- DL manuals

- Xantrex

- Power Supply

- XTR 100-17

- Operating Manual

Xantrex XTR 100-17 Operating Manual

XTR 850 Watt and

1700 Watt Series

Programmable DC

Power Supply

Operating Manual

XTR 6-110 XTR 6-220

XTR 8-100 XTR 8-200

XTR 12-70 XTR 12-140

XTR 20-42 XTR 20-84

XTR 33-25 XTR 33-50

XTR 40-21 XTR 40-42

XTR 60-14 XTR 60-28

XTR 80-10.5 XTR 80-21

XTR 100-8.5 XTR 100-17

XTR 150-5.6 XTR 150-11.2

XTR 300-2.8 XTR 300- 5.6

XTR 600-1.4 XTR 600-2.8

Summary of XTR 100-17

Page 1

Xtr 850 watt and 1700 watt series programmable dc power supply operating manual xtr 6-110 xtr 6-220 xtr 8-100 xtr 8-200 xtr 12-70 xtr 12-140 xtr 20-42 xtr 20-84 xtr 33-25 xtr 33-50 xtr 40-21 xtr 40-42 xtr 60-14 xtr 60-28 xtr 80-10.5 xtr 80-21 xtr 100-8.5 xtr 100-17 xtr 150-5.6 xtr 150-11.2 xtr 300-2...

Page 3: Xtr 850 Watt and 1700

Xtr 850 watt and 1700 watt series programmable dc power supply operating manual.

Page 4

975-0200-01-01 ii about xantrex xantrex technology inc. Is a world-leading supplier of advanced power electronics and controls with products from 50 watt mobile units to 2.5 mw utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup power applications in both grid-con...

Page 5

975-0200-01-01 iii product numbers (fgas) part numbers for rack mount kits contact information 850 watt models 1700 watt models xtr_6-110 xtr_6-220 xtr_8-100 xtr_8-200 xtr_12-70 xtr_12-140 xtr_20-42 xtr_20-84 xtr_33-25 xtr_33-50 xtr_40-21 xtr_40-42 xtr_60-14 xtr_60-28 xtr_80-10.5 xtr_80-21 xtr_100-8...

Page 7: About This Manual

975-0200-01-01 v about this manual purpose the operating manual providesinstallation and operating information for the xtr 850 watt and 1700 watt series programmable dc power supply. Scope the manual provides safety information, features and specifications, installation procedures, functional test p...

Page 8: Related Information

About this manual vi 975-0200-01-01 related information for related information on this product, see also: • xtr 850w and 1700w gpib and ethernet interface option operating manual provides information on the gpib and ethernet interface option. (part number 975-0275-0101) • xtr 850 watt and 1700 watt...

Page 9: Power Supply Safety Markings

975-0200-01-01 vii important safety instructions power supply safety markings warning: high energy and high voltage exercise caution when using a power supply. High energy levels can be stored at the output voltage terminals on a power supply in normal operation. In addition, potentially lethal volt...

Page 10: Standard Warnings

Safety viii 975-0200-01-01 standard warnings 1. Before installing and using the xtr 850 watt or xtr 1700 watt series programmable dc power supply, read all instructions and cautionary markings on the xtr and all appropriate sections of this manual. 2. The xtr is for indoor use only. Do not expose th...

Page 11: 1 Introduction

975-0200-01-01 ix important safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii 1 introduction features and options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2 xtr 850 watt and xtr 1700 watt models - - - - - - - - - ...

Page 12: 3 Local Operation

Contents x 975-0200-01-01 connecting single loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14 connecting multiple loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15 step 7: connecting remote sensing - - - - - - - - - - - - - - - - - - ...

Page 13: (Isol)

Contents xi 975-0200-01-01 current configuration memory settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–27 user setting memory locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–28 saving user setting memory locations - - - - - - - - - - - - - - - ...

Page 14: 5 Remote Operation

Contents xii 975-0200-01-01 voltage-controlled voltage isol setup - - - - - - - - - - - - - - - - - - - - - - - - - - 4–22 voltage-controlled current isol setup - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–23 resistive-controlled voltage isol setup - - - - - - - - - - - - - - - - - - - - ...

Page 15

Contents xiii 975-0200-01-01 standard scpi register structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–32 operation status register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–33 current share sub-register - - - - - - - - - - - - - - - -...

Page 16: A Scpi Command Reference

Contents xiv 975-0200-01-01 calibrating the output voltage- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5 gain calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5 offset calibration - - - - - - - - - - - - - - - - - - ...

Page 17: B Error Messages

Contents xv 975-0200-01-01 b error messages error messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b–2 command error list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - b–2 execution error list - - - - - - - - - - -...

Page 18

Xvi.

Page 19: Figures

975-0200-01-01 xvii figure 1-1 front panel: xtr 850 watt and xtr 1700 watt - - - - - - - - - - - - - - - - - 1–4 figure 1-2 front panel display and controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5 figure 1-3 xtr 850 watt series: 6 v to 40 v models - - - - - - - - - - - - - - - - ...

Page 20

Figures 975-0200-01-01 xviii figure 4-14 programming output current using an isolated external resistor - - - - - 4–25 figure 4-15 isolated voltage monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–29 figure 4-16 isolated current monitoring - - - - - - - - - - - - - - - - - - ...

Page 21: Tables

975-0200-01-01 xix table 1-1 xtr 850 watt series voltage and current ranges - - - - - - - - - - - - - - - - 1–3 table 1-2 xtr 1700 watt series voltage and current ranges - - - - - - - - - - - - - - - 1–3 table 2-1 basic setup procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ...

Page 22

Tables xx 975-0200-01-01 table 5-15 questionable status register - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–42 table 5-16 questionable voltage status register - - - - - - - - - - - - - - - - - - - - - - 5–42 table 5-17 questionable temperature status register - - - - - - - - - - -...

Page 23: Introduction

1 introduction chapter 1, introduction, describes the features of the xtr 850 watt and 1700 watt series programmable dc power supply..

Page 24: Features and Options

Introduction 1-2 975-0200-01-01 features and options the xtr 850 watt and xtr 1700 watt series programmable dc power supplies provide stable, variable output voltage and current for a broad range of development and system requirements. The power supplies have a high power density and numerous indust...

Page 25

Xtr 850 watt and xtr 1700 watt models 975-0200-01-01 1-3 1 xtr 850 watt and xtr 1700 watt models table 1-1 lists the models in the xtr 850 watt series covered by this manual. Table 1-2 lists the models in the xtr 1700 watt series covered by this manual. Table 1-1 xtr 850 watt series voltage and curr...

Page 26

Introduction 1-4 975-0200-01-01 front panel for xtr 850 watt and xtr 1700 watt figure 1-1 front panel: xtr 850 watt and xtr 1700 watt item description 1 front panel power switch 2 front panel display. See figure 1-2 for details. 3 air intake vents 1 3 2.

Page 27

Front panel for xtr 850 watt and xtr 1700 watt 975-0200-01-01 1-5 1 front panel display and controls figure 1-2 front panel display and controls item description 1 rotary knob/enter button 2 constant voltage (cv) mode led (green) 3 output voltage display 4 constant current (cc) mode led (green) 5 ou...

Page 28

Introduction 1-6 975-0200-01-01 rear panel connectors on xtr 850 watt figure 1-3 xtr 850 watt series: 6 v to 40 v models figure 1-4 xtr 850 watt series: 60 v to 150 v models figure 1-5 xtr 850 watt series: 300 v to 600 v models 1 2 3 4 5 7 8 9 10 11 6 2 3 5 6 11 10 8 7 9 4 1 1 2 3 5 6 11 4 10 9 8 7.

Page 29

Rear panel connectors on xtr 850 watt 975-0200-01-01 1-7 1 item description 1 6 v– 40 v models: dc output terminal positive 60 v–150 v models: dc output connectors positive (6.5 mm hole diameter) 300 v–600 v models: dc output connectors positive 2 6 v– 40 v models: dc output terminal negative 60 v–1...

Page 30

Introduction 1-8 975-0200-01-01 rear panel connectors on xtr 1700 watt figure 1-6 xtr 1700 watt series: 6 v to 40 v models figure 1-7 xtr 1700 watt series: 60 v to 600 v models item description 1 6 v– 40 v models: dc output terminal positive (8.5 mm hole diameter) 60 v–600 v models: dc output connec...

Page 31: Installation

2 installation chapter 2, installation, provides information and procedures for inspecting, installing, and testing the power supply..

Page 32: Basic Setup Procedure

Installation 2-2 975-0200-01-01 basic setup procedure table 2-1 provides a summary of the basic setup procedure with references to the relevant sections in this chapter. Refer to this table if you are unfamiliar with the installation requirements for the power supply. Complete each step in the seque...

