- DL manuals

- Xantrex

- Inverter

- PV100S-208

- Operation And Maintenance Manual

Xantrex PV100S-208 Operation And Maintenance Manual - Introduction

Summary of PV100S-208

Page 1

Pv100s 100 kw grid-tied photovoltaic inverter operation and maintenance manual pv100s-208 pv100s-480

Page 3: Pv100S 100 Kw Grid-Tied

S pv100s 100 kw grid-tied photovoltaic inverter operation and maintenance manual.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to one mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Manual

152379 rev c iii about this manual purpose the purpose of this operation and maintenance manual is to provideexplanations and procedures for operating, maintaining, and troubleshooting the pv100s 100 kw grid-tied photovoltaic inverter. Installation instructions are available in the pv100s 100 kw gri...

Page 6: Conventions Used

About this manual iv 152379 rev c conventions used the following conventions are used in this guide. This manual contains information for two models of the pv100s 100 kw grid- tied photovoltaic inverter. One model is designed to operate with a 208 vac utility input, and the other model is designed t...

Page 7: Abbreviations and Acronyms

About this manual 152379 rev c v abbreviations and acronyms related information you can find more information about xantrex technology inc. As well as its products and services at www.Xantrex.Com. Ansi american national standards institute ccu2 converter control unit 2 cfm cubic feet per minute cw c...

Page 8

Vi.

Page 9

152379 rev c vii important safety instructions save these instructions - do not discard this manual contains important safety instructions for the pv100s that must be followed during installation and maintenance procedures. Warning: shock hazard read and keep this operation and maintenance manual fo...

Page 10: General Safety Precautions

Safety viii 152379 rev c general safety precautions 1. When installing the pv100s use only components recommended or sold by xantrex. Doing otherwise may result in a risk of fire, electric shock, injury to persons, and will void the warranty. 2. Do not attempt to operate the pv100s if it has been dr...

Page 11

Safety 152379 rev c ix the terminals are one bolt per pole. See the pv100s 100 kw grid-tied photovoltaic inverter planning and installation manual for the location of these terminals. 5. The ac power conductor wiring interfacing with the ac terminals in the main inverter enclosure are located at tb4...

Page 12: Lockout and Tag

Safety x 152379 rev c operational safety procedures never work alone when servicing this equipment. A team of two is required until the equipment is properly de-energized, locked-out and tagged, and verified de- energized with a meter. Thoroughly inspect the equipment prior to energizing. Verify tha...

Page 13

Safety 152379 rev c xi de-energize/isolation procedure the following procedure should be followed to de-energize the pv100s for maintenance. To isolate the pv100s: 1. Turn the o n /o ff switch to the o ff position. 2. Open the dc interface disconnect switch. 3. Open the ac interface disconnect switc...

Page 14

Xii.

Page 15: Contents

152379 rev c xiii important safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii 1 introduction operation features- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 fixed unity power ...

Page 16

Contents xiv 152379 rev c 2 operation description of system operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2 overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2 faults - - -...

Page 17

Contents 152379 rev c xv 3 commissioning commissioning procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2 starting the commissioning test file - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2 serial numbe...

Page 18

Contents xvi 152379 rev c a specifications system specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a–2 environmental specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a–2 electrical...

Page 19: Figures

152379 rev c xvii figure 1-1 maximum peak power tracking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4 figure 1-2 pv100s major components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6 figure 1-3 dc interface enclosure - - - - ...

Page 20

Figures xviii 152379 rev c figure 2-24 connection configuration screen - general - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–35 figure 2-25 connection configuration screen - telephone fault configuration - - - - - - - - - - - - - -2–36 figure 2-26 connection configuration screen - g...

Page 21: Tables

152379 rev c xix table 2-1 scrolling through the read menu parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9 table 2-2 read menu descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11 table 2-3 data logging menu- - - - - - - - - -...

Page 22

Xx.

Page 23: Introduction

1 introduction chapter 1, “introduction” contains information about the features and functions of the pv100s 100 kw grid-tied photovoltaic inverter..

