- DL manuals

- Xantrex

- Inverter

- XDI2048

- Operating Manual

Xantrex XDI2048 Operating Manual - Return Procedure

Warranty

B-4

TM-DIOP-01XN-01

Return Procedure

1.

Package the unit safely, preferably using the original box and packing materials. Please ensure that

your product is shipped fully insured in the original packaging or equivalent. This warranty will not

apply where the product is damaged due to improper packaging.

2.

Include the following:

•

The RMA number supplied by Xantrex Technology, Inc. clearly marked on the outside of the

box.

•

A return address where the unit can be shipped. Post office boxes are not acceptable.

•

A contact telephone number where you can be reached during work hours.

•

A brief description of the problem.

3.

Ship the unit prepaid to the address provided by your Xantrex customer service representative.

If you are returning a product from outside of the USA or Canada

In addition to the above,

you MUST include return freight funds and are fully responsible for all documents, duties, tariffs, and

deposits.

If you are returning a product to a Xantrex Authorized Service Center (ASC)

A Xantrex

return material authorization (RMA) number is not required. However, you must contact the ASC prior

to returning the product or presenting the unit to verify any return procedures that may apply to that

particular facility.

Out of Warranty Service

If the warranty period for your Xantrex Datacom Inverter has expired, if the unit was damaged by

misuse or incorrect installation, if other conditions of the warranty have not been met, or if no dated

proof of purchase is available, your inverter may be serviced or replaced for a flat fee.

To return your Xantrex Datacom Inverter for out of warranty service, contact Xantrex Customer Service

for a Return Material Authorization (RMA) number and follow the other steps outlined in “Return

Procedure” on page B–4.

Payment options such as credit card or money order will be explained by the Customer Service

Representative. In cases where the minimum flat fee does not apply, as with incomplete units or units

with excessive damage, an additional fee will be charged. If applicable, you will be contacted by

Customer Service once your unit has been received.

Information About Your System

As soon as you open your Xantrex Datacom Inverter package, record the following information and be

sure to keep your proof of purchase.

❐ Serial Number

_________________________________

❐ Purchased From

_________________________________

❐ Purchase Date

_________________________________

Summary of XDI2048

Page 1

Operating manual xantrex datacom inverter xdi2048 2kva/1.5kw.

Page 3: Xantrex Datacom Inverter

Xantrex datacom inverter xdi2048 2kva/1.5kw operating manual.

Page 4

About xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to one mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-connected and stand-a...

Page 5: About This Manual

Tm-diop-01xn-01 iii about this manual purpose the purpose of this operating manual is to provideexplanations and procedures for installing, operating, maintaining, and troubleshooting the xantrex datacom inverter. Scope the manual provides safety guidelines, detailed planning and setup information, ...

Page 6: Conventions Used

About this manual iv tm-diop-01xn-01 chapter 3, “inverter module installation and operation”, chapter 3 contains information and procedures for installing and using the xdi inverter. Chapter 4, “remote communication & monitoring”, chapter 4 contains information and procedures for using the ethernet ...

Page 7: Warning

Tm-diop-01xn-01 v important safety instructions warning operate the inverter in an environment free of flammable gases or fumes. To ensure that the inverter’s safety features are not compromised, use the inverter as specified in this manual and do not substitute parts or make any unauthorized modifi...

Page 8

Vi.

Page 9: Introduction

Tm-diop-01xn-01 vii important safety instructions 1 introduction inverter information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 features and...

Page 10

Contents viii tm-diop-01xn-01 can/sync connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13 overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13 specifications: - - - - - - - - - - - - - - - - - - - - - - - - - - ...

Page 11: Troubleshooting

Contents tm-diop-01xn-01 ix fuses and grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10 incorrect connection protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10 output (ac) alarm - - - - - - - - - - - - - - - - - - - - - - - - ...

Page 12: Specifications

Contents x tm-diop-01xn-01 a specifications inverter specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a–2 electrical specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - a–2 regulatory approvals - - - - - - - - - - -...

Page 13: Figures

Tm-diop-01xn-01 xi figure 2-1 packing list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2 figure 2-2 shipping or storage carton label- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3 figure 2-3 rack mount frame rear view- - - - - - - - - - - - - - -...

