R wyz 48/52/60 zero turn mower operator’s manual worldlawn power equipment, inc. Industrial park 2415 ashland ave. Beatrice, ne 68310 toll free number: 1-800-267-4255.

Operator’s manual this manual contains assembly, operating, maintenance, adjustment, and safety instructions for your wyz 48/52/60 lawn mower. Before operating your mower, read this manual in its entirety carefully. By following the operating, maintenance, adjustment, and safety instructions, you wi...

Table of contents 1. Safety ………………………………………………………………………………… 1 1.1 safety alert symbol………………………………………………………………… 1 1.2 training………………………………………………………………………………. 1 1.3 preparation ……………………………………………………………………….… 1 1.4 operation ………………………………………………………………………...… 3 1.5 maintenance & storage …………………………………………………...

4.2 pre-start……………………………………………………………………………. 20 4.3 mowing …………………………………………………………….……………… 20 4.4 transporting …………………………………………….……………………….… 22 5. Maintenance & adjustments……………………………..……..…………… 23 5.1 periodic maintenance ……………………………………………………………… 23 5.2 adjustments ………………………..………………..……………………………… ………...

1 1. Safety 1.1 safety alert symbol this safety alert symbol is used both in this manual and on the machine to identify important safety messages which must be followed to avoid accidents. This symbol means: attention! Become alert! Your safety is involved! The safety alert symbol above alerts you t...

2 potential hazard · in certain conditions gasoline is extremely flammable and highly explosive. What can happen · a fire or explosion from gasoline can burn you, others, and cause property damage. How to avoid the hazard · do not smoke while refueling. Stay away from an open flame or where gasoline...

3 potential hazard · gasoline vapor can collect inside enclosed trailers and may be ignited by electrical sparks or hot engine/exhaust components. What can happen · explosion and fire may occur, resulting in property damage, personal injury, and/or death. How to avoid the hazard · provide adequate v...

4 potential hazard · mowing on wet grass or steep slopes can cause sliding and loss of control. What can happen · wheels dropping over edges, ditches, steep banks, or water can cause rollovers, which may result in serious injury, death or drowning. How to avoid the hazard · do not mow on slopes when...

5 guards, switches, and other devices in place and in proper working condition. 1.4.7 do not change the engine governor setting or overspend the engine. Operating an engine at excessive speed may increase the hazard of personal injury. 1.4.8 disengage pto before starting engine. 1.4.9 start the engi...

6 appliances are present. 1.5.8 maximum mowing results and safety can only be achieved if the mower is properly maintained and operated correctly. 1.5.9 check all bolts frequently to maintain proper tightness. 1.5.10 keep all guards, shields, and safety devices in place and in safe working condition...

7 5. On the right side of the mower deck 6. On the left side of the mower deck 7. On the middle of the panel in front of the console 8. On the front frame 9. On the lower roll bar 10. On the top left corner of rear front frame.

8 11. On the mower deck 12. On the left side of mower deck 13. On the switch panel 14. On the switch panel 15. On the back of hydraulic fuel tank 16. On the left side of the panel in front of the console 17. On the back of hydraulic fuel tank 18. On the right corner of rear deck 19. On the front of ...

9 22. On the outer height adjustment plate 23. Top of the left and the right sides of the console danger to avoid serious injury or death: avoid blades unless engine and blades are stopped. 24. Top of the left and the right sides of the mower deck 25. Front of mower deck, 48” 26. Front of mower deck...

10 2. Specifications 2.1 model number: wyz5222kw-h kw-kawasaki h-hydro-gear engine hydraulic system engine hp cutting width (inch) model wyz5222kw-h 2.2 engine 2.2.1 engine specifications: see your engine owner’s manual 2.2.2 rpm: full speed: 3600rpm (no load) idle:1500rpm 2.3 fuel system 2.3.1 capa...

