- DL manuals

- Xerox

- Copier

- 5915

- Service Manual

Xerox 5915 Service Manual

Summary of 5915

Page 1

Xerox 5915 service manual issued by : overseas technical group, xerox of shanghai limited. 7 th . July 200

Page 2: Xerox

Xerox the document company xerox 5915 service manual 1st edition •••• this service manual covers the following models: electrostatic copier xerox 5915 manufactured by shanghai xerox. •••• related materials no related materials are issued other than this service manual. •••• confidentiality • this se...

Page 3

Introduction xerox 5915 service manual introduction 1. Scope and comment sheet this service manual is prepared to specify service standards for the xerox 5915. •••• service manual comment sheet when you have comments or corrections, or discover wrong descriptions in the xerox 5915 service manual, en...

Page 4: Section 1

Section 1 service procedure.

Page 5

1-1 contents section 1 service procedure section 1 service procedure 1.1 precautions 1.1.1 safety………………………………………………… 1-2 1.1.2 other precautions……………………………………1-2 1.2 work process when making calls ………… 1-2 1.3 detailed explanation of work when making calls……………………………….. 1-3 1.3.1 what to do first………...

Page 6

1-2 section 1 service procedure 1.1 precautions intentional bank page.

Page 7

1-3 section 1 service procedure 1. Service call procedure first call actions perform the following: 1. Discuss with the customer the required and agreed configuration for the copier. Check that all required hardware and software is installed and/or enabled to meet this specification. 2. If the copie...

Page 8

1-4 section 1 service procedure high frequency service items component indication replacement threshold parts list replacement procedure photoreceptor drum with the drum unit replacement due, the control panel display turns on at 50k copies indicating its replacement is required. After “replace drum...

Page 9: Section 2

Section 2 troubleshooting.

Page 10

2-1 contents section 2 troubleshooting section 2 troubleshooting 2.1 preface 2.1.1 how to troubleshoot………………………………. 2-2 2.1.2 terminology……………………………………….. ..2-2 2.2 diagnostic(c/e) mode 2.2.1 how to enter diagnostic (c/e) mode……………. 2-4 2.2.2 entries of chain codes, function codes & set values………… …...

Page 11

2-2 section 2 troubleshooting 2.1 preface 2.1 preface 2.1.1 how to troubleshoot level 1 troubleshooting • level 1 troubleshooting (level 1 f.I.P.) is the first step toward the diagnosis of a problem. Level 1 f.I.P. Asks you whether or not any status code and other problems exist, guiding you to leve...

Page 12

2-3 section 2 troubleshooting intentional blank page.

Page 13

2-4 section 2 troubleshooting 2.2 diagnostic(c/e) mode 2.2 diagnostic(c/e) mode 2.2.1 how to enter diagnostic(c/e) mode power on while pressing “0” on the keyboard. • all the leds on console panel turn on. When you press the key pad or the stop clear button, the three leds: “el jam”, “e3 jam” and “t...

Page 14

2-5 2.2 diagnostic(c/e) mode section 2 troubleshooting 2.2 diagnostic(c/e) mode 2.2.4 diagnostic functions & operating procedures input check chain code function code part/signal dis- play ref. Bsd 1 1 front interlock switch h/l 1 2 rh upper interlock switch h/l 5 2 1 console button +1 2 3 10 option...

Page 15

2-6 section 2 troubleshooting 2.2 diagnostic(c/e) mode output check function: this operates parts such as the solenoid, the clutch and the motor. You can set parts within the same chain to the on positions simultaneously. Procedure: 1. Enter diagnostic(c/e) mode. 2. Enter the chain code for a part t...

Page 16

2-7 2.2 diagnostic(c/e) mode section 2 troubleshooting output check chain function part/signal on time ref. Bsd 4 1 main motor(& erase lamp) 2,7 6 3 lamp carriage motor(scan) 1sec 3 4 lamp carriage motor(return) 1sec 3 7 exposure lamp(& erase lamp) 30sec 2,3,7 8 1 main motor (& erase lamp) 2,7 2 tra...

Page 17

2-8 section 2 troubleshooting 2.2 diagnostic(c/e) mode parameter (nvm value) adjustment function: this performs the parameter (nvm value) adjustment. Procedure: 1. Enter diagnostic(c/e) mode. 2. Enter chain code “20” and press the start button. 3. Enter the function code for the parameter to be adju...