Page 14

Xii.

Page 15: Tables

Tm-diop-01xn-01 xiii table 2-1 user line connection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12 table 2-2 can/sync pin-out- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14 table 2-3 3-phase configurations- - - - - - - - - - - - - - - - - - - -...

Page 16

Xiv.

Page 17: Introduction

1 introduction chapter 1 contains an introduction to the xdi inverter and the ethernet card. This chapter provides a list of the major features, protections and options included with both the xdi inverter and the ethernet card..

Page 18: Inverter

Introduction 1-2 tm-diop-01xn-01 inverter information description the xantrex datacom inverter (patent pending) is the most versatile modular rack mounted inverter system for telecom and industrial applications requiring constant ac power from standard –48 v battery systems. The xdi consists of a 1 ...

Page 19: Ethernet

Ethernet information tm-diop-01xn-01 1-3 ethernet information description the internal xdi ethernet interface allows you to monitor and operate your inverter from a local or remote computer equipped with an ethernet card. The ethernet interface allows monitoring and configuration of the xdi inverter...

Page 20

Introduction 1-4 tm-diop-01xn-01 monitor functions • dsp firmware version • manufacturer • model • serial number • front panel led status • output voltage • output current • percent load • startup state • current fault status • faults since power on part number and ordering information xdi2048-rm in...

Page 21: Rack Mount Frame

2 rack mount frame assembly and installation chapter 2 contains information and procedures to assemble and install the rack mount, and install the inverter. This chapter describes the following: • rack mounting the inverter • connecting the dc input power • connecting the ac load and signal line • s...

Page 22: Initial Inspection

Rack mount frame assembly and installation 2-2 tm-diop-01xn-01 initial inspection when you first receive your unit, perform a quick physical check. 1. Inspect the unit for scratches and cracks, broken switches, connectors, terminals, and missing accessories. 2. Have a service technician check the un...

Page 23

Initial inspection tm-diop-01xn-01 2-3 packaging for shipping or storage follow these instructions to prepare the unit for shipping or storage. 1. When returning the unit or sending it to the service center, attach a tag to the unit stating its model number (available from the front panel label) and...

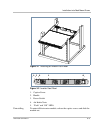

Page 24: Introduction

Rack mount frame assembly and installation 2-4 tm-diop-01xn-01 introduction you can use the inverter in rack-mounted applications. Alternate configurations can be created for custom applications. 1. Ac output terminal block 2. Ac output ground stud 3. Ethernet card (optional) 4. Can/sync connector 5...

Page 25

Location, mounting and ventilation tm-diop-01xn-01 2-5 location, mounting and ventilation when you install the inverter into a rack, allow cooling air to reach the ventilation inlets. At the same time, do not block the air exhaust. See “electrical specifications” on page a–2 for the operating altitu...

Page 26

Rack mount frame assembly and installation 2-6 tm-diop-01xn-01 installation into relay racks use the supplied mounting brackets to secure the backplane in a relay rack. Figure 2-5 installing into relay racks 2. Assemble in relay rack 1. Attach the mounting brackets.

Page 27: Dc Input Power

Dc input power tm-diop-01xn-01 2-7 dc input power input connector and cables the xdi input connector is a 2-pole, double lug terminal block with separate double studs for the ground connection. A minimum of 6 awg copper conductor (rated 85°c minimum) is the recommended wire gauge for all three input...

Page 28: Warning

Rack mount frame assembly and installation 2-8 tm-diop-01xn-01 4. Note the polarity on the input connector as indicated and fasten the positive and negative cable ends onto the terminal block using the brass screws and washers provided. Tighten both securely. See figure 2-6. 5. The dc input wiring s...

Page 29: Ac Output Connector

Ac load and signal line connection tm-diop-01xn-01 2-9 ac load and signal line connection ac output connector this is a two terminal barrier strip for use with up to #12 awg wire. The two terminals, l1 & l2 are floating outputs, l1 or l2 can be grounded to simulate a neutral conductor. The barrier s...

