- DL manuals

- Xantrex

- Inverter

- PROsine 2.0

- User Manual

Xantrex PROsine 2.0 User Manual

Summary of PROsine 2.0

Page 1

Prosine 2.0 inverter/charger user’s manual.

Page 3: Prosine 2.0 Inverter/charger

Prosine 2.0 inverter/charger user’s manual.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to one mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Manual

445-0089-01-01 iii about this manual purpose the purpose of this user’s manual is to provideexplanations and procedures for installing, operating, maintaining, and troubleshooting the prosine 2.0 inverter/ charger. Scope the manual provides safety guidelines, detailed planning and setup information,...

Page 6

About this manual iv 445-0089-01-01 specifications: appendix a contains specifications and performance graphs for the prosine and the display panel. System diagrams: appendix b illustrates typical designs for prosine custom- designed systems. Charging algorithms: appendix c provides information abou...

Page 7: Conventions Used

About this manual 445-0089-01-01 v conventions used the following conventions are used in this guide. Abbreviations and acronyms an appendix to contain them> related documents prosine 2.0 inverter/charger quick installation guide part number: 445-0099-01-01: this document is included with your prosi...

Page 8

Vi.

Page 9

445-0089-01-01 vii important safety instructions 1. Before installing and using the prosine 2.0 inverter/charger (prosine), read all instructions and cautionary markings on the prosine, the batteries, and all appropriate sections of this manual. 2. Do not expose the prosine to rain, snow, spray, or ...

Page 10: Explosive Gas Precautions

Safety viii 445-0089-01-01 explosive gas precautions 1. Working in the vicinity of lead-acid batteries is dangerous. Batteries generate explosive gases during normal operation. Therefore, you must read this guide and follow the instructions exactly before installing or using your prosine. 2. This eq...

Page 11

Safety 445-0089-01-01 ix 9. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters your eye, immediately flood it with running cold water for at least twenty minutes and get medical attention immediately. 10. If you need to remove a battery, always remove the...

Page 12

X.

Page 13: Contents

445-0089-01-01 xi important safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii 1 introduction your prosine- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 the heart of a so...

Page 14

Contents xii 445-0089-01-01 step 4: connecting the ac input wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11 general ac wiring considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11 ac input connections - - - - - - - - ...

Page 15

Contents 445-0089-01-01 xiii 5 operation part 1: system startup check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2 part 2: operating considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3 fan opera...

Page 16

Contents xiv 445-0089-01-01 installing a series system - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–5 connecting ac input wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–5 connecting ac output wiring - - ...

Page 17: Figures

445-0089-01-01 xv figure 1-1 prosine materials as shipped- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8 figure 2-1 ac end view (blank panel option)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2 figure 2-2 panel equipped with gfci and ...

Page 18

Xvi.

Page 19: Tables

445-0089-01-01 xvii table 1-1 prosine default values- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9 table 3-1 required ac wire size vs breaker rating - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6 table 3-2 required dc cable and fuse siz...

Page 20

Xviii.

Page 21: Introduction

1 introduction chapter 1 introduces you to the prosine, explains the inverting, changing and power system management functions.

Page 22: Your Prosine

Introduction 1–2 445-0089-01-01 your prosine congratulations on your purchase of the prosine 2.0 inverter/charger (prosine) as part of the prosine inverter/charger family, the prosine 2.0 gives you quality power, worry-free operation, and outstanding reliability. Its integrated inverting–charging fu...

Page 23

The heart of a sophisticated, independent power system 445-0089-01-01 1–3 the heart of a sophisticated, independent power system your prosine has been designed to be the heart of a sophisticated, independent power system. While the prosine is an extremely “friendly” product to operate, xantrex wants...

Page 24

Introduction 1–4 445-0089-01-01 remote shutdown naturally, when you are not using the prosine, you will disable the inverter to conserve your battery. The prosine still draws up to 50ma of battery current, however—and this will eventually discharge the battery. So when you don’t need the prosine for...

Page 25

The heart of a sophisticated, independent power system 445-0089-01-01 1–5 power system management as we pointed out at the beginning of this introduction, the prosine is designed to be the heart of your power system. In addition to refined charging and inverting functions, the prosine is the control...

Page 26: Materials List

Introduction 1–6 445-0089-01-01 auto restart after errors the prosine protects itself against numerous conditions (e.G. Ac overload or over temperature) by shutting down. You can program the prosine to restart automatically when the cause of the shutdown has corrected itself. . Run without panel the...

Page 27

Materials list 445-0089-01-01 1–7 if any of these materials are missing or are unsatisfactory in any manner, please contact customer service. See page wa–1. Important: p dc wiring enclosure for residential installations, some installation codes may require a wiring enclosure for dc connections and c...