Page 24: Operation Features

Introduction 1–2 152379 rev c operation features the pv100s 100 kw grid-tied photovoltaic inverter is a ul 1741 listed, utility interactive, three-phase power conversion system for grid-connected photovoltaic arrays with a power rating of 100 kw. Designed to be easy to install and operate, the pv100...

Page 25

Operation features 152379 rev c 1–3 peak power tracking an advanced, field-proven, maximum peak power tracker (mppt) algorithm integrated within the pv100s control software ensures the optimum power throughput for harvesting energy from the photovoltaic array. The peak power voltage point of a pv ar...

Page 26

Introduction 1–4 152379 rev c optimization of the pv100s mppt will result in an increase in energy production. The user is encouraged to study the pv array’s i-v curves and to adjust the mppt user settable parameters accordingly. Utility voltage/frequency fault automatic reset in the event of a util...

Page 27: Safety Features

Safety features 152379 rev c 1–5 safety features anti-island protection a condition referred to as "islanding" occurs when a distributed generation source (such as the pv100s grid-tied photovoltaic inverter) continues to energize a portion of the utility grid after the utility experiences an interru...

Page 28: Physical Characteristics

Introduction 1–6 152379 rev c physical characteristics the pv100s comes in two modules comprised of six enclosures to house the electronics described above. The first module includes the main inverter enclosure, inductor enclosure, dc interface enclosure, and communications enclosure. The second mod...

Page 29

Physical characteristics 152379 rev c 1–7 main inverter enclosure the pv100s main inverter enclosure is nema-3r rated and contains the power distribution panel, the converter control unit (ccu2), and power electronics matrix. Also found within the main inverter enclosure are some of the system prote...

Page 30

Introduction 1–8 152379 rev c dc interface enclosure the dc interface enclosure is nema-3r rated. The dc interface serves as the connection interface between the pv array and the pv100s. This enclosure is where the dc disconnect switch and dc contactor reside. Transformer enclosure the transformer e...

Page 31

Physical characteristics 152379 rev c 1–9 communications enclosure the communications enclosure is nema-4 rated. It contains the hardware to enable a personal computer to connect to the unit, either directly or remotely. Hardware could include a pots connect kit, a wireless connect kit, or an ethern...

Page 32: Operator Interface Controls

Introduction 1–10 152379 rev c operator interface controls operator interface controls are located on the front door of the main inverter enclosure. These controls include an on/off switch, 4-line lcd display and keypad called the universal frontpanel control unit (ufcu). Additionally there is an ac...

Page 33

Operator interface controls 152379 rev c 1–11 on/off switch the pv100s incorporates a maintained position o n /o ff switch located on the front door of the main enclosure. Under normal conditions, the on / off switch is in the o n position. Turning the switch to the o ff position will initiate an im...

Page 34: Communication Features

Introduction 1–12 152379 rev c ac and dc disconnect switches both ac and dc interface enclosures are equipped with lockout hasps for personnel safety. The enclosure doors should not be opened while the pv100s is operating. The switch handles and shafts provide a door interlock for both the ac and dc...

Page 35

Communication features 152379 rev c 1–13 system status and fault reporting basic system status and all fault conditions rising from within the pv100s are reported to the ufcu. The unit stores the time and details of all faults in non-volatile memory. The 4-line lcd will display a hexadecimal value a...

Page 36: Communication Methods

Introduction 1–14 152379 rev c communication methods the pv100s communicates system status information to the user using the following methods. • the front panel control unit (ufcu) display • pc connection (direct or remote) - xantrex solar graphic user interface (gui) software required. Communicati...

Page 37

Communication methods 152379 rev c 1–15 pc connection methods personal computers can be used to access the system status and programming features of the pv100s. A computer can be connected either directly or remotely. 1. Remote connect - uses one of the three kits below. • pots kit - uses a multitec...

Page 38

Introduction 1–16 152379 rev c pots access figure 1-11 illustrates the pv100s connected remotely to a personal computer. Wireless access figure 1-12 illustrates the pv100s connected remotely to a personal computer using a wireless network. Figure 1-11 pots access figure 1-12 wireless access.

