- DL manuals

- Xantrex

- Inverter

- DR1512

- Installation And Operation Manual

Xantrex DR1512 Installation And Operation Manual

Summary of DR1512

Page 1

Dr inverter/charger dr1512 dr2412 dr1524 dr2424 dr3624 dr1512w dr1524w dr1512e dr1524e dr1548e dr2424e installation and operations manual.

Page 3: Dr Inverter/charger

Dr inverter/charger installation and operation manual.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to one mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Manual

975-0012-01-02 rev a iii about this manual purpose the purpose of this installation and operation manual is to provideexplanations and procedures for installing, operating, maintaining, and troubleshooting the dr inverter/charger. Scope the manual provides safety guidelines, detailed planning and se...

Page 6: Conventions Used

About this manual iv 975-0012-01-02 rev a conventions used the following conventions are used in this guide. Abbreviations and acronyms related information you can find more information about xantrex technology inc. As well as its products and services at www.Xantrex.Com. Warning warnings identify c...

Page 7: Save These Instructions

975-0012-01-02 rev a v important safety instructions save these instructions this manual contains important instructions for all dr inverter/charger models that shall be followed during installation and maintenance of the inverter. General 1. Before installing and using the dr inverter/charger, read...

Page 8: Wiring Requirements

Safety vi 975-0012-01-02 rev a wiring requirements 1. All wiring methods and materials shall be in accordance with the national electrical code ansi/nfpa 70 (current edition). When sizing conductors and conduits interfacing to the dr inverter, both shall be in accordance with the national electric c...

Page 9

Safety 975-0012-01-02 rev a vii precautions when working with batteries 1. Make sure the area around the battery is well ventilated. 2. Never smoke or allow a spark or flame near the engine or batteries. 3. Use caution to reduce the risk or dropping a metal tool on the battery. It could spark or sho...

Page 10

Viii.

Page 11: Contents

975-0012-01-02 rev a ix important safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v 1 introduction introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 features ...

Page 12

Contents x 975-0012-01-02 rev a batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15 battery types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15 battery bank sizing ...

Page 13

Contents 975-0012-01-02 rev a xi start-up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16 charger mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17 3-sta...

Page 14

Contents xii 975-0012-01-02 rev a battery maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b–13 battery charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b–13 equalization ch...

Page 15: Figures

975-0012-01-02 rev a xiii figure 1-1 front panel features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3 figure 1-2 ac side of the dr inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3 figure 1-3 dc side of...

Page 16

Figures xiv 975-0012-01-02 rev a figure 3-9 battery capacity potentiometer (new) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12 figure 3-10 battery capacity potentiometer (old)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12 figure 3-11 led indicator...

Page 17: Tables

975-0012-01-02 rev a xv table 1-1 model identification and numbering conventions - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5 table 1-2 letter suffix code definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6 table 2-1 peak input filtrate versus cha...

Page 18

Xvi.

Page 19: Introduction

1 introduction chapter 1, “introduction” contains information about the features and functions of the dr inverter/charger..

Page 20: Introduction

Introduction 1–2 975-0012-01-02 rev a introduction thank you for purchasing the dr inverter/charger from xantrex technology inc. The dr inverter is one of the finest inverter/chargers on the market today, incorporating state-of-the-art technology and high reliability. The inverter features an ac pas...

Page 21

Features 975-0012-01-02 rev a 1–3 ac side the ac side of the dr inverter has one 30-amp breaker for pass-thru ac input, and one 30-amp (20 amp in certain models) breaker for charger ac input. Figure 1-1 front panel features dc end front panel controls and indicators battery caps ac end battery sense...

Page 22

Introduction 1–4 975-0012-01-02 rev a dc side the dc side of the dr inverter has the equipment ground lug, the positive (+) battery terminal, and the negative (–) battery terminal. Optional equipment the following options are available for the dr inverter/chargers. Remote control (rc8) the rc8 allow...

Page 23

Features 975-0012-01-02 rev a 1–5 ❐ verify all of the items listed on the packing material sheet are present. Please call xantrex customer service at (800) 670-0707 if any items are missing. ❐ save your proof-of-purchase. This is required if the unit should require warranty service. ❐ save the origi...

