- DL manuals

- Worcester

- Boiler

- Greenstar Danesmoor Utility Regular ErP 12/18

- Installation, Commissioning And Servicing Instruction Manual

Worcester Greenstar Danesmoor Utility Regular ErP 12/18 Installation, Commissioning And Servicing Instruction Manual

Installation, Commissioning and Servicing instruction manual

Floor Standing oil-fired Condensing Boiler Conventional Flue & Room Sealed Flue

Greenstar Danesmoor Utility Regular

ErP

& Utility System

ErP

12/18, 18/25, & 25/32

6720809436-00.1W

o

For fully pumped open vent or sealed central heating systems and domestic hot water cylinders

These appliances are for use with Kerosene (Class C2) only.

6 72

0 813 286 (2014/09)

Summary of Greenstar Danesmoor Utility Regular ErP 12/18

Page 1

Installation, commissioning and servicing instruction manual floor standing oil-fired condensing boiler conventional flue & room sealed flue greenstar danesmoor utility regular erp & utility system erp 12/18, 18/25, & 25/32 6720809436-00.1w o for fully pumped open vent or sealed central heating syst...

Page 2

Contents greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 2 contents 1 key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 general safety instructions...

Page 3

Key to symbols and safety instructions greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 3 1 key to symbols and safety instructions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that coul...

Page 4

Key to symbols and safety instructions greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 4 the combustion air must be kept clear of chemically aggressive substances which can corrode the appliance and invalidate any warranty. Handling instructions and guidelines it is ...

Page 5

Installation regulations greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 5 2 installation regulations 2.1 complying with the building regulations this heating appliance forms part of the controlled services for the building. It is law that all controlled services for...

Page 6

Appliance information greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 6 3 appliance information 3.1 general information standard package: a - floor standing oil fired condensing boiler b - literature pack: • greenstar danesmoor installation, commissioning and servici...

Page 7

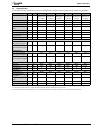

Appliance information greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 7 3.3 energy efficiency the following product data satisfy the requirements of the eu regulations no. 811/2013 and no. 812/2013 supplementing directive 2010/30/eu. Product data symbol unit 77316000...

Page 8

Appliance information greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 8 3.4 layout and components - 18/25 system appliance shown 3 4 5 6 7 8 9 10 11 12 14 13 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 32 31 30 33 1 2 6720813286-01.1w o.

Page 9

Appliance information greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 9 fig. 1 system appliance shown fig. 2 control panel thermostat detail fig. 3 top view connections figure 1 does not include the top, front, left, and right hand side panel 1 return connection 21 o...

Page 10

Appliance information greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 10 3.5 layout and components - 18/25 regular appliance shown fig. 4 18/25 regular appliance shown figure 4 does not include the top, front, and right hand side panel. 1 control box assembly 20 cond...

Page 11

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 11 4 pre-installation 4.1 cleaning primary systems 4.1.1 before cleaning the system: ▶ ensure that the system and pipe work is in good working order. ▶ where possible keep the existing appliance/circula...

Page 12

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 12 4.1.5 inhibitor add a suitable inhibitor or combined inhibitor/anti-freeze, if the system is exposed to freezing conditions, to the heating system in accordance with the dwta code of practice and man...

Page 13

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 13 maximum pipe run for single pipe gravity fed system 4.3.2 double pipe sub-gravity feed system: maximum suction height 3.5 metres. Non-return valves must be fitted to the inlet and return oil line bet...

Page 14

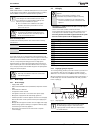

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 14 ▶ offer the pipe to the fitting [2] and tighten the nut [1]. Fig. 10 isolation valve bracket removed for clarity ▶ use flexible hoses to connect from the boiler isolation valve/s and the oil pump. 4....

Page 15

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 15 fig. 13 system boiler system layout filling primary sealed systems • where the system volume is more than 180 litres at 0.5 bar or exceeds 2.65 bar at maximum heating temperature an extra expansion v...

Page 16

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 16 4.5 condensate pipework 4.5.1 internal connections in order to minimise risk of freezing during prolonged cold spells, the following methods of installing condensate drainage pipe should be adopted, ...

