- DL manuals

- Xantrex

- Inverter

- RS3000

- Installation Manual

Xantrex RS3000 Installation Manual

Summary of RS3000

Page 1

Rs3000 sine wave inverter/charger installation guide rs3000

Page 3: Installation Guide

Rs3000 sine wave inverter/charger installation guide.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to one mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Guide

975-0171-01-01 i about this guide purpose the rs3000 sine wave inverter/charger installation guide describes the procedure for installing the rs3000 sine wave inverter/charger (rs3000). Scope the installation guide provides safety guidelines, detailed planning and setup information, and procedures f...

Page 6: Conventions Used

About this guide ii 975-0171-01-01 conventions used the following conventions are used in this guide. Symbols used the following symbols are used on the product labels or in this guide. Abbreviations and acronyms for a listing of abbreviations and acronyms, refer to the rs3000 sine wave inverter/cha...

Page 7: Related Information

About this guide iii 975-0171-01-01 related information for related materials on this xanbus-enabled product and its available accessories, see also: rs3000 sine wave inverter/charger operation guide (975-0170-01-01) automatic generator start owner’s guide (975-0082-01-01) system control panel owner...

Page 8

Iv 975-0171-01-01.

Page 9

975-0171-01-01 v important safety instructions read and save these instructions the rs3000 sine wave inverter/charger installation guide contains important safety instructions. Before you install and use your rs3000 sine wave inverter/charger, be sure to read, understand, and save these safety instr...

Page 10

Safety vi 975-0171-01-01 6. Do not disassemble the inverter/charger; it does not contain user serviceable parts. Take it to a qualified service person when service or repair is required. Incorrect reassembly may result in a risk of electrical shock or fire. Internal capacitors remain charged after a...

Page 11: Explosive Gas Precautions

Safety 975-0171-01-01 vii explosive gas precautions 1. To reduce the risk of battery explosion, follow these instructions and those published by the battery manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery. Review the cautionary markings on these prod...

Page 12: Fcc Information to The User

Safety viii 975-0171-01-01 7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a lead-acid battery. A lead-acid battery can produce a short-circuit current high enough to weld a ring or the like to metal, causing a severe burn. 8. Never charge a frozen b...

Page 13: Contents

975-0171-01-01 ix important safety instructions explosive gas precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii personal precautions when working with batteries - - - - - - - - - - - - - - - - - - - - - - - - - - vii fcc information to the user - -...

Page 14

Contents x 975-0171-01-01 step 2: mounting the inverter/charger - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19 considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19 step 3: connecting the ac input and ac output wires - - -...

Page 15: Figures

975-0171-01-01 xi figure 1 typical xanbus system diagram- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3 figure 2 typical recreational vehicle electrical system - - - - - - - - - - - - - - - - - - - - - 7 figure 3 rs3000 hardware materials as shipped - - - - - - - - - - - - - - - - - ...

Page 16

Xii.

Page 17: Installation

Installation the installation guide provides detailed information for installing the rs3000 sine wave inverter/charger and the battery temperature sensor, wiring the inverter/charger to the ac and dc circuits, and connecting the inverter/charger to the xanbus® system. The rs3000 is a xanbus-enabled ...

Page 18: Installation Information

Installation 2 975-0171-01-01 installation information before you begin the installation before beginning your installation: • read the entire installation guide so you can plan the installation from beginning to end. • read the xanbus system installation guide to plan your network requirements. • a...

Page 19: About The Xanbus System

Installation 975-0171-01-01 3 about the xanbus system the xanbus system includes the rs3000 sine wave inverter/charger and other xanbus-enabled devices, as shown in figure 1, “typical xanbus system diagram”. Each xanbus-enabled device interacts and communicates with the other devices on the network,...

Page 20

Installation 4 975-0171-01-01 xanbus enabled the xanbus-enabled designation means that this product will work on a xanbus network. Xanbus-enabled products are: • easy to use. The xanbus network simplifies operation and automates routine tasks. • reliable. Software control eliminates analog signallin...