Page 24

Introduction 1–6 975-0012-01-02 rev a regulatory the 120 vac/60 hz models of the dr series inverter/charger (models dr1512, dr1524, dr2412, dr2424, and dr3624) are etl listed to ul standard 1741, (first edition) power conditioning units for use in residential and commercial photovoltaic power system...

Page 25: Installation

2 installation chapter 2, “installation” contains information about how to plan for and install the dr inverter/charger..

Page 26: Pre-Installation Planning

Installation 2–2 975-0012-01-02 rev a pre-installation planning take some time prior to installing the equipment to pre-plan the installation. Location, mounting, and ventilation should be taking into consideration before any cabling can be done. Location inverters contain sophisticated electronic c...

Page 27

Pre-installation planning 975-0012-01-02 rev a 2–3 mounting the national building code requires the inverter be mounted on a vertical surface (or wall). The keyhole slots must not be used as the only method of mounting. The purpose of the wall mounting requirement is to orient the inverter so that i...

Page 28

Installation 2–4 975-0012-01-02 rev a hardware / materials required the following hardware or materials may be required to complete this installation. ❐ 4 ft. X 4 ft. Sheet of 3/4" plywood or 2 x 4’s studding material ❐ #12 wood screws (or 1/2" x 1-1/4" lag bolts) ❐ conduit and appropriate fittings ...

Page 29

Pre-installation planning 975-0012-01-02 rev a 2–5 wire routing determine all wire routes both to and from the inverter and which knockouts are best suited for connecting the ac conduits. Possible routing scenarios include: • ac input wiring from the main electrical service panel to the inverter/cha...

Page 30

Installation 2–6 975-0012-01-02 rev a battery location locate the batteries in an accessible location. Two feet clearance above the batteries is recommended for access to the battery caps. They should be located as close to the inverter as possible without limiting access to the inverter’s disconnec...

Page 31

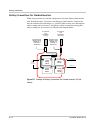

Pre-installation planning 975-0012-01-02 rev a 2–7 figure 2-1 on-grid basic configuration (utility backup) figure 2-2 off-grid configuration (generator only).

Page 32

Installation 2–8 975-0012-01-02 rev a figure 2-3 on-grid configuration - with renewable energy sources.

Page 33

Pre-installation planning 975-0012-01-02 rev a 2–9 figure 2-4 off-grid configuration - with renewable energy sources.

Page 34

Installation 2–10 975-0012-01-02 rev a generators an ac generator can be used as an input source instead of the utility power, or can be connected (using additional hardware) to power the loads when utility is not present (utility outage), and to charge the batteries. The generator must be of the pe...

Page 35

Pre-installation planning 975-0012-01-02 rev a 2–11 inverter mounting the dr series inverter can weigh as much as 45 lb. (20.4 kg). Wallboard is not strong enough to support its weight so additional support must be used or added. The inverter can be mounted directly to the wall studs if the wall stu...

Page 36

Installation 2–12 975-0012-01-02 rev a 3. Secure the 2 x 4 with #10 wood screws (length to penetrate 1½ inches into the studs) as shown in figure 2-7. 4. Measure 7 5/8" from the center of the first 2 x 4 and draw another level line. Place the center of the second 2 x 4 over this line and secure to t...

Page 37: Dc Wiring

Dc wiring 975-0012-01-02 rev a 2–13 dc wiring this section describes the dc wiring requirements and how to make the connections. It provides the required cable and wire sizes, recommended lengths for cables, and disconnect/circuit breaker requirements. Dc circuit grounding grounding is an important ...

Page 38

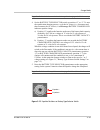

Installation 2–14 975-0012-01-02 rev a figure 2-9 dc grounding.

Page 39

Dc wiring 975-0012-01-02 rev a 2–15 batteries the dr inverter can support either 12-volt battery banks or 24-volt battery banks. Before proceeding, ensure you have the appropriate sized batteries for this inverter. Battery types batteries are available in different sizes, amp-hour ratings, voltage, ...

Page 40

Installation 2–16 975-0012-01-02 rev a battery cable sizing proper cable sizing (diameter and length) is critical to the safe and efficient operation of an inverter system. Larger diameter cables (smaller awg number) have less voltage drop and are, therefore, more efficient when transferring power t...

