- DL manuals

- Worcester

- Thermostat

- GREENSTAR 24i junior

- Installation, Commissioning And Servicing Instructions

Worcester GREENSTAR 24i junior Installation, Commissioning And Servicing Instructions

UK/IE

INSTALLATION, COMMISSIONING AND SERVICING INSTRUCTIONS

WALL HUNG RSF GAS FIRED CONDENSING COMBINATION BOILER

GREENSTAR 24i Junior/28i Junior

6720643895-00.1W

o

FOR SEALED CENTRAL HEATING SYSTEMS AND MAINS FED DOMESTIC HOT WATER

6 72

0 802 047 (2013/05)

The appliance is for use with Natural Gas or

L.P.G. (Cat II 2H3P type C13, C33 & C53)

Model

GC Number

Natural Gas

24i Junior

47-406-54

28i Junior

47-406-56

Liquid Petroleum Gas

24i Junior

47-406-55

28i Junior

47-406-57

Summary of GREENSTAR 24i junior

Page 1

Uk/ie installation, commissioning and servicing instructions wall hung rsf gas fired condensing combination boiler greenstar 24i junior/28i junior 6720643895-00.1w o for sealed central heating systems and mains fed domestic hot water 6 72 0 802 047 (2013/05) the appliance is for use with natural gas...

Page 2

Contents 6 720 802 047 (2013/05) 2 contents 1 key to symbols and safety precautions . . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 appliance inform...

Page 3

Key to symbols and safety precautions 6 720 802 047 (2013/05) 3 1 key to symbols and safety precautions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that could result in damage to property or equipment. • caution indi...

Page 4

Key to symbols and safety precautions 6 720 802 047 (2013/05) 4 benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with ...

Page 5

Appliance information 6 720 802 047 (2013/05) 5 2 appliance information 2.1 appliance 2 4 3 5 * 710mm to top of case front 1 700mm* 400mm 330mm depth to wall (when fitted to wall frame) 6 6720643895-01.3wo standard package: 1 wall hung gas fired condensing combi boiler for central heating and domest...

Page 6

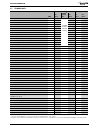

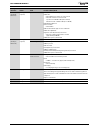

Appliance information 6 720 802 047 (2013/05) 6 2.2 technical data description natural gas lpg unit 24i junior low nox 1) 24i & 28i junior 1) the low nox code plugs for the 24i and 28i junior are available as an optional accessory. 24i junior code plug kit number -7 716 192 356- 28i junior code plug...

Page 7

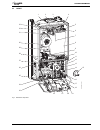

Appliance information 6 720 802 047 (2013/05) 7 2.3 layout fig. 1 main boiler components 6720804530-10.1w o 1 2 33 32 31 30 29 10 12 11 13 14 16 17 18 15 28 27 25 26 24 23 22 21 20 19 3 4 5 6 7 8 9.

Page 8

Appliance information 6 720 802 047 (2013/05) 8 fig. 2 hydraulic block components 1 expansion vessel 26 left side hand-hold for lifting boiler 2 flow temperature sensor (ntc) 27 plate to plate heat exchanger 3 removable panel - for servicing 28 gas valve 4 electrode assembly 29 flue air pressure swi...

Page 9

Pre-installation 6 720 802 047 (2013/05) 9 fig. 3 additional components 3 pre-installation 3.1 cleaning primary systems before cleaning the system: ▶ ensure that the system and pipe work is in good working order. ▶ where possible keep the existing boiler/circulating pump in place when flushing the s...

Page 10

Pre-installation 6 720 802 047 (2013/05) 10 inhibitor add a suitable inhibitor or combined inhibitor/anti-freeze, if the system is exposed to freezing conditions, to the heating system in accordance with the dwta code of practice and manufacturer‘s guidelines. Water treatment products suitable water...

