- DL manuals

- Xantrex

- Power Supply

- XHR 100-10

- Operating manual

Xantrex XHR 100-10 Operating manual

Summary of XHR 100-10

Page 1

Operating manual xhr 1000 watt series programmable dc power supply xhr 7.5-130 xhr 20-50 xhr 33-33 xhr 40-25 xhr 60-18 xhr 100-10 xhr 150-7 xhr 300-3.5 xhr 600-1.7 tm-xrop-01xn.Book page i monday, march 22, 2004 4:10 pm.

Page 2

Tm-xrop-01xn.Book page ii monday, march 22, 2004 4:10 pm.

Page 3: Operating Manual For

Operating manual for xhr series programmable dc power supply tm-xrop-01xn.Book page i monday, march 22, 2004 4:10 pm.

Page 4: Limited

Ii operating manual for xhr series power supply limited warranty what does this warranty cover and how long does it last? This limited warranty is provided by xantrex technology, inc. (“xantrex”) and covers defects in workmanship and materials in your xhr 1000 watt series dc power supply. This warra...

Page 5

Revision a iii direct returns may be performed according to the xantrex return material authorization policy described in your product manual. For some products, xantrex maintains a network of regional authorized service centers. Call xantrex or check our website to see if your product can be repair...

Page 6

Iv operating manual for xhr series power supply disclaimer product this limited warranty is the sole and exclusive warranty provided by xantrex in connection with your xantrex product and is, where permitted by law, in lieu of all other warranties, conditions, guarantees, representations, obligation...

Page 7

Revision a v information without limiting the generality of the foregoing, unless specifically agreed to by it in writing, xantrex a. Makes no warranty as to the accuracy, sufficiency or suitability of any technical or other information provided in manuals or other documentation provided by it in co...

Page 8

Vi operating manual for xhr series power supply warnings and cautions warnings and cautions are defined and formatted in this manual as shown below. Power supply safety warning describes a potential hazard which could result in injury or death, or, a procedure which, if not performed correctly, coul...

Page 9: About This Manual

Revision a vii about this manual this operating manual contains user information for the xhr series dc output power supply, available in several models at 1000 watts. It provides information on features and specifications, installation procedures, and basic functions testing, as well as procedures f...

Page 10

About this manual viii operating manual for xhr series power supply power supply safety markings alternating current off (supply) earth (ground) terminal caution (hot surface) protective conductor terminal caution (check manual for additional information.) on (supply) tm-xrop-01xn.Book page viii mon...

Page 11: Contents

Revision a ix contents about this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii list of figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Xi list of tables . . . . ...

Page 12

X operating manual for xhr series power supply local and remote sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 sense wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 local sensing . . ....

Page 13: List of Figures

Revision a xi list of figures figure 1.1 power supply front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 figure 1.2 rear panel with bus bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 figure 1.3 rear panel with high voltage output connector . . ....

Page 14

List of figures xii operating manual for xhr series power supply tm-xrop-01xn.Book page xii monday, march 22, 2004 4:10 pm.

Page 15: List of Tables

Xiii operating manual for xhr series power supply list of tables table 1.1 sw1 switch functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 table 1.2 electrical specifications for 7.5 v to 40 v models . . . . . . . . . . . . . . 24 table 1.3 electrical specifications for...

Page 16

List of tables xiv operating manual for xhr series power supply tm-xrop-01xn.Book page xiv monday, march 22, 2004 4:10 pm.

Page 17

Revision a 15 section 1. Features and specifications description the 1000 watt dc output power supplies provide low noise, precisely regulated, variable dc output. Typically they are used for bench and automated test equipment (ate) applications. Each unit includes over voltage protection and therma...

Page 18

Features and specifications front panel controls 16 operating manual for xhr series power supply • remote analog voltage and current limit programming with selectable programming ranges. • external monitor signals for output voltage and current. • isolated analog remote programming control of the ou...

Page 19

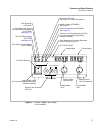

Features and specifications front panel controls revision a 17 figure 1.1 power supply front panel (for all models.) ac power switch output voltage control knob ac fail led (acf) return to local programming (local) (for units with digital programming interface installed.) over temperature protection...