Page 39

Communication methods 152379 rev c 1–17 ethernet lan access the pv100s can be remotely accessed through a local area network. Direct access figure 1-14 illustrates the pv100s connected directly to a personal computer. Figure 1-13 ethernet lan access figure 1-14 direct access.

Page 40

Introduction 1–18 152379 rev c gui software features read-only menu the gui software provides access to the following “read-only menu” information. See table 2-2, “read menu descriptions” on page 2–11 for a specific list of available parameters. • operational values • internal metrics write-menu the...

Page 41: Operation

2 operation chapter 2, “operation” contains information on the basic operation of the pv100s 100 kw grid-tied photovoltaic inverter..

Page 42

Operation 2–2 152379 rev c description of system operation overview the pv100s is a fully automated grid-interactive photovoltaic inverter. System startup, system shutdown, pv power tracking, and fault detection scenarios are all governed and monitored by the ccu2 controller within the pv100s. Manua...

Page 43

Description of system operation 152379 rev c 2–3 figure 2-1 operating states flow chart initializing pv contactor opened. Inverter matrix off. Grid contactor open. Green led on. Red off. Power up key disable pv contactor open. Inverter matrix off. Grid contactor open. System state: key disable inver...

Page 44: Operating States

Operation 2–4 152379 rev c operating states a state machine implemented within the ccu2 control software governs the operation of the pv100s with clearly defined transitions between its operating states. There are five steady-state operating states and numerous intermediate transition states. • powe...

Page 45

Operating states 152379 rev c 2–5 shutdown the line interface controller is idle. The ccu2 monitors the status of the pv array and utility grid, waiting in standby until the pv array is available to produce power to the grid. Fault the pv100s has encountered a fault condition. When this happens, reg...

Page 46: Operator Interface

Operation 2–6 152379 rev c operator interface the purpose of the operator interface is to provide a means of communicating critical operational information to and from the unit. This communication occurs between the operator and the ufcu keypad and lcd display or between the operator and a personal ...

Page 47

Operator interface 152379 rev c 2–7 lcd display - initialization screen any time ac power is applied to the unit, the lcd display will cycle through the following displays while the system initializes. Once it’s done with this process, the standard display will appear. Standard display the standard ...

Page 48

Operation 2–8 152379 rev c menu structure the operator interface consists of three levels: • r ead menu - operation information provided to the user from the pv100s. The read menu consists of all operational values, the date and time. These can be viewed any time the pv100s has control power. • w ri...

Page 49

Operator interface 152379 rev c 2–9 r ead menu the r ead menu includes the following information: • current operating state or goal state • fault code (if applicable) • inverter state • line voltage and current • inverter matrix temperature • inverter power • pv state • pv voltage and current • pv p...

Page 50

Operation 2–10 152379 rev c figure 2-5 scrolling through the read menu system: pwr tracking inv: online hit enter or "." "-" value by id# system: pwr tracking inv: online pv: online goal : pwr tracking system: pwr tracking inv: online pv: online ccu vx.Xx fp vx.X system: pwr tracking inv: online pv:...

Page 51

Operator interface 152379 rev c 2–11 table 2-2 read menu descriptions operational parameter description id units current operating state displays as: system: * where * can be any one of the states listed in the description for this parameter. Current system states include the following. Initializing...

Page 52

Operation 2–12 152379 rev c inverter real power displays as: inv kw: inverter real power 11 kw inverter matrix temperature displays as: inv temp: temperature of the inverter igbt matrix heatsink 12 °c pv state displays as: pv: * where * can be any one of the states listed in the description for this...

Page 53

Operator interface 152379 rev c 2–13 r ead -by-id the read-by-id feature supports the ability of the user to view any read or write parameter available within the menu structure. It also provides a means to view data logging and accumulated values information. See table 2-2 for a list of the read me...

Page 54

Operation 2–14 152379 rev c table 2-3 provides a list of the data logging menu parameters. Table 2-4 provides a list of the accumulated values menu parameters. Table 2-3 data logging menu id# usage 300 data log daily rate in minutes 301 id# of 1st parameter to be logged 302 id# of 2nd parameter to b...

