- DL manuals

- Xantrex

- Inverter

- PV100S-208

- Planning And Installation Manual

Xantrex PV100S-208 Planning And Installation Manual - Planning

Summary of PV100S-208

Page 1

Pv100s 100 kw grid-tied photovoltaic inverter pv100s-208 pv100s-480 planning and installation manual.

Page 3: Pv100S 100 Kw Grid-Tied

Pv100s 100 kw grid-tied photovoltaic inverter planning and installation manual.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to 1.5 mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Manual

152315 rev c iii about this manual purpose the purpose of this planning and installation manual is to provide explanations and procedures for planning and installing the pv100s 100 kw grid-tied photovoltaic inverter. Scope the manual provides safety guidelines, detailed planning and setup informatio...

Page 6: Conventions Used

About this manual iv 152315 rev c conventions used the following conventions are used in this guide. This manual contains information for two models of the pv100s 100 kw grid- tied photovoltaic inverter. One model is designed to operate with a 208 vac utility input, and the other model is designed t...

Page 7: Abbreviations and Acronyms

About this manual 152315 rev c v abbreviations and acronyms related information you can find more information about xantrex technology inc. As well as its products and services at www.Xantrex.Com. Ansi american national standards institute ccu2 converter control unit 2 cfm cubic feet per minute cw c...

Page 8

Vi.

Page 9

152315 rev c vii important safety instructions save these instructions - do not discard this manual contains important safety instructions for the pv100s that shall be followed during installation and maintenance procedures. Warning: shock hazard read and keep this planning and installation manual f...

Page 10: General Safety Precautions

Safety viii 152315 rev c general safety precautions 1. When installing the pv100s use only components recommended or sold by xantrex. Doing otherwise may result in a risk of fire, electric shock, injury to persons, and will void the warranty. 2. Do not attempt to operate the pv100s if it has been dr...

Page 11

Safety 152315 rev c ix terminals must use a crimp-on type ring terminal or compression-type lug. The terminals are one bolt per pole. See figure 3-14 on page 3–15 for the location of these terminals . 5. The ac power conductor wiring interfacing with the ac terminals in the main inverter enclosure a...

Page 12: Lockout and Tag

Safety x 152315 rev c operational safety procedures never work alone when servicing this equipment. A team of two is required until the equipment is properly de-energized, locked-out and tagged, and verified de- energized with a meter. Thoroughly inspect the equipment prior to energizing. Verify tha...

Page 13

Safety 152315 rev c xi de-energize/isolation procedure the following procedure should be followed to de-energize the pv100s for maintenance. To isolate the pv100s: 1. Turn the on / off switch to the off position. 2. Open the dc interface disconnect switch. 3. Open the ac interface disconnect switch....

Page 14

Xii.

Page 15: Contents

152315 rev c xiii important safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii 1 introduction description of the pv100s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 system specifications ...

Page 16

Contents xiv 152315 rev c 3 installation equipment required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2 unloading - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2 ...

Page 17: Tables

152315 rev c xv table 1-1 electrical specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4 table 1-2 over/under voltage and over/under frequency ranges - - - - - - - - - - - - - - - - - - - - - - 1–4 table 1-3 environmental specifications - - - - ...

Page 18

Xvi.

Page 19: Figures

152315 rev c xvii figure 1-1 dimensions (not to scale) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3 figure 1-2 pv100s operator interface components- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7 figure 1-3 on/off switch - - - - - - - -...

Page 20

Figures xviii 152315 rev c figure 3-18 ac terminal connections from the utility- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–18 figure 3-19 pv array cable routing and terminations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–19 figure 3-20 telephone cable routing - -...

Page 21: Introduction

1 introduction chapter 1, “introduction” provides information about the features and functions of the pv100s 100 kw grid-tied photovoltaic inverter..

Page 22: Description of The Pv100S

Introduction 1–2 152315 rev c description of the pv100s the pv100s 100 kw grid-tied photovoltaic inverter is a ul 1741 listed, utility interactive, three-phase power conversion system for grid-connected photovoltaic arrays with a power rating of 100 kw. Designed to be easy to install and operate, th...

