- DL manuals

- Xantrex

- Power Supply

- XFR 100-12

- Operating manual

Xantrex XFR 100-12 Operating manual

Summary of XFR 100-12

Page 1

Operating manual xfr 1200 watt series programmable dc power supply xfr 6-200 xfr 7.5-140 xfr 12-100 xfr 20-60 xfr 35-35 xfr 40-30 xfr 60-20 xfr 100-12 xfr 150-8 xfr 300-4 xfr 600-2.

Page 3: Operating Manual For

Operating manual for xfr 1200 watt series programmable dc power supply.

Page 4: Limited

Ii operating manual for xfr 1.2kw series power supply limited warranty what does this warranty cover and how long does it last? This limited warranty is provided by xantrex technology, inc. (“xantrex”) and covers defects in workmanship and materials in your xfr 1200 watt series dc power supply. This...

Page 5

Release 3.1 iii direct returns may be performed according to the xantrex return material authorization policy described in your product manual. For some products, xantrex maintains a network of regional authorized service centers. Call xantrex or check our website to see if your product can be repai...

Page 6

Iv operating manual for xfr 1.2kw series power supply disclaimer product this limited warranty is the sole and exclusive warranty provided by xantrex in connection with your xantrex product and is, where permitted by law, in lieu of all other warranties, conditions, guarantees, representations, obli...

Page 7

Release 3.1 v information without limiting the generality of the foregoing, unless specifically agreed to by it in writing, xantrex a. Makes no warranty as to the accuracy, sufficiency or suitability of any technical or other information provided in manuals or other documentation provided by it in c...

Page 8

Vi operating manual for xfr 1.2kw series power supply warnings and cautions warnings and cautions are defined and formatted in this manual as shown below. Power supply safety warning describes a potential hazard which could result in injury or death, or, a procedure which, if not performed correctly...

Page 9: About This Manual

Release 3.1 vii about this manual this operating manual contains user information for the xfr series of variable dc output power supplies, available in several voltage models at 1200 watts. It provides information about features and specifications, installation procedures, and basic functions testin...

Page 10

About this manual viii operating manual for xfr 1.2kw series power supply power supply safety markings alternating current off (supply) earth (ground) terminal caution (hot surface) protective conductor terminal caution (check manual for additional information.) on (supply).

Page 11: Contents

Release 3.1 ix contents about this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii list of figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Xi list of tables . . . ....

Page 12

X operating manual for xfr 1.2kw series power supply connecting single loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 connecting multiple loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 local and remote sensing . . ...

Page 13: List of Figures

Release 3.1 xi list of figures figure 1.3 programming and monitoring sw1 switch . . . . . . . . . . . . . . . . . . . . . 19 figure 1.4 programming and monitoring j2 connector . . . . . . . . . . . . . . . . . . . . 20 figure 1.5 typical input current characteristics, 85-130 vac range. . . . . . . ....

Page 14

List of figures xii operating manual for xfr 1.2kw series power supply.

Page 15: List of Tables

Release 3.1 xiii list of tables table 1.1 available voltage and current ranges . . . . . . . . . . . . . . . . . . . . . . . . 15 table 1.2 rear panel sw1 switch assignments. . . . . . . . . . . . . . . . . . . . . . . . . 19 table 1.3 rear panel j2 connector terminals and functions . . . . . . . . ...

Page 16

List of tables xiv operating manual for xfr 1.2kw series power supply.

Page 17

Release 3.1 15 section 1. Features and specifications description this series of power supplies provides low-noise, precisely regulated, variable dc output at 1200 watts of output power. Over voltage protection (ovp) and thermal shutdown are standard. Front panel controls and indicators are extensiv...

Page 18

Features and specifications features and options 16 operating manual for xfr 1.2kw series power supply features and options • simultaneous digital display of both voltage and current. • ten-turn front panel voltage and current controls for high resolution setting of the output voltage and current fr...

Page 19

Features and specifications front panel controls release 3.1 17 front panel controls see figure 1.1 to review the controls, leds, and meters located on the power supply’s front panel. Check the following sections for additional descriptions of front panel controls and functions. • “mechanical specif...

Page 20

Features and specifications rear panel connectors and switch 18 operating manual for xfr 1.2kw series power supply rear panel connectors and switch use the rear panel sw1 programming, monitoring, and shutdown select switch and the rear panel j2 programming and monitoring connector to choose among se...