Page 28

Introduction 1–8 445-0089-01-01 figure 1-1 prosine materials as shipped use r’s m anu al prosine 2.0 inverter•charger dc terminal covers display panel communications cable battery temperature user’s manual quick installation guide quick reference card abyc warning label sensor important:: for marine...

Page 29

Default values for the prosine system 445-0089-01-01 1–9 default values for the prosine system table 1-1 lists the default settings for the prosine system. Record your settings in the right-hand column after you have configured the prosine. This information will be valuable if you need to reconfigur...

Page 30

Introduction 1–10 445-0089-01-01 adjustable from the configure battery menu note settings below are for battery type = generic gel. Battery size 200ah ** default battery temperature warm battery type generic gel ** battery temp. Coefficient –27mv/°c bulk mode settings: • max voltage • max current (%...

Page 31: Product Orientation

2 product orientation chapter 2 will familiarize you with the following components of a prosine system: • prosine features. (start on page 2–2.) • display panel features. (start on page 2–6.) • battery temperature sensor. (see page 2–12.).

Page 32: Prosine Features

Product orientation 2–2 445-0089-01-01 prosine features ac end figure 2-1 ac end view (blank panel option) feature description 1 on/off/rem switch: on: normal operation according to the way the unit has been configured via the display panel. Off: the inverter and charger are off; shorepower is not p...

Page 33

Prosine features 445-0089-01-01 2–3 ac panel options the prosine has two ac panel options, each of which includes one 30a hardwire output circuit: • blank access panel: one hardwire output circuit. See figure 2-1. • panel equipped with 15a gfci receptacle and one hardwire output circuit. See figure ...

Page 34

Product orientation 2–4 445-0089-01-01 dc end figure 2-3 dc end feature description 1 positive dc cabling terminal, 8 mm stud 2 negative dc cabling terminal, 8 mm stud 3 cooling fan. (for details, see “fan operation” on page 5–3.) 4 screw holes for mounting accessory modules 5 chassis ground lug. Pr...

Page 35

Prosine features 445-0089-01-01 2–5 dc terminal covers two covers—red for positive and black for negative—are supplied to prevent accidental contact with the cabling connectors after installation. Figure 2-4 dc terminal cover: top view on left; bottom view on right.

Page 36: Display Panel Features

Product orientation 2–6 445-0089-01-01 display panel features the display panel lets you monitor and control the prosine system. For convenience, the liquid crystal display (lcd) is backlit and the panel can be configured so an audible tone alerts you to any warnings or system faults that occur. The...

Page 37

Display panel features 445-0089-01-01 2–7 display mode switch switch position description on puts the unit in display mode. Data display screens are shown so you can monitor system performance. Off power continues to be available to the panel so vital data like system errors and warning statuses can...

Page 38

Product orientation 2–8 445-0089-01-01 inverter switch this switch is active in all display modes: on, off, configure. Inverter leds the leds are continuously updated whenever the display mode switch is set to on or configure. Switch position description enable the inverter is enabled and will run i...

Page 39

Display panel features 445-0089-01-01 2–9 charger switch this switch is active in all display modes: on, off, configure. Charger leds the leds are continuously updated whenever the display mode switch is set to on or configure. Switch position description enable the charger is enabled and will charg...

Page 40

Product orientation 2–10 445-0089-01-01 lcd panel the lcd panel lets you monitor the prosine system and change its configuration settings. It operates in two basic modes: data display and configuration. Data display mode • in data display mode the screens provide information about prosine system per...

Page 41

Display panel features 445-0089-01-01 2–11 menu navigation and data selection buttons when the display switch is set to configure, the menu navigation and data selection buttons operate as follows: examples of how to change configuration settings are given on page 4–3. Further information about view...

Page 42: Battery Temperature Sensor

Product orientation 2–12 445-0089-01-01 battery temperature sensor the temperature sensor continuously measures the temperature of the battery and adjusts charger output for a more accurate, temperature-compensated charge. Figure 2-6 battery temperature sensor feature description 1 mounting plate. C...

Page 43: Installation

3 installation chapter 3 this section gives complete information for installing a prosine system. Specifically, this section describes: • safety instructions and installation codes that must be observed during installation • installation tools and materials • appropriate locations and environments f...

Page 44: Safety Instructions

Installation 3–2 445-0089-01-01 safety instructions • before you begin the installation, review the “important safety instructions” on “important safety instructions” on page vii, and read the entire “installation” section so you can plan your installation from beginning to end. • disconnect all ac ...