Page 23

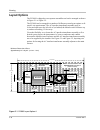

Description of the pv100s 152315 rev c 1–3 figure 1-1 dimensions (not to scale) warning: th is is a class a product . In a domestic environ m e nt this product may cause radio interference s, in which case, the user m a y be requi red to take adequate measures. 60 ¼" (150.5 cm) 44.0" (110 cm) 49 7/8...

Page 24: System Specifications

Introduction 1–4 152315 rev c system specifications the pv100s has been designed for photovoltaic power systems, which operate within the following specifications. Electrical specifications table 1-1 provides the ac and dc specifications for the pv100s. Over voltage, under voltage and frequency rang...

Page 25

System specifications 152315 rev c 1–5 system ground requirements this product is intended to be installed as part of a permanently grounded electrical system per the national electric code ansi/nfpa 70. A copper ground rod must be installed within three feet of the pv100s enclosures and connected t...

Page 26

Introduction 1–6 152315 rev c environmental specifications the following environmental specifications are the same for both models of the pv100s 100 kw grid-tied photovoltaic inverter. Table 1-3 environmental specifications specification value dimensions inverter and dc interface transformer and ac ...

Page 27: Operator Interface Controls

Operator interface controls 152315 rev c 1–7 operator interface controls operator interface controls are located on the front door of the main inverter enclosure. These controls include an on/off switch, 4-line lcd display and keypad called the universal frontpanel control unit (ufcu). Additionally ...

Page 28

Introduction 1–8 152315 rev c on/off switch the pv100s incorporates a maintained position on / off switch located on the front door of the main enclosure. Under normal conditions, the on / off switch is in the on position. Turning the switch to the off position will initiate an immediate controlled ...

Page 29: Communication Features

Communication features 152315 rev c 1–9 ac and dc disconnect switches both ac and dc interface enclosures are equipped with lockout hasps for personnel safety. The enclosure doors should not be opened while the pv100s is operating. The switch handles and shafts provide a door interlock for both the ...

Page 30

Introduction 1–10 152315 rev c system status and fault reporting basic system status and all fault conditions rising from within the pv100s are reported to the ufcu. The unit stores the time and details of all faults in non-volatile memory. The 4-line lcd will display a hexadecimal value and a brief...

Page 31: Communication Methods

Communication methods 152315 rev c 1–11 communication methods the pv100s communicates system status information to the user using the following methods. • the front panel control unit (ufcu) display • pc connection (direct or remote) - xantrex solar graphic user interface (gui) software required. Co...

Page 32

Introduction 1–12 152315 rev c pc connection methods personal computers can be used to access the system status and programming features of the pv100s. A computer can be connected either directly or remotely. 1. Remote connect - uses one of the three kits below. • pots kit - uses a multitech® 56k mo...

Page 33

Communication methods 152315 rev c 1–13 pots access figure 1-7 illustrates the pv100s connected remotely to a personal computer. Wireless access figure 1-8 illustrates the pv100s connected remotely to a personal computer using a wireless network. Figure 1-7 pots access figure 1-8 wireless access.

Page 34

Introduction 1–14 152315 rev c ethernet lan access the pv100s can be remotely accessed through a local area network. Direct access figure 1-10 illustrates the pv100s connected directly to a personal computer. Figure 1-9 ethernet lan access figure 1-10 direct access.

Page 35: Planning

2 planning chapter 2, “planning” provides information to help plan the installation of the pv100s 100 kw grid-tied photovoltaic inverter..

Page 36

Planning 2–2 152315 rev c overview of pv100s installation planning planning for a system requires complete understanding of all the components that are involved to successfully install the pv100s to meet the required national, state, and local codes. Definition a power system (such as the pv100s) is...

Page 37: Pv Planning

Pv planning 152315 rev c 2–3 large gauge wire must conform to the minimum bend radius specified in the nec, article 373-6b, ninth edition. Take care to keep the wire bundles away from any sharp edges which may damage wire insulation over time. All conductors should be made of copper and rated for 90...

Page 38: Ground Requirements

Planning 2–4 152315 rev c ground requirements this product is intended to be installed as part of a permanently grounded electrical system per national electric code ansi/nfpa 70. A copper ground rod must be installed within three feet of the pv100s enclosure. This is the single point earth ground f...

Page 39

Electrical diagrams and schematics 152315 rev c 2–5 utility-side neutral does not affect the operation of the inverter, however connection of the neutral on the inverter-side does affect the operation and must be left floating or disconnected. Single-phase, grounded loads which may be present betwee...

