- DL manuals

- Xantrex

- Power Supply

- XKW 10-300

- Operating manual

Xantrex XKW 10-300 Operating manual

Summary of XKW 10-300

Page 1

Operating manual xkw 3000 watt series programmable dc power supply xkw 8-350 xkw 10-300 xkw 12-150 xkw 20-150 xkw 40-75 xkw 55-55 xkw 60-50 xkw 80-37 xkw 150-20 xkw 300-10 tm-25op-01xn.Book page 1 monday, april 5, 2004 8:58 am.

Page 2

Tm-25op-01xn.Book page 2 monday, april 5, 2004 8:58 am.

Page 3

Operating manual for xkw 3000 watt series programmable dc power supply tm-25op-01xn.Book page i monday, april 5, 2004 8:58 am.

Page 4

Ii operating manual for xkw 3kw series power supply limited warranty what does this warranty cover and how long does it last? This limited warranty is provided by xantrex technology, inc. (“xantrex”) and covers defects in workmanship and materials in your xkw 2500 watt series dc power supply. This w...

Page 5

Revision a iii direct returns may be performed according to the xantrex return material authorization policy described in your product manual. For some products, xantrex maintains a network of regional authorized service centers. Call xantrex or check our website to see if your product can be repair...

Page 6

Iv operating manual for xkw 3kw series power supply disclaimer product this limited warranty is the sole and exclusive warranty provided by xantrex in connection with your xantrex product and is, where permitted by law, in lieu of all other warranties, conditions, guarantees, representations, obliga...

Page 7

Revision a v information without limiting the generality of the foregoing, unless specifically agreed to by it in writing, xantrex a. Makes no warranty as to the accuracy, sufficiency or suitability of any technical or other information provided in manuals or other documentation provided by it in co...

Page 8

Vi operating manual for xkw 3kw series power supply warnings and cautions warnings and cautions are defined and formatted in this manual as shown below. Power supply safety warning describes a potential hazard which could result in injury or death, or, a procedure which, if not performed correctly, ...

Page 9

Revision a vii about this manual this operating manual contains user information for the xkw series of variable dc output power supplies, available in several voltage models at 3000 watts. It provides information about features and specifications, installation procedures, and basic functions testing...

Page 10

About this manual viii operating manual for xkw 3kw series power supply power supply safety markings alternating current off (supply) earth (ground) terminal caution (hot surface) protective conductor terminal caution (check manual for additional information.) on (supply) tm-25op-01xn.Book page viii...

Page 11

Revision a ix contents about this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vii list of figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Xiii list of tables . . . ....

Page 12

X operating manual for xkw 3kw series power supply controls, connectors, and indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 load connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 load conducto...

Page 13

Revision a xi configuring multiple supplies for split supply operation. . . . . . . . . . . . . . . . . . 76 section 4. Calibration introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79 calibration setup . . . . . . . . . . ...

Page 14

Xii operating manual for xkw 3kw series power supply tm-25op-01xn.Book page xii monday, april 5, 2004 8:58 am.

Page 15

Revision a xiii list of figures figure 1.1 power supply front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 figure 1.2 power supply rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 figure 2.1 shipping or storage carton label . . . . . ....

Page 16

List of figures xiv operating manual for xkw 3kw series power supply figure 3.25 split supply operation of multiple supplies . . . . . . . . . . . . . . . . . . . . 76 figure 3.26 split supply operation of multiple supplies . . . . . . . . . . . . . . . . . . . . 77 figure 4.1 calibration adjustment...

Page 17

Revision a xv list of tables table 1.1 available voltage and current ranges . . . . . . . . . . . . . . . . . . . . . . . . 17 table 1.2 electrical specifications for 8 v to 40 v models . . . . . . . . . . . . . . . . . 21 table 1.3 electrical specifications for 55 v to 300 v models . . . . . . . . ...

Page 18

List of tables xvi operating manual for xkw 3kw series power supply tm-25op-01xn.Book page xvi monday, april 5, 2004 8:58 am.

Page 19

Revision a 17 section 1. Features and specifications description this series of power supplies provides highly stable, variable dc output voltage and current at 3000 watts of output power. You can select from several remote control choices: standard analog programming, optional isolated programming ...

Page 20

Features and specifications features and options 18 operating manual for xkw 3kw series power supply features and options • simultaneous digital display of both voltage and current. • ten-turn front panel voltage and current controls for high resolution setting of the output voltage and current from...