Page 21: Planning The Installation

Installation 975-0171-01-01 5 planning the installation this section provides information to help you plan for a basic installation of the rs3000. As your system configuration is determined, record the details in information about your system on page wa-4 of the rs3000 sine wave inverter/charger ope...

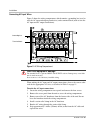

Page 22: Planning

Installation 6 975-0171-01-01 planning ac, dc, and network components for a successful installation, you need to plan for ac, dc, and network components of the power system. The ac and dc components are described in this section and illustrated in figure 2 on page 7. Ac components include: • ac inpu...

Page 23

Installation 975-0171-01-01 7 figure 2 typical recreational vehicle electrical system important: figure 2 does not show all required grounding or overcurrent protection. Sensing and control xanbus-enabled devices generator isolator non-inverter loads automatic generator start system control panel si...

Page 24

Installation 8 975-0171-01-01 ac components ac input ac input to the rs3000 can be supplied from a split-phase or dual-input ac source such as the utility grid (power company), a generator, or the output of a transfer switch. The rs3000 can be operated from the following types of 120 volt 60 hz ac s...

Page 25

Installation 975-0171-01-01 9 ac disconnect and over-current protection device to meet csa, ul, and electrical code requirements, and to protect system wiring, the ac inputs and outputs of the inverter/charger must be provided with over- current protection on both the ac input and output. This prote...

Page 26

Installation 10 975-0171-01-01 tested gfcis compliance with ul standards requires that xantrex test and recommend specific gfcis for use on the output of the inverter. Table 1 lists models that have been tested and will function properly when connected to the ac output of the rs3000. Disconnect devi...

Page 27

Installation 975-0171-01-01 11 size of input wiring wire size must be coordinated with the overcurrent protection provided ahead of the wire involved, in accordance with the electrical codes or regulations applicable to your installation. Therefore, the wiring used between the ac input circuit break...

Page 28

Installation 12 975-0171-01-01 ac output neutral bonding the ac source must have its neutral conductor bonded to ground. Bonding system the rs3000 provides a system that automatically connects the neutral conductor of the inverter’s ac output circuit to safety ground (“bonding” it) while the inverte...

Page 29

Installation 975-0171-01-01 13 dc components batteries the rs3000 system requires a 12 volt, lead-acid deep-cycle battery or group of batteries to provide the dc current that the inverter/charger converts to ac power. The battery may be a flooded, gel, or agm type. See “battery information” on page ...

Page 30

Installation 14 975-0171-01-01 dc cabling definition dc cabling includes all of the cables and connectors between the batteries, the dc disconnect and over-current protection device, and the inverter/charger. Type all installations require multi-strand insulated cables. The dc cables must be copper ...

Page 31

Installation 975-0171-01-01 15 unpacking and inspecting the inverter/charger materials list contents the following materials are in the shipping box: • rs3000 sine wave inverter/charger • dc terminal covers (one red, one black) and four screws • bag containing dc terminal hardware: • two flat washer...

Page 32

Installation 16 975-0171-01-01 3. Save your purchase receipt to use as proof-of-purchase. This is required if the inverter/charger should need warranty service. 4. Save the original shipping carton and packing materials. If the inverter/ charger needs to be returned for service, it should be shipped...

Page 33

Installation 975-0171-01-01 17 installing the inverter/charger overview this section provides detailed information on installing the rs3000. The overall procedure is divided into eight steps: step 1: choosing a location for the inverter/charger step 2: mounting the inverter/charger step 3: connectin...

Page 34

Installation 18 975-0171-01-01 dry do not allow water or other fluids to drip or splash on the inverter. Do not expose to rain, snow or water. Cool normal air temperature should be between 32 °f and 122 °f (0 °c and 50 °c)—the cooler the better within this range. Clearance allow as much space around...