Page 18

2-9 2.2 diagnostic(c/e) mode section 2 troubleshooting chain code 20 table chain code function code setup item min. Value initial value max.Value 1 step change adj 20 1 registration adjustment 16(-4.13mm) 32 64(+4.13mm) 0.2564mm 2.7.6 2 light quantity adj. 100% 0 30 80 0.8% 5.1.4- enlargement/reduct...

Page 19

2-10 section 2 troubleshooting 2.2 diagnostic(c/e) mode feed counter check/clearance. Function: this displays or clears feed counters for all trays . Procedure: 1. Enter diagnostic(c/e) mode. 2. Enter chain code “30” and press the start button. 3. Enter the function code for the feed counter to be c...

Page 20

2-11 2.2 diagnostic(c/e) mode section 2 troubleshooting individual mode setup function: this sets up the execution/ inhibition of certain functions for individual users. Procedure: 1. Enter diagnostic(c/e) mode. 2. Enter chain code “50” and press the start button. 3. Enter the function code for the ...

Page 21

2-12 section 2 troubleshooting 2.3 level1 troubleshooting 2.3 level 1 troubleshooting 2.3.1 level 1 f.I.P.

Page 22

2-13 2.3 level 1 troubleshooting section 2 troubleshooting 2.3.2 chart of jam status codes machine e1-1 e1-2 c1-3 c1-2 e3-3 e3-6 e1-6 c9-3 off check jam off check jam static jam static jam msi miss feed jam on check jam tray 1 regi gate snr fuser exit sw.

Page 23

2-14 section 2 troubleshooting 2.3 level 1 troubleshooting 2.3.3 status code list status code name problem corrective action ref. Bsd u1-1 m/c clock fail m/c clock fails to input the signal to main pwb even once for 0.47 sec., while copying • refer to the u-code f.I.P. 2 u2-1 lamp carriage fail-stan...

Page 24

2-15 2.3 level 1 troubleshooting section 2 troubleshooting status code name problem corrective action ref. Bsd c1-2 tray 1 mis feed jam regi-gate sensor isn’t turned on within 2.7sec. After paper starts to be fed. • refer to the misfeed jam. 4 c9-3 msi misfeed jam regi-gate sensor isn’t turned on wi...

Page 25

2-16 section 2 troubleshooting 2.4 level 2 troubleshooting 2.4 level 2 troubleshooting 2.4.1 general f.I.P (general f.I.P for defective parts) •••• reflective sensor f.I.P [sensed(l)] original size sensors 1~4 preparation : • remove any remaining paper (if there is any). Procedure enter diag. [ ٭ - ...

Page 26

2-17 2.4 level 2 troubleshooting section 2 troubleshooting • switch f.I.P platen intlk switch r/h upper intlk switch procedure enter diag. [ ٭ - ٭ ]. Make the switch turn on/off(cover open/close). If necessary, use output check. Does the display repeat (l) and (h) alternately? Y n does the display r...

Page 27

2-18 section 2 troubleshooting 2.4 level 2 troubleshooting • switch f.I.P r/h upper intlk switch procedure enter diag. [ ٭ - ٭ ]. Make the switch turn on/off(cover open/close). If necessary, use output check. Does the display repeat (l) and (h) alternately? Y n does the display remain (h)? Y n it re...

Page 28

2-19 2.4 level 2 troubleshooting section 2 troubleshooting 2.4 level 2 troubleshooting 2.4.2 u-code f.I.P’s u1-1 m/c clock fail ref. Bsd: 2 preparation: ensure that the following connector is securely connected. • p/j404 of main pwb procedure open the front cover and cheat the front interlock. Enter...

Page 29

2-20 section 2 troubleshooting 2.4 level 2 troubleshooting u2-1 lamp carriage fail-stand-by u2-2 lamp carriage fail-position u2-3 lamp carriage fail-scan u2-4 lamp carriage fail-return ref. Bsd: 3 preparation : ensure that the following connectors are securely connected. • p/j404 of main pwb. • p/j4...

Page 30

2-21 2.4 level 2 troubleshooting section 2 troubleshooting u4-1 fuser thermistor open fail ref. Bsd: 7 preparation: ensure that the following connectors are securely connected. • p/j410 of main pwb • p/j118 of fuser thermistor procedure warning: power off the machine and disconnect the power cord. W...

Page 31

2-22 section 2 troubleshooting 2.4 level 2 troubleshooting u4-3 fuser over heat fail 1 u4-4 fuser over heat fail 2 u4-6 fuser over heat safety fail ref. Bsd: 7 note: at the occurrence of u4-6, open the front cover, enter diagnostic(c/e) mode and clear u4-6 by executing [50-20]. Procedure power on. C...