Page 30: Load Connection

Rack mount frame assembly and installation 2-10 tm-diop-01xn-01 load connection 1. If necessary, remove the output cover by loosening the two securing nuts. Release the clamp on the strain relief and insert one end of the load wire 2. Strip and install appropriately sized spade or ring terminals on ...

Page 31: User Line Connection

Ac load and signal line connection tm-diop-01xn-01 2-11 user line connection overview the user-line interface provides basic remote control and monitoring on the inverter using ttl logic signals. The available signals are an inverter on/off input, fault and inverter-on flags as well as a configurabl...

Page 32

Rack mount frame assembly and installation 2-12 tm-diop-01xn-01 user line connector the user-line is a 6-position wire clamp connector adjacent to the dc input connector. Table 2-1 lists user functions and associated terminal numbers. User line wiring use twisted pairs of 22-24 awg for connections. ...

Page 33: Can/sync Connector

Ac load and signal line connection tm-diop-01xn-01 2-13 can/sync connector overview the can/sync connector provides access to functions necessary for operation of multiple units in parallel, series or three phase. The connector is a 7-position wire clamp adjacent to the user-line. Two sets of signal...

Page 34

Rack mount frame assembly and installation 2-14 tm-diop-01xn-01 can/sync wiring due to high bus speed, use shielded twisted pairs of 22-24 awg for improved noise immunity. Before making any connections, ensure power to the rack has been disconnected. Carefully route the wires away from high power lo...

Page 35: Connection Schemes

Connection schemes tm-diop-01xn-01 2-15 connection schemes stand-alone operation a 120 ohm resistor should be connected across the can-hi and can-lo terminals to properly terminate the bus. No other connections to this port are necessary for single unit operation. Parallel operation when operated in...

Page 36

Rack mount frame assembly and installation 2-16 tm-diop-01xn-01 • the ac output load wires are also connected in parallel ensuring only like terminals l1 and l2 are connected together at the distribution bus or load. Each inverter output should be in series with a suitably rated two pole circuit bre...

Page 37: Split Phase Operation

Connection schemes tm-diop-01xn-01 2-17 split phase operation use this scheme to extend the output voltage. No more than two units should be connected in series though more can be added in parallel with either series unit. To connect two units for split voltage, proceed as follows: • first ensure po...

Page 38: Three Phase Operation

Rack mount frame assembly and installation 2-18 tm-diop-01xn-01 three phase operation overview xdi inverters can be configured for 3-phase operation where necessary. Synchronizing signals are used to achieve this functionality, precisely phase locking the units at 120 phase displacement. For single ...

Page 39

3-phase synchronization and signal wiring tm-diop-01xn-01 2-19 3-phase synchronization and signal wiring refer to table 2-2 for the signal pinouts. To achieve proper three-phase output, units configured for each phase need to be wired to the appropriate phase. Extra care should be exercised when mul...

Page 40

Rack mount frame assembly and installation 2-20 tm-diop-01xn-01 3-phase, 3-wire delta output wiring • all outputs should be wired through an appropriately rated circuit breaker. • on phase-1, connect terminal l1 to phase-3 terminal l2. • on phase-1, connect terminal l2 to phase-2 terminal l1. • on p...

Page 41: Ethernet

Ethernet port tm-diop-01xn-01 2-21 3-phase, 4-wire y-connection output wiring this scheme is the same as the preceding with the addition of a neutral connection. • all outputs should be wired through an appropriately rated circuit breaker. • connect l2 terminals of the three phases to the neutral bu...

Page 42

2-22.

Page 43: Inverter Module

3 inverter module installation and operation chapter 3 contains information and procedures for installing and using the xdi inverter . This chapter describes the following: • installing the inverter • setting up the inverter • protections and alarms • maintaining the inverter.

Page 44: Warning

Inverter module installation and operation 3-2 tm-diop-01xn-01 installation into rack mount frame installing to install an inverter module, slide it into a pre-wired rack mount frame until the mounting ears are flush with the front of the rack. In order to prevent the inverter from being accidentall...

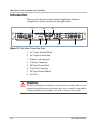

Page 45

Installation into rack mount frame tm-diop-01xn-01 3-3 1. Captive screw 2. Handle 3. Power switch 4. Air intake vents 5. “fault” and “on” led’s uninstalling to uninstall the inverter module, release the captive screws and slide the module out. Figure 3-1 installing an inverter into a rack figure 3-2...