Page 35

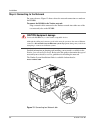

Installation 975-0171-01-01 19 step 2: mounting the inverter/charger considerations before mounting the rs3000, take the following two factors into account. 1. The weight of the inverter/charger requires two people to install it. 2. Mounting considerations are shown in figure 4 on page 20. The rs300...

Page 36

Installation 20 975-0171-01-01 figure 4 mounting orientations orientation approved mounting orientation? Comment desktop mount yes upside-down mount maybe suitable only for applications with no risk of condensation or dripping water. Wall mount dc on left yes on a vertical surface with dc terminals ...

Page 37

Installation 975-0171-01-01 21 step 3: connecting the ac input and ac output wires general ac wiring considerations ac and dc wiring separation do not mix ac and dc wiring in the same conduit or panel. Consult the applicable installation code for details about dc wiring and ac wiring in vicinity to ...

Page 38

Installation 22 975-0171-01-01 connecting ac input wires figure 5 shows the wiring compartment, which contains a grounding bus (used to wire the ac input and output gound wires) and a terminal block (used to wire the ac input and ac output connections). When making the ac input and ac output connect...

Page 39

Installation 975-0171-01-01 23 7. Using a 1/4" blade slot screwdriver, loosen the terminal screws on the terminals. Do not remove the screws. 8. Connect the line and neutral wires to the input terminals (labeled ac input on the terminal block, figure 5 on page 22). Connect line 1 to l1, neutral to n...

Page 40

Installation 24 975-0171-01-01 connecting the ac output wires to make the ac output wiring connections: 1. Remove one of the ac knockouts from the front or side of the unit. Do not leave the knockout inside the wiring compartment. 2. Install a strain-relief clamp in the ac knockout and run the ac wi...

Page 41

Installation 975-0171-01-01 25 step 4: connecting the dc cables dc connection precautions recommended cable sizes and lengths and fuse size for recommended dc cables and fuse size, see table 3 on page 14. Preparing the cables to prepare the dc cables: 1. Cut the negative and positive cables to the r...

Page 42

Installation 26 975-0171-01-01 guidelines for routing the dc cables follow these guidelines to ensure maximum performance. • do not attempt to use the chassis in place of the battery negative connection for grounding. The inverter requires a reliable return path directly to the battery. • to reduce ...

Page 43

Installation 975-0171-01-01 27 connecting the dc cables to the inverter/charger to connect the dc cables: 1. Route the dc cables from the battery bank to the inverter/charger. Observe the “guidelines for routing the dc cables” on page 26. 2. Install a dc fuse and disconnect switch or a dc circuit br...

Page 44

Installation 28 975-0171-01-01 7. Before proceeding, check that the cable polarity is correct: positive (+) on the inverter/charger is connected to the positive (+) on the battery, and negative (–) cable is connected to the negative (–) terminal on the inverter/charger. 8. Connect the other end of t...

Page 45

Installation 975-0171-01-01 29 dc grounding the chassis ground point on the inverter/charger is used to connect the chassis of the inverter/charger to your system’s dc grounding point, as required by regulations for some installations. Use copper wire that is either bare or provided with green insul...

Page 46

Installation 30 975-0171-01-01 step 5: connecting the battery temperature sensor (bts) installing a battery temperature sensor (bts) extends the life of a battery by preventing overcharging in warm temperatures and undercharging in cold temperatures. With a bts monitoring the battery temperature, th...

Page 47

Installation 975-0171-01-01 31 mounting to the negative battery terminal to mount the sensor on the negative battery terminal: see figure 10. 1. Select the battery to be monitored. The bts should be connected to the battery bank that is directly connected to the inverter/charger. 2. Switch off all d...

Page 48

Installation 32 975-0171-01-01 figure 11 connecting the bts cable to battery temp. Jack.

Page 49

Installation 975-0171-01-01 33 mounting to the side of the battery case to mount the sensor on the battery case: see figure 12. 1. Select the battery to be monitored. The bts should be connected to the battery bank that is directly connected to the inverter/charger. 2. Select a side suitable for att...

