- DL manuals

- Xentaur

- Transmitter

- LPDT

- User Manual

Xentaur LPDT User Manual

Summary of LPDT

Page 1

Ock road, medford, ny 11763 usa tel: (516) 345-3434 xenta ur c orp oration loo p po wered dewpoint tr ans mit ter lp dt user's m anu a l.

Page 2

Lpdt user’s manual i when calling your representative for technical support, please have your serial numbers available. The sensor and instrument serial numbers are on the instrument, also see section 3.4.4.4. Sensor serial no.: _______________ instrument serial no.: _______________ your representat...

Page 3

Lpdt user’s manual ii xentaur reserves the right to change or modify the product specification and / or appearance at any time without notice. Therefore, the information in this document is subject to change without notice and does not represent a commitment on the part of xentaur corporation. Swage...

Page 4

Lpdt user’s manual iii examine the lpdt package for damage or mishan- dling. If any damage is evident notify the carrier and request an inspection. Unpack the box, it should contain: the lpdt with sensor in desiccant container, connectorized cable, and this manual. Please read this manual in whole, ...

Page 5

Lpdt user’s manual iv warranty xentaur instruments are warranted to be free from defects in workmanship and materials. Liability under this warranty is lim- ited to servicing, calibrating, and replacing any defective parts of the instrument returned to the factory for that purpose. Fuses are specifi...

Page 6

Lpdt user’s manual v lpdt user’s manual table of contents 1.0 overview of the lpdt .................................................1 2.1 precautions using the sensor .........................................3 2.2 sensor technical specifications ...................................4 2.3 sensor instal...

Page 7

Lpdt user’s manual vi appendix h: uncertainty in lbs & ppmv calculations ..43 appendix i: sensor response time ..................................44 appendix j: return authorization request ......................45.

Page 8: 1.0 Overview Of The Lpdt

Section 1: introduction page 1 1.0 overview of the lpdt the lpdt is a microprocessor based 4-20ma loop powered (2 wire) hygrometer, for measuring moisture content in gases in the range from -100°c to +20°c. The measurement is displayed on the instrument’s custom lcd, and is trans- mitted by varying ...

Page 9

Lpdt user’s manual page 2.

Page 10

Section 2: sensor and sampling techniques page 3 2.1 precautions using the sensor the xentaur htf™ al 2 o 3 sensor is designed and field proven to be highly reliable, rugged and maintenance free. However the user should consider the following precau- tions: • to avoid the need for prolonged dry-down...

Page 11

Lpdt user’s manual page 4 tive. • do not disassemble the porous metal filter encapsula- tion, as this will damage the sensor and void your fac- tory warranty. • prior to installation of the probe, ensure that no contam- inants are present in the system (e.G. Oil, liquid water). 2.2 sensor technical ...

Page 12: 2.3.1 In-Situ Installation

Section 2: sensor and sampling techniques page 5 diameter of tubing, number of interconnecting fittings, dead space in tubing and manifolds; will influence the measure- ment value and response time. The high capacitance htf™ sensors can be installed either directly in the line to be sampled (in-situ...

Page 13

Lpdt user’s manual page 6 • under a pressurized system removal of the sensor with- out the installation of isolation valves can be dangerous. If in-situ installation is required, bypass mounting is prefer- able; make sure to install the sensor at the upper surface of the gas line to minimize its exp...

Page 14

Section 2: sensor and sampling techniques page 7 2.3.2 extractive installation for extractive installations we recommend our sample sys- tem ess, which may be equipped with a variety of features, such as: isolation valve, coalescing or particulate filter, pressure regulator, calibration sample injec...

Page 15

Lpdt user’s manual page 8 it is generally recommended to measure at ambient pressure for the following reasons: • the readings will not be affected by variations in line pressure. • the risk of exposing the sensor to liquid water is signif- icantly reduced. • ppm readings are computed for a pressure...

Page 16

Section 2: sensor and sampling techniques page 9 • do not install any devices upstream of the sensor, such as other measuring systems, flow meters etc., which are not absolutely necessary as these are potential leak sources. • installation of a coalescing and / or particulate filter ahead of the sen...

Page 17

Lpdt user’s manual page 10 troubleshooting unexpected readings (table spans 2 pages) for non-sensor related problems (e.G. No reading on instru- ment) refer to section 3.5 symptom possible cause reading is not changing condensation in sample system. Slow response 1. Water vapor in the system. 2. Flo...

Page 18

Section 2: sensor and sampling techniques page 11 troubleshooting unexpected readings (continued from previous page) symptom diagnostic/remedy reading is not changing condensation will occur if the temperature of the sample system, at any point is below (colder) the dewpoint temperature of the sampl...

Page 19

Lpdt user’s manual page 12.