Page 46: Operation of Inverter Module

Inverter module installation and operation 3-4 tm-diop-01xn-01 operation of inverter module theory of operation the xdi is a digitally controlled power converter. It provides galvanic isolation from the dc input to the ac output. The isolation stage is a resonant full-bridge converter and the invers...

Page 47: Standby Mode

Operation of inverter module tm-diop-01xn-01 3-5 standby mode this low power state allows your inverter to recommence operation quickly but conserves power in the meantime. In this mode the output to your inverter remains off and the green “standby/on” led (see figure 3-2) on the front panel flashes...

Page 48: User Interface

Inverter module installation and operation 3-6 tm-diop-01xn-01 user interface front panel user lines the port with user lines is located at the rear panel of the rack mount frame (figure 2-3). See figure 2-7. The following table lists the signals: table 3-1 front panel led functions red led green le...

Page 49: Protections and Alarms

Protections and alarms tm-diop-01xn-01 3-7 protections and alarms overview the digital signal processor (dsp) in the inverter continuously monitors a number of parameters for purposes of protecting the power source, load, inverter and user from hazardous conditions. Fuses on the dc input and ac outp...

Page 50: Overload Protection

Inverter module installation and operation 3-8 tm-diop-01xn-01 overload protection the inverter will deliver the rated load power continuously at the rated ambient temperature. It will also reliably operate up to 1600 watts without further restriction on the maximum ambient temperature. The internal...

Page 51: Short-Circuit Protection

Protections and alarms tm-diop-01xn-01 3-9 over temperature protection (otp) this feature protects critical components from failure due to temperature stress should a fan fail or the ambient temperature or internal temperature exceed acceptable levels. This module also controls the fans, turning the...

Page 52: Fuses and Grounding

Inverter module installation and operation 3-10 tm-diop-01xn-01 fuses and grounding the inverter is equipped with non-user replaceable, internal fuses for fault protection. The input fuse (fuse f1) is rated at 60 a, 170 vdc, 100 ka 1r and positioned in the return path. Both l1 and l2 output ports ar...

Page 53: To Clear An Alarm

Maintenance tm-diop-01xn-01 3-11 to clear an alarm depending on the cause of the alarm, the alarm may be cleared automatically as soon as the fault condition has elapsed. In some cases, the alarm is cleared by: • cycling the on/off switch on the rear panel, • toggling the shut_down user line, • or t...

Page 54

3-12 figure 3-4 replacing the fan filters 2. Remove the cover 1. Unscrew the cover 5. Remove the fan and fan filters 4. Remove the front panel 3. Remove the fan bracket.

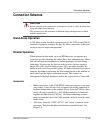

Page 55: Remote

4 remote communication & monitoring chapter 4 contains information and procedures for using the ethernet to provide remote communication and monitoring. This chapter describes the following: • setting up the computer and inverter for the first time • using the ethernet to remotely communicate with t...

Page 56: Introduction

Remote communication & monitoring 4-2 tm-diop-01xn-01 introduction when installed, the optional tcp/ip enabled ethernet communications card and user interface provides remote monitoring and on/stby control of a xantrex datacom inverter module. Web-enabled user interface • provides monitoring capabil...

Page 57

Initial setup tm-diop-01xn-01 4-3 figure 4-1 ethernet interface pcb important: the only way to configure the interface card is through the ethernet port using tcp/ip protocol. Therefore, the ethernet interface must be set up properly the first time. Once it is setup, the parameters (such as, passwor...

Page 58

Remote communication & monitoring 4-4 tm-diop-01xn-01 how to setup for the first time hardware setup in order to communicate to the xdi ethernet for the first time, you will need a cat5/cat5e cable and a computer with an ethernet adapter installed. Setting up to configure for the first time: 1. Wire...

Page 59

Initial setup tm-diop-01xn-01 4-5 ethernet setup you must run a web browser to communicate and configure the xdi ethernet. Microsoft internet explorer or netscape communicator are such examples. Configure ethernet settings: 1. Run your web browser program. 2. In the address box type in the “default ...