Page 17

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 17 fitting an external air break • refer to figure 17 when a rain water down pipe is used to dispose of condensate. • an air break must be installed in the 43mm pipe work, between the boiler condensate ...

Page 18

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 18 fig. 21 pressure relief pipe work [2] outside wall [1, 3] prv discharge pipe [4] external drain 4.7 boiler locations and clearances this boiler is only suitable for installing internally within a pro...

Page 19

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 19 maintenance clearances figure 24 shows the clearances required for maintenance. Fig. 24 maintenance and repair clearances minimum air vent area (cm 3 ) for appliances installed in compartments compar...

Page 20

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 20 [n/a] not allowed [cf] conventional flue [rs(h)] room sealed (horizontal) [rs(v)] room sealed (vertical) [*] minimum distance of the flue terminal from above ground is 2100mm where directed to a publ...

Page 21

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 21 4.9 flue options 4.9.1 conventional flue (cf) • open (conventional) flued appliances must not be installed in a bedroom, bathroom or bed-sitting room. • the flue system must be in accordance with bs ...

Page 22

Pre-installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 22 4.9.2 room sealed flue options fig. 27 room seal ed flue options figure 27 shows the components used and the maximum flue length (l) for each flue configuration. In all cases l is measured from the o...

Page 23

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 23 5 installation 5.1 unpacking the boiler unpacking it is advised that at least two or more persons are involved in the transfer of the packaged boiler from the van to the point of delivery. 1. Once the pa...

Page 24

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 24 pipework connections - regular a - flow connections (optional combined feed and vent) 1” bsp b - return connections 22mmØ copper on 12/18, 18/25 models and 28mmØ copper on 25/32 models c - condensate out...

Page 25

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 25 flue centres fig. 33 flue centres flue opening ▶ follow figure 34 to mark the centre of the flue (1, & 2) for rear opening, (2 & 3) for side opening or (1 & 4) for top opening. ▶ make an opening (f, g or...

Page 26

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 26 3. Unscrew to loosen the retaining ring (h) that secures the flexible air supply tube to the burner (i) and pull the flexible air supply tube free from the burner (see figure 37). Fig. 37 ▶ undo and remo...

Page 27

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 27 5.5 combustion chamber (18/25 regular shown) 1. Remove the control box securing screws (a, bottom screw both sides) and loosen the pivot screws (b, top screw both sides). 2. Pivot down control box. Fig. ...

Page 28

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 28 5.6 pipework connections fig. 46 pipework connections [a] return connection 22mm Ø copper (28mm Ø on 25/32 models) [b] flow & optional combined feed and vent 1” bsp [b1] flow connection 22mm copper (28mm...

Page 29

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 29 5.7 oil burner and pump oil burner 1. Check that the nozzle (a) and the electrode (b) alignment settings are correct as shown in figure 49. ▶ ensure that the nozzle (a) is aligned centrally within the co...

Page 30

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 30 5.9 electrical access to 230v connections 1. Remove the four fascia retaining screws (a) and position the fascia assembly (b) on the two fascia location lugs (c) as shown. 2. Release screws (d) from cabl...

Page 31

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 31 utility - 230v standard wiring diagram fig. 55 230v standard wiring diagram 1 2 3 a b c d green/yellow green/yellow green/y ellow brown red 3 2 orange f brown brown = earth = live = neutral blue e riello...

Page 32

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 32 utility system - 230v standard wiring diagram fig. 56 1 2 3 a b c d green/yellow green/yellow green/y ellow brown red 3 2 orange f brown brown = earth = live = neutral blue e 6720809436-22.1wo key to com...

Page 33

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 33 utility - remote 2 or 3 port valve control set using remote programmer fig. 57 1 2 3 k outside boiler inside boiler • = earth • = live • = neutral • = switched live e key to components: k - remote juncti...

Page 34

Installation greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 34 utility system - remote 2 or 3 port valve control set using remote programmer fig. 58 1 2 3 k outside boiler inside boiler • = earth • = live • = neutral • = switched live e key to components: k - remote...

Page 35

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 35 6 commissioning 6.1 pre-commissioning checks - 18/25 regular shown 1. Check that the service and water pipes are connected correctly. ▶ check that all unused sockets are capped. 2. Check that the oil su...