Page 45

Safety instructions 445-0089-01-01 3–3 installation tools and materials you will need the following to install the prosine, display panel, and battery temperature sensor: p wire stripper p mounting screws or bolts p #2 phillips screwdriver p wrench for dc terminals (1/2 inch or 13mm or adjustable) p...

Page 46

Installation 3–4 445-0089-01-01 step 1: designing the installation all types of prosine installations share common components, and these are briefly described below. Figure 3-1 shows these components and their relationship to each other in a typical recreational vehicle or fleet vehicle installation...

Page 47

Step 1: designing the installation 445-0089-01-01 3–5 ac shorepower a source of 120 volt, 60hz alternating current is needed to provide energy for charging batteries and to pass through to ac loads. This source could be the utility grid (power company) or an ac generator. An automatic or manual ac s...

Page 48

Installation 3–6 445-0089-01-01 ac distribution panels most systems incorporate distribution centers both ahead of the prosine (the ac source panel) and between the prosine and the loads (the ac load panel). A source panel includes a main circuit breaker, which serves as over-current protection and ...

Page 49

Step 1: designing the installation 445-0089-01-01 3–7 dc cabling this includes all the cables and connectors between the batteries, the dc disconnect and over-current protection device, and the prosine. All installations require multi-strand insulated cables as well as disconnect and over-current de...

Page 50

Installation 3–8 445-0089-01-01 installations in marine and recreational vehicles may require gfci protection of branch circuits connected to the ac output of the prosine. In addition, electrical codes require gfci protection of certain receptacles in residential installations. While the true sine w...

Page 51

Step 2: choosing a location for the prosine 445-0089-01-01 3–9 step 2: choosing a location for the prosine the prosine should only be installed in locations that meet the following requirements: p dry. Do not allow water or other fluids to drip or splash on the prosine. Do not mount the prosine in a...

Page 52: Step 3: Mounting The Prosine

Installation 3–10 445-0089-01-01 step 3: mounting the prosine to mount the prosine: 1. Remove the prosine from its shipping container, verify that all components are present, and record relevant product information on “information about your system” on page wa–4. 2. Turn off the on/off/rem switch on...

Page 53

Step 4: connecting the ac input wires 445-0089-01-01 3–11 step 4: connecting the ac input wires general ac wiring considerations ac wiring connectors connect ac wires with twist-on wire nuts or crimp-on splice connectors according to the type of installation: • on a boat, use crimp-on splice connect...

Page 54

Installation 3–12 445-0089-01-01 ac input connections figure 3-4 is a cutaway top view of the prosine wiring compartment. It shows one incoming ac cable and its connections to the prosine wires. To make the ac input connections: 1. Run 10awg 2-conductor-plus-ground cable through one of the cable cla...

Page 55

Step 5: configuring the output neutral bonding system 445-0089-01-01 3–13 step 5: configuring the output neutral bonding system ac output neutral-to-ground bonding system the prosine provides an installer-defeatable system that automatically connects the neutral conductor of the inverter ac output c...

Page 56

Installation 3–14 445-0089-01-01 the prosine is shipped with the screw in the position that enables the automatic bonding system. • to disable the system, move the screw to the other hole. • do not remove the screw from the product: make sure it is always installed in one position or the other, as a...

Page 57

Step 6: connecting the ac output wires 445-0089-01-01 3–15 step 6: connecting the ac output wires two options are available for ac output wiring: • hardwire output. • single hardwire output plus gfci receptacle. Connections for hardwire option to make the ac output wiring connections 1. Run 10awg 2-...

Page 58

Installation 3–16 445-0089-01-01 connections for single hardwire output with gfci figure 3-6 is a cutaway top view of the prosine wiring compartment showing one set of outgoing ac wires with the gfci option. To make the ac output wiring connections 1. Run 10awg 2-conductor-plus-ground through one of...

Page 59

Step 7: connecting the dc cables 445-0089-01-01 3–17 step 7: connecting the dc cables follow the procedure given below to connect the battery leads to the terminals on the dc end. The cables should be as short as possible and large enough to handle the required current, in accordance with the electr...

Page 60

Installation 3–18 445-0089-01-01 to make the dc connections refer to figure 3-8. 1. Cut the cables to the correct length with enough insulation stripped off so you can properly install the type of terminals you will be using. The terminals on the dc end are designed to fit up to 500mcm crimp-on ring...

Page 61

Step 7: connecting the dc cables 445-0089-01-01 3–19 dc grounding to connect the dc ground: the chassis ground lug on the dc end of the prosine is used to connect the chassis of the prosine to your system’s dc grounding point as required by regulations for some installations. Use copper wire that is...