Page 21

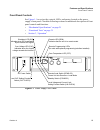

Features and specifications front panel controls revision a 19 front panel controls see figure 1.1 to review the controls, leds, and meters located on the power supply’s front panel. Check the following sections for additional descriptions of front panel controls and functions. • “mechanical specifi...

Page 22

Features and specifications rear panel connectors and switch 20 operating manual for xkw 3kw series power supply rear panel connectors and switch the input ac power, output dc power, as well as the remote program sense and monitor connector are located on the rear panel. The program and monitor func...

Page 23

Features and specifications specifications revision a 21 specifications electrical specifications these specifications are warranted over a temperature range of 0 °c to 50 °c. Specifications are subject to change without notice. Table 1.2 electrical specifications for 8 v to 40 v models models 8-350...

Page 24

Features and specifications specifications 22 operating manual for xkw 3kw series power supply table 1.3 electrical specifications for 55 v to 300 v models models 55-55 60-50 80-37 150-20 300-10 output ratings: output voltage output current output power 0-55 v 0-55 a 3025 w 0-60 v 0-50 a 3000 w 0-80...

Page 25

Features and specifications specifications revision a 23 additional specifications input conditions additional features rise time (no load, full load): 1 ~ 30 ms fall time (no load): 1 ~ 1 s fall time (full load): 1 ~ 50 ms voltage mode transient response: 2 1 ms time delay from power on until outpu...

Page 26

Features and specifications specifications 24 operating manual for xkw 3kw series power supply remote programming and monitoring environmental specification remote start/stop and interlock ttl compatible input. Contact closure, 12-250 vac or 12-130 vdc remote analog programming voltage and current p...

Page 27

Features and specifications specifications revision a 25 mechanical specifications front panel v and i control 10-turn voltage and current potentiometers front panel voltage control resolution 0.02% of v max front panel voltage and current meters 3 or 4 digit led readouts for each. See table 1.2 and...

Page 28

Features and specifications specifications 26 operating manual for xkw 3kw series power supply tm-25op-01xn.Book page 26 monday, april 5, 2004 8:58 am.

Page 29

Revision a 27 section 2. Installation introduction this section provides recommendations and procedures for inspecting, installing, and testing the power supply. Basic setup procedure see table 2.1 for a summary of the basic setup procedure and an overall view of the subsections in section 2 . Use t...

Page 30

Installation inspection, cleaning, and packaging 28 operating manual for xkw 3kw series power supply inspection, cleaning, and packaging initial inspection when you first receive your unit: 1. Inspect the unit for scratches and cracks, and for broken switches, connectors, and displays. 2. Have the s...

Page 31

Installation returning power supplies to the manufacturer revision a 29 returning power supplies to the manufacturer return material authorization policy before returning a product directly to xantrex you must obtain a return material authorization (rma) number and the correct factory “ship to” addr...

Page 32

Installation returning power supplies to the manufacturer 30 operating manual for xkw 3kw series power supply packaging for shipping or storage follow these instructions to prepare the unit for shipping or storage. 1. When returning the unit or sending it to the service center, attach a tag to the u...

Page 33

Installation location, mounting and ventilation revision a 31 location, mounting and ventilation ventilation requirements the power supply may be used in rack mounted or benchtop applications. In either case, sufficient space must be allowed for cooling air to reach the ventilation inlets in the top...

Page 34

Installation ac input power 32 operating manual for xkw 3kw series power supply ac input power ac input connector and voltage selection the ac input connector is a 4-terminal wire clamp located on the power supply’s rear panel. Operate the power supply with either a single phase or three phase ac po...

Page 35

Installation ac input power revision a 33 the ac input cord we recommend is specified in the table below. Add a non-locking plug suitable for use in the country in which you are operating. If you require a special cord, please contact the manufacturer. Ac input wire connection the power supply is sh...

Page 36

Installation ac input power 34 operating manual for xkw 3kw series power supply 6. Route the wires inside the cover to prevent pinching. Fasten the ac input cover to the standoffs on the unit using the 6-32 x 2 in. (2) screws, flat washers, and lock washers provided. Figure 2.2 stripped wire install...

Page 37

Installation functional tests revision a 35 functional tests before connecting the unit to an ac outlet, make sure that the power switch is in the off position and that the voltage and current controls are turned fully counter clockwise. Check that the j3 mating connector on the rear of the unit is ...

Page 38

Installation functional tests 36 operating manual for xkw 3kw series power supply current mode operation to check current mode operation, proceed as follows: 1. Rotate the voltage and current controls fully counterclockwise. 2. Rotate the voltage control 1/2 turn clockwise. 3. Connect a high current...