Page 36

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 36 6.3 water treatment ensure that the system has been cleaned. Refer to section 4.1.2 of these instructions. Flushing (central heating) ▶ ensure the appliance is switched off. ▶ open all drain cocks and d...

Page 37

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 37 fig. 62 ▶ repeat the procedure at least 3 times or until a steady stream of oil, without air, runs from the bleed port, then lock the bleed port. ▶ switch off the boiler. ▶ remove the oil pump filter, c...

Page 38

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 38 ▶ turn off the electrical supply. ▶ isolate the oil supply to the burner. ▶ remove the oil pressure gauge. ▶ refit the blanking plug (a). ▶ check and rectify any oil leaks. 3. Switch on the oil supply. ...

Page 39

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 39 central heating 1. Open all radiator valves. ▶ set room thermostat to maximum. ▶ set programmer to on for ch, off for dhw (if applicable). ▶ turn the thermostat control (a) to max. ▶ ensure all radiator...

Page 40

Commissioning greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 40 fig. 71 6.5.1 hand over ▶ complete the boiler commissioning checklist at the back of this manual and cd11 or an equivalent commissioning form. ▶ set up the controls and show the customer how to operate ...

Page 41

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 41 7 service and spares 7.1 inspection and service - 18/25 regular shown routine servicing to maintain efficient boiler operation, the following should be carried out at least once a year, carry out a...

Page 42

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 42 service requirements see the following instructions for detail of some of the service requirements listed below: ▶ check and clean the burner. ▶ replace the burner nozzle and flexible oil pipe/s. ▶...

Page 43

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 43 fig. 77 burner removal ▶ the internal filter is accessed by removing screws (g) and the oil pump cover (h), refer to figure 78. ▶ replace the standard flexible oil line/s at every annual service to...

Page 44

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 44 fig. 80 baffle detail fig. 81 baffle positioning oil supply system and tank ▶ the oil pipeline, filters, fire valve and tank should be inspected and maintained in accordance with oftec regulations....

Page 45

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 45 re-commissioning the burner 1. Align burner combustion head into burner collar. ▶ locate the burner retainer (a) over the threaded lug on the collar (b). Push the burner firmly onto the flange and ...

Page 46

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 46 7.2 short parts list 12/18 7.3 short parts list 18/25 cleaning tool 8 716 109 428 0 oil nozzle (12kw) 0.35 80° sr 8 716 112 628 0 oil nozzle (15kw) 0.45 60° es 8 716 114 545 0 oil nozzle (18kw) 0.5...

Page 47

Service and spares greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 47 7.4 short parts list 25/32 cleaning tool 8 716 109 428 0 oil nozzle (25 & 28.5kw) 0.75 80° es 8 716 109 387 0 oil nozzle (32kw) 0.85 80° eh 8 716 156 644 0 flexible oil hose kit 8 716 115 310 0 com...

Page 48

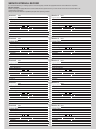

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 48 8 fault finding and diagnosis 8.1 burner functions these fault finding charts are provided to assist competent and suitably qualified engineers to locate and rectify faults. Whilst every e...

Page 49

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 49 8.2 heating and hot water these fault finding charts are provided to assist compe- tent and suitably qualified engineers to locate and rectify faults. Whilst every effort has been taken to...

Page 50

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 50 8.3 boiler function these fault finding charts are provided to assist com- petent and suitably qualified engineers to locate and rectify faults. Whilst every effort has been taken to ensur...

Page 51

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 51 8.4 logic for the 535 se/ld rdb control box.

Page 52

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 52 8.5 oil supply vacuum testing a vacuum gauge can be attached to the oil pump vacuum test port [1] and the boiler operated to check the vacuum readings. Oil pumps can operate if readings ar...

Page 53

Fault finding and diagnosis greenstar danesmoor utility erp and utility system erp - 6 720 813 286 (2014/09) 53.

Page 54

Oil boiler commissioning checklist this commissioning checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating compliance with the appropriate building regulations and then handed to the customer to keep for future reference. Boiler make an...

Page 55

Service interval record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service interval record below, please ensure you have carried out the service as described in the...

Page 56

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0330 123 9559 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 6 720 813 286 (2014/09) worcester, bosch group: technical support: 0330 123 3366 appointments: 0330 123 9339 spares: 0330 12...