Page 55

Operator interface 152379 rev c 2–15 w rite menu the w rite menu includes the following parameters: • ground current max • ppt voltage reference • pv voltage start • pv time (start and stop) • pv power stop • ppt current max % • manual current % • ppt enable • ppt update rate and voltage step table ...

Page 56

Operation 2–16 152379 rev c changing and displaying w rite menu parameter values follow the procedure below to change w rite menu parameters. To change w rite menu parameters: 1. From the standard display or anywhere in the r ead menu, you may access the w rite menu parameters by pressing the m enu ...

Page 57

Operator interface 152379 rev c 2–17 minimum grid voltage displays as: min ac volts%: this parameter sets the trigger point value for “ac voltage low” (0012) fault. If the grid voltage is below this parameter’s value, the fault is triggered. The lower limit of this parameter is restricted by ul requ...

Page 58

Operation 2–18 152379 rev c time delay for pv wake up displays as: pv t start: time delay to transition from pv wake up state to pv on-line state. Once the inverter is in pv wake up mode, it waits for the amount of time determine by this parameter before transitioning into pv on-line mode. During th...

Page 59

Operator interface 152379 rev c 2–19 enable peak power tracker displays as: ppt enable: this parameter switches on and off the power tracker function. When the power tracker is on, the inverter will regulate the bus voltage to optimize output power. When the power tracker is off, the inverter will r...

Page 60

Operation 2–20 152379 rev c commanding goal state changes to change the goal state: 1. From the standard display press the m enu > key. This will prompt the user for a password. The lcd will change the third line of the display to “ type and hit enter ” and fourth line of the display to “ password: ...

Page 61

Operator interface 152379 rev c 2–21 setting the date and time follow the procedure below to change the date and time. To change the date and time: 1. From the standard display, press the m enu > key. This will prompt the user for the password. The lcd will change the third and fourth lines of the l...

Page 62

Operation 2–22 152379 rev c manual state transitions state conditions can also be transitioned manually. Refer to “commanding goal state changes” on page 2–20 for instructions on commanding pv100s goal states for manual transitions. Shutdown → matrix test → shutdown 1. Turn the o n /o ff switch to t...

Page 63: Auto-Restart Feature

Auto-restart feature 152379 rev c 2–23 any state → fault if the pv100s encounters a fault, regardless of operating state, it will transition to the fault state. The pv100s will remain in this state until the fault condition has been remedied and cleared. The fault code number will appear on the firs...

Page 64: Energize Procedure (Startup)

Operation 2–24 152379 rev c energize procedure (startup) to start up the pv100s: 1. Remove any lockout devices from the utility connection circuit breaker and pv disconnect switch. 2. Close the utility connection circuit breaker. 3. Close the ac disconnect switch. 4. Close the dc disconnect switch. ...

Page 65

Computer communications with the pv100s 152379 rev c 2–25 computer communications with the pv100s the pv100s provides multiple options for communicating system status or data logging through a personal computer using the xantrex solar graphic user interface (gui) software. The xantrex solar graphic ...

Page 66

Operation 2–26 152379 rev c installing the graphic user interface (gui) software the following section outlines the minimum system requirements for using the gui software and instructions for installing, configuring, and using the software. Close all programs running on the computer before proceedin...

Page 67

Computer communications with the pv100s 152379 rev c 2–27 starting setup from a command prompt to start the program from a command prompt: 1. Insert the xantrex solar inverter gui – installation cd into your cdrom drive. 2. Click on start and select “run”. 3. Enter the drive letter assigned to your ...

Page 68

Operation 2–28 152379 rev c model specific software installation once the setup program has been started, installation of the gui software can continue. To continue with the gui software installation: 1. After the gui setup splash screen appears (figure 2-11), click on the button i nstall pv100s gui...

Page 69

Computer communications with the pv100s 152379 rev c 2–29 2. Click o k and the following window will appear: if the directory provided in this window is acceptable for the installation, proceed to step 4. If not, click on the c hange d irectory button and provide a new name for the desired destinati...