Page 20

Features and specifications rear panel connectors and switch 18 operating manual for xhr series power supply rear panel connectors and switch the output terminals for the low voltage models (7.5 v to 40 v) are bus bars. The high voltage models (60 v to 600 v) use a wire clamp connector. See figure 1...

Page 21

Features and specifications rear panel connectors and switch revision a 19 figure 1.3 rear panel with high voltage output connector (for 60 v to 600 v models.) sw1 programming switch the sw1 programming, monitoring, and shutdown select switch is an 8-position piano dip switch located on the power su...

Page 22

Features and specifications rear panel connectors and switch 20 operating manual for xhr series power supply see table 1.1 for a list of the functions assigned to each sw1 switch. Table 1.1 sw1 switch functions resetting the switches the rear panel is labelled with off at the top of the switch and o...

Page 23

Features and specifications rear panel connectors and switch revision a 21 see figure 1.5 to identify the function of each of the 12 terminals on the j2 connector. Figure 1.5 j2 programming connector making j2 connections make connections to the j2 connector using its screw-type wire clamps. Before ...

Page 24

Features and specifications rear panel connectors and switch 22 operating manual for xhr series power supply wiring for lowest noise performance, make connections to the j2 connector with either individually or group shielded 18-22 awg (0.3-0.8 mm 2 ) wire. Maintain the shield to within 1.5in. (40 m...

Page 25

Features and specifications specifications revision a 23 specifications electrical specifications specifications are warranted over a temperature range of 0 to 40 °c with default local sensing. The tables on the following pages post maximum values for model-dependent specifications. Specifications w...

Page 26

Features and specifications specifications 24 operating manual for xhr series power supply table 1.2 electrical specifications for 7.5 v to 40 v models models 7.5-130 20-50 33-33 40-25 output ratings: output voltage output current output power at the front panel binding posts: output current output ...

Page 27

Features and specifications specifications revision a 25 table 1.3 electrical specifications for 60 v to 600 v models models 60-18 100-10 150-7 300-3.5 600-1.7 output ratings: output voltage output current output power 0-60 v 0-18 a 1080 w 0-100 v 0-10 a 1000 w 0-150 v 0-7 a 1050 w 0-300 v 0-3.5 a 1...

Page 28

Features and specifications additional electrical specifications 26 operating manual for xhr series power supply additional electrical specifications input conditions voltage mode transient response (time for the output voltage to recover within 0.5% of its previous level after a step change in load...

Page 29

Features and specifications electrical characteristics revision a 27 electrical characteristics remote programming and monitoring switching frequency 7.5 v to 300 v models: nominal 125 khz (250 khz output ripple) 600 v model nominal 62.5 khz (125 khz output ripple) output hold-up time greater than 1...

Page 30

Features and specifications environmental specifications 28 operating manual for xhr series power supply environmental specifications approvals units marked with c(csa)us are csa certified to: canadian safety standard can/csa c22.2 no. 61010.1-92 and usa safety standard ul 61010b-1. Units marked wit...

Page 31

Features and specifications mechanical specifications revision a 29 mechanical specifications front panel voltage and current control 10-turn voltage and current potentiometers front panel voltage control resolution 0.02% of maximum voltage front panel voltage and current meters 3.5-digit numeric le...

Page 32

Features and specifications dimensions 30 operating manual for xhr series power supply dimensions figure 1.6 dimensional drawings (dimensions given are nominal.) 18.78 in. (477 mm) 15.85 in. (403 mm) 16.18 in. (411 mm) 8.45 in. (215 mm) 3.43 in. (87 mm) 3.14 in. (79 mm) tm-xrop-01xn.Book page 30 mon...

Page 33: Section 2. Installation

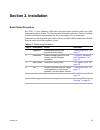

Revision a 31 section 2. Installation basic setup procedure see table 2.1 for a summary of the basic setup procedure and an overall view of the information in this section. Use the procedure as a quick reference if you are familiar with the installation requirements for the power supply. If you want...

Page 34

Installation inspection, cleaning, and packing 32 operating manual for xhr series power supply inspection, cleaning, and packing initial inspection when you first receive your unit, perform a quick physical check. 1. Ensure that each package contains the power supply and an ac input cord. 2. Inspect...

Page 35

Installation returning power supplies to the manufacturer revision a 33 returning power supplies to the manufacturer return material authorization policy before returning a product directly to xantrex you must obtain a return material authorization (rma) number and the correct factory “ship to” addr...