Page 60

Remote communication & monitoring 4-6 tm-diop-01xn-01 you can use table 4-2 to record your own settings. Resetting to reset the ethernet settings the cover will have to be removed to put a jumper onto the control card. When the ethernet is reset, its settings will be changed to the default values as...

Page 61

Initial setup tm-diop-01xn-01 4-7 table 4-3 reset settings setting reset value default ip 192.168.1.1 gateway ip 0.0.0.0 sub-net mask 255.255.255.0 domain name server 1 0.0.0.0 domain name server 2 0.0.0.0 smtp (email) server not changed email alert address not changed password 12345 figure 4-3 remo...

Page 62

Remote communication & monitoring 4-8 tm-diop-01xn-01 figure 4-4 ethernet reset jumper ethernet configuration reset jumper (sw2).

Page 63: Operating Instructions

Operating instructions tm-diop-01xn-01 4-9 operating instructions introduction the ethernet interface card allows you to monitor/configure settings using a web page. It also adds email functionality to the xdi. The unit will automatically send an email when it is powered up or when there is a fault ...

Page 64

Remote communication & monitoring 4-10 tm-diop-01xn-01 figure 4-5 network setup pc pc dhcp server inverter inverter hub pc pc special cross-over cable required network setup (pc to inverter) network setup (pc to hub to inverter) inverter inverter inverter network setup (full network) hub.

Page 65: Using Dhcp

Operating instructions tm-diop-01xn-01 4-11 using dhcp a dhcp server is used to obtain a dynamic ip that is unique on the network. To enable dhcp, set the default ip to “0.0.0.0”. On power up the ethernet interface card will request a unique ip address from the dhcp server which it will set as its a...

Page 66: Password

Remote communication & monitoring 4-12 tm-diop-01xn-01 password the web page interface is password protected. See “password” on page 4–12 for the default password. The web page uses the industry standard md5 algorithm to authenticate the remote user. Network configurations (default ip, smtp server e...

Page 67: Automatic Power-On Email

Operating instructions tm-diop-01xn-01 4-13 automatic power-on email when the inverter is turned on, it will attempt to send an email to the configured “email alert address” using the configured “smtp server”. Contents of the email: from: xdi to: subject: unit powered on body: ip address: how to use...

Page 68

Remote communication & monitoring 4-14 tm-diop-01xn-01 manage page the “manage page” is the first page of the web page. It contains information about the inverter as well as buttons to put the unit into or out of standby mode. Figure 4-7 manage page of web interface table 4-4 manage page of web inte...

Page 69

Operating instructions tm-diop-01xn-01 4-15 setup page the “setup page” allows the user to set the ethernet interface card’s network setting, email settings and refresh rate. It is important that the network settings are correct to ensure proper communication. Important: contact network administrato...

Page 70

Remote communication & monitoring 4-16 tm-diop-01xn-01 table 4-5 setup page of web interface object description monitor page refresh rate the rate at which to automatically refresh the monitor page (the refresh data link on the “monitor page” should be selected for the new refresh rate to take effec...

Page 71

Operating instructions tm-diop-01xn-01 4-17 monitor page the “monitor page” shows the current status of the inverter. It displays the output measurements, output conditions and faults. Figure 4-9 monitor page of web interface.

Page 72

Remote communication & monitoring 4-18 tm-diop-01xn-01 table 4-6 monitor page of web interface object description output voltage last measured output voltage (vrms) output current last measured output current (arms) percent load last measured percent load (%). Indicates percentage of load being draw...

Page 73: Automatic Shutdown Email

Operating instructions tm-diop-01xn-01 4-19 automatic shutdown email when the inverter shuts down due to a fault or a user shutdown, the ethernet interface will attempt to send an email to the configured “email alert address” using the configured “smtp server” (see “network connection” on page 4–9)....

Page 74

Remote communication & monitoring 4-20 tm-diop-01xn-01 important: refer to “protections and alarms” on page 3–7 for a more detailed description of faults..

Page 75: Troubleshooting

5 troubleshooting chapter 5 contains information and procedures for troubleshooting your xdi inverter and ethernet card ..

