Uk/ie user instructions wall hung rsf gas fired condensing regular boiler greenstar ri erp 6720813340-00.1w o for central heating systems 6 7 20 813 340 (201 4/09) if you smell gas: ▶ well away from the building: call the national gas emergency service on 0800 111 999. ▶ l.P.G. Boilers: call the sup...

2 preface greenstar ri erp - 6 720 813 340 (2014/09) preface please read these instructions carefully these instructions are applicable to the worcester, bosch group boiler model stated on the front cover only. These instructions apply in the uk/ie only and must be followed except for any statutory ...

3 contents greenstar ri erp - 6 720 813 340 (2014/09) contents 1 key to symbols and safety instructions 4 1.1 key to symbols 4 1.2 safety precautions 4 2 general information 5 2.1 energy efficiency 5 2.2 servicing 5 2.3 benchmark standard 5 2.4 user caution 5 3 controls 6 3.1 operating the boiler 7 ...

4 key to symbols and safety instructions greenstar ri erp - 6 720 813 340 (2014/09) 1 key to symbols and safety instructions 1.1 key to symbols warnings the following keywords are defined and can be used in this document: • notice indicates a situation that could result in damage to property or equi...

5 general information greenstar ri erp - 6 720 813 340 (2014/09) combustible and corrosive materials: chemically aggressive substances can corrode the appliance and invalidate any guarantee. • do not store or use any combustible materials (paper, thinners, paints, propellants, cleaning agents etc.) ...

6 controls greenstar ri erp - 6 720 813 340 (2014/09) 3 controls fig. 1 controls 1 mains power on/off knob 5 maximum flow temperature position 2 indicator/diagnostic light “mains on/off” (blue) 6 boiler reset position 3 minimum flow temperature position 7 burner on indicator light (green) 4 flow tem...

7 controls greenstar ri erp - 6 720 813 340 (2014/09) 3.1 operating the boiler 3.1.1 switching the boiler on/off ▶ turn the “mains power” knob to 1 to switch on the boiler. ▶ turn the “mains power” knob to 0 to switch off the boiler. Fig. 2 switch on/off boiler. The boiler frost protection function ...

8 controls greenstar ri erp - 6 720 813 340 (2014/09) 3.1.3 turning the central heating off during the summer ▶ to turn your central heating off during warm periods: ▶ set the programmer to off – please refer to the programmer manufacturer's instructions. -or- ▶ turn the room thermostat temperature ...

9 system pressure greenstar ri erp - 6 720 813 340 (2014/09) 4 system pressure 4.1 open vented heating systems if the boiler is fitted to an open vented system, that is a system with a header tank, the pressure will be maintained automatically. 4.2 sealed heating systems if this boiler is fitted to ...

10 system pressure greenstar ri erp - 6 720 813 340 (2014/09) 4.3 external filling loop once the external filling loop has been located, follow the instructions for re-pressurising the system. 1. Unscrew blanking cap. 2. Attach the hose to the valves, screw on hand-tight. 3. Turn the handle/screwdri...

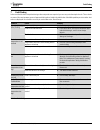

11 service clearances greenstar ri erp - 6 720 813 340 (2014/09) 5 service clearances your installer will have provided adequate space around the boiler for safety and servicing access. Fig. 6 service clearances [*] minimum clearances to removable door [**] minimum clearances required for servicing ...

12 maintaining your appliance greenstar ri erp - 6 720 813 340 (2014/09) 6 maintaining your appliance your new gas-fired appliance represents a long term investment in a reliable, high quality product. Wipe the appliance casing with a soft clean cloth. Please do not use chemical cleaning products wh...

13 fault finding greenstar ri erp - 6 720 813 340 (2014/09) 7 fault finding in the event that the boiler stops functioning or does not perform as expected, you can carry out a few simple checks. These checks are some of the most common causes of apparent faults and are listed in the table below. Sho...

14 fault finding greenstar ri erp - 6 720 813 340 (2014/09) 7.1 boiler reset in the event of a fault, the blue mains indicator light will flash if there is a fault. To reset the boiler: ▶ turn the central heating temperature knob[1] anticlockwise to the “reset” position [2] and hold for approximatel...

15 fault finding greenstar ri erp - 6 720 813 340 (2014/09) 7.2 extreme cold weather in some instances where the condensate pipe work is run externally or in an unheated area, such as a garage, the condensate pipe work can be at risk of freezing, even if well insulated. A frozen/blocked condensate p...

16 fault or breakdown greenstar ri erp - 6 720 813 340 (2014/09) 8 fault or breakdown this boiler is supported in the uk and eire by worcester, bosch group. Specialist service engineers are available to attend a breakdown occurring on this boiler. • no charge will be made for parts and/or labour pro...

17 tips on energy saving greenstar ri erp - 6 720 813 340 (2014/09) 9 tips on energy saving heating economically the appliance provides a high level of comfort whilst keeping gas consumption low and so minimising the environmental impact. The gas supply to the appliance‘s burner is regulated accordi...

18 environment / disposal greenstar ri erp - 6 720 813 340 (2014/09) 10 environment / disposal environmental protection is a fundamental corporate strategy of the bosch group. The quality of our products, their economy and environmental safety are all of equal importance to us and all environmental ...

19 glossary greenstar ri erp - 6 720 813 340 (2014/09) 12 glossary central heating systems all radiators must be heated at an even rate. If the top of a radiator is at a lower temperature than the bottom then it should be bled by releasing air through the bleed screw at the top of the radiator. Ask ...

Worcester, bosch group: technical support: 0330 123 3366 appointments: 0330 123 9339 spares: 0330 123 9779 literature: 0330 123 9119 training: 0330 123 0166 sales: 0330 123 9669 worcester, bosch group cotswold way, warndon, worcester wr4 9sw. Tel. 0330 123 9559 worcester, bosch group is a brand name...