Page 36

Installation returning power supplies to the manufacturer 34 operating manual for xhr series power supply packaging for shipping or storage follow these instructions to prepare the unit for shipping or storage. 1. When returning the unit or sending it to the service center, attach a tag to the unit ...

Page 37

Installation location, mounting, and ventilation revision a 35 location, mounting, and ventilation rack mounting the rack mount kit allows you to mount two units side by side in a standard 19in. (483 mm) rack space. 1. Install commercially available rack slides, if used. Follow the manufacturer’s in...

Page 38

Installation ac input power 36 operating manual for xhr series power supply ac input power we warrant that the unit will perform to specification at ac input voltage range from 85 to 250 vac. The power output derates to 900 w when the ac input voltage is below 95 v. Ac fail led the ac fail (acf) led...

Page 39

Installation functional tests revision a 37 functional tests the functional test procedures include power-on and front panel function checks as well as voltage and current mode operation checks. Equipment required • digital voltmeter (dvm) rated better than 0.5% accuracy. • dc shunt 1 mv/a (±0.25%) ...

Page 40

Installation functional tests 38 operating manual for xhr series power supply current mode operation check 1. Ensure that the front panel power switch is set to off. 2. Turn the voltage and current controls on the front panel fully counter-clockwise. 3. Turn the voltage control one (1) or two (2) tu...

Page 41

Installation load connection revision a 39 load connection this section provides recommendations for load wires and how to connect them for both single and multiple load configurations. Load wiring when connecting load wiring to the power supply, consider the following factors: • current capacity an...

Page 42

Installation load connection 40 operating manual for xhr series power supply load wiring length for operation with sense lines for applications using remote sensing, you must limit the voltage drop across each load line. Figure 2.2 shows some maximum allowable wire lengths for a given load current a...

Page 43

Installation load connection revision a 41 making load connections make load connections to the power supply at output connectors at the rear of the power supply, or at the binding posts on the front panel. Binding posts (all models) the binding posts on the front panel have a built-in current limit...

Page 44

Installation load connection 42 operating manual for xhr series power supply figure 2.3 bus bar shield inductive loads use the following protection methods only when using local sensing. To prevent damage to the power supply from inductive kickback, connect a diode across the output. The diode must ...

Page 45

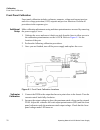

Installation load connection revision a 43 figure 2.4 typical load connection hardware (for 7.5 v to 40 v models.) to make load connections to a 7.5 v, 130 a power supply: 1. Install a connecting wire terminal lug to load wiring. See figure 2.4 . 2. Fasten wire terminal lugs to bus bars with 1/4in. ...

Page 46

Installation load connection 44 operating manual for xhr series power supply 60 v to 600 v models the output connector for the 60 v to 600 v models is a 4-terminal, wire clamp connector located on the rear panel. Two of the terminals are for local sense connections. See figure 2.5 . To prepare and c...

Page 47

Installation load connection revision a 45 connecting single loads figure 2.6 and figure 2.7 show recommended load and sensing connections for single loads. Local sense lines shown are default j2 connections. You do not need remote sensing for basic operation of your supply. However, if you wish to ...

Page 48

Installation load connection 46 operating manual for xhr series power supply radial power distribution method to connect distributed loads, we recommend that you use radial power distribution. With this method, you connect power to each load individually from a single pair of terminals designated as...

Page 49

Installation load connection revision a 47 figure 2.9 multiple loads with remote sensing tm-xrop-01xn.Book page 47 monday, march 22, 2004 4:10 pm.

Page 50

Installation local and remote sensing 48 operating manual for xhr series power supply local and remote sensing use connections on the rear panel j2 connector to set up the power supply for local or remote sensing of output voltage. Sense wiring local sensing we ship the power supply with wire jumper...

Page 51

Installation local and remote sensing revision a 49 use remote sensing during voltage mode operation to shift the power supply’s regulation point from its output terminals to the load or distribution terminals by using a separate pair of wires to allow the control circuitry to monitor the load volta...

Page 52

Installation local and remote sensing 50 operating manual for xhr series power supply . Figure 2.10connecting remote sense lines tm-xrop-01xn.Book page 50 monday, march 22, 2004 4:10 pm.