Page 40: Layout Options

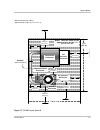

Planning 2–6 152315 rev c layout options the pv100s is shipped as two separate assemblies and can be arranged as shown in figure 2-1 or figure 2-2. The pv100s can be arranged in a number of different system layout options to fit specific site requirements. The ac interface/transformer assembly may b...

Page 41

Layout options 152315 rev c 2–7 figure 2-2 pv100s layout option b transformer enclosure ac interface enclosure dc interface enclosure inverter enclosure communications enclosure 36" minimum clearance 12" 12" conduit minimum clearance minimum clearance (not to exceed 15') 7 ft (2.1 m) 9 ft (2.7 m) 36...

Page 42: Conduit Penetration

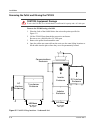

Planning 2–8 152315 rev c conduit penetration the following illustrations show the recommended locations for electrical conduit entry into the pv100s enclosures. These drawings are to be used for system planning purposes, such that the shaded areas are representative of the maximum allowable area an...

Page 43

Conduit penetration 152315 rev c 2–9 figure 2-4 inductor enclosure conduit entry, left side figure 2-5 transformer enclosure conduit entry, right side 6" 12" 6" 2" 6" (15 cm) 2" (5 cm) 12" (30 cm) 6" (15 cm) 2" 6" 12" 6" 6" (15 cm) 2" (5 cm) 12" (30 cm) 6" (15 cm).

Page 44

Planning 2–10 152315 rev c figure 2-6 ac interface enclosure conduit entry, left side figure 2-7 dc interface enclosure, bottom side figure 2-8 communications enclosure conduit entry, bottom side 8" (20 cm) ac disconnect switch (s1) 8" (20 cm) 1" (2.5 cm) 5" (13 cm) backside of transformer enclosure...

Page 45: Conductor and Conduit Sizing

Conductor and conduit sizing 152315 rev c 2–11 conductor and conduit sizing all wiring methods and materials shall be in accordance with the national electrical code ansi/nfpa 70. When sizing conductors and conduits interfacing to the pv100s, both shall be in accordance with the national electric co...

Page 46

Planning 2–12 152315 rev c step 3. Size the cable. This example assumes that the conduit length is less than 24 inches. Nec table 310.16 (ninth edition) indicates the temperature correction factor for 90 °c thhn cable in a 50 °c ambient is 0.82. With a required ampacity from step 1 above of 347 amps...

Page 47: Anchoring The Pv100S

Anchoring the pv100s 152315 rev c 2–13 anchoring the pv100s the pv100s is designed to be installed in either an indoor or outdoor location. It must be placed on and anchored to a level concrete floor or pad. The concrete floor or pad, upon which the pv100s is anchored, must be structurally designed ...

Page 48

Planning 2–14 152315 rev c the floor or pad should either be pre-drilled to accept masonry anchors or have pre-installed anchoring bolts. Figure 2-10 ac interface/transformer anchor bolt pattern (not to scale) ¾" (1.9 cm) (x6) 25" (63.5 cm) 17 ½" (44 cm) 29" (73.7 cm).

Page 49: Installation

3 installation chapter 3, “installation” describes the procedures needed to install the pv100s 100 kw grid-tied photovoltaic inverter. This section includes unpacking and moving instructions, mounting instructions, and cabling instructions..

Page 50: Equipment Required

Installation 3–2 152315 rev c equipment required the following is a list of required tools and equipment to aid in the installation of the pv100s. This list is not a comprehensive list, but is intended to help identify the minimum recommended tools and equipment used during the installation. • forkl...

Page 51

Unloading 152315 rev c 3–3 moving the pv100s to move the pv100s while it is still inside the shipping crates: 1. Place the forks of the forklift below the shipping crate at the points specified on the shipping crate. 2. Lift the main inverter and the ac interface enclosure and transformer enclosure ...

Page 52

Installation 3–4 152315 rev c removing the pallet and moving the pv100s to move the pv100s using a forklift: 1. Place the forks of the forklift below the unit at the points specified in figure 3-2. 2. Lift the pv100s from beneath the respective enclosures. Be sure to use a forklift with a 26" fork s...