11 2.5.2 pto switch: engine electric clutch ( to drive belt) which engages mower blades. 2.5.3 parking brake lever: engages parking brakes. 2.5.4 deck height adjustment lever: sets cutting height to desired position. Foot pedal used to assist in raising the deck. 2.6 seat 2.6.1 type: standard seat: ...

12 2.9.3 blade size: (3ea.) wyz48 deck wyz52 deck wyz60 deck 16.5in(419mm)×3 18in(457mm) ×3 20.5in(520mm) ×3 2.9.4 blade spindles: solid steel spindles with 25mm bearings. 2.9.5 deck drive: electric clutch mounted on vertical engine shaft. Blades are driven by one “b” section belt (w/self-tensioning...

13 2.10.6 overall weight: wyz48 is 992 lbs (450 kg) wyz52 is 1025 lbs (465 kg) wyz60 is 1080 lbs (490kg) 2.11 torque requirements bolt location torque cutter housing spindle nut 140-145ft-lb (190-197n-m) blade mounting bolt 115-120ft-lb (156-163n-m) engine deck/front frame mount bolts 30-35ft-lb (41...

14 3. Assembly instructions 3.1 uncrate mower 3.2 install roller protection system (roll bar) 3.2.1 disassemble roll bar from the crate. Loosen rollover protection system (roll bar) mounting bolts in the crate. Take roll bar with its bolts out. 3.2.2 raise the rear of the unit and support it with ja...

15 fig 3 u–shaped bar installation 3.3 service battery battery posts, terminals, and related accessories contain lead compounds, chemicals known to cause cancer and reproductive harm. The machine is shipped with a filled lead acid battery without protection. 3.3.1 unhook seat latch and tilt seat to ...

16 potential hazard ·if the ignition is in the “on” position, there is potential for sparks and engagement of components. What can happen ·sparks could cause an explosion or moving parts could accidently engage causing personal injury. How to avoid the hazard · be sure ignition switch is in the “off...

17 lever so the bolts are in the center of the slots on the lever mounting plate and tighten until snug. Repeat on opposite side of unit. Note: there are two lever height options available. Place the bolts in the first and the third hole (from the top) to increase height of the levers or in the firs...

18 4. Operation instructions 4.1 controls 4.1.1 familiarize yourself with all controls before operating the mower. 4.1.2 motion control levers: located on each side of the console. The left lever controls the flow of hydraulic oil from the left hydrostatic pump to the left drive wheel motor. The rig...

19 potential hazard · machine can spin very rapidly by positioning one lever too much ahead of the other. What can happen · operator may lose control of the machine, which may cause damage to the machine or injury. How to avoid the hazard · use caution when making turns. · slow the machine down befo...

20 number of hours that the engine has run. If ignition switch is left on without engine running, hour meter will not run. Note: this switch is not a low oil sensor and will not alert the operator if the engine oil is low. 4.1.10 fuel shut-off valve: located directly below center of console. The fue...

21 important:do not crank the engine continuously for more than 10 seconds at a time. If the engine does not start, allow a 60 second cool-down period between starting attempts. Failure to follow these guidelines can burn out the starter. After starting a cold engine, gradually return choke to the “...

22 4.4 transporting 4.4.1 transporting a unit: use a heavy-duty trailer or truck to transport the machine. Lock brake and block wheels. Securely fasten the machine to the trailer or truck with straps, chains, cable, or ropes. Be sure that the trailer or truck has all necessary lighting and marking a...

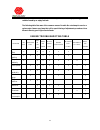

23 5. Maintenance & adjustments 5.1 periodic maintenance 5.1.1 check the engine oil level: service interval: daily a) make sure unit is on a level surface, stop engine, and wait for all moving parts to stop. B) engine should be cold before checking engine oil. C)clean area around dipstick. Remove di...

24 5.1.4 clean grass build-up under deck: service interval: daily a) stop engine, wait for all moving parts to stop, and remove key. B) raise deck to the transport position. Lift the front of the unit and support unit using jack stands or equivalent support. Potential hazard · raising the mower deck...