Page 11

Pre-installation 6 720 802 047 (2013/05) 11 showers/bidets: • ensure that the shower is suitable for use with mains water pressure. • if a shower head can be immersed in water or comes closer than 25mm from the top edge of a bath or shower tray spill over level then an anti-syphon device must be fit...

Page 12

Pre-installation 6 720 802 047 (2013/05) 12 fig. 7 disposal to soil vent stack alternatively if the first option is not possible an internal kitchen or bathroom waste pipe, washing machine waste pipe etc. Can be used. Ensure that the condensate drain pipe is connected “down stream” of the waste trap...

Page 13

Pre-installation 6 720 802 047 (2013/05) 13 ▶ the use of fittings, elbows etc. Should be kept to a minimum and any internal “burrs” on cut pipe work should be removed so that the internal pipe section is as smooth as possible. Fitting an external air break • refer to figure 10 when a rain water down...

Page 14

Pre-installation 6 720 802 047 (2013/05) 14 3.5 pressure relief pipe work • the pressure relief drain pipe (1) from the boiler should be at least 15mm diameter copper pipe and run downwards, away from any electrical equipment or other hazard, preferably to an external drain or soak away. • pipe (1) ...

Page 15

Pre-installation 6 720 802 047 (2013/05) 15 3.6.6 bathrooms a boiler fitted with a mechanical timer or rf mechanical timer (receiver) or fw100 controller may only be installed outside the shaded area. A boiler with any other timer fitted (or blanking panel for an optional programmer) can be installe...

Page 16

Pre-installation 6 720 802 047 (2013/05) 16 fig. 18 plumbing manifold 3.8 flue options flue lengths the flue systems have different maximum flue lengths the greenstar series has the option of two horizontal 60/100 rsf (telescopic and longer telescopic) and one horizontal 80/125 rsf (telescopic) flue...

Page 17

Pre-installation 6 720 802 047 (2013/05) 17 350 mm - 570 mm 130 mm min flat roof 300 mm 500 mm pitched roof 2 3 4 5 6 10 9 8 7 1 6720643895-12.1wo.

Page 18

Pre-installation 6 720 802 047 (2013/05) 18 3.9 flue terminal positions fig. 19 flue terminal positions key to illustration 1. 300mm adjacent to a boundary line. 2. The dimension below eaves, gutters, pipes and drains can be reduced to 25mm, as long as the flue terminal is extended to clear any over...

Page 19

Pre-installation 6 720 802 047 (2013/05) 19 3.10 plume management terminal positions fig. 20 plume terminal positions key to illustration 1. This feature allows some basic plume re-direction options on a standard telescopic horizontal flue terminal. 300mm minimum clearances to a opening e.G. Window....

Page 20

Installation 6 720 802 047 (2013/05) 20 4 installation 4.1 unpacking wall frame & ancillary items 1. Wall mounting frame 2. Wall mounting template 3. Inner packaging 4. Installer pack 5. Bottom panel 6. Front fascia 7. Syphon assembly fig. 21 unpacking important handling instructions: • it is advise...

Page 21

Installation 6 720 802 047 (2013/05) 21 fig. 22 marking the flue position 4.3 unpacking the appliance 1. Outer carton 2. Inner sleeve (unwrap from front) 3. Packing base 4. Protective wrapping 5. Appliance outer case ▶ remove outer carton (1) and place safely away from the working area. ▶ with the o...

Page 22

Installation 6 720 802 047 (2013/05) 22 fig. 26 outer case screw removal 4.4 boiler connections gas, water and condensate connections ▶ remove wall mounting template and secure the wall mounting frame to the wall with the appropriate fixings for the boiler weight and wall type. ▶ system pipes may be...

Page 23

Installation 6 720 802 047 (2013/05) 23 hanging the boiler ▶ hang the boiler on to the wall mounting frame by the two brackets positioned left and right at the top rear of the appliance. Do not lift the appliance by the air gas manifold. There are two handling holes incorporated into the inner casin...