Page 70

Operation 2–30 152379 rev c 4. Click c ontinue to confirm the program group to be used. The following setup progress indication window will appear. 5. When completed, you will see this: 6. Click ok. The gui is now installed on the computer. Figure 2-15 gui setup progress indicator window figure 2-16...

Page 71

Computer communications with the pv100s 152379 rev c 2–31 running the gui to run the gui software program, log onto the computer and click the following menu items in the order shown below. 1. Window’s s tart button 2. P rograms 3. X antrex _s olar 4. X antrex s olar gui remote/lan connection if no ...

Page 72

Operation 2–32 152379 rev c direct connection if the serial communication port of the inverter is connected to the com1 serial port of the computer, the following screen will appear. Figure 2-18 gui interface screen if connected directly.

Page 73

Computer communications with the pv100s 152379 rev c 2–33 gui configuration - adding inverters once the gui has started, you will need to configure each inverter icon to reflect the appropriate operational parameters for each inverter that is connected to the system. The software automatically defau...

Page 74

Operation 2–34 152379 rev c 5. Fill out the operational configurations information in the form shown in figure 2-21 through figure 2-23. This section has four sub-menu pages to cover the following parameters. A) fill out operational limits information requested. B) click on the pv sub-menu to contin...

Page 75

Computer communications with the pv100s 152379 rev c 2–35 e) fill out the power tracking information requested. F) click on the connections form tab to continue. 6. Fill out the connection - general information in the form in figure 2-24. 7. Click on the telephone fault configuration sub-menu to con...

Page 76

Operation 2–36 152379 rev c 8. Fill out the connection - telephone fault configuration information in the form shown in figure 2-25. 9. Click on the telephone configuration sub-menu to continue. 10. Fill out the connection - telephone configuration information in the form shown in figure 2-26. 11. O...

Page 77

Computer communications with the pv100s 152379 rev c 2–37 gui help the gui software program has a built-in help program. Once the program is started, click on the h elp menu item to start the help program. The help interface is divided into the following sections. • getting started - important: read...

Page 78

2–38.

Page 79: Commissioning

3 commissioning chapter 3, “commissioning” contains information on safely commissioning the pv100s 100 kw grid-tied photovoltaic inverter..

Page 80: Commissioning Procedure

Commissioning 3–2 152379 rev b commissioning procedure this section provides the procedure necessary to safely and correctly commission a pv100s inverter. Summary to commission the pv100s: 1. Ensure the verification tests have been completed and have passed successfully. See the pv100s 100 kw grid-t...

Page 81

Starting the commissioning test file 152379 rev b 3–3 serial number 1. Enter the information required by gui in the white text boxes on the form that appears next. The converter serial number is located on a label placed on the lower-left front of the main inverter enclosure door. 2. Once you finish...

Page 82

Commissioning 3–4 152379 rev b a) if pv voltage is not available and the commissioning test must be stopped, save the commissioning file. This file will be used once pv dc voltage has been applied and verified. 6. Once you finish verifying pv dc voltages, go back to the gui commissioning procedure a...

Page 83

Starting the commissioning test file 152379 rev b 3–5 5. If not, refer to the “setting the date and time” on page 2–21. 6. Scroll thru the parameters and verify that they are present. 7. Once you finish checking the front panel display, go back to the gui commissioning procedure and click on the che...

Page 84

Commissioning 3–6 152379 rev b confirm dc operational parameters 1. Verify the inverters pv settings. 2. Make any necessary changes. 3. Record these values. 4. Once you finish these tasks, go back to the gui commissioning procedure and click on the check box to indicate the task is complete. Go to t...

Page 85

Starting the commissioning test file 152379 rev b 3–7 operate inverter 1. Make sure all doors are closed and locked. 2. Using the front panel or the gui, set the i ppt max percent to 25%. 3. Place the o n /o ff switch (s3) in the o n position. If the pv voltage is above pv start voltage threshold, f...

Page 86

3–8.

Page 87: Troubleshooting

4 troubleshooting chapter 4, “troubleshooting” contains information and procedures for troubleshooting the pv100s 100 kw grid-tied photovoltaic inverter. It provides descriptions of common situations and errors that may occur and provides possible solutions for resolving fault conditions. It also pr...

