

Supplied by www.Heating spares.Co tel. 0161 620 6677 troubleshooting - td 200 8 716 115 748 (2009/09) 70 complaint cause remedy required temperature not reached thermostat valve(s) in the control room set to low fully open the thermostat valve(s) or replace them with manual valve(s). Flow temperatur...

Page 71: 12 Appendix

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 71 12 appendix 12.1 ntc sensor values, cdi appliances 12.1.1 ch flow ntc sensor and hot water ntc sensor 12.2 cdi fan speeds 12.3 highflow cdi & fs cdi regular fan speeds temperature ( °c) measurement tolerance ± 1...

Page 72

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 72 12.4 ntc sensor characteristics highflow cdi & fs cdi regular appliances 12.4.1 siemens ntc sensor characteristic table 12.4.2 elmwood ntc characteristic table 12.4.3 outdoor ntc sensor characteristic table 12.4...

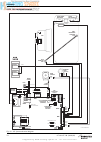

Page 73

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 73 12.5 electrical wiring diagrams 12.5.1 cdi combi appliances fig. 18 cdi combi electrical diagram 230 v 9v/25 v 230v/ac st8 st9 st17 st18 st5 st4 st10 l n ls ns l r earth mains supply pump control pump white blac...

Page 74

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 74 12.5.2 cdi system appliances fig. 19 cdi system electrical diagram 230 v 9v/25 v 230v/ac st8 st9 st17 st18 st5 st4 st10 l n ls ns l r earth mains supply pump control pump white black purple pump supply neut ral ...

Page 75

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 75 12.5.3 cdi regular appliances fig. 20 cdi regular electrical diagram 230 v 9v/25 v 230v/ac st8 st9 st17 st18 st5 st4 st10 l n ls ns l r earth mains supply pump supply neut ral live spark transformer flame sense ...

Page 76

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 76 12.5.4 highflow cdi appliances fig. 21 highflow cdi electrical diagram st19 b b 2 4 f 1 a high level sensor diverter valve flow turbine tank overheat 230 v 9v/25 v 230v/ac st9 st18 st5 st10 l n ls ns l r st8 ear...

Page 77

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 77 12.5.5 fs cdi appliances fig. 22 fs cdi electrical diagram 230 v 9v/25 v 230v/ac st9 st18 st5 st10 l n ls ns l r st8 earth mains supply pump control pump pump supply ignition transformer flame sense electrode sp...

Page 78

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 78 12.6 code plugs used with cdi appliances 12.7 code plugs used with highflow cdi & fs cdi regular appliances component order no. Remarks code plug 27cdi n.G. 8 714 431 020 0 - 30cdi n.G. 8 714 431 012 0 37cdi n.G...

Page 79

Supplied by www.Heating spares.Co tel. 0161 620 6677 appendix 8 716 115 748 (2009/09) 79 12.8 approved corrosion inhibitors and anti-freeze for central heating water corrosion inhibitor b add a suitable* inhibitor (or combined inhibitor/anti- freeze if the system is exposed to freezing conditions) t...

Page 80

Supplied by www.Heating spares.Co tel. 0161 620 6677 dedicated to heating comfort worcester, bosch group cotswold way, warndon, worcester wr4 9sw tel. 01905 754624 fax. 01905 754619 worcester, bosch group is a brand name of bosch thermotechnology ltd. Www.Worcester-bosch.Co.Uk 8 716 115 748 contact ...