Page 62

Installation 3–20 445-0089-01-01 step 8: mounting the display panel the communications cable supplied with the display panel is 70 feet long (21 meters). If you want to replace the cable with one that is longer or shorter, use a high quality, 6-wire telephone extension cable. You can install the pan...

Page 63

Step 9: connecting the battery temperature sensor 445-0089-01-01 3–21 step 9: connecting the battery temperature sensor mounting options you can mount the battery temperature sensor (bts) in one of two ways: • mounting the sensor to the negative battery post allows the internal battery temperature t...

Page 64

Installation 3–22 445-0089-01-01 1. Decide which battery is to be monitored. When all battery banks are located in the same compartment, select the battery that requires the most frequent charging (in a boat or an rv, this is usually the “house” battery). Where a battery is located in a separate com...

Page 65

Step 9: connecting the battery temperature sensor 445-0089-01-01 3–23 mounting to the side of the battery case to mount the sensor on the battery case see figure 3-10. 1. Select the battery to be monitored (see step 1 in the preceding procedure). 2. Select a side suitable for attaching the sensor. T...

Page 66

Installation 3–24 445-0089-01-01 step 10: connecting the remote shutdown some installations may require remote shutdown capability. This feature enables you disable all circuitry in the prosine and remove all power from the display panel using a remote shutdown switch (e.G. The ignition switch in a ...

Page 67

Step 10: connecting the remote shutdown 445-0089-01-01 3–25 next steps at this point, you have installed the prosine system and are now ready to configure it. 1. Read the configuration procedures in chapter 4, “configuration”. 2. Reconnect the ac shorepower supply. 3. Use the display panel to config...

Page 68

Installation 3–26 445-0089-01-01.

Page 69: Configuration

4 configuration chapter 4 explains how to configure the prosine to best meet your electrical system requirements. It is divided into three parts: • general configuration information on page 4–2. Tells you how to enter configure mode and installer mode, how to scroll through the configuration screens...

Page 70

Configuration 4–2 445-0089-01-01 part 1: general configuration information all changes to the operation of the prosine are made via the display panel. The unit must be in configure mode or installer-only mode before you can change system settings. It is essential that you understand the implications...

Page 71

Part 1: general configuration information 445-0089-01-01 4–3 changing settings to change system settings: 1. Set the display switch to configure . 2. Press up s menu or down t menu to display the menu you want. 3. Press enter once, and then press up s menu or down t menu until the menu item you want...

Page 72

Configuration 4–4 445-0089-01-01 resetting to factory defaults to reset the prosine to the factory defaults: 1. Disable invert and charge mode. 2. Set the display switch to configure . 3. Press down t menu until configure prosine—advanced menu appears. 4. Press the enter button once. 5. Press down t...

Page 73

Part 2: configuration menus and screens 445-0089-01-01 4–5 table 4-1 menu structure—overview configure prosine—basic configure prosine—advanced configure display panel configure battery diagnostics ac breaker size load sensing equalize load sensing load sense power load sense interval low ac transfe...

Page 74

Configuration 4–6 445-0089-01-01 part 3: configuration options this section gives you information about the options on each configuration menu. Refer to this section when you are changing system settings. The information in this section is arranged as follows: • each configuration menu is identified...

Page 75

Part 3: configuration options 445-0089-01-01 4–7 configure prosine—basic menu menu choices or information displayed ac breaker size set the ac breaker size to match the shorepower circuit breaker size to reduce circuit breaker “nuisance” tripping. Values range from 0–30 amps. Load sensing select ena...

Page 76

Configuration 4–8 445-0089-01-01 configure prosine—advanced menu menu choices or information displayed load sensing select enabled if you want the unit to periodically search for the presence of an ac load while it is inverting. The unit will “sleep” if the load it detects is less than the load sens...

Page 77

Part 3: configuration options 445-0089-01-01 4–9 low ac transfer (v) this is the voltage below which the unit will no longer recognize ac as “good”, will open the relay, and will attempt to transfer to invert mode if invert is enabled. The range of values is 85–110vac. Low ac transfer (hz) this the ...

Page 78

Configuration 4–10 445-0089-01-01 auto restart after error if you select yes, the prosine will attempt to restart (five attempts) after a fault has occurred. If you select no, the prosine ceases operation when an error occurs. It then requires that you manually restart the unit by going to the confi...

Page 79

Part 3: configuration options 445-0089-01-01 4–11 configure display panel menu menu choices or information displayed this menu lets you change display panel settings to suit your preferences and environment. Audible alarm select all faults if you want a beeper to alert you to each warning and error ...

Page 80

Configuration 4–12 445-0089-01-01 configure battery menu menu display (if different from menu item) menu items access battery size installer dflt batt temp default batt temp user battery type installer view / change battery details: batt temp coeff mode settings: bulk charge • bulk - maximum voltage...