Page 76: User Diagnostics

Troubleshooting 5-2 tm-diop-01xn-01 user diagnostics if your xdi is not performing as described in this manual, run through the procedures and checks in this section before calling your service technician. These procedures are confined to operator-level functions only and do not require cover-off se...

Page 77: Diagnostic Guide

User diagnostics tm-diop-01xn-01 5-3 diagnostic guide i table 5-1 inverter diagnostics symptom check further checks and corrections no output. No front panel indication. Is input breaker and power to rack enabled? Check for availability of power source. Is unit fully recessed and secured in rack? Se...

Page 78

Troubleshooting 5-4 tm-diop-01xn-01 table 5-2 ethernet diagnostics symptom check further checks and corrections ip address doesn’t work 1. Static ip already being used by another device on the network 1. Change the static ip to an unused address 2. Dhcp server failed to assign ip 2. Ip was not confi...

Page 79: Specifications

A specifications appendix a supplies information about specifications for the xdi inverter and the ethernet..

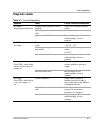

Page 80: Inverter

Specifications a-2 tm-diop-01xn-01 inverter specifications electrical specifications input voltage, current, power, frequency ranges output voltage, current, power, frequency ranges nominal input - 48 vdc input range - 40 to - 60 v (meets all specification) safe input range ± 80 vdc (will not damage...

Page 81

Inverter specifications tm-diop-01xn-01 a-3 power factor • linear – powers all loads with 0 leading to 0 lagging pf • stable with constant power type loads like power factor corrected power supplies • non-linear – powers rectified loads with up to 2.8 crest factor at full load motor starting 4 kva o...

Page 82: Regulatory Approvals

Specifications a-4 tm-diop-01xn-01 efficiency • minimum 85% efficiency at full power, peak efficiency 89% • no load draw: less than 60 w start up behavior • hot-swap capable, with controlled inrush current • no arcing of connectors when unit inserted or withdrawn • output phase locked to parallel co...

Page 83: Mechanical Specifications

Inverter specifications tm-diop-01xn-01 a-5 mechanical specifications ventilation air intake from front of unit no additional clearance required top or bottom mounting 1 u rack height in rack mount frame, no additional clearance required top or bottom chassis for 19” rack holds 1 module weight 22 lb...

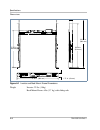

Page 84

Specifications a-6 tm-diop-01xn-01 dimensions weight inverter: 22 lbs. (10kg) rack mount frame: 6 lbs (2.7 kg) with sliding rails figure a-1 inverter and rack mount frame dimensions 17.25 in. (438 mm) 20.24 in. (514 mm) 22.14 in. (562 mm) 1.71 in. (43 mm) 19.00 in. (483 mm).

Page 85: Ethernet

Ethernet specifications tm-diop-01xn-01 a-7 ethernet specifications specifications the specifications in this section are warranted at 25°c ± 5°c unless otherwise specified. All specifications are subject to change without notice. Readback resolution voltage current percent load 0.1 v 0.1 a 0.1% rea...

Page 86

A-8.

Page 87: Warranty and Product

Tm-diop-01xn-01 b-1 warranty and product information warranty what does this warranty cover? This limited warranty is provided by xantrex technology, inc. ("xantrex") and covers defects in workmanship and materials in your xantrex datacom inverter. This warranty period lasts for three (3) years from...

Page 88: Disclaimer

Warranty b-2 tm-diop-01xn-01 what proof of purchase is required? In any warranty claim, dated proof of purchase must accompany the product and the product must not have been disassembled or modified without prior written authorization by xantrex. Proof of purchase may be in any one of the following ...

Page 89: Exclusions

Return material authorization policy tm-diop-01xn-01 b-3 exclusions if this product is a consumer product, federal law does not allow an exclusion of implied warranties. To the extent you are entitled to implied warranties under federal law, to the extent permitted by applicable law they are limited...

Page 90: Return Procedure

Warranty b-4 tm-diop-01xn-01 return procedure 1. Package the unit safely, preferably using the original box and packing materials. Please ensure that your product is shipped fully insured in the original packaging or equivalent. This warranty will not apply where the product is damaged due to improp...

Page 92: Xantrex Technology Inc.

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com tm-diop-01xn-01 printed in canada.