Page 20

Section 3: instrument page 13 3.1 precautions using the lpdt the lpdt uses state-of-the-art microelectronics to provide a miniature full functioning instrument. The user should consider the following precautions when using any sensitive electronic device. • do not install the unit near heat sources ...

Page 21

Lpdt user’s manual page 14 • any circuitry which is activated by relay contacts should account for the contact bounce, one simple debouncing method is placing a capacitor across the relay contacts. • ac power wiring should be routed as far away from the lpdt and its wiring as practical. 3.2 instrume...

Page 22: 3.3 Installation

Section 3: instrument page 15 (and pressure if installed) can be read. In the digital mode multiple units can operate on the same loop cable as a multi-channel instrument. Alarms:..............................The 4-20ma signal or the digital output may be used by an external device to operate relays...

Page 23

Lpdt user’s manual page 16 lpdt (the tension washer should be compressed), so that it does not come loose during use. 3.3.2 electrical installation the lpdt will operate properly with 10vdc to 33vdc at its input, if this voltage is exceeded the internal fuse may blow. When selecting the power supply...

Page 24: 3.4.1 Starting Up

Section 3: instrument page 17 3.4 operating the instrument 3.4.1 starting up the instrument is ready for use as soon as the power cable is installed. When power is applied the instrument will initial- ize its program and for a moment display ;(1, then it will enter the operating state. If the mode b...

Page 25

Lpdt user’s manual page 18 not to change any parameter inadvertently. 3. °c°f appear simultaneously, to indicate the sensors’ attenuation in decibels. 4. Values larger than ±1999 or smaller than ±0.01 are dis- played in powers of 10 ±3 . As required, either a “10 3 ” or “10 -3 ” will appear above an...

Page 26: 3.4.3 Push Buttons

Section 3: instrument page 19 3.4.3 push buttons three push buttons are located on the front panel. Each button is marked with an icon engraved above it. In general the mode button navigates through the different user options “modes”; the up and down buttons modify the units, values or choices in th...

Page 27

Lpdt user’s manual page 20 3.4.4.1 viewing dewpoint mode in this mode the user can view the dewpoint, this is indi- cated by the presence of the ‘dewpoint’ legend on the lower left of the display. The available engineering units in which to view the moisture content are °c, °f, ppm, lbs and g/m 3 ; ...

Page 28

Section 3: instrument page 21 3.4.4.3 start calibration (spancheck™) mode the instrument is calibrated at the factory with the sensor it is shipped with and does not need to be re-calibrated prior to installation. Instrument calibration is recommended in approximately 12 month intervals, and the xtr...

Page 29

Lpdt user’s manual page 22 2. Push the mode key a few times until the display shows &$/. 3. Press the up button. The display will show &1), prompt- ing you to confirm that you want to start the calibration procedure. You can abort the calibration procedure by pressing the mode key. 4. Remove the sen...

Page 30

Section 3: instrument page 23 calibration procedure. 7. Install the sensor in the sample cell or adapter fitting or put it back into the packaging container for later use. The instrument will retain the calibration even if the power is turned off. Under certain conditions, an over (super) saturated ...

Page 31: 3.4.5 Setup State

Lpdt user’s manual page 24 taken that the sensor temperature is not below the tempera- ture of the hand, as in such case condensation could occur and super saturate the sensor. For the same reason, avoid exhaling directly onto the sensor. 3.4.4.4 viewing serial number mode in this mode the user can ...

Page 32

Section 3: instrument page 25 diagram of the setup state. The setup state provides nine capabilities, each one con- trolled from its own mode. Depressing the mode button navigates through the modes in the following order: nse- lect alternate display units ‹ oselect sensor type ‹ pset measured attenu...

Page 33

Lpdt user’s manual page 26 tainer is labeled with the proper values. 5. Calibration adjustment: in this mode the user can enter a sensor specific adjustment value to improve the instruments’ accuracy in the range of -50°c to -10°c, this adjustment has very little or no effect outside this range. The...

Page 34

Section 3: instrument page 27 f. Observe the display, if the buttons are not being pressed; the display will every few seconds show for a short duration the dewpoint as being computed at the moment (utilizing the current cal-adjust value in the computation). G. Use the up or down buttons to modify t...

Page 35

Lpdt user’s manual page 28 the current loop output, refer to appendix g. 9. Lock/unlock the instrument: this mode is used to block access to parameter settings, protecting the instru- ment from unauthorized or inadvertent changes of parameters. Attempting to change settings while instru- ment is loc...

Page 36

Section 3: instrument page 29 legend: denotes alternately flashing messages. Display explanation required action lo (55 prom check sum failed. Pow er on t es ts hi (55 ram write/read test failed. Cycle power % (55 unidentified power-up failure. If problem persists, &6) eeprom check sum failed. Retur...

Page 37

Lpdt user’s manual page 30 the instrument contains a fuse which may open if the instrument is subjected to voltages exceeding the specifica- tions. Under these circumstances the unit display will be blank and the instrument will not draw any current when powered up. The fuse is not user replaceable,...

