- DL manuals

- Worcester

- Boiler

- Greenstar Heatslave II 12/18

- Installation, Commissioning & Servicing Instructions

Worcester Greenstar Heatslave II 12/18 Installation, Commissioning & Servicing Instructions

Installation, Commisioning and Servicing instructions

Floor standing oil fired condensing combination boiler balanced flue

Greenstar Heatslave II External

ErP

12/18, 18/25 & 25/32

6 720 805 210-00.1TL

For fully pumped open vent or sealed central heating systems and domestic hot water cylinders.

These appliances are for use with Kerosene (Class C2) only.

6 72

0 813 345 (2014/09)

Summary of Greenstar Heatslave II 12/18

Page 1

Installation, commisioning and servicing instructions floor standing oil fired condensing combination boiler balanced flue greenstar heatslave ii external erp 12/18, 18/25 & 25/32 6 720 805 210-00.1tl for fully pumped open vent or sealed central heating systems and domestic hot water cylinders. Thes...

Page 2

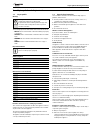

Contents greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 2 contents 1 key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3 1.1 key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1.2 general safety instructions . . . . . . . . . ...

Page 3

Key to symbols and safety instructions greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 3 1 key to symbols and safety instructions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that could result in damage ...

Page 4

Installation regulations greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 4 fitting and modification fitting the appliance and any controls to the appliance may only be carried out by a competent engineer in accordance with these instructions and the relevant installation regulations. F...

Page 5

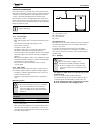

Appliance information greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 5 3 appliance information 3.1 general information standard package fig. 1 standard package [a] floor standing oil fired condensing combination boiler for sealed central heating and mains fed domestic hot water. [b] l...

Page 6

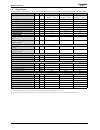

Appliance information greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 6 3.3 energy efficiency the following product data satisfy the requirements of the eu regulations no. 811/2013 and no. 812/2013 supplementing directive 2010/30/eu. Product data symbol unit 7731600050 7731600051 77316...

Page 7

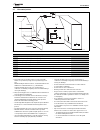

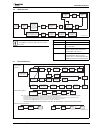

Appliance information greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 7 3.4 layout & components the diagram below excludes the top, front and rh side casing panels. Fig. 2 10 11 12 13 14 18 15 16 19 20 21 22 23 24 25 26 27 29 28 a 36 37 38 40 39 42 44 43 45 45 46 47 41 7 8 9 5 31 32 33...

Page 8

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 8 legend: a: [1] control box assembly [2] service mode button [3] ch temperature control knob [4] lcd display [5] casing side panel [6] flue opening section [7] tank temperature control knob [8] diagnosis port - worcester...

Page 9

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 9 artificially softened water it is possible to have an ion exchange water softener fitted to the cold water system of the property. However, the boiler requires an untreated cold water connection taken from the mains sup...

Page 10

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 10 single pipe gravity feed system the oil storage tank [1] must be positioned so that the oil level does not exceed 4 metres above the level of the burner oil pump [9] and in addition the oil level must be at least 300mm...

Page 11

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 11 ▶ fit a fire valve in accordance with bs 5410. The fire valve [5] should be fitted externally to the building with the fire valve sensor [8] located within the appliance case. A fire valve with a shut off temperature o...

Page 12

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 12 fig. 10 showers/bidets: • if a shower head can be immersed in water or comes closer than 25mm from the top edge of a bath or shower tray spill over level then an anti-siphon device must be fitted to the shower hose. On...

Page 13

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 13 fig. 12 disposal into a rainwater down pipe where the pipe terminates over an open drain or gully, the pipe should terminate below the grating level, but above water level, in order to minimise “wind chill” at the open...

Page 14

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 14 4.5 pressure relief pipework • the pressure relief discharge pipe [2]should be at least 15mm diameter copper pipe and run downwards away from the boiler and discharge away from any electrical or other hazard, preferabl...

Page 15

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 15 4.7 flue terminal positions fig. 20 external boiler flue terminal positions 1. An opening means an openable element, such as an openable window, or a permanent opening such as a permanently open air vent. Notwithstandi...

Page 16

Pre-installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 16 4.8 flue options 4.8.1 cabinet mounted balanced horizontal flue options • the horizontal flue is fitted to the rear or either side of the cabinet. Fig. 21 flue options 4.8.2 plume management 1. Measure the plume manage...