Page 39

Installation controls, connectors, and indicators revision a 37 controls, connectors, and indicators please refer to figure 1.1, “power supply front panel” on page 19 for front panel controls and indicators, figure 1.2, “power supply rear panel” on page 20 for rear panel connectors and switch detail...

Page 40

Installation load connection 38 operating manual for xkw 3kw series power supply load conductor ratings as a minimum, load wiring must have a current capacity greater than the output current rating of the power supply. This ensures that the wiring will not be damaged even if the load is shorted. Tab...

Page 41

Installation load connection revision a 39 noise and impedance effects to minimize noise pickup or radiation, use shielded-twisted pair wiring of as short a length as possible for load wires. Connect the shield to the chassis via a rear panel mounting screw. Where shielding is impossible or impracti...

Page 42

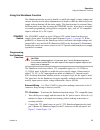

Installation load connection 40 operating manual for xkw 3kw series power supply figure 2.5 single load with local sensing (default) figure 2.6 single load with remote sensing possible and shortest length use the largest gauge load lines load negative load positive load terminal terminal power suppl...

Page 43

Installation load connection revision a 41 load connection and grounding proper connection of distributed loads is an important aspect of power supply application. A common mistake is to connect leads from the power supply to one load, from that load to the next load, and so on for each load in the ...

Page 44

Installation load connection 42 operating manual for xkw 3kw series power supply figure 2.7 multiple loads with local sensing figure 2.8 multiple loads with remote sensing possible possible and shortest length and shortest length use the largest gauge use the largest gauge load lines load lines load...

Page 45

Installation local and remote sensing revision a 43 local and remote sensing local programming mode operation units are shipped from the factory configured for local programming mode operation. • output voltage and current limit settings are adjusted with the front panel controls. • the sense point ...

Page 46

Installation using remote sensing 44 operating manual for xkw 3kw series power supply 8. Press the standby switch to its out position to apply power to the load. Using remote sensing remote sensing is used during voltage mode operation to shift the power supply's regulation point from its output ter...

Page 47

Installation using remote sensing revision a 45 • if the power supply is operated without remote sense lines or local sense jumpers in place, the supply will continue to work, but supply regulation will be degraded and/or erratic. Figure 2.10connecting remote sense lines pos load wire load wire one ...

Page 48

Installation using remote sensing 46 operating manual for xkw 3kw series power supply tm-25op-01xn.Book page 46 monday, april 5, 2004 8:58 am.

Page 49

Revision a 47 section 3. Operation introduction all power supplies in this series offer the following features as part of their standard configuration. Accessing advanced features accessing these features may require that you use one or more of the following procedures: • using the front panel rem/l...

Page 50

Operation configuring for remote programming, sensing, and monitoring 48 operating manual for xkw 3kw series power supply configuring for remote programming, sensing, and monitoring this section lists switch, connector, and jumper functions for the power supply. Subsequently, it provides a location ...

Page 51

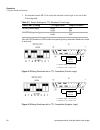

Operation configuring for remote programming, sensing, and monitoring revision a 49 figure 3.1 j3 program, sense, and monitor connector description 15 not use d no t use d cal ibra t ed out p ut v o lt a g e m o nit o r 0-5v a nd 0-10v out p ut re p r e s e nt s 0-100% out p ut v o lt a g e 15 tm-25...

Page 52

Operation configuring for remote programming, sensing, and monitoring 50 operating manual for xkw 3kw series power supply internal switch and jumpers if you should need to change any of the standard configurations of the supply, internal jumpers jmp1 and jmp2, and switch sw1 enable you to select: • ...

Page 53

Operation configuring for remote programming, sensing, and monitoring revision a 51 locating jumpers, switch, and connector switch sw1 and jumpers jmp1 and jmp2 are located on the main printed circuit board (a2) inside the power supply. “resetting jumpers and switch” on page 51 provides a procedure ...

Page 54

Operation configuring for remote programming, sensing, and monitoring 52 operating manual for xkw 3kw series power supply dissipating stored energy 1. Ensure the power supply is turned off. Disconnect the ac input connector. Allow five (5) minutes to elapse to dissipate stored energy before removing...

Page 55

Operation configuring for remote programming, sensing, and monitoring revision a 53 14. Reinstall the jack screws with the nut driver. 15. Reconnect any external cables and connector. Replacing the cover 16. Place the cover in its original location. 17. Reinstall the eight (8) flathead philips screw...

