- DL manuals

- Worldlawn

- Lawn Mower

- WYK52ECV7495 KingCobra

- Operator's Manual

Worldlawn WYK52ECV7495 KingCobra Operator's Manual

Summary of WYK52ECV7495 KingCobra

Page 1

Wyk52fx730v5 wyk52ecv7495 wyk60fx801v5 wyk60ecv7495 operators manual.

Page 2

2 worldlawn power equipment, inc. Worldlawnpowerequipment.Com 2415 ashland ave beatrice, ne 68310 800-267-4255 fax – 402-223-4103.

Page 3

3 contents safety ....................................................................................................................................................................6 safety alert symbol ...................................................................................................

Page 4

4 raise the rollover protection structure (rops) ................................................................................ 18 starting the engine .................................................................................................................................... 18 blade engag...

Page 5

5 change hydraulic system filter and fluid............................................................................................ 29 hydraulic system air purge ...................................................................................................................... 29 thread lockin...

Page 6: Safety

6 safety safety alert symbol this symbol means: attention! Become alert! Your safety is involved! The safety alert symbol appears above information which alerts you to unsafe actions or situations and will be followed by the word danger, warning, or caution. Danger: white lettering/red background. I...

Page 7

7 a fire or explosion from gasoline can burn you, others and cause property damage. Refuel outdoors, on level ground while engine is cold. Never remove fuel cap or add fuel when engine is running or when engine is hot. Never fill the fuel tank so that gasoline level rises above the bottom of the fil...

Page 8

8 allow engine parts, especially the muffler, to cool before touching. Remove accumulated debris from muffler and engine area. Warning engine exhaust contains carbon monoxide, which is an odorless deadly poison that can kill you. Do not run engine indoors or in a small confined area where dangerous ...

Page 9

9 danger mowing on wet grass or steep slopes can cause sliding and loss of control. Keep rops in raised & locked position and use seat belt. Mow across slopes, never up and down. Do not mow slopes when grass is wet. Do not mow near drop-offs or near water. Do not mow slopes greater than 15 degrees. ...

Page 10

10 disconnect the battery cable from the negative battery post when the unit will be allowed to sit for more than 30 days without use. Store fuel in a container specifically designed for this purpose in a cool, dry place. Gasoline powered equipment or fuel containers should not be stored in a baseme...

Page 11

11 safety and instructional decals keep all safety signs legible. Remove all grease, dirt and debris from safety signs and instructional labels. Replace all worn, damaged, or missing safety signs. When replacement components are installed, be sure that current safety signs are affixed to the replace...

Page 12

12 543395 8324 543433 543393 543392 543394 543391 543397 543398.

Page 13

13 543396 543401.

Page 14: Specifications

14 specifications model number wyk52fx730v5 wyk60fx801v5 weight & dimensions 52” 60” width without deck 49.8” 55.0” width – deflector up 52.8” 61.1” width – deflector down 65.4” 73.6” length 76.6” 79.4” height – rops up 68.6” 68.6” height – rops down 46.6” 46.6” wheelbase 47.0” 49.75” curb weight wy...

Page 15: Operation

15 operation operator controls steering and motion control : the motion control levers control the forward and reverse rotation of the respective tire. Speed is proportional to amount the levers are moved; moving the levers to the center (neutral) position brakes the movement of the machine. Safety ...

Page 16

16 the fuel shut-off valve is used to shut off the fuel when the machine will not be used for a few days, during transport to and from the jobsite, and when parked inside a building. Align valve handle with the fuel line to open. Rotate to horizontal position to close. Ignition switch located on the...

Page 17: Pre-Start

17 transport lock located at rear of height of cut plates on rh side of floor pan. Transport pawl engages side link when deck is raised to up-stop, preventing deck from being lowered. To lower deck, apply pressure to foot pedal, pull rearward on pawl handle, and reduce pressure on foot pedal until d...

Page 18: Operating

18 operating instructions perform daily maintenance check fuel level open fuel valve adjust seat raise the rollover protection structure (rops) important: the roll bar is an integral and effective safety device. Keep the roll bar in the raised and locked position when operating the mower. Lower the ...

Page 19

19 stopping the engine 1. Bring the unit to a full stop. 2. Move the motion control levers to the neutral position; move the control levers out to the neutral lock position. 3. Engage the parking brake. 4. Push down on the pto switch to disengage the blades. 5. Place the throttle midway between the ...

Page 20

20 adjusting the cutting height the cutting height of the mower deck is adjusted from 1.0 to 5.5 inches (2.5 cm to 14.0 cm) in 1/4 inch (6.4 cm) increments. 1. Stop the machine and move the motion control levers to the neutral position. 2. Disengage the pto. 3. Raise and lock the deck to the 5-1/2 i...

Page 21: Transporting

21 transporting transporting a unit use a heavy-duty trailer or truck to transport the machine. Lock brake and block wheels. Securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes. Be sure that the trailer or truck has all necessary lighting and marking as required ...

Page 22: Maintenance

22 maintenance note: the left and right side of the machine is determined by sitt ing in the normal operator’s position. Warning remove the key from the ignition switch, engage parking brake, and pull the wire(s) off the spark plug(s) before you do any maintenance. Also push the wire(s) aside so acc...