Page 17

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 17 5 installation 5.1 unpacking the boiler unpacking it is advised that two or more persons are involved in the transfer of the packaged boiler from the van to the point of delivery. ▶ once the packaged boiler has been delive...

Page 18

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 18 5.3 boiler installation fig. 26 1. Mark position of the 100mm services duct on the exterior wall and make a hole through. 2. Remove the screws securing the base panel to the transit pallet and lift the boiler off the palle...

Page 19

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 19 fig. 27 ▶ ensure one piece baffle set [c] is in the right location [d], correctly resting on the baffle rests [f] on either side of the combustion chamber and pushed securely into place. Fig. 28 ▶ refit combustion chamber ...

Page 20

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 20 water connections ▶ ensure all pipework is clean. ▶ align water pipework and connect ▶ check that all unused sockets have been capped. Oil supply connections ▶ route the oil supply pipe [w] along either side of the boiler ...

Page 21

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 21 fig. 31 [1] inlet pipe connection [2] return plug [3] by-pass screw [4] brass air defector washer (12/18 models only) [5] locating circlip [6] electrode fixing screw 5.8 refitting components 1. Align burner combustion head...

Page 22

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 22 access to electrical connections access to all wiring connections are via the installer access cover at the bottom front of the control board. 1. Release the 3 captive screws [c] and remove the installer access cover [d]. ...

Page 23

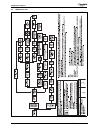

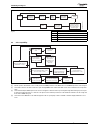

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 23 5.10 electrical schematic fig. 36 6 720 805 209-24.1tl.

Page 24

Installation greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 24 5.11 weather compensation the appliance will modulate the ch flow temperature based on the outside temperature when an outdoor sensor is connected to the outdoor sensor connection on the control board and the weather compe...

Page 25

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 25 6 commissioning 6.1 pre-commissioning checks-appliance 1. Check that the service and water pipes are connected correctly. 2. Check that the oil supply is kerosene and that the pipework is connected correctly to the oil pu...

Page 26

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 26 if an extra expansion vessel is fitted to the central heating return, adjust this to the same pressure as the appliance internal expansion vessel, refer to separate instructions supplied with the extra expansion vessel. 4...

Page 27

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 27 fig. 46 if no oil comes out of the port valve a, then re-prime the oil line as detailed above ▶ wait 2 minutes then press the lockout reset button [k]. ▶ repeat the procedure until a steady stream of oil without air, runs...

Page 28

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 28 fig. 51 control board: [1] spanner/return button [2] reset button [3] eco button [4] boiler lcd display [5] central heating temperature control [6] scroll up button [7] ok - select/confirmation button [8] scroll down butt...

Page 29

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 29 [6] centigrade symbol displays next to the temperature reading. [7] confirmation symbol this symbol confirms a manual change. [8] alpha/numerical display displays a temperature or boiler status code. [9] text display disp...

Page 30

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 30 menu 2 parameter reset to factory settings to reset any or all changes made in menu 2 back to the factory default setting: 1. Press and hold the and buttons for at least five seconds. The screen will then display code be ...

Page 31

Commissioning greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 31 6.4 water treatment flushing (central heating) 1. Switch off the boiler. ▶ open all radiator valves/drain cocks [c] and drain the system while the appliance is hot. ▶ close drain cocks [c]. Fig. 61 2. Add a suitable flush...

Page 32

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 32 6.5 finishing commissioning - appliance 1. Rotate the control box [a] towards you. Slide back into position [b]. 2. Refit the top panel [c] and press down to compress the seal when fitting the securing screws at each...

Page 33

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 33 ▶ check and clean the baffle retainers. ▶ check and clean the baffles. ▶ check and clean the heat exchangers surfaces. ▶ check the combustion chamber access door insulation board. ▶ check that the flue system is unob...

Page 34

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 34 ▶ release the trap locking tab [i] and move the trap up and back to remove from its mountings. ▶ clean the trap by flushing with water. ▶ check the o ring seals and replace if necessary, grease the seals with a solve...

Page 35

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 35 fig. 71 fig. 72 re-commission the burner 1. Align burner combustion head into the boiler collar. ▶ locate the burner retainer [a] over the threaded lug on the collar [b], push the burner firmly into the flange and se...