Page 56

Operation remote programming of output voltage and current limit 54 operating manual for xkw 3kw series power supply remote programming of output voltage and current limit remote programming allows control of the power supply's output voltage and/or current limit to shift from local operation at the...

Page 57

Operation remote programming of output voltage and current limit revision a 55 notes for programming with a 0-10v source: 1. Programming with a 0-10v external voltage source requires that you reset internal jumpers jmp1 and/or jmp2 in addition to performing any external operations. 2. Resetting inte...

Page 58

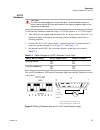

Operation remote programming of output voltage and current limit 56 operating manual for xkw 3kw series power supply figure 3.4 programming output voltage and current limit (with the rem/loc switch) notes: 1. If you are programming both output voltage and current limit with a 0-10v source and using ...

Page 59

Operation remote programming of output voltage and current limit revision a 57 programming output voltage programming output voltage with a 0-5vdc source 1. Remove the jumpers connecting pins 8 to 9 and 20 to 21 on connector j3. 2. Connect the external programming source between pins 9 (voltage prog...

Page 60

Operation remote programming of output voltage and current limit 58 operating manual for xkw 3kw series power supply figure 3.6 programming output voltage with a 0-10vdc source programming output voltage with a 0-1ma source 1. Remove the jumper between pins 20 and 21 of connector j3. 2. Connect the ...

Page 61

Operation remote programming of output voltage and current limit revision a 59 programming output voltage with a 0-5k resistance 1. Remove the jumpers connecting pins 8 to 9 and pins 20 to 21 on connector j3. 2. Connect pins 9 (voltage programming input/positive) and 21 (1 ma current source for volt...

Page 62

Operation remote programming of output voltage and current limit 60 operating manual for xkw 3kw series power supply programming output current limit with a 0-10vdc source 1. Set jumper jmp2 to its a-b location. 2. Remove the jumpers connecting pins 10 to 11 and 22 to 23 on connector j3. 3. Connect ...

Page 63

Operation remote programming of output voltage and current limit revision a 61 programming output current limit with a 0-1ma source 1. Remove the jumper between pins 22 and 23 of connector j3. 2. Connect the external programming source between pin 10 (current limit programming input/positive) and pi...

Page 64

Operation using over voltage protection (ovp) 62 operating manual for xkw 3kw series power supply using over voltage protection (ovp) the ovp circuit allows for protection of the load in the event of a remote programming error, an incorrect voltage control adjustment, or a power supply failure. The ...

Page 65

Operation using over voltage protection (ovp) revision a 63 programming ovp with an external voltage source to set the ovp trip level with a 0-5vdc or a 0-10vdc external voltage source: 1. Ensure the power supply is turned off and that both the ac power source and the load are disconnected. Allow fi...

Page 66

Operation using over temperature protection (otp) 64 operating manual for xkw 3kw series power supply figure 3.14remote programming of ovp (with a 0-10vdc external voltage source) using over temperature protection (otp) the otp circuit protects the power supply in the event of excessive temperature....

Page 67

Operation using the shutdown function revision a 65 using the shutdown function the shutdown function is used to disable or enable the supply's output voltage and current. It can be used to allow adjustments to be made to either the load or the power supply without shutting off the entire supply. Th...

Page 68

Operation using the shutdown function 66 operating manual for xkw 3kw series power supply 3. Set internal switch sw1-8 to select the desired circuit logic as set out in the following table. Table 3.2 switch settings for ttl shutdown circuit logic the red s/d (shutdown) led on the front panel lights ...

Page 69

Operation using the shutdown function revision a 67 ac/dc shutdown to activate the shutdown function using a 12-250vac input or a 12-130vdc input: 1. Turn off the power supply and disconnect the ac power source. Allow five (5) minutes to elapse to dissipate stored energy before making connections or...

Page 70

Operation using the shutdown function 68 operating manual for xkw 3kw series power supply figure 3.18using shutdown with an ac or dc input (negative logic) shutdown application contact closure an external relay, whether normally open or normally closed, may be used to activate the shutdown circuit. ...

Page 71

Operation using the shutdown function revision a 69 table 3.4 relay and switch settings for contact closure the red s/d (shutdown) led on the front panel lights up when the shutdown circuit is activated. Figure 3.19using shutdown with contact closure of a normally open relay (positive logic) relay s...

Page 72

Operation using the shutdown function 70 operating manual for xkw 3kw series power supply figure 3.20using shutdown with contact closure of an open relay (negative logic) figure 3.21using shutdown with contact closure of a closed relay (positive logic) relay coil de-energized = output off relay coil...