Page 33: Initial Inspection

Step 1: inspecting and cleaning 975-0200-01-01 2-3 2 step 1: inspecting and cleaning initial inspection when you first receive your unit, perform a physical check: 1. Inspect the unit for any scratches and cracks, broken switches, connectors or displays. 2. For the xtr 850 watt only, ensure that the...

Page 34: Rack Mounting

Installation 2-4 975-0200-01-01 step 2: location and mounting the power supply may be rack-mounted or used in benchtop applications. Rack mounting the xtr 850 watt power supply is designed to fill half of a standard 19 inch (483 mm) equipment rack. The xtr 1700 watt is designed to fill a standard 19...

Page 35: Warning: Shock Hazard

Step 3: connecting ac input power 975-0200-01-01 2-5 2 step 3: connecting ac input power xtr 850 watt ac input connector on the xtr 850 watt, the ac input connector is a standard iec 16 a 250 v male connector located on the rear panel of the power supply. The ac input cord provided is rated for 30 a...

Page 36

Installation 2-6 975-0200-01-01 xtr 1700 watt ac input connector on the xtr 1700 watt, the ac input connector is a 3-terminal wire clamp located on the rear panel of the power supply. See figure 2-1. Figure 2-1 xtr 1700 watt ac input cover and strain relief screw (1 place) ac cover 100 - 240 vac 47-...

Page 37: Xtr 1700 Watt Ac Input Wire

Step 3: connecting ac input power 975-0200-01-01 2-7 2 xtr 1700 watt ac input wire the xtr 1700 watt is not supplied with a power cord or a non-locking ac plug. Table 2-2 specifies the recommended ac input wire size. You must also purchase and install the correctly rated non-locking plug for your in...

Page 38

Installation 2-8 975-0200-01-01 6. Route the wires inside the cover to prevent pinching. Fasten the ac cover to the unit using the screw provided. See figure 2-1..

Page 39: Step 4: Selecting Load Wires

Step 4: selecting load wires 975-0200-01-01 2-9 2 step 4: selecting load wires this section provides recommendations for selecting minimum load wire sizes. Load wiring to select the wiring for connecting the load to the power supply, consider the following factors: • insulation rating of the wire. •...

Page 40

Installation 2-10 975-0200-01-01 maximum load wiring length for operation with sense lines noise and impedance effects to minimize noise pickup or radiation, use shielded twisted pair wiring of the shortest possible length for load sense wires. Connect the shield to the power supply chassis. Where s...

Page 41

Step 5: performing functional tests 975-0200-01-01 2-11 2 step 5: performing functional tests the functional test procedures include: • power-on and front panel functional checks • voltage mode operation and current mode operation checks. For information on local operation, see “local operation” on ...

Page 42

Installation 2-12 975-0200-01-01 voltage and current mode operation checks to perform the voltage and current mode operation checks: 1. Ensure that the front panel power switch is in the on position and the output is disconnected. 2. If the output on/off button is illuminated, press the button to tu...

Page 43: Step 6: Connecting Loads

Step 6: connecting loads 975-0200-01-01 2-13 2 step 6: connecting loads this section describes how to connect loads to the power supply for both single and multiple loads. Dc output connectors 6 v–40 v models the 6 v–40 v models of the xtr 850 watt and xtr 1700 watt are equipped with output terminal...

Page 44: Inductive Loads

Installation 2-14 975-0200-01-01 inductive loads to prevent damage to the power supply from inductive kickback, connect a diode across the output. The diode must have a voltage rating at least 20% greater than the power supply's output voltage and have a current rating greater than or equal to the p...

Page 45: Connecting Multiple Loads

Step 6: connecting loads 975-0200-01-01 2-15 2 connecting multiple loads the proper connection of distributed loads is an important aspect of power supply use. The common method of connection is a radial load connection. Power is connected to each load individually from a single pair of terminals de...

Page 46: Warning: Shock Hazard

Installation 2-16 975-0200-01-01 step 7: connecting remote sensing remote sensing permits you to shift the regulation point of the power supply from the output terminals to the load or other distribution terminals. Use shielded twisted pair wiring of 20 to 26 awg for best noise performance. Make sur...

Page 47: Caution

Step 7: connecting remote sensing 975-0200-01-01 2-17 2 3. Connect one end of the shielded twisted pair wire to the chassis ground point on the power supply. 4. Connect the positive sense line (+sns) from the positive regulation point as close as possible to the load terminals to pin j1.1. 5. Connec...

Page 48

2-18.

Page 49: Local Operation

3 local operation chapter 3, local operation, provides the procedures for local (front panel) operation such as: • configuring settings. • operating in constant voltage mode and constant current mode. • using the protection features. • using multiple power supplies..

Page 50: Introduction

Local operation 3-2 975-0200-01-01 introduction once you have installed the power supply and connected both the ac input power and the load (covered in “installation” on page 2–1), the power supply is ready for local operation. To turn the power supply on, see “powering the power supply on/off” on p...

Page 51

Configuring settings from the front panel 975-0200-01-01 3-3 3 fine adjustment mode pressing the rotary knob/enter button to change the mode to fine adjustment mode provides the ability to manipulate the last significant digit. Once the exact desired value for the setting has been selected, press th...

Page 52: Navigating The Menu System

Local operation 3-4 975-0200-01-01 navigating the menu system the menu system of the xtr follows a select and set model with the exception of the vol and cur modes. See “setting vol and cur modes”. The general procedure for setting up the features in the select and set model is: 1. To select a mode,...

Page 53

Navigating the menu system 975-0200-01-01 3-5 3 • when the cur mode is selected, the current set point will blink in the output current display. 2. Use the rotary knob/enter button to adjust the set point. The adjustments you make to the set point affect the opposing output value (voltage when in cu...

Page 54

Local operation 3-6 975-0200-01-01 normal display mode and inactivity timeout normal display mode appears on the output voltage and current displays when the configuration changes from the front panel have been completed or when the inactivity timeout occurs (default is 3 seconds). Normal display mo...

Page 55

Navigating the menu system 975-0200-01-01 3-7 3 figure 3-2 front panel menu system legend: press rotary knob/enter button when no modification of the tracking value has been made. Mode knob state setting/value press rotary knob/enter button rotate rotary knob/enter button vol cur fld prt sav rcl cap...

Page 56

Local operation 3-8 975-0200-01-01 display messages on the front panel the front panel displays on the power supply will use text as shown in table 3-2 to indicate the status or mode. Table 3-2 front panel display text display text text description 0 negative polarity 232 rs 232 485 rs 485 8888 all ...

Page 57

Display messages on the front panel 975-0200-01-01 3-9 3 a blinking numeric value is either a voltage or current set point in tracking mode. The display in which the set point appears, output voltage or output current display, indicates the type of set point, voltage or current. Le u voltage apg lev...

Page 58: Standard Operation

Local operation 3-10 975-0200-01-01 standard operation the power supply can be controlled by two methods, either from the front panel or from any of the remote interfaces. Front panel control is referred to as local operation (default setting) while control via any of the remote interfaces is called...

Page 59

Standard operation 975-0200-01-01 3-11 3 output disabled the mode of operation is not determined until the output is enabled. The cv and cc mode leds will not indicate the mode while the output is disabled. Constant voltage mode operation if the output is enabled and the configured current set point...

Page 60

Local operation 3-12 975-0200-01-01 the reverse operating mode change can also occur if the load resistance is increased to the point that the required load current drops below the i set value. At that point the power supply would crossover to cv mode and the load current would be free to vary as th...

Page 61

Standard operation 975-0200-01-01 3-13 3 5. Once the desired value has been set, press the rotary knob/enter button to commit the setting. Quick tip remote operation uses these scpi commands. See page 5–1. The scpi command (s) for these instructions are: [[:]source[]]:voltage[:level][:immediate] [:a...

Page 62: Turning The Output On/off

Local operation 3-14 975-0200-01-01 shipped configuration (local operation) the power supply is configured for local operation at the factory. See table 3-3 for a summary of this configuration. For more information on default settings, see table 3-9 on page 3–35. Turning the output on/off turning th...

Page 63

Turning the auxiliary output on/off 975-0200-01-01 3-15 3 turning the auxiliary output on/off to turn on the auxiliary output: u press the aux on/off button on the front panel. The aux on/off button will illuminate. To turn off auxiliary output: u press the aux on/off button on the front panel again...

Page 64: Auxiliary Auto Start Mode

Local operation 3-16 975-0200-01-01 auxiliary auto start mode the auxiliary auto start mode determines the state of the auxiliary output after a complete power cycle (all front panel leds are not illuminated). With auxiliary auto start mode turned to on, the auxiliary output will be activated after ...