Page 32

2-23 2.3 level 1 troubleshooting section 2 troubleshooting u6-4 nvm fail ref. Bsd: 2 preparation: • install the ground wire. • ensure that the power voltage hasn’t dropped 10% or more (with power on or power off). • ensure that there is neither operating power sources nor devices generating high fre...

Page 33

2-24 section 2 troubleshooting 2.4 level 2 troubleshooting u8-1 exposure control fail ref. Bsd: 3 problem area : initial light quantity control(optics) cause/corrective action • defective main pwb • defective ac drive pwb • open harnesses or improper p/j connections of the circuits controlling the a...

Page 34

2-25 2.4 level 2 troubleshooting section 2 troubleshooting 2.4.3 misfeed jam c1-3 tray 1 misfeed jam preparation: • ensure that no paper jam occurred. • ensure that the feed roller has not worn out and the friction is proper. Procedure clear paper jam, start copying. Does the feed roller rotate? Y n...

Page 35: Section 4

Section 4 disassembly/assembly/adjustment.

Page 36

4-1 contents section 4 disassembly/assembly/adjustment section 4 disassembly/ assembly/ adjustment 1. Main drive 1.1.1 main motor replacement ………..…………… 4-3 2. Paper handling 2.1.1 side registration adjustment ……………..…… 4-3 2.2.1 msi feeder assy removal/installation ……….. 4-4 2.2.2 msi retard pad re...

Page 37: Intentional Blank Page

4-2 section 4 disassembly/assembly/adjustment intentional blank page.

Page 38

4-3 1. Main drive/2. Paper handling section 4 disassembly/assembly/adjustment 1.1.1 main motor replacement removal 1. Warning: power off the machine and disconnect the power cord. 2. Open the front cover and the machine. 3. Remove the drum unit ……………....... (5.1.1) 4. Remove the rear upper cover. 5....

Page 39

4-4 section 4 disassembly/assembly/adjustment 2. Paper handling 2.2.1 msi feeder assy removal/installation removal 1. Warning: power off the machine and disconnect the power cord. 2. Open the rear upper cover. 3. Open the right upper cover. 4. (figs. 1 & 2): remove the msi tray. ➀. Open msi tray. ➁....

Page 40

4-5 2. Paper handling section 4 disassembly/assembly/adjustment 2.3.2 msi feed roller replacement note: • you should clear the feed counter in diag. Mode [30-4] at the time of replacement. Removal 1. Warning: power off the machine and disconnect the power cord. 2. Remove the msi feeder assy……….. (2....

Page 41

4-6 section 4 disassembly/assembly/adjustment 2. Paper handling 2.5.1 feed roller replacement 2.5.3 no paper sensor replacement note: • when replacing the feed roller, clear the feed counter of the appropriate tray, using the diag. Mode applicable: content diag mode tray 1 feed counter 30-1 replacem...

Page 42

4-7 2. Paper handling section 4 disassembly/assembly/adjustment replacement procedure for pick up gear only 6. (fig. 5): remove the pick up gear. ➀. Remove the spring. ➁. Keep pushing the hook of the pick up gear using the small screw gear. ➂. Remove the pick up gear. (fig. 5) replacement procedure ...

Page 43

4-8 section 4 disassembly/assembly/adjustment 4. Paper handling 2.5.4 transport cover intlk switch replacement removel 1. Warning: power off the machine and disconnect the power cord. 2. Open the transport cover. 3. Remove the transport cover. ➀. Remove screw. ➁. Push transport cover to rear side. ➂...

Page 44

4-9 2 paper handling section 1 service procedure 2.5.5 tray 1 switch replacement removal 1. Warning: power off the machine and disconnect the power cord. 2 remove the rear lower cover. 3 remover the lvps 4 (fig1) remove the switch bracket. ➀remove screw. (fig.1) installation 1. Perform the installat...

Page 45

4-10 section 4 disassembly/assembly/adjustment 2. Paper handling 2.7.1 registration assy removal/installation removal 1. Power off the machine and disconnect the power plug. 2. Remove the drum unit and place a black bag over it ……………………………….. (5.1.1) 3. Remove the deve. Unit. ………………. (6.2.1) 4. Remo...