25 potential hazard · operating a mower deck with loose or weakened blade bolts can be dangerous. What can happen · a loose or weakened blade could allow a blade rotating at a high speed to come out from under the deck, causing serious injury or property damage. How to avoid the hazard · do not lubr...

26 5.1.8 check for loose hardware. Service interval: daily a) stop engine, wait for all moving parts to stop , and remove key. B) visually inspect machine for any loose hardware or any other possible problem. Tighten hardware or correct the problem before operating. 5.1.9 service air cleaner. Servic...

27 b) check tire pressure in drive tires: proper inflation for zhengxin tires is 13psi (89.7kpa) proper inflation for carlisle tires is 18psi (124.2kpa) c) check tire pressure in caster tires: proper inflation for caster tires is 25psi (172.5kpa). 5.1.13 check condition of belts: service interval: 4...

28 c) lubricate bronze bushing on each end of brake rod shafts with a spray type lubricant or a light oil. One shaft is located under the console .The other is below and behind the seat. 5.1.18 lubricate motion control bronze bushing: service interval: 160hrs a) stop engine, wait for all moving part...

29 g) start engine and move throttle control ahead to full throttle position. Move the speed control levers to full speed and run for several minutes. Shut down machine and recheck oil level. Do not change hydraulic system oil (except for what can be drained when changing filter), unless it is felt ...

30 fig 7 5.2.3 deck leveling: a) position mower on a flat surface. B) stop engine, wait for all moving parts to stop, and remove key. C) check tire pressure in drive tires: proper inflation for zhengxin tires is13psi (89.7kpa) proper inflation for carlisle tires is 18psi (124.2kpa) d) check tire pre...

31 5.2.6 adjust seat switch: if necessary, adjust the seat actuator rod length to where the machine will shut off when the operator raises off the seat (with brake disengaged or pto engaged) but will continue to run with operator in seat. Normal adjustment is when length of spring is 1 3/4" (45mm). ...

32 5.2.9 adjust throttle lever tension: a) stop engine wait for all moving parts to stop, and remove key. B) tension in throttle lever can be adjusted by adjusting the tightness of the lever pivot bolt, which is located under the console. 5.2.10 electric clutch adjustment: no adjustment necessary. 5...

33 f) the reverse indicator spring must be correct before the following adjustments can be made. Note: the motion control lever needs to be in neutral while making any necessary adjustments. The left rod assembly controls the left wheel and the right rod assembly controls the right wheel. G) bring t...

34 fig 12 caster adjustment 6. Troubleshooting 6.1 mower pulls left or right (w/levers fully forward). A) refer to tracking adjustment section 4.1. 3. B) check air pressure in tires (see 5.1.12). 6.2 mower cuts unevenly. A) check air pressure in tires (see 5.1.12). B) check deck support chains. C) c...

35 when a problem occurs, do not overlook the simple causes. For example, starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. Do not attempt to service or replace major items or any items that call for special timing of adjustments...

36 7. Hydraulic diagram.

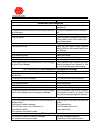

37 7.1 hydraulic pump troubleshooting possible cause corrective action transaxle won't run in straight line incorrect inflation on both sides. Refer to the inflation pressure offered by the manufacturer. To prevent the control connection rod from bending, loosening, or not adjusting. Fix, adjust, or...

38 8. Electrical diagram.

39 limited warranty worldlawn power equipment, inc wyz48/52/60 mower worldlawn power equipment, inc, (“worldlawn”) warrants that the worldlawnwyz48/52/60 mower (“mower”) will be free from defects in material and workmanship for a period of one year commercial from the original date of purchase. Duri...

Notes:.

Notes:.

Worldlawn power equipment, inc . Industrial park 2415 ashland ave. Beatrice, ne 68310 phone: (402) 228-4255 fax: (402) 223-4103 www.Worldlawnpowerequip.Com form no. 52102-201110 r.