- DL manuals

- Worcester

- Boiler

- Greenstar CDi Compact

- Installation, Commissioning And Servicing Instructions

Worcester Greenstar CDi Compact Installation, Commissioning And Servicing Instructions

UK/IE

INSTALLATION COMMISSIONING AND SERVICING INSTRUCTIONS

WALL HUNG RSF GAS FIRED CONDENSING COMBINATION BOILER

Greenstar CDi Compact

6720646608-00.1W

o

FOR SEALED CENTRAL HEATING SYSTEMS AND MAINS FED DOMESTIC HOT WATER

6 72

0 803 800 (2012/11)

The appliances are for use with:

Natural Gas or L.P.G. (Cat.II 2H 3P type C13, C33 & 53)

Natural Gas: 28CDi Compact GC number 47-406-44

32CDi Compact GC number 47-406-46

36CDi Compact GC number 47-406-48

L.P.G.: 28CDi Compact GC number 47-406-45

32CDi Compact GC number 47-406-47

36CDi Compact GC number 47-406-49

Summary of Greenstar CDi Compact

Page 1

Uk/ie installation commissioning and servicing instructions wall hung rsf gas fired condensing combination boiler greenstar cdi compact 6720646608-00.1w o for sealed central heating systems and mains fed domestic hot water 6 72 0 803 800 (2012/11) the appliances are for use with: natural gas or l.P....

Page 2

Contents 6 720 803 800 (2012/11) 2 contents 1 key to symbols and safety instructions . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 appliance informa...

Page 3

Key to symbols and safety instructions 6 720 803 800 (2012/11) 3 7 fault finding and diagnosis . . . . . . . . . . . . . . . . . . . . . . 54 7.1 internal wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . 54 7.2 central heating function . . . . . . . . . . . . . . . . . . . . . . . . 55...

Page 4

Key to symbols and safety instructions 6 720 803 800 (2012/11) 4 1.2 safety precautions if you smell gas a gas leak could potentially cause an explosion. If you smell gas, observe the following rules. ▶ prevent flames or sparks: – do not smoke, use a lighter or strike matches. – do not operate any e...

Page 5

Appliance information 6 720 803 800 (2012/11) 5 2 appliance information 2.1 appliance standard package 1. Wall hung gas-fired condensing combi boiler for central heating and domestic hot water 2. Wall mounting frame 3. Integral filling loop kit 4. Hardware literature pack: – greenstar cdi compact in...

Page 6

Appliance information 6 720 803 800 (2012/11) 6 2.2 layout fig. 1 main boiler components 49 48 47 46 45 44 43 42 41 40 39 38 37 36 28 56 55 54 53 50 52 31 30 29 32 33 35 12 13 14 1 2 3 4 5 6 7 8 6720646608-02.4wo 51 17 18 19 20 21 24 25 23 26 27 16 22 9 10 15 11 34.

Page 7

Appliance information 6 720 803 800 (2012/11) 7 boiler features • high pressure die-cast aluminium heat exchanger • low nox emissions • fixed gas valve settings • direct burner ignition • zero pressure governor gas valve with fully modulating fan • display for boiler status and access to diagnostics...

Page 8

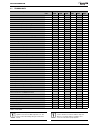

Appliance information 6 720 803 800 (2012/11) 8 2.3 technical data description cdi compact natural gas l.P.G. Unit 28kw 32kw 36kw 28kw 32kw 36kw domestic hot water minimum heat input kw 7.15 7.15 7.15 7.15 7.15 7.15 maximum rated heat output kw 28 32 36 28 32 36 maximum rated heat input kw 28.57 32....

Page 9

Pre-installation 6 720 803 800 (2012/11) 9 3 pre-installation 3.1 cleaning primary systems before cleaning the system: ▶ ensure that the system and pipe work is in good working order. ▶ where possible keep the existing boiler/circulating pump in place when flushing the system. Follow the guidance of...

Page 10

Pre-installation 6 720 803 800 (2012/11) 10 use in hard water areas: normally there is no need for water treatment to prevent scale formation as the maximum temperature of the dhw heat exchanger is limited by the electronic control. In areas where temporary water hardness exceeds 200 ppm, considerat...

Page 11

Pre-installation 6 720 803 800 (2012/11) 11 3.4 condensate pipe work 3.4.1 internal connections in order to minimise risk of freezing during prolonged cold spells, the following methods of installing condensate drainage pipe should be adopted, in order of priority. Wherever possible, the condensate ...