Page 23

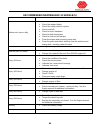

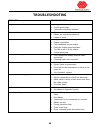

23 recommended maintenance schedule(s) maintenance service interval maintenance procedure before each use or daily check the engine oil level check the mower blades check the safety interlock system check seat belt check for loose hardware check for belt obstructions check for fuel and oil leakage c...

Page 24

24 check engine oil level check the engine oil daily before starting the engine otherwise shortage of the engine oil may cause serious damage to the engine such as seizure. Place the engine on a level surface. Clean area around the oil gauge before removing it. Remove the oil gauge and wipe it with ...

Page 25

25 recommended jump starting procedure service interval: as required 1. Check the weak battery for terminal corrosion (white, green, or blue “snow”), it must be cleaned off prior to jump starting, clean and tighten connections as necessary caution corrosion or loose connections can cause unwanted el...

Page 26

26 check mower blades service interval: before each use or daily stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. 1. Lift deck and secure in raised position as stated in the clean grass build-up under deck section. 2. Inspect blades and sharpen or replace as requ...

Page 27

27 one second has elapsed if the handles are in. The delay will be 1/2 second if the handles are out. Run engine at one-third throttle, with brake disengaged, move levers in and raise off seat (but do not get off of machine) engine must initiate shutdown after 1/2 second has elapsed. Again, run engi...

Page 28

28 change engine oil filter service interval: 200 hours 1. Follow steps 1 through 3 above for engine oil change 2. Replace the oil filter per the engine owner’s manual. Clean around the oil filter and carefully remove the filter by unscrewing it. Make sure no oil drains onto the belt drive or clutch...

Page 29

29 check spark plugs service interval: every 100 hours remove spark plugs, check condition and reset gaps, or replace with new plugs. See engine owner’s manual. Change hydraulic system filter and fluid service interval: every 400 hours this transaxle is designed with a serviceable filter. To ensure ...

Page 30

30 air trapped in the oil may cause the following symptoms: noisy operation. Lack of power or drive after short-term operation. High operation temperature and excessive expansion of oil. Before starting make sure the reservoir is at the proper oil level. If it is not, fill to the vehicle manufacture...

Page 31

31 check v-belts service interval: every 100 hours deck belt removal: 1. Stop engine 2. Lower deck to lowest position 3. Remove belt shields 4. Place ratchet strap hook in notch on deck idler arm (loc a in figure) and in hole in the rh lower strap (loc b in figure) 5. Tighten ratchet strap to rotate...

Page 32: Adjustments

32 adjustments note: disengage pto, shut off engine, wait for all moving parts to stop, engage parking brake, and remove key before servicing, cleaning, or making any adjustments to the unit. Caution raising the mower for service or maintenance relying solely on mechanical or hydraulic jacks could b...

Page 33

33 14. Re-tighten front and rear height-of-cut plate mounting bolts. Important: torque the front and rear height- of-cut plate mounting bolts to 27-33 ft-lb (37- 45 n-m). 15. Repeat steps 6 through 10. Pump drive belt tension self-tensioning – no adjustment necessary. Mower deck drive belt tension s...

Page 34

34 because of the jumper wire being used. Run engine at full throttle and release brake. 6. Run the unit at least 5 minutes with the drive levers at full forward speed to bring hydraulic oil up to operating temperature. Note: the motion control lever needs to be in neutral while making any necessary...

Page 35

35 motion control handle adjustment adjusting the height: the motion control levers can be adjusted highter or lower for maximum operator comfort. 1. Remove the two bolts holding the control lever to the control arm shaft (a) 2. Move the control lever to the next set of holes (b). Secure the lever w...

Page 36: Cleaning

36 cleaning service interval: before each use or daily (may be required more often in dry or dirty conditions.) caution excessive debris around engine cooling air intake and exhaust system area can cause engine exhaust area and hydraulic system to overheat which can create a fire hazard. Clean all d...

Page 37: Troubleshooting

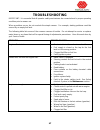

37 troubleshooting important: it is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example, starting problems could be caused by an empty fuel tank. The following table lis...

Page 38: Troubleshooting

38 troubleshooting problem possible cause engine seems weak clogged air filter fouled spark plugs. Carburetor incorrectly adjusted machine vibrates. Blades are loose. Blades are incorrectly balanced. Engine is loose. Engine overheats. Clogged air intake or cooling fins. Engine overloaded. Poor venti...

Page 39: Storage

39 storage winter storage the machine should be readied for storage at the end of the mowing season, or if it will not be in use for more than 30 days. Fuel allowed to stand for long periods of time (30 days or more) can leave sticky residues that can plug the carburetor and disrupt engine function....

Page 40: Wiring Schematics

40 wiring schematics.

Page 41

41 evaporative emission control warranty statement california evaporative emission control warranty statement your warranty rights and obligations the california air resources board and worldlawn power equipment is pleased to explain the evaporative emission control system's warranty on your 2014 mo...

Page 42

42 worldlawn power equipment. Any such part repaired or replaced under the warranty must be warranted for a time not less than the remaining warranty period. (2) any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period def...

Page 43: Wyk52 / 60Mowers

Wyk52 / 60mowers 43 limited warranty : worldlawn power equipment, inc, (“worldlawn”) warrants that the worldlawn wyk52/60 mower (“mower”), purchased from an authorized worldlawn dealer, will be free from defects in material and workmanship for a period of three years commercial/residential from the ...

Page 44

All rights reserved king cobra operators manual 933263 contents subject to change 201402.