Page 81

Part 3: configuration options 445-0089-01-01 4–13 menu choices or information displayed the configure battery menu lets you read (as a user) and change (installer-only) settings associated with the battery system. The parameters that can be set include battery size, temperature, and type. Battery si...

Page 82

Configuration 4–14 445-0089-01-01 bulk charge mode settings • max voltage this is the maximum available charging voltage for the bulk charging stage. • max current (%c) the maximum available charging current (in a) as a percentage of battery capacity (in ah) for the bulk charging stage. • threshold ...

Page 83

Part 3: configuration options 445-0089-01-01 4–15 equalize mode settings • max voltage this is the maximum available charging voltage for the equalize charging stage. • max current (%c) this is the maximum available charging current (in a) as % of battery capacity in (ah) for the equalize charging s...

Page 84

Configuration 4–16 445-0089-01-01 charger type choose one of the three charger types listed below. For information about multi- stage charging, see application note: battery banks for inverter systems (976- 0114-01-01). P 3-step the prosine will perform the bulk, absorption/overcharge, and float ste...

Page 85

Part 3: configuration options 445-0089-01-01 4–17 diagnostics menu menu choices or information displayed the screens on the diagnostics menu are read-only. They let you monitor and troubleshoot the status of your prosine system. For example, if the unit is continually recording warnings about low ba...

Page 86

Configuration 4–18 445-0089-01-01 view last 10 panel faults the display panel records the last ten faults that have occurred in the display panel. You can view these for diagnostic and troubleshooting purposes. See “display panel faults” on page 6–9. Ac bad cause if the input ac is not acceptable ac...

Page 87: Operation

5 operation chapter 5 begins with a system startup check that you carry out after installation and configuration to verify that the prosine is operating correctly. The chapter also provides information that will guide you during routine, ongoing operations. For your convenience, the information is d...

Page 88: Part 1: System Startup Check

Operation 5–2 445-0089-01-01 part 1: system startup check to test the charging and inverting functions: 1. Close the battery disconnect and turn on the prosine’s on/off/rem switch. 2. To test the inverter, set the inverter switch to enable and disconnect the ac input source breaker. 3. Place a load ...

Page 89

Part 2: operating considerations 445-0089-01-01 5–3 part 2: operating considerations fan operation the internal cooling fan operates for a number of conditions: • one of the internal operating temperatures is greater than 55°c. The fan will continue to run until one minute after the temperature drop...

Page 90

Operation 5–4 445-0089-01-01 without this hysteresis the prosine might continually transfer between invert and charge mode as the shorepower voltage goes up and down a small amount. This concept is applied to the following: • invert low voltage shutdown hysteresis: 2.5v, if the unit stopped invertin...

Page 91

Part 3: operation in inverter mode 445-0089-01-01 5–5 part 3: operation in inverter mode once the prosine is installed, you can operate it in inverter mode. To operate in inverter mode: 1. Place prosine’s on/off/rem switch in the on position. 2. Set the inverter switch to enable. 3. If ac is present...

Page 92

Operation 5–6 445-0089-01-01 you have problems starting certain loads, ensure that the battery connections are solid, the dc cabling is short and of sufficient size, the ac wiring is of sufficient size, and the battery is of sufficient capacity and is fully charged. As with all inverters, the amount...

Page 93

Part 4: operation in charger mode 445-0089-01-01 5–7 part 4: operation in charger mode to operate the prosine in charger mode: 1. Turn on the prosine’s on/off/rem switch. 2. Connect ac shorepower. • the batteries are charged according to the three-step algorithm you have selected. • the ready led co...

Page 94

Operation 5–8 445-0089-01-01 follow the battery manufacturer’s recommendations for equalizing your batteries. 10 provides some background on different batteries. As a guide, a heavily used flooded battery may need to be equalized once a month and a battery in light service every two to four months. ...

Page 95

Part 4: operation in charger mode 445-0089-01-01 5–9 5. During equalization, measure the s.G. When all cells have an s.G. Of approximately 1.265, terminate the charge by setting the charger switch to disable. As a safety feature, the prosine will exit equalize mode after a specified period (dependin...

Page 96: Part 5: Display Mode Screens

Operation 5–10 445-0089-01-01 part 5: display mode screens when the display switch is on, you can view the screens shown below. (the values shown here are examples only.) display mode screens are updated continuously to show current prosine operating data. You can scroll through them by pressing the...

Page 97: Troubleshooting

6 troubleshooting chapter 6 describes how to troubleshoot the prosine this section is divided the following parts: • general troubleshooting guidelines on page 6–2. • shutdown / restart without error message on page 6–3. • ac bad causes on page 6–3. • warning messages on page 6–4. • error messages o...