Page 36

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 36 nominal boiler rating at normal operating temperature using kerosene (class c2) oil pump pressure fuel flow rate approximate flue gas temperature approximate air setting input (appliance) output (appliance) air dampe...

Page 37

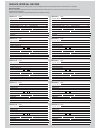

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 37 7.2 short parts lists 12/18 fig. 74 short parts list 12/18 7 8 11 15 16 17 13 12 14 2 3 4 5 6 9 10 1 18 19 20 22 21 24 23 26 25 28 27 30 29 31 32 6 720 805 210-17.1tl no. Description part no. 1 combustion head - ld2x...

Page 38

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 38 7.3 short parts lists 18/25 fig. 75 short parts list 18/25 7 8 11 15 16 17 13 12 14 2 3 4 5 6 9 10 1 18 19 20 22 21 24 23 26 25 28 27 30 29 31 6 720 805 210-18.1tl no. Description part number 1 combustion head - ld2s...

Page 39

Service and spares greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 39 7.4 short parts lists 25/32 fig. 76 short parts list 25/32 7 8 11 15 16 17 13 12 14 2 3 4 5 6 9 10 1 18 19 20 22 21 24 23 26 25 28 27 29 30 6 720 805 210-19.1tl no. Description part number 1 combustion head - t2 sh 2...

Page 40

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 40 8 fault finding and diagnosis 8.1 status cause codes these cause codes are displayed during the normal operation of the boiler. They are not faults, they just give information on the current status of the bo...

Page 41

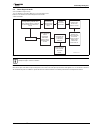

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 41 8.3 service menus selecting service menus 1. Press and hold the and buttons together for 1 second, the display will show menu 1. – double up or down arrows indicate that the menu can only be scrolled up or d...

Page 42

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 42 fig. 81 8.4 factory reset and fault codes 8.4.1 factory reset to reset changes made in menu 2 back to the factory default setting: fig. 82 1. Press and hold the and buttons for at least 5 seconds. The screen...

Page 43

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 43 8.4.3 cause and fault codes cause code fault code description reset type blocking locking possible cause 210 e9 max temperature thermostat activated reset x flue gas or tank thermostat overheat. Reset the ov...

Page 44

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 44 8.5 dhw function chart fig. 84.

Page 45

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 45 8.6 ch function chart fig. 85 8.7 protection functions fig. 86 appliance mains power supply on pump off 3wv to dhw [200] 230v on ch lr and fascia mounted programmer ch = on (if fitted) (and no current dhw/ h...

Page 46

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 46 fig. 87 8.8 solar compatibility fig. 88 [1] normal operation: the tank will cool more slowly for the same dhw performance if the dcw is above normal dcw temperature, thus saving fuel. [2] solar tank hot: the...

Page 47

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 47 8.9 burner diagnostics mode service/installation engineers only. To access the burner control box diagnostics or to use the burner reset button to reset the burner, the burner diagnostic mode must be activat...

Page 48

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 48 8.10 riello digital control boxes fig. 90 riello mo535 mrf digital control box fault finding logic pre-heater link fitted fit pre-heater link a ( ) at ?.

Page 49

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 49 fig. 91 6 720 805 209-76.1tl.

Page 50

Fault finding and diagnosis greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 50 8.11 oil supply vacuum testing a vacuum gauge can be attached to the oil pump vacuum test port [1] and the boiler operated to check the vacuum readings. Oil pumps can operate if readings are between plus 0.4...

Page 51

Greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 51 notes.

Page 52

Greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 52 notes.

Page 53

Greenstar heatslave ii external erp - 6 720 813 345 (2014/09) 53 notes.

Page 54

Oil boiler commissioning checklist this commissioning checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating compliance with the appropriate building regulations and then handed to the customer to keep for future reference. Boiler make an...

Page 55

Service interval record it is recommended that your heating system is serviced regularly and that the appropriate service interval record is completed. Service provider before completing the appropriate service interval record below, please ensure you have carried out the service as described in the...

Page 56

Worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0330 123 9559 worcester, bosch group is a brand name of bosch thermotechnology ltd. Worcester-bosch.Co.Uk 6 720 813 345 (2014/09) worcester, bosch group: technical support: 0330 123 3366 appointments: 0330 123 9339 spares: 0330 12...