Page 21

Features and specifications rear panel connectors and switch release 3.1 19 rear panel sw1 switch the sw1 programming, monitoring, and shutdown select switch is an 8-position piano dip switch located on the power supply’s rear panel. See figure 1.3. The sw1 switch enables you to choose: • resistive ...

Page 22

Features and specifications rear panel connectors and switch 20 operating manual for xfr 1.2kw series power supply resetting the switches before making any changes to the switch settings, disable the power supply output by pushing the front panel standby switch to its in position. This temporarily s...

Page 23

Features and specifications rear panel connectors and switch release 3.1 21 table 1.3 rear panel j2 connector terminals and functions connector reference name function j2-1 vrmt remote output voltage programming select selects remote output voltage programming when jumpered to pin 3. J2-2 irmt remot...

Page 24

Features and specifications rear panel connectors and switch 22 operating manual for xfr 1.2kw series power supply making j2 connections make connections to the j2 connector using its screw-type wire clamps. Before making any connections, turn the power supply off and wait until the front panel disp...

Page 25

Features and specifications specifications release 3.1 23 specifications electrical specifications these specifications are warranted over a temperature range of 0 °c to 50 °c. Nominal ambient temperature assumed is 25 °c. Nominal line voltages are 120 vac and 230 vac. See table 1.4 and table 1.5 fo...

Page 26

Features and specifications specifications 24 operating manual for xfr 1.2kw series power supply table 1.4 electrical specifications for 6 v to 35 v models models 6-200 7.5-140 12-100 20-60 35-35 output ratings: output voltage 1 output current 2 output power 0-6 v 0-200 a 3 1200 w 0-7.5 v 0-140 a 10...

Page 27

Features and specifications specifications release 3.1 25 1. Minimum output voltage is 2. Minimum output current is full power load. 3. For rack mounted 6 v models, derate output current by 1.5 a per °c for operating temperatures between 30 °c and 50 °c. See “environmental specification” on page 32 ...

Page 28

Features and specifications specifications 26 operating manual for xfr 1.2kw series power supply table 1.5 electrical specifications for 40 v to 600 v models models 40-30 60-20 100-12 150-8 300-4 600-2 output ratings: output voltage 1 output current 2 output power 0-40 v 0-30 a 1200 w 0-60 v 0-20 a ...

Page 29

Features and specifications specifications release 3.1 27 1. Minimum output voltage is 2. Minimum output current is full power load. 3. For input voltage variation over the ac input voltage range, with constant rated load. 4. For 0-100% load variation, with constant nominal line voltage. 5. Current ...

Page 30

Features and specifications specifications 28 operating manual for xfr 1.2kw series power supply additional specifications input conditions rise time (no load, full load): 1 6 v to 60 v models: 100 ms; 100 v to 600 v models: 170 ms fall time (no load): 1 6 v model: 1.5 s; 7.5 v to 60 v models: 3 s; ...

Page 31

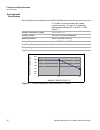

Features and specifications specifications release 3.1 29 figure 1.5 typical input current characteristics, 85-130 vac range (based on 60 v, 20 a model.) figure 1.6 typical input current characteristics, 190-264 vac range (based on 60 v, 20 a model.) i n p u t c u r r e n t (a) 100% at 85 vac 50% 10...

Page 32

Features and specifications specifications 30 operating manual for xfr 1.2kw series power supply additional features switching frequency 6 v to 40 v models: nominal 78 khz (156 khz output ripple); 60 v to 600 v models: nominal 62.5 khz (125 khz output ripple). Output hold-up time greater than 20 ms ...

Page 33

Features and specifications specifications release 3.1 31 remote programming and monitoring remote start/stop and interlock 2.5-15 v signal or ttl-compatible input, selectable logic. Ttl input impedance: 2 k (in series with one diode drop). Remote analog programming (full scale input) voltage and cu...

Page 34

Features and specifications specifications 32 operating manual for xfr 1.2kw series power supply environmental specification figure 1.7 current derating for rack mounted 6 v models operating temperature range 0 °c to 50 °c. 6 v model: for rack mounted units, derate output current by 1.5 a per °c for...

Page 35

Features and specifications specifications release 3.1 33 mechanical specifications front panel v and i control 10-turn voltage and current potentiometers front panel voltage control resolution 0.02% of maximum voltage front panel voltage and current meters 3.5-digit green numeric led displays. For ...