Page 98

Troubleshooting 6–2 445-0089-01-01 general troubleshooting guidelines this section will help you narrow down the source of any problem you encounter. Before contracting xantrex, please work through the steps listed below: 1. Check for a warning, error, or panel fault message. (see table 6-2, table 6...

Page 99

General troubleshooting guidelines 445-0089-01-01 6–3 shutdown / restart without error message while inverting, the prosine could shut down for a few seconds and then restart inverting without reporting an error. This has likely been caused by a reset of the internal microprocessor, which was probab...

Page 100: Warning Messages

Troubleshooting 6–4 445-0089-01-01 warning messages warning messages appear on the display panel lcd to alert you to an impending system change. Warnings do not affect operation. • you can retrieve the previous twenty warning and/or error messages by placing the unit in configure mode and then selec...

Page 101

Warning messages 445-0089-01-01 6–5 inv hi bat v -w high battery voltage, invert mode. Check for external charging sources and disable if necessary. Chg hi bat v -w battery voltage exceeds 15.5v in charge mode. Ac in rev pol -w input ac line and neutral wiring polarity is reserved. Check to see that...

Page 102: Error Messages

Troubleshooting 6–6 445-0089-01-01 error messages error messages indicate that there has been a change in system operation due to a detected condition. • you can retrieve the previous twenty error messages by placing the unit in configure mode and then selecting view last 20 prosine faults fromthe d...

Page 103

Error messages 445-0089-01-01 6–7 invert hi bat v inverter battery voltage greater than 16v. Check for external charging sources and disable if necessary. Ac out overload ac output overload. Reduce the ac load so that even for short times, the ac output current does not exceed 26a. Ext comm timeout ...

Page 104

Troubleshooting 6–8 445-0089-01-01 chg bad ac qlty in charger or bypass mode the prosine is being powered from an incompatible ac source, probably a very low quality generator. The prosine is compatible with virtually all nominal 120v 60hz ac sources (including modified sine wave) but it is possible...

Page 105: Display Panel Faults

Display panel faults 445-0089-01-01 6–9 display panel faults a message is displayed for any fault that is detected in the display panel. If a panel fault message appears, you can clear it from the screen by pressing any button on the panel. Since this type of fault does not trigger a shutdown, opera...

Page 106: Unexplained Faults

Troubleshooting 6–10 445-0089-01-01 unexplained faults sometimes the prosine may not show a fault at the panel, but may be acting in an unexplained way. Table 6-5 unexplained faults error details shorepower is present but the prosine will not transfer the voltage or frequency of the shorepower is no...

Page 107: Inverter Applications

Inverter applications 445-0089-01-01 6–11 inverter applications the prosine performs differently depending on the ac loads connected to it. If you are having problems with any of your loads, read this section. Resistive loads these are the loads that the inverter finds the simplest and most efficien...

Page 108

Troubleshooting 6–12 445-0089-01-01 freewheel when power is removed (e.G. A grinder). This long transfer may cause computers or other sensitive equipment to operate incorrectly. If power glitches must be minimized then xantrex recommends that motor loads not be operated when the sensitive equipment ...

Page 109: Series Operation

7 series operation chapter 7 provides information about installing and operating two prosines in series: • designing a series system on page 7–2. • installing a series system on page 7–5. • configuring a series system on page 7–9. • series system startup test on page 7–10. • series system operation ...

Page 110: Designing A Series System

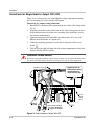

Series operation 7–2 445-0089-01-01 designing a series system system overview series operation refers to a specific wiring configuration that allows you to connect two prosines in a way that produces two 120v phases which are synchronized to produce 240v. This is commonly referred to as a “120/240va...

Page 111

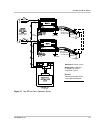

Designing a series system 445-0089-01-01 7–3 figure 7-1 two prosine series operation system * ground * ground battery 1 battery 2 dc fuse / disconnect or circuit breaker dc fuse / disconnect or circuit breaker solid lines: 2 bank system dashed lines: add cross- tie jumpers to create a single bank sy...

Page 112

Series operation 7–4 445-0089-01-01 ac input the ac input (shorepower) supply to the system must be a 120/240vac split- phase system that provides two line conductors (referred to as l1 and l2), a neutral, and ground. Each prosine requires a line, neutral, and ground run to it, so 2-conductor-plus-g...

Page 113: Installing A Series System

Installing a series system 445-0089-01-01 7–5 installing a series system • xantrex recommends that you have an electrician set up the two prosines because knowledge of the electrical code, split-phase systems, and load balancing is required. • see page 3–3 for a list of tools and materials required ...