Page 12

Pre-installation 6 720 803 800 (2012/11) 12 if no other discharge method is possible then the use of an externally run condensate drainage pipe terminating at a suitable foul water discharge point, or purpose-designed soak away, may be considered. If this method is chosen then the following measures...

Page 13

Pre-installation 6 720 803 800 (2012/11) 13 fig. 11 soak away 3.5 pressure relief pipe work • the pressure relief drain pipe (1) from the boiler should be at least 15mm diameter copper pipe and run downwards, away from any electrical equipment or other hazard, preferably to an external drain or soak...

Page 14

Pre-installation 6 720 803 800 (2012/11) 14 fig. 14 bathroom installations 3.7 plumbing manifold 3.7.1 connections use the fittings supplied in the hardware literature pack. • for further ease of fitting, an optional vertical pre-piping assembly kit is available, comprising four pre-formed copper wa...

Page 15

Pre-installation 6 720 803 800 (2012/11) 15 3.8 flue options the flue systems have different maximum flue lengths the greenstar series has the option of two horizontal 60/100 rsf (telescopic and longer telescopic) and one horizontal 80/125 rsf (telescopic) flue system and two vertical rsf (60/100 or...

Page 16

Pre-installation 6 720 803 800 (2012/11) 16 350 mm - 570 mm 130 mm min flat roof 300 mm 500 mm pitched roof 2 3 4 5 6 10 9 8 7 1 6720643895-12.1wo.

Page 17

Pre-installation 6 720 803 800 (2012/11) 17 3.9 flue terminal positions fig. 17 flue terminal positions key to illustration 1. 300mm adjacent to a boundary line. 2. The dimension below eaves, balconies and car ports can be reduced to 25mm, as long as the flue terminal is extended to clear any overha...

Page 18

Pre-installation 6 720 803 800 (2012/11) 18 3.10 plume management terminal positions fig. 18 plume terminal positions key to illustration 1. This feature allows some basic plume re-direction options on a standard telescopic horizontal flue terminal. 300mm minimum clearances to a opening e.G. Window....

Page 19

Installation 6 720 803 800 (2012/11) 19 3.10.1 determine the plume management system length fig. 19 effective lengths l and m fig. 20 effective flue lengths versus plume management lengths [min] minimum plume kit length 500mm [m] plume management length allowed (mm) [l] effective flue length (mm) [1...

Page 20

Installation 6 720 803 800 (2012/11) 20 is used make sure the outer carton is not pierced and that the implement is used in such a way so that it may not cause personal injury. • all sharp objects must be covered or the blade retracted after use and put away in a safe place. Care should be taken whe...

Page 21

Installation 6 720 803 800 (2012/11) 21 4. Remove the protective cardboard (5) from over the isolating valves. 5. Remove the protective cardboard (6) from around the expansion vessel. 6. Remove the inner packing (2) from the back of the boiler. 7. Lie the boiler on the floor ensuring that the v shap...

Page 22

Installation 6 720 803 800 (2012/11) 22 fig. 28 prv pipe connection once the wall frame has been mounted the prv discharge pipe can be fitted. Fig. 29 prv elbow fitting ▶ connect the prv discharge pipe to the pre-plumbing connector. ▶ the discharge pipe can be routed as required. ▶ the pre-plumbing ...

Page 23

Installation 6 720 803 800 (2012/11) 23 ▶ connect the system pipes using the compression nuts and olives supplied in the literature/hardware pack. 1. Ch flow (22mm), 2. Dhw outlet (15mm), 3. Gas inlet (22mm bonded washer), 4. Domestic cold water inlet (15mm), 5. Ch return (22mm), ▶ fit sealing washe...

Page 24

Installation 6 720 803 800 (2012/11) 24 ▶ hang the boiler on to the wall mounting frame utilising the two mounting points positioned left and right at the top rear of the appliance. The expansion vessel is shown removed for clarity. Fig. 35 hanging the boiler ▶ connect the prv discharge pipe on the ...

Page 25

Installation 6 720 803 800 (2012/11) 25 4.6.1 measuring the flue (standard flue): ▶ measure from the outside of the wall to the centre line of the flue turret to determine length l. ▶ subtract 50mm from the length l to give the correct dimension to the flue elbow connection. ▶ if the length l falls ...

Page 26

Installation 6 720 803 800 (2012/11) 26 fig. 43 aligning the turret ▶ fit the screws removed in step 1 to secure flue turret. ▶ if fitting the outer seal from outside the building, slide the outer wall seal onto the terminal as shown. ▶ “make good” the gap between the flue and inner wall and if poss...