Page 24

Installation 6 720 802 047 (2013/05) 24 4.5 flue installation horizontal flue (60/100mm diameter) for vertical flues and 80/125mm horizontal flues, please refer to separate instructions supplied with the flue kit. Basic instructions for the 60/100mm diameter flue are shown below. Fig. 34 flue turret...

Page 25

Installation 6 720 802 047 (2013/05) 25 4.5.3 installing the telescopic flue refer to figure 38. 1. Set the flue length to the distance required, secure with screws provided. 2. Seal the joint with the aluminium tape provided. 3. Slide the inner wall seal onto the terminal. 4. If fitting from inside...

Page 26

Installation 6 720 802 047 (2013/05) 26 fig. 42 plume redirection fig. 43 plume distance to opening 4.6 condensate connection never terminate or discharge into any open source, including; sink, bath, shower, bidet, toilet etc. • ensure that the condensate drain is a 22mm diameter plastic pipe. The p...

Page 27

Installation 6 720 802 047 (2013/05) 27 fig. 46 fitting syphon maintenance there is no need to remove the syphon assembly for servicing unless cleaning is required. To drain debris from the syphon, during the annual service: ▶ release the clips and remove the drainage cap (1) from the bottom of the ...

Page 28

Installation 6 720 802 047 (2013/05) 28 4.7.1 mounting optional plug-in controls plug-in programmer/timers the programmers/timers listed can be used with the boilers stated on the front of this manual. Removing the blanking plate ▶ remove boiler casing to access control panel. ▶ refer to figure 48 a...

Page 29

Installation 6 720 802 047 (2013/05) 29 integrated timer and two zones fig. 55 two room thermostats, one integrated timer existing installations for boiler replacements on an existing system, it is not necessary to zone the upstairs and downstairs separately, compliance with the zone requirements ca...

Page 30

Commissioning 6 720 802 047 (2013/05) 30 optional external frost stat connection st6: fig. 59 frost thermostat ▶ connect frost thermostat cables to terminals f s & f r . ▶ these are not polarity sensitive. ▶ the external frost thermostat only operates the pump (see page 58 for internal frost protect...

Page 31

Commissioning 6 720 802 047 (2013/05) 31 5.2 filling the system 1. Turn on the water main and open the system valves. 2. Open all radiator valves. 3. Fill the system via a wras approved filling loop to 1 bar then turn the valve anti-clockwise to close. 4. Vent (1) any air from the boiler heat exchan...

Page 32

Commissioning 6 720 802 047 (2013/05) 32 5.4 starting the appliance fig. 65 control panel switching the appliance on/off: ▶ turn on mains power, the power on indicator (5) illuminates blue. ▶ turn on any external controls ▶ set the thermostatic radiator controls to maximum temperature ▶ set the cloc...

Page 33

Commissioning 6 720 802 047 (2013/05) 33 fig. 67 natural gas pressures fig. 68 l.P.G. Pressures 5.5.2 checking the gas rate ▶ the gas rate should be measured at the gas meter after 10 minutes operation at maximum. See technical data section at the front of this manual. ▶ where a gas meter is not ava...

Page 34

Service and spares 6 720 802 047 (2013/05) 34 5.6.3 installing bottom panel ▶ the bottom panel slides onto two ledges either side of the boiler frame. ▶ hold the panel up against the underside of the boiler and slide towards the rear, until there is no more movement. ▶ slide the panel forward until ...

Page 35

Service and spares 6 720 802 047 (2013/05) 35 fig. 72 control panel into service position 6.2 check the gas inlet pressure refer to section 5.5.1 for more information ▶ check the gas supply working pressures in the system conform to the readings shown in the table below: fig. 73 natural gas pressure...

Page 36

Service and spares 6 720 802 047 (2013/05) 36 fig. 76 flue integrity test 6.4 fan pressure test setting the boiler to maximum 1. Press and hold service button for more than 10 seconds 2. Set the central heating temperature to maximum. – the service button will illuminate continually and the blue pow...