Page 53: Section 3. Local Operation

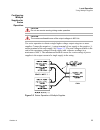

Revision a 51 section 3. Local operation standard operation once you have installed the power supply and as covered in section 2. Installation , the power supply is ready to operate in local control mode (that is, operation at the front panel). The power supply has two basic operating modes: constan...

Page 54

Local operation standard operation 52 operating manual for xhr series power supply figure 3.1 operating modes constant voltage mode operation the power supply will operate in constant voltage mode whenever the load current i l is less than the current limit setting i set , or: i l set (note: i l = v...

Page 55

Local operation standard operation revision a 53 shipped configuration (local control mode) the factory ships units already configured for local control (front panel) operation. Table 3.1 summarizes this configuration. Table 3.1 shipped configuration (local control mode) setting output voltage and c...

Page 56

Local operation using multiple supplies 54 operating manual for xhr series power supply using multiple supplies you can operate power supplies of the same model with outputs in series or in parallel to obtain increased load voltage or increased current. Split supply operation gives you two positive ...

Page 57

Local operation using multiple supplies revision a 55 configuring multiple supplies for series operation use series operation to obtain a single higher voltage output using two or more supplies. Connect the negative (–) output terminal of one supply to the positive (+) output terminal of the next su...

Page 58

Local operation using multiple supplies 56 operating manual for xhr series power supply configuring multiple supplies for parallel operation use parallel operation to obtain a higher current through a single output using two or more supplies. Set all of the ovp set points to maximum. Set all of the ...

Page 59

Local operation using multiple supplies revision a 57 configuring multiple supplies for split supply operation split supply operation uses two power supplies to obtain two positive voltages with a common ground, or to obtain a positive-negative supply. Two positive voltages to obtain two positive vo...

Page 60

Local operation using multiple supplies 58 operating manual for xhr series power supply positive-negative supply to obtain a positive-negative supply, connect the negative output terminal of one supply to the positive output terminal of the second supply. See figure 3.5 . The positive output termina...

Page 61

Local operation using over voltage protection (ovp) revision a 59 using over voltage protection (ovp) the ovp circuit protects the load in the event of a remote programming error, an incorrect voltage control adjustment, or a power supply failure. The protection circuit monitors the output voltage a...

Page 62

Local operation using over voltage protection (ovp) 60 operating manual for xhr series power supply resetting the ovp circuit to reset the ovp circuit after it activates: 1. Reduce the power supply’s output voltage setting to below the ovp set point. 2. Press the standby switch in. The s/d (shutdown...

Page 63

Local operation using the shutdown function revision a 61 using the shutdown function use the shutdown function to disable or enable the supply’s output so that you can make adjustments to either the load or the power supply without shutting off the entire supply. Activate this function from the fro...

Page 64

Local operation using the shutdown function 62 operating manual for xhr series power supply figure 3.6 shutdown programming with active low signal figure 3.7 shutdown programming with active high signal shutdown signal source: high = output off low = output on sw1-7: off (open) sw1-7: on (closed) sh...

Page 65

Local operation over temperature protection (otp) revision a 63 over temperature protection (otp) the over temperature protection circuit shuts down the power supply’s output when the power supply exceeds internal temperature limits. When an otp shutdown occurs, the otp led on the front panel turns ...

Page 66

Local operation user diagnostics 64 operating manual for xhr series power supply user diagnostics if your power supply is not performing as described in this manual, run through the procedures and checks in this section before calling your service technician. These procedures are confined to operato...

Page 67

Local operation user diagnostics revision a 65 table 3.4 quick diagnostics symptom check further checks and corrections no output and the display is blank. Is input voltage in the specified range? Connect to appropriate voltage source. Power switch on? Turn on power. Internal circuit. See your servi...

Page 68

Local operation user diagnostics 66 operating manual for xhr series power supply symptom check further checks and corrections output voltage fluctuating or regulation poor. Is unit at current limit? Increase current limit setting or reduce load. See “standard operation” on page 51 . Is input voltage...

Page 69: Section 4. Remote Operation

Revision a 67 section 4. Remote operation remote analog programming of output voltage and current limit remote analog programming allows control of the output voltage and/or current limit to shift from local operation at the front panel controls to external analog sources. As you vary the external p...