Page 36

Features and specifications specifications 34 operating manual for xfr 1.2kw series power supply figure 1.8 dimensional drawings (dimensions given are nominal.) 1. Fuses are located on the a4 pcb (printed circuit board). The fuses are not operator-replaceable. 1.71 in. (43.4 mm) 19 in. (483 mm) 16.9...

Page 37: Section 2. Installation

Release 3.1 35 section 2. Installation introduction this section provides recommendations and procedures for inspecting, installing, and testing the power supply. Basic setup procedure see table 2.1 for a summary of the basic setup procedure and an overall view of the subsections in this section. Us...

Page 38

Installation inspection, cleaning, and packaging 36 operating manual for xfr 1.2kw series power supply inspection, cleaning, and packaging initial inspection when you first receive your unit, perform a quick physical check. 1. Inspect the unit for scratches and cracks, and for broken switches, conne...

Page 39

Installation returning power supplies to the manufacturer release 3.1 37 returning power supplies to the manufacturer return material authorization policy before returning a product directly to xantrex you must obtain a return material authorization (rma) number and the correct factory “ship to” add...

Page 40

Installation returning power supplies to the manufacturer 38 operating manual for xfr 1.2kw series power supply packaging for shipping or storage follow these instructions to prepare the unit for shipping or storage. 1. When returning the unit or sending it to the service center, attach a tag to the...

Page 41

Installation location, mounting, and ventilation release 3.1 39 location, mounting, and ventilation use the power supply in rack-mounted or in benchtop applications. Rack mounting the power supply is designed to fit in a standard 1 in. (483 mm) equipment rack. To install: 1. Use the integral rack-mo...

Page 42

Installation ac input power connection 40 operating manual for xfr 1.2kw series power supply ac input power connection ac input connector and voltage selection the ac input connector is a 3-terminal wire clamp located on the power supply’s rear panel. See figure 2.2 ac input cover and strain relief....

Page 43

Installation ac input power connection release 3.1 41 table 2.2 operational ac input voltage ranges and frequency ac fail led the ac fail (acf) led turns on when the input voltage is outside of the range specified for the power supply. The led turns off when the input voltage is within the range. Ac...

Page 44

Installation ac input power connection 42 operating manual for xfr 1.2kw series power supply 3. Slide the helix-shaped body onto the ac cable. Insert the stripped wires through the strain relief base until the outer cable jacket is flush with the edge of the base. Tighten the body to the base while ...

Page 45

Installation functional tests release 3.1 43 functional tests these functional test procedures include power-on and front panel function checks as well as voltage and current mode operation checks. Equipment required • digital voltmeter (dvm) rated better than 0.5% accuracy. • dc shunt 1mv/a (±0.25%...

Page 46

Installation functional tests 44 operating manual for xfr 1.2kw series power supply current mode operation check 1. Ensure that the front panel power switch is set to off. 2. Turn the voltage and current controls on the front panel fully counter-clockwise. 3. Connect the dc shunt across the output t...

Page 47

Installation load connection release 3.1 45 load connection this section provides recommendations for load wires and how to connect them for both single and multiple load configurations. Load wiring to select wiring for connecting the load to the power supply, consider the following factors: • insul...

Page 48

Installation load connection 46 operating manual for xfr 1.2kw series power supply load wiring length for operation with sense lines for applications using remote sensing, you must limit the voltage drop across each load line. Figure 2.3 shows some maximum allowable wire lengths for a given load cur...

Page 49

Installation load connection release 3.1 47 making load connections make load connections at the rear of the power supply at the positive and negative output bus bars or to the 4-terminal wire clamp connector, depending on the model. 6 v to 40 v models the 6 v to 40 v (low voltage) models have outpu...

Page 50

Installation load connection 48 operating manual for xfr 1.2kw series power supply to make load connections to a 7.5 v, 140 a power supply: 1. Install a connecting wire terminal lug to load wiring (see figure 2.5). 2. Fasten wire terminal lugs to bus bars with 1/4 in. X 1/2 in. (m6 x 12 mm) screws, ...

Page 51

Installation load connection release 3.1 49 the 60 v to 600 v (high voltage) models have a 4-terminal, wire clamp output connector. See inset of figure 2.6 for a labelled drawing of the wire clamp connector. The units are shipped with a protective shield attached (see figure 2.6). To prepare and con...

Page 52

Installation load connection 50 operating manual for xfr 1.2kw series power supply inductive loads to prevent damage to the power supply from inductive kickback, connect a diode across the output. The diode must be rated at greater than or equal to the supply’s output voltage and have a current surg...