Page 38

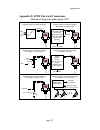

Appendices page 31 appendix a: operating state user interface flowchart temp ˚f xentaur lpdt set xentaur lpdt set xentaur lpdt xentaur lpdt press together to reset the instrument. Then quickly press and hold mode to go to set-up state. Sensor reading too low ok viewing dewpoint viewing sensor temper...

Page 39

Lpdt user’s manual page 32 appendix b: set-up state user interface flowchart / set set lo dewpoint ˚c set lo ˚c˚f choose alter nate units to sho w when displa ying de wpoint choose sensor type set measured atten uation at a kno wn lo w de wpoint set lo w de wpoint f or the abo ve set atten uation ca...

Page 40

Appendices page 33 user interface flow diagram - set-up state (continued from previous page ) legend: 1. Arro ws leading out from belo w a b utton depict the flo w as a result of pressing the b utton. 2. A slash ' / ' in the displa y area, is used to depict tw o alter nately sho wn (flashing bac k a...

Page 41

Lpdt user’s manual page 34 appendix c: lpdt mechanical drawing flats f or 1 " wrench 7 8/ 1.750" oint transmitter ma se mo think safety read man ual www.Xentaur.Com set % hilo temp dewpoint psi g/m³ lbs x10¯³ ppm ˚c˚f xent a u r lpdt 14mm x 12.5mm 3/4"-16 viton a o-r ing 2.230" 1.850" 0.600" power j...

Page 42

Appendices page 35 appendix d: lpdt electrical connections operation with wall transformer dewpoint viewed on instrument display operation with relay option board dewpoint viewed on instrument display and available as 4-20ma output operation with remote option board dewpoint viewed on instrument dis...

Page 43

Lpdt user’s manual page 36 appendix e: sensor/spancheck™ theory of operation the sensor is constructed as a capacitor whose dielectric consists of porous aluminum oxide as well as the gas that has entered in the pores of the aluminum oxide. The plates (electrodes) of this capacitor are an aluminum s...

Page 44

Appendices page 37 tion for small manufacturing deviations. As the sensor is used in real world applications, it is exposed to various elements and stress; like any other sen- sor it may over time drift from calibration. However one must note that the intrinsic capacitance will not change with use b...

Page 45

Lpdt user’s manual page 38.

Page 46

Appendices page 39 appendix f: pressure correction sensor pressure is used in the context that this is the pres- sure inside the sampling chamber when performing the measurement, i.E. It is the operating pressure of the sensor. Gas pressure is used in the context that this is the pressure at which t...

Page 47

Lpdt user’s manual page 40 appendix g: current vs. Dewpoint the current being pulled by the lpdt, varies with the dew- point being measured by the lpdt. To use the current to calculate the value of the dewpoint measurement, one must know the settings of the low and high ends of the analog output ran...

Page 48

Appendices page 41 vide a useful output. Consider an example where the area of interest to be monitored is 10 to 100 ppmv, and the analog output is set up with the factory defaults of -100°c to +20°c (which is 0.014 to 23612 ppmv); then the current loop out- put will vary only from ~4.1 to ~4.2 ma i...

Page 49

Lpdt user’s manual page 42 relationship of 4-20ma output and instrument reading in ppmv or lbs instrument reading in ppmv instrument reading in lbs of h2o / million cubic feet 10 100 1000 10000 4.1ma 5ma 0.1 1 1 0 100 1000 12ma 8ma 20ma 4.5ma 4/20 ma output 0.56 lbs = -60˚c = 10.66 ppmv 1.97 lbs = -...

Page 50

Appendices page 43 appendix h: uncertainty in lbs & ppmv calculations uncertainty of lbs & ppmv calculations due to +/-3˚c measurment accuracy calculated ppmv calculated lbs h 2 o / mmscf -80 -75 -70 -65 -60 -55 -50 -45 -40 -35 -30 -25 -20 0.5 0.5 0.25 2.5 0.05 0.6 0.7 0.8 0.9 1 1 0.1 2 3 4 5 5 6 7 ...

Page 51

Lpdt user’s manual page 44 appendix i: sensor response time time (minutes) % of step change 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 65% of step change 95% of step change response time of xentaur al 2 o 3 sensors ...

Page 52

Appendices page 45 appendix j: return authorization request xentaur must approve and assign a return authorization number (ran) to any instrument being returned. The ran must appear on all paperwork and packag- ing. The issuance of a ran does not automatically imply that the instrument is covered by...

Page 53

Lpdt user’s manual page 46.

Page 54

Xentaur corporation, 3661 horseblock road, medford, ny 11763 usa tel: (516) 345-3434 xenta ur c orp oration loo p po wered dewpoint tr ans mit ter lp dt user's m anu a l.