Page 27

Installation 6 720 803 800 (2012/11) 27 fig. 47 plume distance to opening 4.7 electrical • the mains electrical supply to the boiler must be through either a fused double pole isolator or a fused three pin plug and unswitched socket situated, where practicable, adjacent to the boiler. • the isolator...

Page 28

Installation 6 720 803 800 (2012/11) 28 mains voltage connections fig. 50 mains voltage connectors 4.7.1 mounting optional plug-in controls refer the to programmer/timer manual for set up and operation of the unit. Removing the blanking plate the control panel must be released and swung forward slig...

Page 29

Installation 6 720 803 800 (2012/11) 29 fig. 53 fitting the programmer/timer 4.7.2 new complete system installations if a new complete heating system installation is in a new build property or is a first time installation in an existing property, heating systems must conform to current building regu...

Page 30

Commissioning 6 720 803 800 (2012/11) 30 external 230v programmer and room thermostat fig. 56 room thermostat with programmer room thermostat only fig. 57 room thermostat with plug in timer programmable thermostat fig. 58 programmable thermostat ▶ remove the link between l r (ch) and l at the 230v o...

Page 31

Commissioning 6 720 803 800 (2012/11) 31 5.2 filling the system 1. Turn on the water main and open the system valves. 2. Open all radiator valves. 3. Fill the system via a wras approved filling loop or the optional worcester integral filling link accessory to 1 bar then close the filling loop valve(...

Page 32

Commissioning 6 720 803 800 (2012/11) 32 fig. 60 control panel switching the appliance on/off: ▶ turn on the mains power supply, initially the “boiler start up screens” will be displayed (refer to figure 61). ▶ turn on any external controls ▶ set the thermostatic radiator controls to maximum tempera...

Page 33

Commissioning 6 720 803 800 (2012/11) 33 ▶ as soon as an adjustment is made, the screen will light up and the relevant information will be displayed. Status codes refer to section 7.5 for status codes and service menus. These are not faults, but provide information concerning the current status of t...

Page 34

Commissioning 6 720 803 800 (2012/11) 34 fig. 63 setting boiler to maximum ▶ check the gas supply working pressure at the gas valve conforms to values shown in fig. 64 or fig. 65 . ▶ press the button to return to normal operation. ▶ the boiler will run for 15 minutes in service mode and return to no...

Page 35

Commissioning 6 720 803 800 (2012/11) 35 ▶ do not allow the product to come into contact with the electrical wiring. 5.6 domestic hot water controlling the hot water temperature: the hot water temperature can be set to between approximately 40°c and 60°c using the dhw temperature control. Domestic h...

Page 36

Service and spares 6 720 803 800 (2012/11) 36 5.7.5 hand over ▶ complete the benchmark gas boiler commissioning checklist at the back of this manual. ▶ open the fascia flap by hinging the flap downwards using the curved hand hold in the centre of the flap. ▶ set up the controls and show the customer...

Page 37

Service and spares 6 720 803 800 (2012/11) 37 6.2 checking flue integrity the integrity of the flue system and performance of the boiler can be checked via the flue turret sample points. Fig. 70 flue turret test points with the boiler case on and the boiler running at maximum output (refer to sectio...

Page 38

Service and spares 6 720 803 800 (2012/11) 38 6.5 fan pressure test before setting the boiler to maximum output for the fan pressure test, refer to figure 74: ▶ switch the boiler off. ▶ remove the combustion air intake pipe (1). ▶ remove the fan pressure test point cover (2). ▶ connect the digital m...

Page 39

Service and spares 6 720 803 800 (2012/11) 39 6.6 flue gas analysis combustion test ▶ connect the flue gas analyser to the flue gas sampling point (1) as shown in the figure below. ▶ ensure that the probe reaches the centre of the flue gas exhaust, adjust the cone on the probe so that it seals the s...

Page 40

Service and spares 6 720 803 800 (2012/11) 40 6.7.1 cleaning the siphon 1. Protect the controller from water ingress and disconnect the black discharge hose from the wall frame connector. 2. Rotate the siphon body clockwise to release the bayonet connection. 3. Pull the siphon body down and away fro...

Page 41

Service and spares 6 720 803 800 (2012/11) 41 ▶ use the brush to dislodge the debris and pour water down the channels to flush out the debris. Fig. 81 cleaning the front channels 6.8 replacement of parts 6.8.1 removing the outer case removing the bottom panel: 1. Pull the catch down. 2. Slide the pa...