Page 53

Installation load connection release 3.1 51 connecting multiple loads proper connection of distributed loads is an important aspect of power supply use. Two common methods of connection are the parallel power distribution method and the radial power distribution method. Parallel power distribution t...

Page 54

Installation load connection 52 operating manual for xfr 1.2kw series power supply figure 2.10 multiple loads with remote sensing.

Page 55

Installation local and remote sensing release 3.1 53 local and remote sensing use connections at the rear panel j10 sense connector to configure thepower supply for local or remote sensing of output voltage. See figure 2.11 for a drawing of the sense connector. Sense wiring for lowest noise performa...

Page 56

Installation local and remote sensing 54 operating manual for xfr 1.2kw series power supply table 2.5 rear panel j10 sense connector terminals and functions using remote sensing use remote sensing during voltage mode operation to shift the power supply’s regulation point from its default position at...

Page 57

Installation local and remote sensing release 3.1 55 to connect remote sense lines: 1. Turn off the power supply. 2. Remove the local sense jumpers connecting j10 mating connector terminal 5 (positive sense) to terminal 4 (positive output) and terminal 1 (return sense) to terminal 2 (power supply re...

Page 58

Installation local and remote sensing 56 operating manual for xfr 1.2kw series power supply figure 2.12connecting remote sense lines.

Page 59: Section 3. Local Operation

Release 3.1 57 section 3. Local operation introduction once you have installed the power supply and have connected both the ac input power and the load as covered in section 2. Installation, the power supply is ready to operate in local control mode (that is, operation at the unit’s front panel). • ...

Page 60

Local operation standard operation 58 operating manual for xfr 1.2kw series power supply figure 3.1 operating modes constant voltage mode operation the power supply will operate in constant voltage mode whenever the load current i l is less than the current limit setting i set , or: i l set (note: i...

Page 61

Local operation standard operation release 3.1 59 shipped configuration the factory ships units already configured for local control (front panel) operation. See table 3.1 for a summary of this configuration. Table 3.1 shipped configuration (local control mode) local control configuration additional...

Page 62

Local operation standard operation 60 operating manual for xfr 1.2kw series power supply setting output voltage and current limit install the power supply and connect the load as described in section 2. Installation. Ensure that the power supply is set up for local control as described in “shipped c...

Page 63

Local operation using over voltage protection (ovp) release 3.1 61 using over voltage protection (ovp) the ovp circuit protects the load in the event of a remote programming error, an incorrect voltage control adjustment, or a power supply failure. The protection circuit monitors the output voltage ...

Page 64

Local operation using over voltage protection (ovp) 62 operating manual for xfr 1.2kw series power supply resetting the ovp circuit to reset the ovp circuit after it activates: 1. Reduce the power supply’s output voltage setting to below the ovp set point. 2. Press the standby switch in. The red s/d...

Page 65

Local operation using the shutdown function release 3.1 63 using the shutdown function use the shutdown function to disable or enable the supply’s output so that you can make adjustments to either the load or the power supply without shutting off the power supply. Activate this function from the fro...

Page 66

Local operation using the shutdown function 64 operating manual for xfr 1.2kw series power supply table 3.2 switch settings for shutdown circuit logic switch sw1-7 setting source signal signal level supply output s/d led off (open) (active low, default) 2-15 v high off on 0-0.4 v low on off on (clos...

Page 67

Local operation using multiple supplies release 3.1 65 using multiple supplies you can operatepower supplies of the same model with outputs in series or in parallel to obtain increased load voltage or increased current. Split supply operation gives you two positive outputs, or a positive and a negat...

Page 68

Local operation using multiple supplies 66 operating manual for xfr 1.2kw series power supply configuring multiple supplies for series operation use series operation to obtain a single higher voltage output using two or more supplies. Connect the negative (–) output terminal of one supply to the pos...

Page 69

Local operation using multiple supplies release 3.1 67 configuring multiple supplies for parallel operation use parallel operation to obtain a higher current through a single output using two or more supplies. Set all of the ovp setpoints to maximum. (see “using over voltage protection (ovp)” on pag...

Page 70

Local operation using multiple supplies 68 operating manual for xfr 1.2kw series power supply configuring multiple supplies for split supply operation split supply operation uses two power supplies to obtain two positive voltages with a common ground, or to obtain a positive-negative supply. Two pos...