Page 88: Faults and Fault Codes

Troubleshooting 4–2 152379 rev c faults and fault codes fault states are automatic from any state of operation. In the event of a fault condition, the pv100s will immediately stop processing power and execute an immediate orderly shutdown, open both the main ac and dc contactors, and remain in a fau...

Page 89: Clearing Faults Manually

Clearing faults manually 152379 rev c 4–3 clearing faults manually faults associated with a grid disturbance clear automatically. These faults include: • 0010 (ac frequency low), • 0011 (ac frequency high), • 0012 ac voltage low), and • 0013 (ac voltage high) only. Once the ac voltage and frequency ...

Page 90: Fault Code Descriptions

Troubleshooting 4–4 152379 rev c fault code descriptions table 4-1 provides a complete description of all the fault conditions that may occur on the pv100s. Table 4-1 fault codes error code fault source(s) fault type h=hardware s=software fault description possible causes 0000 no faults n/a n/a n/a ...

Page 91

Fault code descriptions 152379 rev c 4–5 0013 ac voltage high s this fault indicates that the utility grid voltage is above or rose above the maximum allowed value of 110% of nominal vac for greater than 2 seconds, or 137% of nominal vac for greater than 2 cycles. This fault is auto-clearing. Once t...

Page 92

Troubleshooting 4–6 152379 rev c 0021 pv over-voltage s this fault indicates that the pv100s has detected a dc input voltage of greater than the maximum allowed value of 600 vdc. • pv system wiring short • lightning strike on pv system wiring 0023 bus voltage high h this fault indicates that the pv1...

Page 93

Fault code descriptions 152379 rev c 4–7 0040 programming software s this code indicates that the pv100s has detected that the system is in programming mode. This fault does not indicate any malfunction with the pv100s, but is merely an indication that the system software is in the process of being ...

Page 94

Troubleshooting 4–8 152379 rev c 0047 software test s this fault indicates that the pv100s has detected that a software test fault has occurred. This is a simulated fault used for debugging purposes. 0048 bad memory s this fault indicates that the pv100s has detected that the sram dimm on the ccu2 c...

Page 95

Fault code descriptions 152379 rev c 4–9 xx62 matrix temperature s this fault indicates that the pv100s has detected that the temperature of the igbt matrix aluminum heatsink has exceeded the maximum allowed value of 95 °c. • fuses f15 or f16 blown • external cooling fan inoperable • air flow on hea...

Page 96

Troubleshooting 4–10 152379 rev c 0075 shutdown remotely s this fault indicates that the pv100s has detected that the system was commanded via the gui to transition to the shutdown state. This fault is not indicative of a failure or malfunction, but primarily used to disable the system remotely. • r...

Page 97: Preventative

5 preventative maintenance chapter 5, “preventative maintenance” contains information and procedures for performing preventative maintenance on the pv100s 100 kw grid-tied photovoltaic inverter..

Page 98: Maintenance Safety

Preventative maintenance 5–2 152379 rev c maintenance safety prior to following any maintenance procedures, follow the system shutdown and lock-out and tag procedure. Operational safety procedures never work alone when servicing this equipment. A team of two is required until the equipment is proper...

Page 99

Maintenance safety 152379 rev c 5–3 lockout and tag safety requirements mandate that this equipment not be serviced while energized. Power sources for the pv100s must be locked-out and tagged prior to servicing. Each energy source should have a padlock and tag installed on each energy source prior t...

Page 100

Preventative maintenance 5–4 152379 rev c figure 5-1 inverter ac terminal locations in the main inverter enclosure figure 5-2 utility ac terminal connections in the ac interface enclosure tb4-a tb4-b tb4-c tb1 ground bar ac interface enclosure enlargement of terminal connectors in the ac interface e...

Page 101

Maintenance safety 152379 rev c 5–5 figure 5-3 pv terminal locations pv positive cable (tb3-1) pv negative cable (tb3-2) conduit entry from pv array ground (tb3-3).

Page 102: Periodic Maintenance

Preventative maintenance 5–6 152379 rev c periodic maintenance xantrex technology recommends that the following preventative maintenance procedures be carried out on the pv100s. Monthly intervals or as required perform the following preventative maintenance tasks on a monthly basis or as required. A...