Page 41

Dc wiring 975-0012-01-02 rev a 2–17 dc disconnect and over-current protection for safety and to comply with regulations, battery over-current protection is required. Fuses and disconnects must be sized to protect the wiring in the system and are required to open before the wire reaches its maximum c...

Page 42

Installation 2–18 975-0012-01-02 rev a battery cable connections battery cables must have crimped (or preferably, soldered and crimped) copper compression lugs unless aluminum mechanical lugs are used. Soldered connections alone are not acceptable. High quality, ul-listed battery cables are availabl...

Page 43

Dc wiring 975-0012-01-02 rev a 2–19 connecting the battery bank to the inverter follow the procedure below to connect the battery bank to the inverter. To connect the battery bank to the inverter: 1. Determine the correct size battery cable to use for installation from table 2-3 on page 2–16. 2. Det...

Page 44

Installation 2–20 975-0012-01-02 rev a 8. Observing battery polarity, connect the positive battery cable (from the over-current device) to the inverter’s positive terminal. 9. Observing battery polarity, connect the negative battery cable to the inverter’s negative terminal. 10. Use an insulated ½ i...

Page 45

Dc wiring 975-0012-01-02 rev a 2–21 installing a battery temperature sensor a battery temperature sensor (bts) option can easily be installed in the system to ensure proper charging of the batteries based on temperature. Installing a bts extends battery life by preventing overcharging in warm temper...

Page 46: Ac Wiring

Installation 2–22 975-0012-01-02 rev a ac wiring this section describes the ac wiring requirements and how to make the connections. It provides the required wire sizes, recommended lengths for conductors, and disconnect/circuit breaker requirements. Ac distribution panel (sub-panel) mounting and con...

Page 47

Ac wiring 975-0012-01-02 rev a 2–23 before wiring the input of the inverter, refer to table 2-5 below for the minimum recommended wire size. Important: the lower ac cover varies depending on the model. Dr24xx and dr36xx models are equipped with a conduit box and not a plate. The conduit box is requi...

Page 48

Installation 2–24 975-0012-01-02 rev a to connect the ac input to the inverter: 1. Disconnect the main breaker at the main electrical service panel (if used) or disconnect the ac generator. 2. Install an appropriately sized circuit breaker in the electrical service panel. This will serve as both an ...

Page 49

Ac wiring 975-0012-01-02 rev a 2–25 ac output wiring to the ac distribution panel (sub-panel) to connect the ac output wiring to the sub-panel: 1. Connect the ground wire to the inverter’s ac ground chassis terminal. Connect the other end of this wire to the ground bus in the sub-panel. 2. Connect t...

Page 50

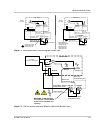

Installation 2–26 975-0012-01-02 rev a the following diagrams illustrate the ac wiring for the following basic 120/240 vac scenarios. Consult your system design for other possible configurations. • on-grid application (see figure 2-18) • on-grid using with a generator backup (see figure 2-19) • on-g...

Page 51

Ac wiring 975-0012-01-02 rev a 2–27 ac input wiring using a generator in an on-grid application if a generator is used as a backup for the utility, then a manual transfer switch must be added to provide a means to switch the generator power to the inverter’s inputs. The generator can be used during ...

Page 52

Installation 2–28 975-0012-01-02 rev a ac input wiring - off-grid applications using a 120 vac generator follow the example below to complete the wiring for an off-grid application. Figure 2-20 ac wiring using a 120 vac generator - off-grid application.

Page 53

Ac wiring 975-0012-01-02 rev a 2–29 ac input wiring - off-grid applications using a 240 vac generator for 120 vac loads follow the example below to complete the wiring for an off-grid application. Figure 2-21 ac wiring using a 240 vac generator with 120 vac loads only- off-grid application.

Page 54

Installation 2–30 975-0012-01-02 rev a series stacking (120 vac/60 hz models only) this com port allows two dr inverters (120 vac/60 hz models only) to be used in the same system in a “series” configuration to operate 240 vac loads. Series stacking can also be used to connect to 240 vac only power s...

Page 55

Ac wiring 975-0012-01-02 rev a 2–31 figure 2-22 ac wiring for dual-inverters - on-grid application (120 vac models only).

Page 56

Installation 2–32 975-0012-01-02 rev a figure 2-23 wiring for dual-inverters - on-grid application (120 vac models only).