Page 65: Alarms and Errors

Alarms and errors 975-0200-01-01 3-17 3 alarms and errors several conditions can cause alarms in the xtr. Some conditions are: • from user configurable features. • controlled in hardware and will trigger regardless of configuration. All alarms, with the exception of the fan alarm, will result in the...

Page 66: Clearing Alarms

Local operation 3-18 975-0200-01-01 clearing alarms clearing triggered and manual alarms to clear a triggered alarm, use one of the following methods: • turn the power supply off and then on. • press and hold the rotary knob/enter button for 3 seconds. • press the reset key combination (flash fail o...

Page 67: Front Panel Alarm Led

Alarms and errors 975-0200-01-01 3-19 3 clearing automatic alarms some alarms will clear automatically when the condition that caused the alarm is no longer present. When an alarm automatically clears, the output voltage and current displays will return to normal, but the alarm led will remain illum...

Page 68: Alarm Masking

Local operation 3-20 975-0200-01-01 the alarm led will remain illuminated until the alarm is manually cleared (see “clearing triggered and manual alarms” on page 3–18) or by turning the main output on if the alarm has automatically been cleared. Alarm masking it is possible to completely disable som...

Page 69: Alarm Output Latching

Alarms and errors 975-0200-01-01 3-21 3 alarm output latching when an alarm is triggered, the output will be disabled with the exception of the fan alarm. When an alarm is cleared, the alarm output latch determines if the output should be re-enabled to the state before the alarm occurred or if the o...

Page 70: Setting Foldback Mode

Local operation 3-22 975-0200-01-01 setting foldback mode foldback mode is used to disable the output when a transition is made between the operating modes. The power supply will turn off/disable the output and lock in foldback mode after a specified delay if the power supply transitions into cv mod...

Page 71

Setting foldback mode 975-0200-01-01 3-23 3 4. Press the rotary knob/enter button to commit the setting once the desired value has been set. 5. The green fld led will turn off and the display will return to the normal display mode. The scpi command (s) for these instructions are: [:]output[]:protect...

Page 72: Defining The Ovp Set Point

Local operation 3-24 975-0200-01-01 using over voltage protection (ovp) the ovp circuit protects the load in the event of an analog programming error, an incorrect voltage control adjustment, or a power supply failure. The ovp circuit monitors the output voltage at the output of the power supply and...

Page 73: Defining The Uvp Set Point

Using under voltage protection (uvp) 975-0200-01-01 3-25 3 using under voltage protection (uvp) the uvp prevents voltage settings below a set value. The uvp lets you create a voltage window of operation when used in conjunction with the ovp setting. The uvp range is variable from 0 v to v set –5%. T...

Page 74: Defining The Otp Mode

Local operation 3-26 975-0200-01-01 using over temperature protection lock (otp) the otp lock protects the power supply in the event of an over temperature alarm. This alarm could be caused by ventilation restriction or overheating due to fan failure. Two modes are available: • auto recovery (otp of...

Page 75

Current configuration memory settings 975-0200-01-01 3-27 3 current configuration memory settings the power supply will save the unit settings at the time of power down. These settings will be loaded when the power is restored to the unit or the power supply is powered up again. Table 3-7 lists the ...

Page 76

Local operation 3-28 975-0200-01-01 user setting memory locations there are three user setting memory locations available for storing frequently used configurations. These user setting memory locations help to facilitate multiple users of an xtr power supply who have different setups or when multipl...

Page 77

User setting memory locations 975-0200-01-01 3-29 3 4. The setting has now been saved to the selected user setting memory location. The scpi command (s) for these instructions are: *sav or [:]system[]:save recalling user setting memory locations this feature recalls settings that were previously sav...

Page 78: Local Lockout

Local operation 3-30 975-0200-01-01 local lockout local lockout is a feature that allows the front panel to be locked so that accidental button presses are ignored. This feature is often used to lockout the front panel when you are controlling the power supply from a remote location. When in local l...

Page 79

Using the external shutdown function 975-0200-01-01 3-31 3 using the external shutdown function use the external shutdown function to enable or disable the output of the power supply via a logic level signal. When the external shutdown is triggered, the power supply will display sd pol on the output...

Page 80

Local operation 3-32 975-0200-01-01 3. Press the rotary knob/enter button to display sd 0 (shutdown on logic 1) or sd1 (shutdown on logic 0). 4. Press the rotary knob/enter button to commit the desired polarity setting. For example: if you set the shutdown logic to 1 (sd1) and apply a logic high (gr...

Page 81: Interlock Function

Interlock function 975-0200-01-01 3-33 3 interlock function the interlock function can be used to wire an external shutoff switch that can be used to enable or disable the power supply output. When the switch is closed the power supply will operate normally. If the switch is opened, the power supply...

Page 82: Hardware Malfunction Alarms

Local operation 3-34 975-0200-01-01 • shutdown activated (rear panel shutdown). • internal hardware malfunction • fan failure hardware malfunction alarms the power supply will turn off the output. An error message will be displayed in the event that: • ovp trips • voltage deviation in cv mode reache...

Page 83: Resetting The Power Supply

Resetting the power supply 975-0200-01-01 3-35 3 resetting the power supply the reset is used to clear the parameters to the factory default values. To perform a reset: 1. Turn the power supply to off then on. When the unit is powering on, 8888 8888 is displayed on the output voltage and current dis...

Page 84

Local operation 3-36 975-0200-01-01 to reset the power supply: 1. Turn the front panel power switch to the off position. 2. Allow the unit to power down. 3. When the fans are off and the front panel displays are not illuminated, turn the power switch to the on position. 4. Press and hold the output ...

Page 85: Warning: Shock Hazard

Using multiple power supplies 975-0200-01-01 3-37 3 using multiple power supplies you can operate power supplies of the same model with the outputs in series to obtain increased load voltage or with the outputs in parallel to obtain increased current, also called current sharing. Split supply operat...

Page 86

Local operation 3-38 975-0200-01-01 figure 3-4 split supply operation v v common power supply power supply load.

Page 87: Caution

Using multiple power supplies 975-0200-01-01 3-39 3 configuring multiple supplies for series operation a maximum of two power supplies of the same rating can be connected in series to increase the output voltage. Connecting to the load in local sensing mode connect the negative (–) output terminal o...

Page 88: Caution

Local operation 3-40 975-0200-01-01 connecting to the load in remote sensing mode connect the negative (–) output terminal of one power supply to the positive (+) output terminal of the next power supply. The more positive supply’s positive sense line should connect to the positive terminal of the l...

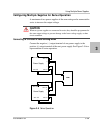

Page 89: Method)

Using multiple power supplies 975-0200-01-01 3-41 3 configuring multiple supplies for current sharing operation (apg method) up to four power supplies can be connected in parallel to increase the output current. One of the units will operate as the master unit and the remaining units will operate as...

Page 90

Local operation 3-42 975-0200-01-01 setting over voltage protection (ovp) the master unit’s ovp should be programmed to the desired ovp level. The ovp of the slave units should be programmed to a higher value than the master ovp. When the master unit shuts down, it will program the outputs of the sl...

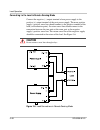

Page 91: Method)

Using multiple power supplies 975-0200-01-01 3-43 3 connecting to the load in local sensing mode (parallel control method) connect the power supplies in parallel to obtain a single output supply with a higher output current set point. Set all of the outputs to the same voltage before connecting the ...

Page 92: Method)

Local operation 3-44 975-0200-01-01 connecting to the load in remote sensing mode (parallel control method) figure 3-8 load connections in remote sensing mode (parallel control method).

Page 93: Analog

4 analog programming (apg) and isolated analog programming (isol) chapter 4, analog programming (apg) and isolated analog programming (isol), provides information and procedures for analog and isolated analog programming of the power supply..

Page 94: Introduction

Analog programming (apg) and isolated analog programming (isol) 4-2 975-0200-01-01 introduction the rear panel connectors j1 and j3 provide an option to control and monitor the output of the power supply with analog signals. Connector j1 provides a non-isolated analog interface where all signals are...

Page 95: Remote Programming Options

Introduction 975-0200-01-01 4-3 4 remote programming options analog monitor signals there are four monitor lines for analog programming the pin name and the related apg mode, which are listed in table 4-1. All of these lines are provided to give analog feedback. The output from these monitor lines i...

Page 96

Analog programming (apg) and isolated analog programming (isol) 4-4 975-0200-01-01 table 4-2 remote programming options control of… programming scale 1 1.The resolution can be adjusted in increments of 0.1 volts. For more info… output voltage 2–10 v voltage source (adjustable) see page 4–10. Current...

Page 97

Introduction 975-0200-01-01 4-5 4 analog programming (apg) connector j1 the apg connector is an 18-pin connector. See figure 4-1. The apg connector provides access to the following functions: • sense control • analog programming and monitoring. Figure 4-1 apg connector terminals table 4-3 apg pins a...