Page 103

Periodic maintenance 152379 rev c 5–7 six-month intervals perform the following preventative maintenance tasks on a six-month basis or as required. Enclosure seals ❐ inspect the enclosure access panel seal. If damaged, replace with equivalent closed cell foam gasket. Call your xantrex technology dis...

Page 104

5–8.

Page 105: Specifications

A specifications appendix a provides the environmental and electrical specifications for the pv100s 100 kw grid-tied photovoltaic inverter..

Page 106: System Specifications

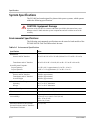

Specifications a–2 152379 rev c system specifications the pv100s has been designed for photovoltaic power systems, which operate within the following specifications. Environmental specifications the following environmental specifications are the same for both models of the pv100s 100 kw grid-tied ph...

Page 107

System specifications 152379 rev c a–3 electrical specifications table a-2 provides the ac and dc specifications for the pv100s. Over voltage, under voltage and frequency ranges table a-3 provides the over voltage, under voltage, over-frequency, and under- frequency detection limits for the pv100s. ...

Page 108

Specifications a–4 152379 rev c wire gauge and torque requirements table a-4 provides acceptable wire gauges, bolt sizes, and torque values for ac terminal connections. *see cautionary note in the pv100s 100 kw grid-tied photovoltaic inverter planning and installation manual regarding hardware lengt...

Page 109

Appendix a schematics 152379 rev c a-5 figure a-1 electrical diagram (sample).

Page 110

Schematics appendix a a-6 152379 rev c figure a-2 pv100s-480 schematic for main power distribution (152316 e1).

Page 111

Appendix a schematics 152379 rev c a-7 figure a-3 pv100s-480 schematic for control power distribution (152316 e2).

Page 112

Schematics appendix a a-8 152379 rev c figure a-4 pv100s-480 schematic for converter control unit (152316 e3).

Page 113

Appendix a schematics 152379 rev c a-9 figure a-5 pv100s-208 schematic main power distribution (152376 c1).

Page 114

Schematics appendix a a-10 152379 rev c figure a-6 pv100s-208 schematic for control power distribution (152376 c2).

Page 115

Appendix a schematics 152379 rev c a-11 figure a-7 pv100s-208 schematic for converter control unit (152376 c3).

Page 116

Schematics appendix a a-12 152379 rev c this page intentionally left blank..

Page 117: Xantrex Limited Warranty

152379 rev c wa–1 warranty and product information xantrex limited warranty pv100s grid tie inverter (pv series inverter) 1. What does this warranty cover and how long does it last? This limited warranty is provided by xantrex technology inc. (“xantrex”) and covers defects in workmanship and materia...

Page 118

Warranty and return wa–2 152379 rev c 4. Product disclaimer this limited warranty is the sole and exclusive warranty provided by xantrex in connection with your xantrex product and is, where permitted by law, in lieu of all other warranties, conditions, guarantees, representations, obligations and l...

Page 119: Product Registration

Warranty and return 152379 rev c wa–3 product registration to ensure the fastest possible service, please ensure your system information submitted to xantrex. Please fill the required information in and send a copy of this page to xantrex technology inc. Fax number: 925 455 0382 mail to: xantrex tec...

Page 120

Warranty and return wa–4 152379 rev c.

Page 121: Index

A ac interface enclosure 1–8 accumulated values 1–18 anti-island protection 1–5 auto-restart feature 2–23 autorun 2–26 c clearing faults manually 4–3 command prompt 2–27 commissioning 3–2 communication enclosure 1–9 communications 2–25 configurable parameters 1–18 controls 1–10 converter control uni...

Page 122

Index ix–2 152379 rev c p period maintenance monthly 5–6 six month intervals 5–7 power distribution panel 1–7 power electronics matrix 1–7 pv ground fault detection 1–5 r remote monitor and control features 1–18 remote/lan connection 2–31 running the gui 2–31 s self-protection features 1–2 shutdown ...

Page 124

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 152379 rev c pc printed in usa.