Page 57: Operation

3 operation chapter 3, “operation” contains information about how to operate the dr inverter/charger..

Page 58

Operation 3–2 975-0012-01-02 rev a front panel controls and indicators all operating controls, indicators and sense connectors are located on the front panel of the unit. The controls are easily accessible, and the leds provide inverter/charger status at a glance. Power on/off switch the power on/of...

Page 59

Front panel controls and indicators 975-0012-01-02 rev a 3–3 ports there are two ports on the inverter/charger. Both ports are rj11 type telephone style connectors. One is used for connecting a remote control to the inverter. The other is used for regulating the charger voltage based on the temperat...

Page 60

Operation 3–4 975-0012-01-02 rev a • erratic blinking (0 to 3 and 2 to 5 flashes @ 2 second intervals) - the inverter has detected an error condition caused by overheating, low battery voltage, or high battery voltage. • off - the inverter is off. The remote control must be connected prior to switch...

Page 61

Front panel controls and indicators 975-0012-01-02 rev a 3–5 see important notes that follow. Table 3-1 battery type selector switch settings switch position description 12-volt models 24-volt models charge function float voltage bulk/ equalize* voltage float voltage bulk/ equalize* voltage equalize...

Page 62

Operation 3–6 975-0012-01-02 rev a search mode watts potentiometer the search mode watts potentiometer adjusts the current threshold required to bring the inverter out of search mode into full wave operation. With search mode enabled, the inverter pulses the ac output looking for an applied load. Wi...

Page 63

Front panel controls and indicators 975-0012-01-02 rev a 3–7 battery charger rate the battery charger rate potentiometer sets the maximum charge current supplied to the battery bank and is also used to regulate constant current in the bulk charge mode. The level should be adjusted to provide a charg...

Page 64

Operation 3–8 975-0012-01-02 rev a use table 3-2 to find the approximate setting of the battery charge rate potentiometer. The settings do not need to be exact, but should be as close as possible to the actual value required. Over discharge protection/ac transfer voltage the over discharge protectio...

Page 65

Front panel controls and indicators 975-0012-01-02 rev a 3–9 over discharge protection (odp) when enabled, odp shuts down the inverter at a specified voltage (low battery cutoff) to protect the batteries from over discharge damage. The inverter circuitry calculates the lowest (safe) dc voltage (leav...

Page 66

Operation 3–10 975-0012-01-02 rev a ac transfer voltage during normal operation, the inverter supplies ac power to the applied loads through the pass-through circuit and simultaneously charges the system batteries. Whenever the external ac source drops below the ac transfer voltage (set by the poten...

Page 67

Front panel controls and indicators 975-0012-01-02 rev a 3–11 figure 3-7 odp enabled/disabled positions important: most ac appliances will operate properly with an ac pass-through voltage between 95 and 105 volts. Setting the ac transfer voltage potentiometer between these values will allow the inco...

Page 68

Operation 3–12 975-0012-01-02 rev a battery capacity the battery capacity potentiometer is used to set the correct charge profile for the battery capacity (amp-hours) used with the inverter (see illustration below). The setting allows the inverter to calculate over-discharge protection values and al...

Page 69

Front panel controls and indicators 975-0012-01-02 rev a 3–13 led indicators there are four leds on the inverter’s front panel, indicating inverter status, battery condition, over temperature/overload conditions and charger status. These leds blink or change color depending on the condition or funct...

Page 70

Operation 3–14 975-0012-01-02 rev a whenever the battery voltage drops to its lowest (safe) level (as calculated by the odp), the led lights green to indicate the condition. If the condition persists, the inverter will shut down until the battery voltage returns to a safe level and then restart. Cha...

Page 71

Front panel controls and indicators 975-0012-01-02 rev a 3–15 circuit breakers the dr inverter contains two circuit breakers located on the right-hand side of the chassis, directly above the ac input terminal block. The pass-through ac input circuit breaker protects the ac wiring and connected load....

Page 72: Start-Up

Operation 3–16 975-0012-01-02 rev a start-up once the inverter is properly connected to the batteries, ac source, and loads (using a sub-panel) the inverter is ready for operation. Recheck the controls and ensure they are in the proper position. Recheck all wiring and ensure it is correct. Starting ...