Page 98

Analog programming (apg) and isolated analog programming (isol) 4-6 975-0200-01-01 j1.9 vol_pr analog voltage programming input j1.10 cur_pr analog current programming input j1.11 vol_res_pr voltage resistive programming j1.12 cur_res_pr current resistive programming j1.13 vol_mon voltage monitor. S...

Page 99: Caution

Introduction 975-0200-01-01 4-7 4 making control connections to connect the output wires to the apg and dc output connector: 1. Insert a 3/32 inch slot-head screwdriver into the orange-colored box of the connector until the end of the spring is reached. See figure 4-2. 2. Hold the connector open and...

Page 100: Warning: Shock Hazard

Analog programming (apg) and isolated analog programming (isol) 4-8 975-0200-01-01 wiring for most connectors and jumpers, use any suitable wire such as 20 to 26 awg stranded wire. For lowest noise performance, use shielded twisted pair wiring of 20 to 26 awg of the shortest length possible. Ground ...

Page 101: Analog Programming Mode

Analog programming mode 975-0200-01-01 4-9 4 analog programming mode for more details about connections for your particular model, see “rear panel connectors on xtr 850 watt” on page 1–6 or “rear panel connectors on xtr 1700 watt” on page 1–8. Analog programming with external voltage source the pin ...

Page 102

Analog programming (apg) and isolated analog programming (isol) 4-10 975-0200-01-01 voltage-controlled voltage apg setup activating apg voltage mode to activate apg voltage mode using an external voltage source: 1. Turn the mode control knob to the vap position or press the rotary knob/enter button ...

Page 103

Analog programming mode 975-0200-01-01 4-11 4 the output voltage display should read le u and the output current display will display apg level. 4. Press the rotary knob/enter button to return to normal mode. 5. If the apg mode was modified in step 2, execute the procedure to deactivate the apg volt...

Page 104

Analog programming (apg) and isolated analog programming (isol) 4-12 975-0200-01-01 voltage-controlled current apg setup activating apg current mode to activate apg current mode using an external voltage source: 1. Turn the mode control knob to the cap position or press the rotary knob/enter button ...

Page 105

Analog programming mode 975-0200-01-01 4-13 4 3. Press the rotary knob/enter button to select the apg mode. The output voltage display should read le c and the output current display will display apg level. 4. Press the rotary knob/enter button to return to normal mode. 5. If the apg mode was modifi...

Page 106

Analog programming (apg) and isolated analog programming (isol) 4-14 975-0200-01-01 analog programming with external resistor the pin numbers are described in table 4-3 on page 4–5. T figure 4-6 programming output voltage using an external resistor figure 4-7 programming output current using an exte...

Page 107

Analog programming mode 975-0200-01-01 4-15 4 resistive-controlled voltage apg setup to activate apg voltage mode using an external resistor: 1. Turn the mode control knob to the vap position or press the rotary knob/enter button if the control knob is already at the vap position. Uapr is displayed ...

Page 108

Analog programming (apg) and isolated analog programming (isol) 4-16 975-0200-01-01 the output voltage display should read le u and the output current display will display apg level. 4. Press the rotary knob/enter button to return to normal mode. 5. If the apg mode was modified in step 2, execute th...

Page 109

Analog programming mode 975-0200-01-01 4-17 4 resistive-controlled current apg setup to activate apg current mode using an external resistor source: 1. Turn the mode control knob to the cap position to press the rotary knob/enter button if the control knob is already at cap position. Capr is display...

Page 110: Voltage and Current Readback

Analog programming (apg) and isolated analog programming (isol) 4-18 975-0200-01-01 4. Press the rotary knob/enter button to return to normal mode. 5. If the apg mode was modified in step 2, execute the procedure to deactivate the apg voltage mode. Quick tip remote operation uses these scpi commands...

Page 111

Isolated analog programming mode (isol) 975-0200-01-01 4-19 4 isolated analog programming mode (isol) see “rear panel connectors on xtr 850 watt” on page 1–6 or “rear panel connectors on xtr 1700 watt” on page 1–8 for more details about connections. Aux output and isolated analog programming (isol) ...

Page 112: Caution: Equipment Damage

Analog programming (apg) and isolated analog programming (isol) 4-20 975-0200-01-01 table 4-4 aux output and isol connector pins and functions j3 pin reference function j3.1 aux_on_off auxiliary on/off j3.2 com_isolated isolated common (isolated from main output and communication. Return wire for +5...

Page 113: Caution

Isolated analog programming mode (isol) 975-0200-01-01 4-21 4 making isol control connections for most connectors and jumpers, use any suitable wire such as 22 awg stranded wire. For lowest noise performance, use shielded twisted pair wiring of 22 awg. Use the shortest leads possible. +5 v and +15 v...

Page 114

Analog programming (apg) and isolated analog programming (isol) 4-22 975-0200-01-01 voltage-controlled voltage isol setup activating isol programming voltage mode to activate isol programming voltage mode with an external voltage source: 1. Turn the mode control knob to the vap position or press the...

Page 115

Isolated analog programming mode (isol) 975-0200-01-01 4-23 4 2. If the mode is currently none then select any other isol mode. If this step is done, be sure to restore the isol setting to none when the operation is complete. Otherwise, do not rotate the rotary knob/ enter button to keep the current...

Page 116

Analog programming (apg) and isolated analog programming (isol) 4-24 975-0200-01-01 deactivating isol current mode to deactivate the isol current mode: 1. Turn the mode control knob to the vap position or press the rotary knob/enter button if the control knob is already at the vap position. 2. Capr ...

Page 117

Isolated analog programming mode (isol) 975-0200-01-01 4-25 4 analog programming with external resistor the pin numbers are described in table 4-4 on page 4–20. Figure 4-13 programming output voltage using an isolated external resistor figure 4-14 programming output current using an isolated externa...

Page 118

Analog programming (apg) and isolated analog programming (isol) 4-26 975-0200-01-01 resistive-controlled voltage isol setup activating isol programming voltage mode to activate isol programming voltage mode using an external resistor: 1. Turn the mode control knob to the vap position or press the ro...

Page 119

Isolated analog programming mode (isol) 975-0200-01-01 4-27 4 2. If the mode is currently none then select any other isol mode. If this step is done, be sure to restore the isol setting to none when the operation is complete. Otherwise, do not rotate the rotary knob/ enter button to keep the current...

Page 120

Analog programming (apg) and isolated analog programming (isol) 4-28 975-0200-01-01 deactivating isol current mode to deactivate the isol current mode: 1. Turn the mode control knob to the cap position or press the rotary knob/enter button if the control knob is already at the cap position. 2. Capr ...

Page 121

Voltage and current readback (isolated) 975-0200-01-01 4-29 4 voltage and current readback (isolated) the pin numbers are described in table 4-4 on page 4–20. Query remote control source state quick tip remote operation uses these scpi commands. See page 5–1. The scpi command (s) for these instructi...

Page 122

4-30

Page 123: Remote Operation

5 remote operation chapter 5, remote operation, describes the remote operation of the xtr power supply via the communication ports..

Page 124: Introduction

Remote operation 5-2 975-0200-01-01 introduction in addition to the front panel interface, the xtr can be remotely controlled through the various remote interfaces. The xtr implements the scpi standard as its command line interface for remotely controlling the power supply. Additionally, a small sub...

Page 125

Hardware and connection setup 975-0200-01-01 5-3 5 figure 5-1 remote control connectors table 5-1 remote control connector pins and functions j4 and j6 1 1.All references and directions indicated in this table are with respect to the xtr. Pin reference direction function j4.1 rx-232 input rs-232 j4....

Page 126

Remote operation 5-4 975-0200-01-01 rs-232 communication cable with rj-45 to db-9 communication control cable with db-9 connector (male) on the pc side and rj-45 shielded connector on the power supply. The cable length should be 9.84 feet (3 m) or longer. Figure 5-2 db-9 pinout table 5-2 db-9 pinout...

Page 127

Hardware and connection setup 975-0200-01-01 5-5 5 rs-232 communication cable with rj-45 to db-25 communication control cable with db-25 pinout (male) on the pc side and rj-45 shielded connector on the power supply. The cable length should be 9.84 feet (3 m) or longer. Figure 5-3 rs-232 communicatio...

Page 128

Remote operation 5-6 975-0200-01-01 completing the setup to complete the setup: u configure the xtr to use the 232 remote interface and set up the terminal that will be used on the connected pc. See the sections entitled“selecting the appropriate communication port” on page 5–20 and “terminal config...

Page 129

Hardware and connection setup 975-0200-01-01 5-7 5 configuring remote control using rs-485 rs-485 communication cable with rj-45 to db-9 communication control cable with db-9 pinout (female) on the pc side (see figure 5-2) and rj-45 shielded connector on the power supply. The cable length should be ...