Page 42

Service and spares 6 720 803 800 (2012/11) 42 fig. 83 removing outer case 6.8.2 draining the boiler many of the tasks in this section require that the boiler be isolated and drained. 1. Connect a suitable hose firmly to the drain point and run the hose outside to a suitable point or container. 2. Tu...

Page 43

Service and spares 6 720 803 800 (2012/11) 43 6.8.5 maximum safety sensor (ntc) ▶ disconnect the lead to the maximum safety sensor. 1. Remove the screw securing the sensor. 2. Remove the sensor from the heat exchanger. ▶ when replacing the sensor, ensure that the assembly is properly located on the ...

Page 44

Service and spares 6 720 803 800 (2012/11) 44 6.8.9 fan assembly to remove the fan, disconnect the electrical mains and gas supplies, and remove the following components: • flueway • combustion air inlet pipe and gas pipe flueway removal 1. Release the two screws securing the flueway to the sump. 2....

Page 45

Service and spares 6 720 803 800 (2012/11) 45 fan removal 3. Rotate the exhaust pipe anticlockwise to gain access to the fan assembly securing screws. 4. Support the weight of the fan and remove the two screws securing the fan. Fig. 94 fan removal 1 5. Rotate the exhaust pipe clockwise. 6. Pull the ...

Page 46

Service and spares 6 720 803 800 (2012/11) 46 fig. 98 electrode assembly 6.8.13 burner housing, burner/ gasket to remove the burner housing. 1. Release and remove the four spring pins from the castellated nuts. 2. Undo the front two castellated nuts/springs and remove and retain along with the front...

Page 47

Service and spares 6 720 803 800 (2012/11) 47 4. Lift the heat exchanger until the lower connection clears the hole in the air box. 5. Pull the heat exchanger towards you to remove. ▶ re-assemble in the reverse order. Fig. 102 heat exchanger removal 6.8.15 diverter valve motor and diverter valve rem...

Page 48

Service and spares 6 720 803 800 (2012/11) 48 fig. 105 pump head removal 6.8.18 flow sensor, flow restrictor and filter removal ▶ isolate the cold mains and ensure that the dhw circuit is fully drained. ▶ disconnect the electrical connection to the turbine. ▶ undo the nut connecting the flow sensor ...

Page 49

Service and spares 6 720 803 800 (2012/11) 49 6.8.22 drain tap ▶ ensure that the boiler is full drained down. ▶ the drain tap rotates anticlockwise for a ¼ turn to open. 1. Rotate the drain tap fully anticlockwise passed the ¼ turn stop point to release. 2. Push in and withdraw from the housing. Fig...

Page 50

Service and spares 6 720 803 800 (2012/11) 50 5. Remove the two screws securing the ch pressure relief valve mounting. 6. Remove the screws securing the hydraulic block assembly. Fig. 114 hydraulic block 6.8.27 bypass valve remove the hydraulic block from the boiler. 1. Remove the clip on the return...

Page 51

Service and spares 6 720 803 800 (2012/11) 51 6.8.29 replacing the control unit with the installer access cover removed: 1. Remove all the connectors 2. Slide out all the cable strain relief clamps fig. 118 disconnect external connections with the control unit in the service position: 1. Remove the ...

Page 52

Service and spares 6 720 803 800 (2012/11) 52 expansion vessel replacement (boiler fitted) ▶ isolate the power from the boiler. ▶ lower the control panel into the service position. ▶ isolate the boiler from the heating system using the service valves. ▶ drain the boiler. ▶ at the pump manifold, rele...

Page 53

Service and spares 6 720 803 800 (2012/11) 53 6.9 short parts list fan 8 718 603 05a by pass valve 8 716 106 434 0 gas valve 8 718 600 04a 0 control panel 8 718 686 274 0 flue overheat thermostat 8 717 206 213 0 electrodes (including gasket) 8 718 600 28a 0 burner seal 8 718 600 24a 0 spark generato...

Page 54

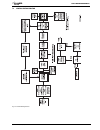

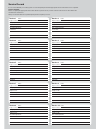

Fault finding and diagnosis 6 720 803 800 (2012/11) 54 7 fault finding and diagnosis 7.1 internal wiring diagram 1 13 1 13 1 13 ems 230v in 230v out fr fs lr lr l n l n l n l n l n pump supply flame sense electrode spark electrodes flow ntc max safety ntc flue stat diverter valve dhw ntc return ntc ...

Page 55

Fault finding and diagnosis 6 720 803 800 (2012/11) 55 7.2 central heating function fig. 123 central heating function.