Page 73: Charger Mode

Charger mode 975-0012-01-02 rev a 3–17 charger mode 3-stage charging process the charging cycle uses a 3-stage charging process to maintain the batteries. Whenever nominal ac is present at the inverter’s input, it passes power through to the connected load and begins charging the batteries, indicate...

Page 74

Operation 3–18 975-0012-01-02 rev a equalize charging equalize charging is a special mode of battery charging. During use, the battery’s cells can become unequal in the voltage and current they can deliver. This is due to a buildup of sulfate on the plates as well as stratified electrolyte. Sulfate ...

Page 75

Charger mode 975-0012-01-02 rev a 3–19 4. Set the battery type selector switch to position “0” or “1”. To start the equalization charging process, cycle the ac power (i.E., disconnect and then reconnect the ac source). A solid orange battery charger led indicates equalize charge. A) position “0” equ...

Page 76

Operation 3–20 975-0012-01-02 rev a figure 3-16 equalize 1 battery charger rate potentiometer (position “1”) see table 3-1 switch position “1”. Figure 3-17 equalize 2 battery capacity rate potentiometer (position “0”) see table 3-1 switch position “0”..

Page 77: Troubleshooting

4 troubleshooting chapter 4, “troubleshooting” contains information about how to troubleshoot possible error conditions while using the dr inverter/charger..

Page 78

Troubleshooting 4–2 975-0012-01-02 rev a troubleshooting the dr inverter table 4-1 provides a list of possible error conditions that may occur, their possible causes, and possible solutions to resolve the error condition. Table 4-1 troubleshooting the dr inverter error condition possible cause solut...

Page 79: Problem Loads

Problem loads 975-0012-01-02 rev a 4–3 problem loads the inverter can drive most loads, however, there are special conditions that can cause a load to behave differently than expected. The following describes some of the common problems encountered when using an inverter. Ceiling fans most large dia...

Page 80

Troubleshooting 4–4 975-0012-01-02 rev a clocks the inverter’s crystal controlled oscillator keeps the frequency accurate to within a few seconds a day; however, external loads in the system may alter the inverter’s output waveform causing clocks to run at different speeds. There may be periods wher...

Page 81

Problem loads 975-0012-01-02 rev a 4–5 printers most inkjet type printers work well in inverter applications. Laser printers, however, require high current for their fusing circuit and are not recommended for use with an inverter. Rechargeable devices when first using a rechargeable device, monitor ...

Page 82

4–6.

Page 83: Specifications

A specifications appendix a, “specifications” contains information about the electrical specifications and environmental specifications of the dr inverter/charger..

Page 84

Specifications a–2 975-0012-01-02 rev a specifications of the dr inverter table a-1 provides the electrical specifications for the dr inverter/charger (120 vac/60 hz. Models). Table a-2 provides the electrical specifications for the dr inverter/charger (220 vac/60 hz. Models). Table a-3 provides the...

Page 85

Specifications of the dr inverter 975-0012-01-02 rev a a–3 dc input voltage (nominal) c 12.6 vdc 12.6 vdc 25.2 vdc 25.2 vdc 25.2 vdc dc input voltage range 10.8 to 15.5 vdc 10.8 to 15.5 vdc 21.6 to 31.0 vdc 21.6 to 31.0 vdc 21.6 to 31.0 vdc auto low battery protection enabled 11 v 11 v 22 v 22 v 22 ...

Page 86

Specifications a–4 975-0012-01-02 rev a table a-2 electrical specifications for the dr inverter/chargers a - 220 vac/60 hz models model dr1512w dr2412w ac input voltage 220 vac 220 vac ac input low transfer voltage 80 to 210 vac 80 to 210 vac ac input current b 45 amps 55 amps continuous power (@ 25...

Page 87

Specifications of the dr inverter 975-0012-01-02 rev a a–5 temperature comp probe (bts) optional remote control (rc8) d optional a.Specifications subject to change without notice. B.This is the minimum ac current required to obtain full pass-through and maximum battery charging. C.Product may not me...

Page 88

Specifications a–6 975-0012-01-02 rev a auto low battery protection enabled 11 v 11 v 22 v 22 v dc charger rate (adjustable) 0 to 70 amps 0 to 35 amps 0 to 17.5 amps 0 to 70 amps common specifications: voltage regulation (maximum) ± 5% voltage regulation (typical) ±2. 5% waveform modified sine wave ...