Page 130

Remote operation 5-8 975-0200-01-01 rs-485 communication cable with two rj-45s use the top connector of the two 8-pin rj-45 jacks, as shown in figure 5-1, to connect to the rs-485 remote interface. Communication cable with two rj-45 shielded connectors (see figure 5-3 ) connecting the master unit to...

Page 131

Hardware and connection setup 975-0200-01-01 5-9 5 completing the setup to complete the setup: u configure the xtr to use the 485 remote interface and setup the terminal that will be used on the connected pc. See sections entitled “selecting the appropriate communication port” on page 5–20 and “term...

Page 132

Remote operation 5-10 975-0200-01-01 3. Download the appropriate virtual com port (vcp) drivers for your operating system (with enhanced bm series support). 4. Create a folder c:\ftdi. 5. Unzip files from the archive into this folder. 6. Connect your device to a spare usb port on your computer. The ...

Page 133

Hardware and connection setup 975-0200-01-01 5-11 5 9. In the locate driver files dialog box, in the field optional search locations, select specify a location and click next. 10. On the next screen, enter the file path “c:\ftdi” and click ok. 11. On the next screen, select “driver files search resu...

Page 134

Remote operation 5-12 975-0200-01-01 this completes the first part of the installation during which the usb to serial converter is installed. The second part involves the installation of a serial port, which should follow automatically once the converter installation is complete. Installation of the...

Page 135

Hardware and connection setup 975-0200-01-01 5-13 5 5. In the com port list, scroll to the required com port. Figure 5-11 device manager figure 5-12 communications port (com1) properties.

Page 136

Remote operation 5-14 975-0200-01-01 6. Click ok. Ensure that you do not select a com port which is already in use. This selection is particularly useful for programs, such as hyperterminal, which only work with com1 through to com4. Complete the setup to complete the setup: u configure the xtr to u...

Page 137

Hardware and connection setup 975-0200-01-01 5-15 5 multiple power supply connections to rs-485 bus up to 30 units may be connected to the rs-485 bus. The first unit (master unit) connects to the controller via any appropriate port, and the other units (slave units) are connected with the rs-485 bus...

Page 138

Remote operation 5-16 975-0200-01-01 2. Turn the rotary knob/enter button to select sla and press the enter button. 3. Set a unique address. See “multichannel address setting” on page 5– 21. Multiple power supply connections to enet flexible configurations are possible, as shown in figure 5-10 . Fig...

Page 139: Terminal Configuration

Terminal configuration 975-0200-01-01 5-17 5 terminal configuration the terminal program allows serial communication with the power supply. To use a terminal program, set it up using the parameters from the following sections. If you wish to use hyperterminal, see “hyperterminal” on page 5–17 for in...

Page 140

Remote operation 5-18 975-0200-01-01 this is the com port that you have your serial cable hooked up to or in the case of usb the one that was configured to be used in the fdti software. 5. Click ok when done. 6. Setup the data format to be used. See “data format” on page 5–17 for details. 7. Set up ...

Page 141

Terminal configuration 975-0200-01-01 5-19 5 11. Check the following boxes: • send line ends with line feeds. • echo typed characters locally. • append line feeds to incoming line ends. • wrap lines that exceed terminal width. 12. Click ok in the ascii setup window. 13. Click ok in the properties wi...

Page 142

Remote operation 5-20 975-0200-01-01 selecting the appropriate communication port five ports are available for remote digital programming and readback: • rs-232 • rs-485 • usb • gpib (optional) • enet (optional) to select a communication port: 1. Turn the mode control knob to pgm. Re is displayed in...

Page 143: Multichannel

Terminal configuration 975-0200-01-01 5-21 5 multichannel address setting the power supply multichannel address can be set to any address between 1 to 30. All units that are connected together via the rs-232 or rs-485 connector must have a unique multichannel address. To set the address: 1. Select t...

Page 144

Remote operation 5-22 975-0200-01-01 where: address is an integer value from 1 to 30. Multichannel commands explained the use of multichannel addressing allows you to send messages to one device, more than one device or to all devices. Any of the remote interface types can be used to send a multicha...

Page 145: Status Reporting In Scpi

Terminal configuration 975-0200-01-01 5-23 5 multichannel commands are particularly useful for configuring groups of devices that require identical configurations. The scpi commands for these instructions are: [:] [,[ ]][,[ ]][,...]: for example: sour 1, 2, 3, 7:volt 4.5 syst4,5,6:oper:enab 255 syst...

Page 146

Remote operation 5-24 975-0200-01-01 represents the logical or of all the bits from the enable register. The model has several ellipses which are there to indicate that the pattern of logic shown is repeated for all bits in the registers. Figure 5-18 scpi status reporting model.

Page 147

Status registers model from ieee 488.2 975-0200-01-01 5-25 5 status registers model from ieee 488.2 the ieee 488.2 registers shown in the bottom rectangle of figure 5-18 follow the ieee 488.2 model for status registers. The ieee 488.2 register only has enable registers for masking the summary bits. ...

Page 148: Status Byte

Remote operation 5-26 975-0200-01-01 status byte the status byte register contains the stb and rqs (mss) messages as defined in 488.1. You can read the status byte register using a 488.1 serial poll or the 488.2 *stb? Common command. The *stb? Query causes the device to send the contents of the stat...

Page 149: Message Available (Mav)

Status byte 975-0200-01-01 5-27 5 message available (mav) this bit is true whenever the power supply is ready to accept a request by the digital programming interface to output data bytes. This message is false when the output queue is empty. Standard event status summary (esb) this bit is true when...

Page 150

Remote operation 5-28 975-0200-01-01 for example: sending *sre 8 sets bit 3 of the service request enable register. This will cause the summary bit of the questionable status register (bit 3) in the status byte to generate a service request message whenever it gets set. (see “status byte” on page 5–...

Page 151

Status byte 975-0200-01-01 5-29 5 standard event status register (sesr) the standard event status register sets bits for specific events during power supply operation. All bits in the standard event status registers are set through the error event queue. The register is defined by ieee 488.2 registe...

Page 152

Remote operation 5-30 975-0200-01-01 figure 5-20 summarizes the standard event status register. Figure 5-20 summary of standard event status register table 5-10 standard event status register bit bit weight bit name description 0 1 operation complete (opc) set if *opc command has been received and a...

Page 153

Status byte 975-0200-01-01 5-31 5 operation complete the operation complete command causes the power supply to generate the operation complete message in the standard event status register when all pending operations have been finished. See bit 0 in table 5-10 for more details. Command: *opc, *opc? ...

Page 154

Remote operation 5-32 975-0200-01-01 standard scpi register structure all registers except the sers and status registers will have the following structure which control how they report status information. In all subsequent figures that have scpi registers, this structure will be condensed down into ...

Page 155: Operation Status Register

Operation status register 975-0200-01-01 5-33 5 operation status register the operation status register is a standard scpi, 16-bit register which contains information about conditions which are part of the power supply's normal operation. The operation status data structure has the operation status ...

Page 156

Remote operation 5-34 975-0200-01-01 the operation shutdown status register describes the cause of the power supply shutting down the output. More than one bit may be active and multiple actions will be required to restart the unit. The protection shutdown sub-register indicates which protection mec...

Page 157: Current Share Sub-Register

Operation status register 975-0200-01-01 5-35 5 current share sub-register this register shows the state of the current share configuration, which can either be set through the front panel current share config menu, or through the scpi command. The scpi command (s) for these instructions are: [[:]so...

Page 158

Remote operation 5-36 975-0200-01-01 operation status register commands the response format for all register queries will be in decimal notation. Query operation status register event scpi command: [:]status[]:operation[:event]? Query operation status register condition scpi command: [:]status[]:ope...

Page 159

Operation status register 975-0200-01-01 5-37 5 set operation status negative transition filter scpi command: [:]status[]:operation:ntransition enable> query format: [:]status[]:operation:ntransition? Current sharing sub-register commands query current share event scpi command: [:]status[]:operation...

Page 160

Remote operation 5-38 975-0200-01-01 set current share negative transition filter scpi command: [:]status[]:operation:cshare:ntransition query format: [:]status[]:operation:cshare:ntransition? Shutdown sub-register commands query shutdown event scpi command: [:]status[]:operation:shutdown[:event]? Q...

Page 161

Operation status register 975-0200-01-01 5-39 5 set shutdown negative transition filter scpi command: [:]status[]:operation:shutdown:ntransition query format: [:]status[]:operation:shutdown:ntransition? Protection sub-register commands query protection event scpi command: [:]status[]:operation:shutd...

Page 162: Questionable Status Register

Remote operation 5-40 975-0200-01-01 query format: [:]status[]:operation:shutdown:protection:ptran sition? Set protection negative transition filter scpi command: [:]status[]:operation:shutdown:protection:ntran sition query format: [:]status[]:operation:shutdown:protection:ntran sition? Questionable...