Page 53

Mounting and anchoring the units 152315 rev c 3–5 mounting and anchoring the units to mount and anchor the pv100s: 1. Predrill the floor or pad to accept 1/2" diameter masonry anchors or ensure it has pre-installed anchoring bolts that will fit the 5/8" mounting holes. 2. Lift the main inverter from...

Page 54

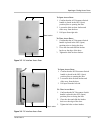

Installation 3–6 152315 rev c opening or closing access doors to lock or unlock the front door on the main inverter: 1. Use the 7 mm triangle key provided with the unit. A) insert the key in the lock and turn counterclockwise to open; clockwise to lock. B) pull front door open from the right side. F...

Page 55

Opening or closing access doors 152315 rev c 3–7 figure 3-5 ac interface access door figure 3-6 dc interface access door door latches to open access door: 1. Confirm that the ac disconnect switch handle is placed in the off (open) position prior to opening the door. 2. Loosen the bolts on door latch...

Page 56

Installation 3–8 152315 rev c figure 3-7 transformer access panels figure 3-8 inductor access panels transformer access panel to remove the access panel : loosen and remove the 1/4" self-tapping sheet metal screws (x6). To replace the access panel : replace and tighten the 1/4" self-tapping sheet me...

Page 57: Conduit Installation

Conduit installation 152315 rev c 3–9 conduit installation given the flexible nature of the system, conduit installation will be dependent upon the final configuration of the system. Procurement and installation of the conduit, therefore, is the responsibility of the installer. Since the layout will...

Page 58: Wiring - General

Installation 3–10 152315 rev c wiring - general all wiring methods and materials shall be in accordance with the national electrical code ansi/nfpa 70. When sizing conductors and conduits interfacing to the pv100s, both shall be in accordance with the national electric code ansi/nfpa 70, as well as ...

Page 59

Wiring - general 152315 rev c 3–11 overcurrent protection ac overcurrent protection for the utility interconnect (grid-tie) must be provided by the installer as part of the pv100s installation. Conductor termination the pv100s has terminals and bus bars for making all wiring connections required for...

Page 60

Installation 3–12 152315 rev c wire gauge and torque requirements table 3-1 provides acceptable wire gauges, bolt sizes, and torque values for ac terminal connections. Table 3-2 provides acceptable wire gauges, bolt sizes, and torque values to be connected to the pv100s dc terminal connections. Grou...

Page 61

Wiring - general 152315 rev c 3–13 chassis ground the chassis ground is a copper bus bar in the main inverter enclosure and has 3/8-16" bolts for terminating the ac ground. The ground conductor size depends on the size of the main circuit breaker. Nec table 250.122 (ninth edition) requires that the ...

Page 62: Wiring - Specific

Installation 3–14 152315 rev c inter-tie. The pv100s is a balanced, three-phase, current-sourcing inverter and only operates with the presence of a stable utility voltage. The transformer is also supplied with a neutral connection on the utility interconnect. Connection of this utility-side neutral ...

Page 63

Wiring - specific 152315 rev c 3–15 3. In addition to the power conductors, route the ac sense harness assembly (xantrex p/n 1-152403-01) between the main inverter to the ac interface/transformer assembly. Prior to completing the installation of the ac sense harness, secure the harness to the ac pow...

Page 64

Installation 3–16 152315 rev c 5. Connect the ac power conductors in the main inverter enclosure at tb4-a (a phase), tb4-b (b phase), and tb4-c (c phase) with a box connector using a 5/16" hex screw. This hardware should be tightened to a torque value of 275 in-lb (31 nm). Connect the ground conduct...

Page 65

Wiring - specific 152315 rev c 3–17 6. The ac sense harness is pre-terminated within the ac interface/transformer assembly and the opposite end is mated with its 9-pin plug to the corresponding 9-pin jack within the main inverter enclosure. See figure 3-17. 7. Replace the access panels on the front ...

Page 66

Installation 3–18 152315 rev c 4. Connect the neutral conductor at tb6. Connect the ground conductor at tb2. Terminations for the neutral and ground conductors within the ac interface enclosure at the tb6 and tb2 locations are made with 3/8-16" hardware. Cables to these terminals must use a crimp-on...