Page 114

Series operation 7–6 445-0089-01-01 connecting ac output wiring to connect each prosine to the load panel: 1. Connect 2-conductor-plus-ground cable to the line 1 prosine’s ac output line and neutral conductors, and connect the cable’s ground wire to one of the output ground screws on the prosine. 2....

Page 115

Installing a series system 445-0089-01-01 7–7 the system can be run from a single battery bank or from two separate banks. A large single bank provides better surge capability for 120v loads and ensures that unbalanced 120v loads don’t run down the battery on one inverter before the other. The two p...

Page 116

Series operation 7–8 445-0089-01-01 • single bank: if your system has a single bank, install both sensors on the battery (or batteries) which will be the hottest. • two separate banks: if your system has two separate battery banks, connect one sensor to either prosine and then to the battery it is c...

Page 117: Configuring A Series System

Configuring a series system 445-0089-01-01 7–9 configuring a series system configure each prosine through its display panel. Refer to “part 2: configuration menus and screens” on page 4–4 for an overview of configuration options. Refer to “part 3: configuration options” on page 4–6 for specific conf...

Page 118: Series System Startup Test

Series operation 7–10 445-0089-01-01 series system startup test to test the system’s inverting and charging functions 1. Apply dc to both prosines by closing the battery disconnect(s). Remove ac by opening the ac input source breaker. On both prosines, set the on/off/ rem switch to on. 2. Set the in...

Page 119: Series System Operation

Series system operation 445-0089-01-01 7–11 series system operation invert mode the two prosines will operate strictly as a pair in invert mode. Before each cycle of ac output, the two units confer over the sync cable to verify that the other unit has no errors and is ready to put out the next cycle...

Page 120

Series operation 7–12 445-0089-01-01.

Page 121: Specifications

A specifications appendix a contains specifications and performance graphs for the prosine and the display panel. Specifications subject to change without notice..

Page 122

Specifications a–2 445-0089-01-01 electrical specifications: invert mode dc input operating voltage range 10.0v–16.0v safe non-operating voltage range 0–18vdc nominal current at full load 200a ac output output voltage 117vac continuous power 2.0kw, 2.0kva to 40°c max. Ambient surge power 4.5kw for 5...

Page 123

Electrical specifications: charge mode 445-0089-01-01 a–3 electrical specifications: charge mode ac input operating voltage range 90–135vac nominal current 15aac at 100a charge, 120vac in power factor (100a charge, 120vac in) ≥0.98 on sine input nominal frequency 60hz dc output nominal voltage 12.0v...

Page 124: Environmental Specifications

Specifications a–4 445-0089-01-01 environmental specifications system regulatory approvals ambient temperature: operating temperature range storage temperature range –20–60ºc, with output derated above 40 ° c –40–70ºc humidity: operation/storage 5–95% rh, non-condensing transfer relay rating 30a, 1....

Page 125: Inverter Overload Operation

Inverter overload operation 445-0089-01-01 a–5 inverter overload operation this graph shows how long the prosine will operate for given output current. Typical inverter efficiency time to shutdown vs. Current 0.01 0.10 1.00 10.00 100.00 1000.00 10000.00 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 9...

Page 126

Specifications a–6 445-0089-01-01 invert power derating vs. Ambient temperature if the unit is in elevated ambient temperature above 40°c, you are required to reduce power draw according to the following chart to maintain regulatory compliance and to avoid over-temperature shutdown. Prosine charger ...

Page 127: Prosine Dimensions

Prosine dimensions 445-0089-01-01 a–7 prosine dimensions figure a-1 prosine dimensions (4 50mm (17 .7” ) 10 1/2” (267mm) 11 3/8” (289mm) 5 3/4” (1 46 m m ) 17 3/ 4 ” (4 50 mm ) 1 1 /2” ( 3 8 m m) 4 3/ 8 ” (1 11 m m ) 7 3 /16 ” ( 1 83mm ) 10 1/1 6 ” (25 6 m m ) 11 1/ 16” ( 2 8 1 mm ).

Page 128

A–8.

Page 129: System Diagrams

B system diagrams appendix b illustrates typical designs for prosine custom-designed systems. • residential backup. (see page b–2.) • marine installations. (see page b–3.) for a typical rv or fleet vehicle installation, see figure 3-1 on page 3–4..

Page 130: Residential Backup System

System diagrams b–2 445-0089-01-01 residential backup system figure b-1 illustrates a typical residential backup system with the following features: 1. Ac power supplied by a utility system 2. Dc power supplied by a battery bank and protected by a dc fuse in the positive cable 3. An ac source panel ...

