Worksaver EM/2 60, EM/2 72 Owner's Manual

OWNER’S

MANUAL

MODEL NO’s

EM/2 60

EM/2 72

CAUTION

For Safe Operation

Read Rules And

Instructions Carefully

SINO LEEINGLES, PIDA AYUDA

A AIGUIEN QUE SI LO LEA

PARA QUE LE TRADUZCA LAS

MEDIDAS DE SEGURIDAD.

OWNER’S

MANUAL

MODEL NO’s

EM/2 60

EM/2 72

APRIL 2000

FS-FM001-OG

FA R M S TA R

P.O. BOX 100 LITCHFIELD, IL 62056-0100 (217) 324-5973

3 PT. REAR FINISHING MOWER

For Cat. I 3-Pt. Hitch Tractors up to 35 HP

Safety Instructions

Operating Instructions

Maintenance

Tractor Preparation

Assembly & Mounting

Repair Parts

3 PT. REAR FINISHING MOWER

For Cat. I 3-Pt. Hitch Tractors up to 35 HP

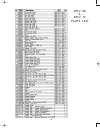

WHEN ORDERING REPAIR PARTS, ALWAYS

GIVE THE FOLLOWING INFORMATION:

1. PART NUMBER

3. MODEL NUMBER

2. PART DESCRIPTION

4. NAME OF ITEM

FARM STAR LIMITED WARRANTY

Farm Star

warrants its implements, parts and accessories to be free from

defects in materials and workmanship for a period of six (6) months from date

of purchase. Upon written approval,

Farm Star

will repair or exchange with-

out charge any part, which upon examination by

Farm Star

or its authorized

agent, shall disclose to be defective.

This does not apply to (1) parts that have worn out in normal use, (2) parts

broken because of improper assembly or operation by the customer, (3) parts

accidentally damaged, (4) failure of parts traceable to improper care, (5) parts

failing through use of implement for purposes other than those for which it

was designed.

The obligations assumed by

Farm Star

and the limitations expressed

herein are in lieu of all other warranties expressed or implied.

S A F E T Y P R E C A U T I O N S

MOST ACCIDENTS OCCUR BECAUSE OF NEGLECT OR CARELESSNESS.

AVOID NEEDLESS ACCIDENTS BY FOLLOWING ALL OF THE SAFETY PRECAUTIONS LISTED BELOW.

•

Machinery should be operated only by those who are

responsible and are authorized to do so.

•

Stop the engine, lower all equipment, lock the brakes,

and remove the ignition key before dismounting from the

tractor.

•

Never stand between tractor and implement while tractor

is being backed to hitch.

•

Loose fitting clothing should not be worn, to avoid catch-

ing on various parts.

•

Detach implement in area where children normally do not

play.

•

When performing adjustments or maintenance on an

implement, first lower it to the ground or block it securely

at a workable height.

•

Only a qualified operator should be permitted on tractor

when in operation; no riders allowed.

•

Make certain everyone is in the clear before starting

tractor or raising or lowering equipment.

•

Operate the tractor and implement only while seated in

the driver’s seat.

•

Reduce speed when transporting mounted implements to

avoid bouncing and momentary loss of steering control.

•

A heavy load can cause instability of the tractor. Use

extreme care during road travel. Slow down on turns and

watch out for bumps. Tractor may need front counter-

weights to counter-balance the weight of the implement.

•

Reduce speed on hillsides or curves so there is no

danger of tipping.

•

Avoid driving too close to the edge of ditches or creeks.

•

Do not transport implement on public roads without

reflectors and slow moving vehicle emblem in daylight

and with approved warning lights at night and other

periods of poor visibility.

•

Due to the width of some implements, use extra caution

on highways, farm roads, and when approaching gates.

•

Always be sure the implement is in the proper position for

transport.

•

Keep alert and watch the front as well as the rear when

working with the implement.

C A U T I O N

THE FOLLOWING SAFETY PRECAUTIONS SHOULD BE THOROUGHLY UNDERSTOOD

BEFORE ATTEMPTING TO BEGIN ASSEMBLING THIS MACHINE

1. Select an area for assembly that is clean and free of any

debris which might cause persons working on the

assembly to trip.

2. Do not lift heavy parts or assemblies. Use crane, jack,

tackle, fork trucks or other mechanical devices.

3. Preview the assembly instructions in your operator’s

manual before proceeding further.

4. If the assembly instructions call for parts or assemblies to

be blocked up, use only blocking material that is in good

condition and is capable of handling the weight of the

assembly to be blocked. Also insure that the blocking

material is on a clean, dry surface.

5. Never put hands, or any part of body, under blocked up

assemblies if at all possible.

6. After completing assembly, thoroughly inspect the

machine to be sure that all nuts, bolts, hydraulic fittings

or any other fastened assemblies have been thoroughly

tightened.

7. Before operating the machine, thoroughly read the

operation section of your operator’s manual.

8. Before operating, read the maintenance section of your

operator’s manual to be sure that any parts requiring

lubrication, such as gearboxes, are full, to avoid any

possible damage.

9. Before operating equipment – If you have any

questions regarding the proper assembly or

operation, contact your Worksaver dealer or repre-

sentative.

B / F - FM001 12/6/00 3:31 PM Page 1