Page 56

Fault finding and diagnosis 6 720 803 800 (2012/11) 56 7.3 preheat and dhw function fig. 124 preheat and dhw function w ait until temperature is below set value ig n iti o n se qu e nce (see detail) no ye s mai n s po we r sup p ly on t ap open (recognised by flow turbine) diverter valve in d h w po...

Page 57

Fault finding and diagnosis 6 720 803 800 (2012/11) 57 7.4 protection function fig. 125 protection function.

Page 58

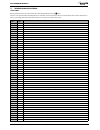

Fault finding and diagnosis 6 720 803 800 (2012/11) 58 7.5 information and service menus status codes during normal boiler operation various status codes can be displayed by pressing the button. The first screen of the information menu displays the current status code, this will change as the boiler...

Page 59

Fault finding and diagnosis 6 720 803 800 (2012/11) 59 270 power up mode 271 d4 temperature difference between flow and safety sensor exceeding limit 272 f0 internal error 273 c4 airflow present during last 24 hours 274 ionisation signal present during last 24 hours 276 e9 flow temperature exceeded ...

Page 60

Fault finding and diagnosis 6 720 803 800 (2012/11) 60 7.5.1 selecting the information menu the information menu is a "read only" menu. Information about the boiler is displayed here, some of the values are updated in real time to give the current status of the boiler. All menus time-out after two m...

Page 61

Fault finding and diagnosis 6 720 803 800 (2012/11) 61 i1 current status every operation and mode of the boiler has a related boiler status code. The boiler status code is displayed on the screen as a three figure number. Refer to table on page 58 or error table for information on the boiler status ...

Page 62

Fault finding and diagnosis 6 720 803 800 (2012/11) 62 7.5.2 selecting service menus 1. Press and hold and buttons together for one second, the display will show menu 1. Double up or down arrows indicate that the menu can only be scrolled up or down, an up and down arrow combination indicates positi...

Page 63

Fault finding and diagnosis 6 720 803 800 (2012/11) 63 7.5.5 reset to factory settings to reset any or all changes made in menu 2 back to the factory defaults setting: 1. Press and hold the , and arrow button for at lest five seconds. The screen will then display code 8e with the spanner symbol. 2. ...

Page 64

Fault finding and diagnosis 6 720 803 800 (2012/11) 64 fig. 130 menu 3 selection 7.5.7 using the test menu this menu enables the testing of the functionality of components in an on/off mode.The duration of each test is up to 60 seconds. 1. Select menu test via the and scroll buttons. 2. Press the bu...

Page 65

Fault finding and diagnosis 6 720 803 800 (2012/11) 65 testing the component ▶ select a component to test. ▶ press the button, the value 0 will flash. ▶ use the arrow button to change the value to a flashing 1. ▶ press to confirm the change, the value 1 will stop flashing and a will displayed for 3 ...

Page 66

Fault finding and diagnosis 6 720 803 800 (2012/11) 66 test note that it could be up to 10 seconds after the button is pressed before the selected component responds. T1 igniter test. Checking the igniter spark. The igniter will spark for a maximum of 30 seconds. The spark will be audible if the ign...

Page 67

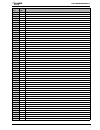

Fault finding and diagnosis 6 720 803 800 (2012/11) 67 7.6 fault codes should a fault develop with this boiler (or the system), the boiler will enter a locking or blocking condition, and fault code information will be generated as described in this section. Locking errors locking error the boiler di...

Page 68

Fault finding and diagnosis 6 720 803 800 (2012/11) 68 blocking errors f0 237 internal error call worcester, bosch group technical helpline 0844 892 3366 238 gas valve error reset button leaking gas valve 239 242 - 256 258 259 262 263 267 272 279 290 internal error call worcester, bosch group techni...

Page 69

Fault finding and diagnosis 6 720 803 800 (2012/11) 69 e9 224 max thermostat activated flue gas thermostat overheat. 276 flow temperature exceeds 95°c primary overheat - boiler waits for temperature to reduce; if not it becomes a locking error. 277 safety temperature exceeds 95°c main heat exchanger...

Page 70

Failure to install and commission according to the manufacturer’s instructions and complete this benchmark commissioning checklist will invalidate the warranty. This does not affect the customer’s statutory rights. If yes, and if required by the manufacturer, has a water scale reducer been fitted? Co...

Page 71

Service record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service record below, please ensure you have carried out the service as described in the manufacturer’s in...

Page 72

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0844 892 9900 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 6 720 803 800 (2012/11) worcester, bosch group: technical support: 0844 892 3366 appointments: 0844 892 3000 spares: 01905 7...