Page 89

Specifications of the dr inverter 975-0012-01-02 rev a a–7 table a-4 environmental specifications for the dr inverter/charger a a.Specifications subject to change without notice. Model dr1512 dr2412 dr1524 dr2424 dr3624 dimensions b b.Allows for hardware extensions such as mounting rails, dc termina...

Page 90

A–8.

Page 91: Battery Information

B battery information appendix b, “battery information” supplies general information about batteries such as battery types, battery bank sizing, battery configurations, and battery care. For detailed information, see your battery manufacturer or your system designer..

Page 92: Introduction

Battery information b–2 975-0012-01-02 rev a introduction batteries batteries are available in different sizes, amp-hour ratings, voltage, liquid or gel, vented or non-vented, chemistries, etc. They are also available for starting applications (such as an automobile starting battery) and deep discha...

Page 93

Battery types 975-0012-01-02 rev a b–3 sealed batteries (gel and agm) description gel cell and absorbed glass mat (agm) batteries are sealed and do not require the addition of distilled water. Since these batteries are valve regulated, over-charging can cause irreversible damage. Attributes attribut...

Page 94: Battery Bank Sizing

Battery information b–4 975-0012-01-02 rev a understanding battery capacity ratings discharge rate deep cycle batteries have their amp-hour rating expressed as “at the x-hour rate”. The hour rating refers to the time it takes to discharge the batteries. A faster hour rate (6 hour rate) means more cu...

Page 95

Battery bank sizing 975-0012-01-02 rev a b–5 back up power systems which use utility power for recharging should use the estimated number of days of maximum power outage for determining days of autonomy. Understanding amp-hour requirements amp-hours to estimate the battery bank requirements, you mus...

Page 96

Battery information b–6 975-0012-01-02 rev a considerations when calculating battery bank size, consider the following: • motors typically require 3 to 6 times their running current when starting. Check the manufacturer’s data sheets for their starting current requirements. If you will be starting l...

Page 97

Battery bank sizing 975-0012-01-02 rev a b–7 battery bank size worksheet calculation to calculate the battery bank size, use the average amp-hours per day that you calculated using table b-1, then make the other calculation shown in table b-2 to calculate the battery bank size you need to support yo...

Page 98: Battery Configurations

Battery information b–8 975-0012-01-02 rev a battery configurations the battery bank must be wired to match the inverter’s dc input voltage specifications (12 or 24 vdc). In addition, the batteries can be wired to provide additional run time. The various wiring configurations are: series wiring batt...

Page 99

Battery configurations 975-0012-01-02 rev a b–9 wiring batteries in parallel effect wiring the batteries in a parallel configuration increases the current of the battery string. The voltage of the battery bank remains the same as an individual battery. “parallel” configurations extend the run times ...

Page 100

Battery information b–10 975-0012-01-02 rev a wiring batteries in series-parallel effect wiring the batteries in a series-parallel configuration increases the current and voltage of the battery bank. “series-parallel” wiring is more complicated and care should be taken when wiring these banks. Steps...

Page 101

Battery configurations 975-0012-01-02 rev a b–11 connect to inverter to connect to the inverter: 1. Connect a cable from the positive terminal of the first battery string to the inverter’s positive dc terminal (via a fused device). 2. Connect the negative terminal of the last battery string to the n...

Page 102

Battery information b–12 975-0012-01-02 rev a battery connections for stacked inverters when using inverters in a stacked configuration, the same battery bank must be used for both inverters. To ensure even charging of the batteries, each inverter must be connected to both strings (i.E., positive ca...

Page 103: Battery Maintenance

Battery maintenance 975-0012-01-02 rev a b–13 battery maintenance maintenance strategy to get the best performance from an inverter system, the batteries must be properly setup and maintained. This includes setting the proper voltages for bulk and float charging. See the “cautions” in the section on...

Page 104

Battery information b–14 975-0012-01-02 rev a temperature compensation is based on battery type — 5 mv/cell for lead acid type batteries and 2 mv/cell for alkaline type batteries (nicad or nife). The temperature compensation calculations are derived from table b-5. Table b-4 variances in charging vo...