Page 70

Remote operation remote analog programming of output voltage and current limit 68 operating manual for xhr series power supply remote analog programming procedure 1. Turn the power supply off. 2. Using table 4.1 , set switches sw1-1, sw1-2, sw1-3, and sw1-4 according to the selected programming sour...

Page 71

Remote operation remote analog programming of output voltage and current limit revision a 69 table 4.1 power supply settings for different programming sources output voltage programming source output current limit programming source 0-5 vdc 0-10 vdc 0-5 k resistor 0-10 k resistor none (front panel c...

Page 72

Remote operation remote analog programming of output voltage and current limit 70 operating manual for xhr series power supply figure 4.1 connecting programming sources to j2 connector sample configuration the sample configuration in figure 4.2 shows the required settings and connections for: • 0-10...

Page 73

Remote operation remote monitoring of output voltage and current revision a 71 remote monitoring of output voltage and current readback signals the j2 connector on the rear panel provides access to calibrated readback signals for remote monitoring of the output voltage and current. Use rear panel sw...

Page 74

Remote operation using the isolated programming (isol) interface option 72 operating manual for xhr series power supply figure 4.4 0-10 vdc output voltage and current monitoring using the isolated programming (isol) interface option with the 4-channel isolated (isol) programming interface installed,...

Page 75

Remote operation using the isolated programming (isol) interface option revision a 73 isol setup and operating instructions 1. Ensure that the rear panel sw1 switch is set to its default configuration as in figure 1.4 , on p. 19 . 2. Connect the 0-5 v programming source to the j2 connector on the po...

Page 76

Remote operation using the isolated programming (isol) interface option 74 operating manual for xhr series power supply tm-xrop-01xn.Book page 74 monday, march 22, 2004 4:10 pm.

Page 77: Section 5. Calibration

Revision a 75 section 5. Calibration calibration setup service environment and precautions • follow established antistatic procedures. • work at a bench with adequate room and support for the test unit and for all equipment required. • to reduce shock hazard, use only an insulated, straight-bladed s...

Page 78

Calibration front panel calibration 76 operating manual for xhr series power supply front panel calibration front panel calibration includes voltmeter, ammeter, voltage and current preview and over voltage protection (ovp) setpoint and preview functions. Perform all procedures in the sequence give. ...

Page 79

Calibration front panel calibration revision a 77 3. Press the front panel standby switch to its in position. Check that the output voltage drops to 0v in less than 2 seconds. Check that the s/d led turns on. 4. While holding the front panel v/i check switch in, adjust the voltage check calibration ...

Page 80

Calibration calibrating for programming accuracy 78 operating manual for xhr series power supply calibrating for programming accuracy the factory calibrates the offset and range of the voltage and current programming circuits to within 1% for the default 0-5 vdc programming signals. You may need to ...

Page 81

Calibration calibrating for programming accuracy revision a 79 voltage programming circuit calibration 1. Ensure that the power supply is turned off. Disconnect any load. 2. Connect the programming source between j2 terminals 7 (output voltage programming input) and 6 (program/monitor signal return)...

Page 82

Calibration calibrating for readback accuracy 80 operating manual for xhr series power supply calibrating for readback accuracy the factory calibrates the offset and range of the output voltage and current monitor circuits to within 1% for the default 0-5 vdc scales. Recalibration may be necessary w...

Page 83

Calibration calibrating for readback accuracy revision a 81 output voltage monitor circuit calibration 1. Ensure that the power supply is turned off. Disconnect any load. 2. Connect a dvm across the power supply output to read the output voltage. 3. Connect a second dvm to the rear panel j2 terminal...

Page 84

Calibration calibrating for readback accuracy 82 operating manual for xhr series power supply output current monitor circuit calibration 1. Ensure that the power supply is turned off. Disconnect any load. 2. Connect the shunt and dvm across the power supply output to read the output current. 3. Conn...

Page 85

Tm-xrop-01xn.Book page 83 monday, march 22, 2004 4:10 pm.

Page 86

Xantrex technology inc. 8999 nelson way burnaby, british columbia canada v5a 4b5 360 925 5097 tel 360 925 5143 fax 800 670 0707 toll free north america prg.Info@xantrex.Com www.Xantrex.Com tm-xrop-01xn printed in canada tm-xrop-01xn.Book page 84 monday, march 22, 2004 4:10 pm.