Page 50

Installation 34 975-0171-01-01 step 6: connecting to the network for your reference, figure 13 shows where the network connections are made on the rs3000. To connect the rs3000 to the xanbus network: u plug a network cable connected to the xanbus network into either one of the two network jacks on t...

Page 51

Installation 975-0171-01-01 35 step 7: performing checks prior to initial start-up before testing your installation, ensure these conditions are met: p chassis and ac grounds are properly installed. P ac input connections and ac output connections are wired correctly on the terminal block and not re...

Page 52

Installation 36 975-0171-01-01 step 8: testing your installation there are several tests to be performed for testing your installation. These tests will verify that: • the rs3000 works in invert mode • the rs3000 works in charge mode • the rs3000 works in ac bypass mode if the test fails at any poin...

Page 53

Installation 975-0171-01-01 37 3. Press the inverter enable button. Verify that: • the inverter enable button light illuminates • the invert on light illuminates 4. Connect the rs3000 to the test load by closing the ac breaker that controls the circuit that the test load is connected to. If the ligh...

Page 54

Installation 38 975-0171-01-01 inverter/charger physical specifications for complete inverter/charger specifications, refer to the rs3000 sine wave inverter/charger operation guide . The physical specifications of the rs3000 are shown in figure 15 on page 39 and described in table 4. Table 4 rs3000 ...

Page 55

Installation 975-0171-01-01 39 figure 15 inverter/charger dimensions 14.2" [361].

Page 56: Battery Information

Installation 40 975-0171-01-01 battery information battery bank sizing battery capacity battery size or capacity is just as important as the battery type selected for use with the rs3000. The batteries are the most important part of your system, so xantrex recommends that you purchase as much batter...

Page 57

Installation 975-0171-01-01 41 4. Enter this information on the blank calculation worksheet (page 42). Step 2: calculate battery size 5. Complete the rest of the worksheet; see table 1-1, “battery sizing example” on page 41 for an example. Size the batteries at approximately twice the estimated tota...

Page 58

Installation 42 975-0171-01-01 battery banks as your power requirements increase, you may need to use more than one battery to obtain sufficient capacity. Batteries can be connected in parallel, in series, or in series-parallel to create higher capacity systems. See “cabling and hook-up configuratio...

Page 59

Installation 975-0171-01-01 43 table 1-2 battery sizing worksheet appliance (a) power consumption (watts) (b) operating time per day (hours) daily watt-hours needed for this appliance (= a × b) w hours wh w hours wh w hours wh w hours wh w hours wh w hours wh w hours wh w hours wh total daily watt-h...

Page 60

Installation 44 975-0171-01-01 cabling and hook-up configurations several smaller batteries can be connected to create a battery bank of substantial size. You can connect batteries in three ways: in parallel, series, or series-parallel. To make a larger battery bank, connect individual batteries wit...

Page 61

Installation 975-0171-01-01 45 series connection when batteries are connected with the positive terminal of one battery to the negative terminal of the next battery, they are connected in series. In a series configuration, the battery bank has the same ah rating of a single battery, but an overall v...

Page 62

Installation 46 975-0171-01-01 series-parallel connections as the name series-parallel implies, both the series and parallel configurations are used in combination. The result is an increase in both the voltage and the capacity of the total battery bank. This is common with all battery-inverter syst...

Page 63: Index

A ac and dc wiring separation 21 ac input wiring connections 22 ac input, defined 8 ac knockout dimensions 21 ac output neutral bonding 12 ac output wiring connections 24 ac wiring defined 10 size 11 type 10 ac wiring compartment, illustrated 21 ac wiring considerations 21 ac wiring terminal, illust...

Page 64

Index 48 975-0171-01-01 t tools, installation 16 two key performance factors 5 v ventilation openings, recommended clearance 18 x xanbus-enabled designation, meaning of 3 xantrex, web site iii.

Page 66

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 975-0171-01-01 printed in china.