Page 67

Wiring - specific 152315 rev c 3–19 pv array connections to make the connections from the pv array/combiner to dc interface enclosure: 1. Remove the door clamps and open the door to the dc interface enclosure. 2. Route the pv array cables conductors positive (pv+), negative (pv-), and pv gnd through...

Page 68: Pc Communications

Installation 3–20 152315 rev c pc communications personal computers can be used to access the system status and programming features of the pv100s. A computer can be connected either directly or remotely. 1. Remote connect - uses one of the three kits below. • pots kit - uses a multitech® 56k modem,...

Page 69

Pc communications 152315 rev c 3–21 establishing a pots connection to connect a personal computer using the pots connection: 1. Ensure the personal computer to be used has a 56k modem installed. 2. Open the communications enclosure. 3. Plug the local phone line into the rj11 port on the sa2 surge ar...

Page 70

Installation 3–22 152315 rev c establishing wireless connection to connect a personal computer using the gsm wireless modem: 1. Ensure the personal computer has the appropriate hardware installed to support this feature. 2. Install the gui software following the instructions in the pv100s 100 kw gri...

Page 71

Pc communications 152315 rev c 3–23 direct connection the direct connection provides the means to use the features of the gui by connecting a pc directly to the ccu2. This allows field personnel to monitor and control the inverter from a nearby laptop computer directly connected by a serial cable. T...

Page 72

Installation 3–24 152315 rev c figure 3-22 direct connect installation 5 db25-to-db25 gender changer adapter db25/db9 serial cable re232/fo converter 3.

Page 73: Verification

4 verification chapter 4, “verification” provides a checklist to ensure the installation of the pv100s is correct and complete..

Page 74

Verification 4–2 152315 rev c verification procedure summary the following procedures are intended to verify correct installation and proper wiring of the pv100s. Prior to performing the following verification steps on the pv100s, review all safety requirements and procedures outlined in this manual...

Page 75

Visual inspection of mechanical connections 152315 rev c 4–3 visual inspection of mechanical connections to perform a visual inspection of the pv100s mechanical connections: visual inspection of electrical connections to perform a visual inspection of the pv100s electrical connections: 1. Ensure tha...

Page 76: Corrective Action

Verification 4–4 152315 rev c visual inspection, isolation transformer wye/wye to perform a visual inspection of the isolation transformer wye/wye: corrective action perform after initial inspection (if required): 1. Correct any necessary repairs pertaining to the previous inspection steps. 2. Repla...

Page 77: Schematics

A schematics appendix a contains useful schematics to aid with installation..

Page 78

Schematics a–2 152315 rev c this page intentionally left blank..

Page 79

Appendix a schematics 152315 rev c a-3 figure a-1 electrical diagram (sample).

Page 80

Schematics appendix a a-4 152315 rev c figure a-2 pv100s-480 schematic for main power distribution (152316 e1).

Page 81

Appendix a schematics 152315 rev c a-5 figure a-3 pv100s-480 schematic for control power distribution (152316 e2).

Page 82

Schematics appendix a a-6 152315 rev c figure a-4 pv100s-480 schematic for converter control unit (152316 e3).

Page 83

Appendix a schematics 152315 rev c a-7 figure a-5 pv100s-208 schematic main power distribution (152376 c1).

Page 84

Schematics appendix a a-8 152315 rev c figure a-6 pv100s-208 schematic for control power distribution (152376 c2).

Page 85

Appendix a schematics 152315 rev c a-9 figure a-7 pv100s-208 schematic for converter control unit (152376 c3).

Page 86

Schematics appendix a a-10 152315 rev c this page was intentionally left blank..

Page 87: Index

A abbreviations and acronyms v access doors 3 – 6 anchoring 2 – 13 array grounding 3 – 13 c ccu2 v cfm v chassis grounds 3 – 13 clearance 2 – 2 communication 2 – 4 communications 3 – 20 components 2 – 2 conductor and conduit sizing 2 – 11 conduit installation 3 – 9 conduit penetration 2 – 8 conduits...

Page 88

Index ix–2 152315 rev c r removing the pallet 3 – 4 s safety vii t torque and wire gauge specifications 3 – 12 u ufcu v unloading 3 – 2 unpacking 3 – 3 utility side isolation transformer requirements 1 – 5 v verification procedure summary 4 – 2 visual inspection of electrical connections 4 – 3 visua...

Page 90

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 152315 rev c printed in usa.