Page 37

Service and spares 6 720 802 047 (2013/05) 37 fig. 80 sump access 6.5 flue gas analysis combustion test: ▶ connect the flue gas analyser to the flue gas sampling point as shown in the figure below. ▶ run the boiler at maximum output for at least 10 minutes. ▶ check the co/co 2 readings against the i...

Page 38

Service and spares 6 720 802 047 (2013/05) 38 fig. 83 gas valve adjustment 6.7 cleaning the heat exchanger ▶ isolate the power to the appliance and remove outer case and base panel. 1. Refer to figure 84 and remove the clip from gas valve outlet. 2. Pull the gas outlet elbow free from the gas valve....

Page 39

Service and spares 6 720 802 047 (2013/05) 39 burner removal refer to figure 87 1. Remove clamping plate. 2. Remove spark/flame electrode assembly and seal from the top of the heat exchanger. 3. Remove burner. Fig. 87 burner removal checking and cleaning the electrode assembly: ▶ inspect the conditi...

Page 40

Service and spares 6 720 802 047 (2013/05) 40 ▶ clean heat exchanger flue ways using the cleaning brush removing any debris from the access point in the sump. ▶ clean around the sealing surface on the sump. ▶ replace the access cover. ▶ using a suitable container to collect water from syphon connect...

Page 41

Service and spares 6 720 802 047 (2013/05) 41 6.8.2 primary sensor (ch ntc) refer to figure 92 for removal. 1. Remove electrical connection by pulling upwards. Squeeze retaining clip on plastic moulding of sensor and pull back and up until clear of pocket in heat exchanger. 2. Pull forward to remove...

Page 42

Service and spares 6 720 802 047 (2013/05) 42 6.8.6 gas valve refer to figure 96 ▶ isolate gas supply at boiler gas cock. 1. Remove wire clip from gas valve outlet. 2. Pull the gas pipe free from the gas valve. If the pipe will not pull out, unscrew the nut to aid removal. Fig. 96 gas valve upper co...

Page 43

Service and spares 6 720 802 047 (2013/05) 43 6.8.8 fan remove the air/gas manifold as described in the previous section. 1. Remove two screws retaining the fan to the air/gas manifold. 2. Remove the air/gas manifold. 3. Remove the screw. 4. Remove the retaining plate. 5. Remove three screws and the...

Page 44

Service and spares 6 720 802 047 (2013/05) 44 fig. 103 initial location of the clamping plate [1] retaining plate assembly [2] clamping plate [3] gasket [4] bracket [5] underside view of the clamping plate [6] mating surface [7] location edge [8] air/gas manifold assembly ▶ tighten the nut on the re...

Page 45

Service and spares 6 720 802 047 (2013/05) 45 refer to figure 108. 1. Release the clip. 2. Move the lower exhaust connector up ▶ remove the complete exhaust assembly. Fig. 108 release lower exhaust connection refer to figure 109. 1. Unscrew the plastic nut. 2. Remove the nut from the bottom of the b...

Page 46

Service and spares 6 720 802 047 (2013/05) 46 6.8.14 access to pcb refer to figure 114 and disconnect all electrical connections from the control. 1. Remove five screws retaining the rear panel of the control. 2. Remove the rear panel. Fig. 114 pcb access refitting the control board cover: ▶ ensure ...

Page 47

Service and spares 6 720 802 047 (2013/05) 47 6.8.16 syphon removal to release the syphon from the sump: 1. Disconnect the discharge hose from the condensate outlet pipe. 2. Using a screwdriver, disengage the retaining clip on top of the syphon. 3. Pull the syphon towards you and remove the complete...

Page 48

Service and spares 6 720 802 047 (2013/05) 48 6.8.20 dhw temperature sensor ▶ ensure the domestic hot water circuit is fully drained. ▶ disconnect the electrical connection from the sensor. 1. Withdraw the spring clip. 2. Withdraw the sensor from the housing. Fig. 123 dhw temperature sensor ▶ to ref...