Page 163

Questionable status register 975-0200-01-01 5-41 5 figure 5-23 scpi questionable registers fanout 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 voltage not used not used not used 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 not used over voltage protection (ovp) not used under voltage protection (uvp) not used not...

Page 164: Voltage Sub-Register

Remote operation 5-42 975-0200-01-01 voltage sub-register this shows whether the present voltage level is over or under the specified trip limit. Table 5-15 questionable status register bit bit weight bit name description 0 1 voltage summary of voltage register 1 2 current not implemented 2 4 time n...

Page 165: Temperature Sub-Register

Questionable status register 975-0200-01-01 5-43 5 temperature sub-register this shows whether the temperature of critical components is near or over the maximum operating temperature. Questionable status register commands query questionable status register event scpi command: [:]status[]:questionab...

Page 166

Remote operation 5-44 975-0200-01-01 set questionable status negative transition filter scpi command: [:]status[]:questionable:ntransition enable> query format: [:]status[]:questionable:ntransition? Voltage status register commands query voltage status register event scpi command: [:]status[]:questi...

Page 167

Questionable status register 975-0200-01-01 5-45 5 set voltage status negative transition filter scpi command: [:]status[]:questionable:voltage:ntransition query format: [:]status[]:questionable:voltage:ntransition? Temperature status register commands query temperature status register event scpi co...

Page 168: Scpi Error/event Queue

Remote operation 5-46 975-0200-01-01 query format: [:]status[]:questionable:voltage:temperature :ptransition? Set temperature status negative transition filter scpi command: [:]status[]:questionable:voltage:temperature :ntransition query format: [:]status[]:questionable:voltage:temperature :ntransit...

Page 169

Scpi error/event queue 975-0200-01-01 5-47 5 any time the queue overflows, the least recent errors/events remain in the queue, and the most recent error/event is discarded. The error queue implemented in the xtr is capable of holding 4 errors. When the error queue is not empty the error queue bit in...

Page 170: Reset Command

Remote operation 5-48 975-0200-01-01 querying for the number of errors in the queue to query the device for the number of errors currently stored in the error queue you should use the following command. Command: [:]system:error:count? Example: :syst:err:coun? Response might be: 3 reset command the r...

Page 171: Clear All Status Registers

Scpi error/event queue 975-0200-01-01 5-49 5 commands: *rst [:]system[]:reset clear all status registers clear status command clears all event registers, including the status byte, the standard event status and the error queue. Command: *cls [:]status[]:clear scpi preset status configures the status...

Page 172: Command Line Help System

Remote operation 5-50 975-0200-01-01 scpi command: [:]status[]:preset command line help system the help system is made up of a series of commands that can be used to get help on all available commands and details on their syntax. The help commands are: [:]system[]:help:headers? [:]system[]:help:synt...

Page 173

Scpi error/event queue 975-0200-01-01 5-51 5 it shall contain all the nodes from the root. The mnemonic> contains the node in standard scpi format. The short form shall use uppercase characters while the additional characters for the long form shall be in lowercase characters. Default nodes shall be...

Page 174

Remote operation 5-52 975-0200-01-01 [:]output:protection:foldback[:mode] [:]output:protection:foldback:delay [:]output:polarity [:]output[:power][:state] [:]output[:power]:pon[:state] [:]output:auxilliary[:state] [:]output:auxilliary:pon[:state] [:]measure[:scalar][:voltage][:dc]?/qonly/ [:]measure...

Page 175

Scpi error/event queue 975-0200-01-01 5-53 5 command: [:]system[]:help:legacy? For example: :syst2:help:leg? Might return: aux out err?/qonly/ clr/nquery/ fold dly vset iset trg/nquery/ ovp uvp help?/qonly/ hlp?/qonly/ querying help for command syntax the system[]:help:syntax? Query causes the devic...

Page 176

Remote operation 5-54 975-0200-01-01 command: [:]system[]:help:syntax? {} where: is the command to look up the syntax help on. The following examples demonstrate how to use the syntax help command. Example 1: :syst:help:synt? '*adr' gets the response: select the psu (power supply) to communicate wit...

Page 177: Auto Sequence Programming

Locking and unlocking the front panel 975-0200-01-01 5-55 5 locking and unlocking the front panel locking out the front panel will prevent any of the buttons from functioning. All the buttons and knobs on the front panel will display the locl loc message to be display on the current and voltage disp...

Page 178

Remote operation 5-56 975-0200-01-01 setting dwell time the dwell time is the amount of time that is delayed between each command during the execution of an auto sequence program. The dwell time can be from 0 to 180 seconds and can be changed during the program execution. The dwell time has a minimu...

Page 179

Locking and unlocking the front panel 975-0200-01-01 5-57 5 :prog:dwel 0 :prog:stop this program will send a 12 v square wave with 120 seconds 50% duty cycle. When the program is finished, the dwell time is restored to 0 seconds. Saving an auto sequence program to file: the following procedure indic...

Page 180

Remote operation 5-58 975-0200-01-01 another benefit to the readback command is it allows the auto sequence program to be captured and stored on the client side for reloading when the program is to persist beyond power cycles. Command: [:]program[]:readback? For example: :prog:start *cls :volt 5.4 :...

Page 181

Locking and unlocking the front panel 975-0200-01-01 5-59 5 4. From the hyper terminal (or any other terminal program) select the transfer>send text file… 5. Navigate to and select the text file that was previously stored. Click the open button. 6. Execute the program recording stop command: :prog:s...

Page 182

Remote operation 5-60 975-0200-01-01 :prog:stat run the output after the last command might be as follows: xantrex, xtr 150-5.6, sn# e00123456, 1.00 build 10, 21/11/2005 xantrex, xtr 150-5.6, sn# e00123456, 1.00 build 10, 21/11/2005 repeating an auto sequence program: an auto sequence program can be...

Page 183

Locking and unlocking the front panel 975-0200-01-01 5-61 5 xantrex, xtr 150-5.6, sn# e00123456, 1.00 build 10, 21/11/2005 xantrex, xtr 150-5.6, sn# e00123456, 1.00 build 10, 21/11/2005.

Page 184: Foldback Protection

Remote operation 5-62 975-0200-01-01 configure other protection mechanisms foldback protection foldback protection causes the supply to shut down if the selected regulation mode is entered and the configured delay time expires. A delay time may be specified as well. The only way to clear foldback is...

Page 185: Over Temperature Protection

Configure other protection mechanisms 975-0200-01-01 5-63 5 to set the foldback delay, send the command: command: [:]output[]:protection:foldback:delay where: is a value in the range of 0.5-50 seconds. The unit of second is the default and no units should be used with this parameter. (increments of ...

Page 188

Remote operation 5-66 975-0200-01-01 where is the bit mask for disabling the alarms. See table 5-19 for details. See “alarms and errors” on page 3–17. Table 5-19 alarms bit mask bit bit weight bit name description 0 1 n/a not used. 1 2 fan stop fan on the main board. 2 4 fan slave fan on the slave b...

Page 189: Calibration and

6 calibration and troubleshooting chapter 6, calibration and troubleshooting, contains information and procedures for calibrating and troubleshooting the power supply..

Page 190: Introduction

Calibration and troubleshooting 6-2 975-0200-01-01 introduction the calibration of the power supply is software dependent, and there are no potentiometers to adjust. Calibration is performed via scpi commands. The following items need to be calibrated: • programmed voltage • voltage readback • progr...

Page 191: Step 1: Gain Calibration

Calibration and troubleshooting 975-0200-01-01 6-3 6 step 1: gain calibration adjust the gain so that the real line and ideal line intersect at a programmed value of 90%. Figure 6-1 offset (intercept) error and gain (slope) error figure 6-2 calibration: step 1 gain calibration programmed value idea ...

Page 192: Step 2: Offset Calibration

Calibration and troubleshooting 6-4 975-0200-01-01 step 2: offset calibration adjust the offset so that the real and ideal lines intersect at a programmed value of 10%. Step 3: recalibrate gain repeat step 1 for best results. Figure 6-3 calibration: step 2 offset calibration figure 6-4 calibration: ...

Page 193: Gain Calibration

Calibration and troubleshooting 975-0200-01-01 6-5 6 calibrating the output voltage gain calibration of the power supply has the greatest affect on the accuracy in the high voltage range. Offset calibration has the greatest affect on accuracy of the power supply at low voltages. The same calibration...

Page 194: Gain Calibration

Calibration and troubleshooting 6-6 975-0200-01-01 the scpi command (s) for these instructions are: [:]calibration[]:output{:voltage]{ reading in volts>} calibrating the output current gain calibration to perform gain calibration: 1. Disconnect the power supply from the load. 2. Connect the output t...