Page 131: Marine System

Marine system 445-0089-01-01 b–3 marine system figure b-2 illustrates a typical marine system with the following components: 1. Ac power supplied from a shorepower connector 2. An ac source panel that includes a max 30a circuit breaker that supplies the prosine 3. An ac load panel with branch circui...

Page 132

B–4.

Page 133: Charging Algorithms

C charging algorithms appendix c provides information about the charging algorithms for prosine 2.0. • charge algorithms. (see page c–2.) • battery type—charge algorithm guide. (see page c–3.).

Page 134: Charge Algorithms

Charging algorithms c–2 445-0089-01-01 charge algorithms table c-1 summarizes the voltage and current setpoints for the charging algorithms. These voltage setpoints are applied for a battery temperature of 20°c. To determine the voltage setpoints at other temperatures, apply the temperature coeffici...

Page 135

Battery type—charge algorithm guide 445-0089-01-01 c–3 battery type—charge algorithm guide use the information in table c-2 to match your battery type with the appropriate charge algorithm and charger type. Different battery manufacturers suggest different battery charging algorithms. The following ...

Page 136

Charging algorithms c–4 445-0089-01-01 johnson controls flooded - starting/deep cycle 12 3 step keystone solid energy (flooded) 16 3 step keystone solid energy (gel) 15 3 step metra electronic - tsunami, normal 19 3 step optima blue top 19 3 step optima red top 19 3 step optima yellow top 19 3 step ...

Page 137: Warranty

445-0089-01-01 wa–1 warranty and return information warranty what does this warranty cover? This limited warranty is provided by xantrex technology inc. ("xantrex") and covers defects in workmanship and materials in your prosine 2.0 inverter/charger. This warranty period lasts for 2 years (24 months...

Page 138: Disclaimer

Warranty and return wa–2 445-0089-01-01 what does this warranty not cover? This limited warranty does not cover normal wear and tear of the product or costs related to the removal, installation, or troubleshooting of the customer's electrical systems. This warranty does not apply to and xantrex will...

Page 139: Return Procedure

Warranty and return 445-0089-01-01 wa–3 return material authorization policy before returning a product directly to xantrex you must obtain a return material authorization (rma) number and the correct factory "ship to" address. Products must also be shipped prepaid. Product shipments will be refused...

Page 140

Warranty and return wa–4 445-0089-01-01 information about your system as soon as you open your prosine 2.0 inverter/charger package, record the following information and be sure to keep your proof of purchase. If you need to contact customer service, please record the following details before callin...

Page 141: Index

445-0089-01-01 ix-1 a abbreviations and acronyms v abyc compliance a–4 abyc warning label 1–8, b–3 ac bad cause 4–18, 6–3 ac breaker size 3–6, 4–5, 4–7 ac cabling 3–6 ac circuit breaker 3–5 ac disconnect devices 3–5 ac distribution center. See ac source panel and ac load panel. Ac fuses 3–5 ac input...

Page 142

Index ix–2 445-0089-01-01 general configuration information 4–2 how to change settings 4–3 minimum settings after installation 1–9, 4–5 overview of menu structure 4–5 series systems 7–9 configuration mode 2–10 configure battery menu 4–12 configure display panel menu 4–11 configure mode, entering 4–2...

Page 143

Index 445-0089-01-01 ix–3 frozen batteries 6–4 fuse sizes ac 3–5 dc 3–7 g gases, battery precautions 5–7, 7–8 venting 3–22 generators 3–5 gfci 2–3, 3–7, 3–16 gfci models, tested 3–8 i incandescent lights 6–12 induction motors 6–11 information about your system form wa–4 input voltage range 5–6 insta...

Page 144

Index ix–4 445-0089-01-01 menu up button 2–11 menus configure battery 4–12 configure display panel 4–11 configure prosine—advanced 4–8 configure prosine—basic 4–7 diagnostics 4–17 navigating 2–11 selecting data 2–11 microwave 1–2 motor loads 6–11 motors capacitor start 6–11 induction 6–11 universal ...

Page 145

Index 445-0089-01-01 ix–5 running current 6–11 rv system, illustrated 3–4 s safety instructions viii search mode. See load sensing mode. Serial number wa–4 series operation charge mode 7–11 invert mode 7–11 series sync cable installing 7–8 to order 1–7 series sync connection 7–4 series system batter...

Page 146

Index ix–6 445-0089-01-01 warranty out of warranty service wa–3 terms and conditions wa–1 wire sizes, ac 3–6 wiring enclosure, dc 3–3, 3–18 wiring, separation of ac and dc 3–11 x xantrex web site v.

Page 148

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 445-0089-01-01 printed in china.