Page 73

Operation using the shutdown function revision a 71 figure 3.22using shutdown with contact closure of a closed relay (negative logic) relay coil de-energized = output on relay coil energized = output off normally closed (as shown) relay 15 6 2 14 1 25 13 j3 open (off) closed (on) 2 3 4 5 6 7 8 1 sw1...

Page 74

Operation remote monitoring of readback signals and status indicators 72 operating manual for xkw 3kw series power supply remote monitoring of readback signals and status indicators readback signals calibrated readback signals for remote monitoring of the output voltage and current are available via...

Page 75

Operation using multiple supplies revision a 73 using multiple supplies power supplies of the same model in this series may be operated with outputs in series or in parallel to obtain increased load voltage or increased current. Split supply operation allows two positive or a positive and a negative...

Page 76

Operation using multiple supplies 74 operating manual for xkw 3kw series power supply figure 3.23series operation of multiple supplies (local sense lines shown are default j3 connections.) configuring multiple supplies for parallel operation parallel operation is used to obtain a higher current thro...

Page 77

Operation using multiple supplies revision a 75 sensing for parallel operation use default local sensing to enhance power sharing between units, as the impedance of the load lines will tend to correct for current imbalance. If you use remote sensing at the load for better voltage regulation, one sup...

Page 78

Operation using multiple supplies 76 operating manual for xkw 3kw series power supply configuring multiple supplies for split supply operation split supply operation uses two power supplies to obtain two positive voltages with a common ground, or to obtain a positive-negative supply. To obtain two p...

Page 79

Operation using multiple supplies revision a 77 figure 3.26split supply operation of multiple supplies (positive-negative supply) (local sense lines shown are default j3 connections.) common load power supply 2 power supply 1 possible and shortest length use the largest gauge load lines load negativ...

Page 80

Operation using multiple supplies 78 operating manual for xkw 3kw series power supply tm-25op-01xn.Book page 78 monday, april 5, 2004 8:58 am.

Page 81

Revision a 79 section 4. Calibration introduction adjustments to programming and readback accuracy for the power supply are made using cover-off procedures which must be performed by a service technician. Calibration setup service environment and precautions • follow established antistatic procedure...

Page 82

Calibration calibration setup 80 operating manual for xkw 3kw series power supply removing the cover 1. Unscrew and remove the eight (8) flathead philips screws from the top of the cover: two (2) are located near the front panel, six (6) near the rear panel. Use a #1 philips screwdriver. 2. Loosen b...

Page 83

Calibration calibration setup revision a 81 figure 4.1 calibration adjustment locations r60 r93 r66 r95 r23 r56 r24 r55 tm-25op-01xn.Book page 81 monday, april 5, 2004 8:58 am.

Page 84

Calibration calibrating for programming accuracy 82 operating manual for xkw 3kw series power supply calibrating for programming accuracy the offset and range of the voltage and current programming circuits are calibrated for default 0-5vdc programming signals at the factory. Recalibration may be ne...

Page 85

Calibration calibrating for programming accuracy revision a 83 current programming circuit calibration table 4.2 current programming calibration procedures repeat this procedure until the current programming is adjusted to the desired accuracy. Notes: 1. The dc shunt-dvm combination must be rated be...

Page 86

Calibration calibrating for programming accuracy 84 operating manual for xkw 3kw series power supply voltage readback calibration the factory calibrates the offset and range of the output voltage and current monitor circuits to within 1% for the default 0-5vdc scales. Should you need to recalibrate,...

Page 87

Calibration calibrating for programming accuracy revision a 85 current readback calibration table 4.4 current readback calibration repeat this procedure until the monitor scale is adjusted to the desired accuracy. Notes: 1. The recommended accuracy of the dvm and dc shunt-dvm combination is four tim...

Page 88

Calibration battery charging 86 operating manual for xkw 3kw series power supply battery charging when using this power supply to charge a battery, take the following precautions to prevent damage to the supply and/or the battery in case the overvoltage protection (ovp) circuit is activated. 1. Sele...

Page 89

Tm-25op-01xn.Book page 3 monday, april 5, 2004 8:58 am.

Page 90: Xantrex Technology Inc.

Xantrex technology inc. 1 800 670 0707 tel toll free na 1 360 925 5097 tel direct 1 800 994 7828 fax toll free na 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com tm-25op-01xn printed in canada tm-25op-01xn.Book page 4 monday, april 5, 2004 8:58 am.