Page 195

Calibration and troubleshooting 975-0200-01-01 6-7 6 after performing offset calibration, it is highly recommended that you repeat gain calibration. Scpi command [:] calibration[]:output:current{ reading in amps>} over voltage protection calibration to calibrate the over voltage protection: 1. Turn ...

Page 196

Calibration and troubleshooting 6-8 975-0200-01-01 non-isolated analog programming calibration prior to this, the main output must be calibrated first. Non-isolated voltage monitoring calibration to calibrate the non-isolated voltage monitoring: 1. Disconnect the load and connect the voltmeter to th...

Page 197

Calibration and troubleshooting 975-0200-01-01 6-9 6 non-isolated current monitoring calibration to calibrate the non-isolated current monitoring: 1. Short the main output with a shunt. Connect a multimeter to measure the voltage across the shunt. 2. Connect the voltmeter to the non-isolated current...

Page 198

Calibration and troubleshooting 6-10 975-0200-01-01 5. Set the input source as voltage non-isolated for voltage programming. The scpi command is: syst:rem:sour avol 6. Turn the main output to on by pressing the output on/off button on the front panel or send the command: :outp on the output on/off b...

Page 199

Calibration and troubleshooting 975-0200-01-01 6-11 6 8. Press any key other than the + or – keys to exit from interactive calibration mode. Non-isolated voltage programming of current calibration to calibrate the non-isolated voltage programming of current: 1. Short the main output with a shunt. Co...

Page 200

Calibration and troubleshooting 6-12 975-0200-01-01 syst:comm:apr:lev:curr 4 4. Set the input source as resistive non-isolated for current programming. The scpi command is: syst:rem:sour:curr ares 5. Turn the main output to on by pressing the output on/off button on the front panel or send the comma...

Page 201

Calibration and troubleshooting 975-0200-01-01 6-13 6 calibration procedure for isolated modes the main output and the non-isolated mode must be calibrated first. Isolated voltage monitoring calibration to calibrate the isolated voltage monitoring: 1. Disconnect the load and connect the voltmeter to...

Page 202

Calibration and troubleshooting 6-14 975-0200-01-01 3. Set the current apg level to 4 v. The scpi command is: syst:comm:apr:lev:curr 4 4. Set the input source to local for voltage analog programming. The scpi command is: syst:rem:sour:curr:isol loc 5. Set the main output voltage to 100% by sending t...

Page 203

Calibration and troubleshooting 975-0200-01-01 6-15 6 the output on/off button will illuminate. 7. Enter the interactive calibration mode by sending the scpi command: cal:outp:anal:isol 8. Press on the terminal keys – or + to reduce or increase the main output voltage value. Adjust the main output v...

Page 204

Calibration and troubleshooting 6-16 975-0200-01-01 isolated voltage programming of current calibration to calibrate the isolated voltage programming of current: 1. Short the main output with a shunt. Connect a multimeter to measure the voltage across the shunt. 2. Connect the input voltage source t...

Page 205

Calibration and troubleshooting 975-0200-01-01 6-17 6 syst:rem:sour:curr:isol ares 5. Turn the main output on or send the command: :outp on 6. Enter the interactive calibration mode by sending the scpi command: cal:outp:anal:curr:res:isol 7. Press the terminal keys – or + to reduce or increase the m...

Page 206: Restore Factory Calibration

Calibration and troubleshooting 6-18 975-0200-01-01 to restore the xtr with a set of previously save calibration values can be done as follows. :cal:par #269#h16af,#h0000,#h03e3,#h0000,#h05be,#h0000,#hffff,#h0 000,#h1a89,#h03e8 :cal:par:apr #259#h7b,#h7f,#h7f,#h7f,#h7f,#h7f,#h7f,#h7f,#h7f,#h7f,#h 7f...

Page 207: Unusual Or Erratic Operation

Calibration and troubleshooting 975-0200-01-01 6-19 6 unusual or erratic operation if the power supply displays any unusual or erratic operation, follow these steps: 1. Shut the power supply off immediately. 2. Disconnect the power supply from the load and external programming. 3. Test the power sup...

Page 208

6-20

Page 209: Scpi Command

A scpi command reference appendix a, scpi command reference, provides a summary of the standard commands for programmable instruments (scpi) that are supported by the xtr 850 watt and 1700 watt series programmable dc power supply..

Page 210: Scpi Conformance Information

Scpi command reference a-2 975-0200-01-01 scpi conformance information codes and standards this power supply conforms to the following international standards: • ieee std. 488.2-1992, “ieee standard codes, formats, protocols, and common commands for use with ieee std. 488.1-1987” • ieee std. 488.1-1...

Page 211: Scpi Command Hierarchy

Scpi conformance information 975-0200-01-01 a-3 a scpi command hierarchy scpi is an ascii-based command language designed for use in test and measurement equipment. The command structure is organized around common roots, or nodes, which are the building blocks of scpi subsystems. An example of a com...

Page 214: Parameter Types

Scpi command reference a-6 975-0200-01-01 terminating characters every command string must end with a terminating character. It is also acceptable to use a followed by a . Terminating a command string always resets the scpi command path to the root level. Common commands the ieee-488.2 standard incl...

Page 215

Scpi conformance information 975-0200-01-01 a-7 a numeric parameters numeric parameters are number representations such as decimal points, optional signs, and scientific notation. Values such as minimum and maximum are accepted as substitutes for numbers. When default is provided as a parameter, the...

Page 216: Spci Command Tree

Scpi command reference a-8 975-0200-01-01 spci command tree the scpi commands are organized into a tree structure. To illustrate the tree structure, the following tree has been provided. Each level of indentation presents a branch. The command to execute can then be found by following the tree from ...

Page 217

Spci command tree 975-0200-01-01 a-9 a :resistive :isolated [:voltage] :protection [:over] :restore [:]initiate [:immediate] [:]measure [:scalar] [:voltage] [:dc]? :current [:dc]? [:]output :protection :clear :foldback [:mode] :delay :latch :polarity [:power] [:state] :poweron [:state] :auxilliary [...

Page 218

Scpi command reference a-10 975-0200-01-01 :stop :delete [:all] :repeat [:step] :dwell [[:]source] :combine :cshare [:mode] :voltage [:level] [:immediate] [:amplitude] :protection [:overvoltage] [:level] :latch :tripped? :under [:level] :tripped? :current [:level] [:immediate] [:amplitude] [:]sense:...

Page 219

Spci command tree 975-0200-01-01 a-11 a :questionable [:event]{?} :enable :condition :ptransition :ntransition :voltage [:event]? :enable :condition? :ptransition :ntransition :current [:event]? :enable :condition? :ptransition :ntransition :temperature [:event]? :enable :condition? :ptransition :nt...

Page 220

Scpi command reference a-12 975-0200-01-01 :ntransition :shutdown [:event]? :enable :condition ptransition ntransition protection [:event]? :enable :condition? :ptransition :ntransition :standard [:event]? :enable :clear :sbyte [:event]? :srequest [:enable] [:]system :fpanel [:timeout] :protection :...

Page 221

Spci command tree 975-0200-01-01 a-13 a [:voltage] :isolated [:nisolated] :current :isolated [:nisolated] :communicate :aprogram :level [:voltage] [:isolated] :current [:isolated] [:mchannel] :address :save :recall :version? :error [:next]? :code :next]? :count? :help [:headers]? :syntax?.

Page 222

A-14 975-0200-01-01 s c pi c o mm an d r e fe re n ce scpi command summary the scpi commands supported by this programmable power supply are described in the tables in the remainder of this section. These tables use the following column headings: • function the commonly used name for the function. •...

Page 223

Spc i co mmand t ree 975-0200 -01-01 a-15 a display all scpi command headers *help? Display all the scpi command headers available on this device. Yes identification query *idn? [:]system[]:identify? Query device identification string. Yes operation complete command *opc operation complete command n...

Page 224

A-16 975-0200-01-01 s c pi c o mm an d r e fe re n ce trigger *trg trigger system n/a self-test query *tst? [:]system[]:test? Perform unit self test (pass=0). Yes wait to continue *wai [:]system[]:wait wait to continue command. N/a table a-2 readback commands function scpi command description parame...

Page 226

A-18 975-0200-01-01 s c pi c o mm an d r e fe re n ce table a-4 scpi commands for calibration function scpi command description parameter and range query restore factory calibration [:]calibration[]:restore restores the calibration to the factory defaults. N/a n/a calibrate ovp protection. [:]calibr...

Page 229

Spc i co mmand t ree 975-0200 -01-01 a-21 a table a-5 scpi commands to clear all protection mechanisms function scpi command description parameter and range query clear output protection [:]output[]:protection:clear clears the currently set alarms. N/a table a-6 scpi commands for foldback protection...