Page 49

Service and spares 6 720 802 047 (2013/05) 49 6.8.24 drain tap ▶ ensure the appliance has been fully drained. 1. Rotate the drain tap fully anti-clockwise and push in. 2. Withdraw the drain tap from its housing fig. 127 drain tap and pressure gauge removal ▶ apply silicone lubricant to the seals to ...

Page 50

Service and spares 6 720 802 047 (2013/05) 50 6.8.27 ch pressure relief valve ▶ remove the hydraulic block from the boiler (see 6.8.26 removing the hydraulic block). 1. Release the spring clip from the pressure relief valve housing. 2. Withdraw the pressure release valve from its housing. Fig. 130 p...

Page 51

Service and spares 6 720 802 047 (2013/05) 51 6.8.31 expansion vessel the expansion vessel can be replaced with the boiler in position if there is a side exit flue fitted and a minimum clearance of 340mm above the boiler casing. If a vertical flue is fitted then a similar clearance to one side of th...

Page 52

Service and spares 6 720 802 047 (2013/05) 52 6.9 short parts list fan 8 716 116 067 0 gc no. H26 536 burner 8 718 120 619 0 gc no. H26 538 gas valve 8 716 111 325 0 gc no. H26 540 control board ht3 bus enabled 8 748 300 713 0 flue overheat thermostat (grommet type) 8 710 506 267 0 electrodes (inclu...

Page 53

Fault finding and diagnosis 6 720 802 047 (2013/05) 53 7 fault finding and diagnosis 7.1 fault finding the electronic control system for this boiler incorporates a blue central indicator. This normally confirms the permanent mains supply but, by flashing at different rates during a fault, provides a...

Page 54

Fault finding and diagnosis 6 720 802 047 (2013/05) 54 slow flash (mostly off, flashes on) flashing (reset required) ignition lockout ▶ gas present and at correct pressure? ▶ gas valve – check that there is 35v d.C. To each solenoid – check the resistance of each solenoid: top solenoid = 380 Ω ± 10%...

Page 55

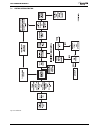

Fault finding and diagnosis 6 720 802 047 (2013/05) 55 7.1.1 circuit diagram fan fs fr np lp l n s n l s l r st8 st9 st17 st18 st5 st4 st10 earth mains supply pump supply spark transformer flame sense electrode spark electrodes overheat stat flow turbine diverter valve flue overheat stat st1 diagnos...

Page 56

Fault finding and diagnosis 6 720 802 047 (2013/05) 56 7.2 central heating function fig. 136 ch function.

Page 57

Fault finding and diagnosis 6 720 802 047 (2013/05) 57 7.3 preheat and dhw function fig. 137 pre-heat and dhw.

Page 58

Fault finding and diagnosis 6 720 802 047 (2013/05) 58 7.4 protection function fig. 138 protection functions internal boiler temperature between 8°c & 5°c boiler automatic frost function (monitors internal boiler primary temperature) internal boiler temperature below 5°c internal boiler temperature ...

Page 59

6 720 802 047 (2013/05) 59 notes.

Page 60

6 720 802 047 (2013/05) 60

Page 61

6 720 802 047 (2013/05) 61.

Page 62

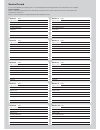

Failure to install and commission according to the manufacturer’s instructions and complete this benchmark commissioning checklist will invalidate the warranty. This does not affect the customer’s statutory rights. If yes, and if required by the manufacturer, has a water scale reducer been fitted? Co...

Page 63

Service record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufacturer’s in...

Page 64

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0844 892 9900 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk document no. 6 720 802 047 (2013/05) worcester, bosch group: technical support: 0844 892 3366 appointments: 0844 892 3000 sp...