Page 71

Local operation using multiple supplies release 3.1 69 figure 3.5 split supply operation of multiple supplies (positive-negative supply) (local sense lines shown are default j10 connections.).

Page 72

Local operation over temperature protection (otp) 70 operating manual for xfr 1.2kw series power supply over temperature protection (otp) the otp function allows you to select how the power supply recovers from an over temperature shutdown using the rear panel switch sw1-8. See table 3.3 for the swi...

Page 73

Local operation user diagnostics release 3.1 71 user diagnostics if your power supply is not performing as described in this manual, run through the procedures and checks in this section before calling your service technician. These procedures are confined to operator level functions only and do not...

Page 74

Local operation user diagnostics 72 operating manual for xfr 1.2kw series power supply table 3.4 user diagnostics symptom check further checks and corrections no output and the display is blank. Is input voltage within specified range? Connect to appropriate voltage source. See page 40. Power switch...

Page 75: Section 4. Remote Operation

Release 3.1 73 section 4. Remote operation introduction the rear panel switches and connector on the power supply allow you to program the supply with an analog device or to output readback signals. This section covers the following topics: • see “remote analog programming of output voltage and curr...

Page 76

Remote operation remote analog programming of output voltage and current limit 74 operating manual for xfr 1.2kw series power supply remote analog programming of output voltage and current limit remote analog programming allows control of the power supply’s output voltage and/or current limit to shi...

Page 77

Remote operation remote analog programming of output voltage and current limit release 3.1 75 5. Set the programming sources to the desired levels and turn the power supply on. The rem led turns on. Adjust the external programming source to change the power supply’s output. Please remember: 1. Any o...

Page 78

Remote operation remote analog programming of output voltage and current limit 76 operating manual for xfr 1.2kw series power supply table 4.2 power supply settings for different programming sources output voltage programming source output current limit programming source 0-5 vdc 0-10 vdc 0-5 k resi...

Page 79

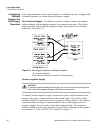

Remote operation remote analog programming of output voltage and current limit release 3.1 77 figure 4.1 connecting programming sources to j2 connector.

Page 80

Remote operation remote monitoring of output voltage and current 78 operating manual for xfr 1.2kw series power supply remote monitoring of output voltage and current readback signals the j2 connector on the rear panel provides access to calibrated readback signals for remote monitoring of the outpu...

Page 81: Section 5. Calibration

Release 3.1 79 section 5. Calibration introduction adjustments to programming and readback accuracy for the power supply are made using cover-off procedures which must be performed by a service technician. Calibration setup service environment and precautions • follow established antistatic procedur...

Page 82

Calibration calibration setup 80 operating manual for xfr 1.2kw series power supply accessing calibration potentiometer you will need to remove the power supply’s cover to access the programming and readback calibration potentiometers which are located on the a2 pcb. See figure 5.1 to locate the pot...

Page 83

Calibration calibration setup release 3.1 81 figure 5.1 programming and monitoring calibration locations (top view.).

Page 84

Calibration calibrating for programming accuracy 82 operating manual for xfr 1.2kw series power supply calibrating for programming accuracy the factory calibrates the offset and range of the voltage and current programming circuits to within 1% for the default 0-10 vdc programming signals. You may n...

Page 85

Calibration calibrating for programming accuracy release 3.1 83 current limit programming circuit calibration 1. Ensure that the power supply is turned off. Disconnect any load. 2. Connect the program source between j2 connector terminals 8 (output current limit programming input) and 7 (current pro...

Page 86

Calibration calibrating for readback accuracy 84 operating manual for xfr 1.2kw series power supply calibrating for readback accuracy the factory calibrates the offset and range of the output voltage and current monitor circuits to within 1% for the default 0-10 vdc scales. You may need to recalibra...

Page 87

Calibration calibrating for readback accuracy release 3.1 85 output current monitor circuit calibration 1. Ensure that the power supply is turned off. Disconnect any load. 2. Set sw1 switch 6 open to select 0-5 v output current monitor range, closed for 0-10 v. 3. Connect the shunt and dvm across th...

Page 88

Calibration calibrating for readback accuracy 86 operating manual for xfr 1.2kw series power supply.

Page 90

Xantrex technology inc. 8999 nelson way burnaby, british columbia canada v5a 4b5 604 422 8595 tel 604 421 3056 fax 800 667 8422 toll free north america prg.Info@xantrex.Com www.Xantrex.Com tm-f1op-c1xn printed in canada.