Page 105

Battery maintenance 975-0012-01-02 rev a b–15 equalization charging purpose an equalize charge helps to remove sulfate buildup on the battery plates and balances the charge of individual cells. Effect equalize charging also produces gassing which stirs up the electrolyte mixture and helps distribute...

Page 106

Battery information b–16 975-0012-01-02 rev a general maintenance water levels flooded lead acid batteries require periodic water refills in each battery cell. Only distilled water should be used in a battery, as tap or mineral water may contain contaminants which will upset the battery chemistry an...

Page 107

Battery maintenance 975-0012-01-02 rev a b–17 state of charge the battery’s state-of-charge should be checked often and only when the battery at a state of rest (when the battery is not powering loads or actively being charged). First thing in the morning is usually the best time to check the state ...

Page 108

B–18.

Page 109: Multi-Wire Branch Circuit

C multi-wire branch circuit wiring appendix c, “multi-wire branch circuit wiring” supplies information about multi-wire branch circuit wiring precautions when using stand-alone 120 vac inverters or generators. Warning a possible fire hazard can exist if 120 vac only sources (such as inverters and ge...

Page 110: Multi-Wire Branch Circuits

Multi-wire branch circuit wiring c–2 975-0012-01-02 rev a multi-wire branch circuits problem a potential safety problem exists when installing stand-alone 120 vac inverters into existing 120/240 vac wired panels where multi-wire branch circuit wiring methods were used. Legacy situation multi-wire br...

Page 111

Multi-wire branch circuits 975-0012-01-02 rev a c–3 figure c-2 multi-wire branch circuit wiring and current flow figure c-3 120 vac inverter incorrectly wired in a multi-wire branch circuit load center l1 l2 neutral ground 120 vac 120 vac 15 a breaker (ganged) 240 vac from grid bare - ground single ...

Page 112

Multi-wire branch circuit wiring c–4 975-0012-01-02 rev a identifying multi-wire branch circuits identifying characteristic multi-wire branch circuits can be identified by removing the cover on the load center and inspecting the wiring. Conventional 120 vac circuits are identified by a 2-wire-plus-g...

Page 113

Correcting multi-wire branch circuit wiring 975-0012-01-02 rev a c–5 correcting multi-wire branch circuit wiring acceptable options correcting multi-wire branch circuit wiring is not easy. Two options which will correct multi wiring branch circuit wiring are: • rewire existing multi-wire branch circ...

Page 114

Multi-wire branch circuit wiring c–6 975-0012-01-02 rev a figure c-5 using a step-down autotransformer in multi-wire branch circuit wiring load center l1 l2 neutral ground 120 vac 120 vac 15 a breaker (ganged) bare - ground single white - neutral (current flow 0 a) black - hot (current flow 15 a) re...

Page 115: Warranty

975-0012-01-02 rev a wa–1 warranty and return information warranty what does this warranty cover? This limited warranty is provided by xantrex technology, inc. ("xantrex") and covers defects in workmanship and materials in your dr inverter/charger. This warranty period lasts for warranty period from...

Page 116: Disclaimer

Warranty and return wa–2 975-0012-01-02 rev a what does this warranty not cover? This limited warranty does not cover normal wear and tear of the product or costs related to the removal, installation, or troubleshooting of the customer's electrical systems. This warranty does not apply to and xantre...

Page 117: Return Procedure

Warranty and return 975-0012-01-02 rev a wa–3 return material authorization policy before returning a product directly to xantrex you must obtain a return material authorization (rma) number and the correct factory "ship to" address. Products must also be shipped prepaid. Product shipments will be r...

Page 118

Warranty and return wa–4 975-0012-01-02 rev a information about your system as soon as you open your dr inverter/charger package, record the following information and be sure to keep your proof of purchase. If you need to contact customer service, please record the following details before calling. ...

Page 119: Index

A am radios 4–3 awg 2–4 b batteries battery care and maintenance equalization charging b–15 temperature compensation b–13 battery types absorbed glass mat b–3 flooded lead acid (fla) b–2 gel cell b–3 golf cart b–2 industrial (electric forklift) b–2 nicad and nife b–3 charging bulk voltage b–13 charg...

Page 120

Ix-2.

Page 122

Xantrex technology inc. 1 800 670 0707 tel. Toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 975-0012-01-02 rev a pc printed in the dr.