Page 231

Spc i co mmand t ree 975-0200 -01-01 a-23 a self test [:]system[]:test? Perform unit self test, returns 0 if pass, non zero value for failure. Yes id query [:]system[]:identify query device id string. Yes save user preset [:]system[]:save save the user preset values. Select any slot from 1-5. (1–5)>...

Page 238

A-30 975-0200-01-01 s c pi c o mm an d r e fe re n ce preset enable, positive transition and negative transition status registers [:]status[]:preset restores the configuration of the scpi status registers to known reporting conditions, ie transition registers and enable register. See “status reporti...

Page 244

A-36.

Page 245: Error Messages

B error messages appendix b, error messages, provides information on the error messages which may appear. Errors are placed in a queue as they are detected..

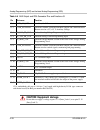

Page 246: Error Messages

Error messages b-2 975-0200-01-01 error messages errors are placed in a queue as they are detected. The queue works on a first in, first out (fifo) basis. If the queue overflows, the last error in the queue is replaced with error –350, “queue overflow”. When all errors have been read from the queue,...

Page 247: Execution Error List

Error messages 975-0200-01-01 b-3 b execution error list an error in the range [-299, -200] indicates that an error has been detected by the instrument’s execution control block. The occurrence of any error in the class causes the execution error bit (bit 4) in the event status register to be set. E...

Page 248: Device-Specific Error List

Error messages b-4 975-0200-01-01 device-specific error list an error in the range [-399, 300] or [1, 32767] indicates that the instrument has detected an error which is not a command error, a query error, or an execution error; some device operations did not properly complete, possibly due to an ab...

Page 249: Query Error List

Error messages 975-0200-01-01 b-5 b query error list an error number in the range [-499, -400] indicates that the output queue control of the instrument has detected a problem with the message exchange protocol described in ieee 488.2, chapter 6. The occurrence of any error in this class causes the ...

Page 250

B-6.

Page 251: Specifications

C specifications appendix c, specifications, provides the product specifications for the xtr 850 watt and 1700 watt series programmable dc power supply. • these specifications are represented over the full operating temperature range. • nominal line input voltage should be assumed unless otherwise s...

Page 252

C-2 975-0200-01-01 speci fications electrical specifications for xtr 850 watt table c-1 xtr 850 watt electrical specifications for 6 v to 600 v models models 6-110 8-100 12-70 20-42 33-25 40-21 60-14 80-10.5 100-8.5 150-5.6 300-2.8 600-1.4 output ratings: output voltage 1 output current 2 output pow...

Page 253

975-0200-01-01 c-3 electrical specificat ions for xtr 850 w a tt c efficiency 11 75/77% 77/80% 81/84% 82/85% 83/86% 83/87% 83/87% 83/87% 83/87% 83/87% 83/87% 83/87% 1.Minimum voltage is guaranteed to maximum 0.2% of the rated output voltage. 2.Minimum current is guaranteed to maximum 0.4% of the rat...

Page 254

C-4 975-0200-01-01 speci fications electrical specifications for xtr 1700 watt table c-2 xtr 1700 watt electrical specifications for 6 v to 600 v models models 6-220 8-200 12-140 20-84 33-50 40-42 60-28 80-21 100-17 150-11.2 300-5.6 600-2.8 output ratings: output voltage 1 output current 2 output po...

Page 255

A-26 975-0200-01-01 s c pi c o mm an d r e fe re n ce alarm masking [:]system[]:protection[:mask] enable/disable alarms/ protection. ?

Page 256: Remote Operation

C-6 975-0200-01-01 speci fications remote operation table c-3 remote operation programming mode apg isol digital voltage and current output voltage programming 0–100%, 2~ up to 10 v, programmable current output resistor programming 0–100%, 2~ up to 10 k Ω, programmable voltage output resistor progra...

Page 257

975-0200-01-01 c-7 common speci fications for all m o del s c common specifications for all models output voltage and current monitor 0–100%, 2~ up to 10 v, programmable on/off control ttl level aux on/off control ttl level or dry contact power supply status signal ttl high: ok ttl low: fail interlo...

Page 258

C-8 975-0200-01-01 speci fications environmental specifications (indoor use) operating temperature range 0 °c to 50 °c, 100% load storage temperature range –20 °c to 70 °c operating humidity range 30–90% rh (no condensation) storage humidity range 10–95% rh (no condensation) operating altitude up to...

Page 259

Common specifications for all models 975-0200-01-01 c-9 c figure c-1 xtr 850 watt mechanical dimensions: 6 to 40 v models 8.4 in. 214.2 mm 1.05 in. 26.8 mm 1.72 in. 43.6 mm optional dc output cover 1.98 in. 50.2 mm 18.9 in. 479.9 mm 18.5 in. 469.9 mm 17. 99 in. 456.9 mm .60 in. 15.2 mm .26 in. 6.5 m...

Page 260

Specifications c-10 975-0200-01-01 figure c-2 xtr 850 watt mechanical dimensions: 60 v to 600 v models 43.6 mm 1.7 in. 214.2 mm 8.4 in. 0.22 in. 7.2 mm 0.28 in. 447.5 mm 17.6 in. 5.5 mm.

Page 261

Common specifications for all models 975-0200-01-01 c-11 c figure c-3 xtr 1700 watt mechanical dimensions: 6 v to 40 v models 18.8 in 477.4 mm 17.81 in. 452.4 mm 4.11 in. 104.3 mm 5.90 in. 149.8 mm .20 in. 5.0 mm x 4 .33 in. 8.5 mm x 2 1.06 in. 26.9 mm x 2 25 mm .98 in. 25 mm .98 in..

Page 262

Specifications c-12 975-0200-01-01 figure c-4 xtr 1700 watt mechanical dimensions: 6 v to 40 v models dc output cover 19.07 in. 484.4 mm 2.75 in. 69.99 mm 7.28 in. 184.9 mm.

Page 263

Common specifications for all models 975-0200-01-01 c-13 c figure c-5 xtr 1700 watt mechanical dimensions: 60 v to 600 v models 489 mm 19.25 in. 17.50 in. 444.4 mm 16.87 in. 428.5 mm 1.24 in. 31.6 mm 1.72 in. 43.6 mm .41 in. 10.4 mm 1.08 in. 27.4 mm 41.6 mm 1.63 in. 46.1 mm 1.81 in..

Page 264

C-14.

Page 265: Warranty

975-0200-01-01 wa-1 warranty and product information warranty what does this warranty cover? This limited warranty is provided by xantrex technology inc. ("xantrex") and covers defects in workmanship and materials in your xtr 850 watt or 1700 watt series programmable dc power supply. This warranty p...

Page 266: Disclaimer

Warranty and return wa-2 975-0200-01-01 what proof of purchase is required? In any warranty claim, dated proof of purchase must accompany the product and the product must not have been disassembled or modified without prior written authorization by xantrex. Proof of purchase may be in any one of the...

Page 267: Exclusions

Warranty and return 975-0200-01-01 wa-3 exclusions if this product is a consumer product, federal law does not allow an exclusion of implied warranties. To the extent you are entitled to implied warranties under federal law, to the extent permitted by applicable law they are limited to the duration ...

Page 268: Return Procedure

Warranty and return wa-4 975-0200-01-01 return procedure 1. Package the unit safely, preferably using the original box and packing materials. Please ensure that your product is shipped fully insured in the original packaging or equivalent. This warranty will not apply where the product is damaged du...

Page 269: Numerics

975-0200-01-01 ix–1 numerics 7 segment font, use of vi 9-position mode control knob illustrated 3–2 positions described 3–3 a ac input connector, 1700 w defined 2–6 illustrated 2–6 ac input connector, 850 w defined 2–5 illustrated 1–7 active power factor correction 1–2 alarm conditions 3–17 alarm le...

Page 270

Index ix–2 975-0200-01-01 setting protection 3–22 foldback mode, defined 3–22 front panel display 7 segment font 3–8 illustrated 1–5 g gain calibration, effect of 6–5 gain error, described 6–2 i ieee gpib cable 5–14 std. 488.1 1987 a–2 std. 488.1999 2 17.1.2 5–48 std. 488.2 1992 a–2 std. 488.2 1999 ...

Page 271

Index 975-0200-01-01 ix–3 terminating characters a–6 using queries a–5 select and set mode, described 3–4 standard operation, described 3–10 t tia/eia-232 f a–2 tracking mode, described 3–4 u user setting memory locations 1–2 described 3–6 , 3–28 number available 3–28 stored valaues 3–28 w warranty ...

Page 272

Ix-4.

Page 274: Xantrex Technology Inc.

Xantrex technology inc. 1 800 667 8422 tel toll free na 1 408 987 6030 tel direct 1 360 925 5143 fax direct customerservice@xantrex.Com www.Xantrex.Com 975-0200-01-01 printed in canada.