Page 46

4-11 2. Paper handling section 4 disassembly/assembly/adjustment ➂. (fig. 3): remove one-way clutch and gear. (spring disengages together.) ➃. Remove e clip and then bearing. (fig. 3) ➄. (fig. 4): turn over registration assy. ➅. Push in registration gate solenoid plunger with your finger. ➆. Remove ...

Page 47

4-12 section 4 disassembly/assembly/adjustment 2. Paper transport 3.1.1 vacuum transport belt replacement removal 1. Power off the machine and disconnect the power plug. 2. Open the front cover and then the machine. 3. Remove the drum unit and place a black bag over it ……………………………... (5.1.1) 4. Remo...

Page 48

4-13 4. Optics section 4 disassembly/assembly/adjustment 4.1.1 platen glass replacement removal 1. Power off the machine and disconnect the power plug. 2. Open the platen cover. 3. (fig. 1): remove the platen glass. ➀. Remove screws (2). ➁. Remove platen glass support. ➂. Remove platen glass. (fig. ...

Page 49

4-14 section 4 disassembly/assembly/adjustment 4. Optics 4.2.1 optical regi-sensor replacement removal 1. Power off the machine and disconnect the power plug. 2. Remove the platen glass. ........…….... (4.1.1) 3. Open the front cover and remove the console assy. ………………………... (10.2.1) 4. (fig. 1): lo...

Page 50

4-15 4. Optics section 4 disassembly/assembly/adjustment 4.2.3 carriage cable replacement note: • the cable winding procedure is described only for the front cable because the front and rear cables are symmetrically wound. • prepare scotch tape. • replace cables one by one. Refer to the location of ...

Page 51

4-16 section 4 disassembly/assembly/adjustment 4. Optics 2. (fig. 7): route the ball-attached side of cable to the pulley via the far left pulley as shown in fig. 7, then fasten the ball into the left-hand frame hole. (fig. 7) 3. (fig. 8): route the ring-attached side of cable to the pulley via the ...

Page 52

4-17 4. Optics section 4 disassembly/assembly/adjustment 8. (fig. 3): move gently the full/half-rate carriages toward their home positions by rotating the capstan pulley shaft manually to check the following: • the half-rate carriage convex contacts block a’s at its front and rear. • block b’s insta...

Page 53

4-18 section 4 disassembly/assembly/adjustment 4. Optics 4.3.2 exposure lamp replacement note: • do not touch the exposure lamp glass tube with your hand. If you touch it, wipe it with the drum cleaner. • take care not to hit the exposure lamp glass tube. It is fragile. Removal 1. Power off the mach...

Page 54

4-19 4. Optics section 4 disassembly/assembly/adjustment check 1. Align test chart(499t247) with the regi- guide and make a size- for-size copy of it on a3 paper. 2. (fig. 1): measure a, b, c & d each. Check that the values each obtained by subtracting b from a and d from c are in the specifications...

Page 55

4-20 section 4 disassembly/assembly/adjustment 4. Optics adjustment • vertical magnification change the vertical magnification (scan direction) referring to table 1. • horizontal magnification change the horizontal magnification (drum axis direction) referring to table 1. Chain code content min. Ini...

Page 56

4-21 4. Optics section 4 disassembly/assembly/adjustment installation 1. (fig. 5): check that the lens carriage timing hole aligns with the rail timing hole. Tape the lens carriage to the frame. (fig. 5) 2. Hook the shorter side of cable from its ball on the lens carriage. Note: • (fig. 5): hook the...

Page 57

4-22 section 4 disassembly/assembly/adjustment 4. Optics 4.5.4 lens motor replacement removal 1. Select 100%. After the lens stops, power off the machine and disconnect the power plug. 2. Remove the right/rear upper covers. 3. Open the front cover, and then the machine. 4. Remove the drum unit and p...

Page 58

4-23 5. Xerographic section 4 disassembly/assembly/adjustment 5.1.1 drum unit replacement note: • be careful of the following in handling the drum unit: a. Place the removed unit on a flat surface. B. Keep the drum away from direct strong light. Put a protective cover over it. C. Do not rotate the d...

Page 59

4-24 section 4 disassembly/assembly/adjustment 5. Xerographic 5.1.3 charge corotron wire replacement removal 1. Power off the machine and disconnect the power plug. 2. Open the front cover and then the machine. 3. Remove the drum unit. ……................ (5.1.1) 4. (fig. 1): remove the charge corotr...

Page 60

4-25 5. Xerographic section 4 disassembly/assembly/adjustment 6. Go to one of the following steps per the result of the evaluation. Within spec. → perform steps 3 through 5 in 70%/141% magnification modes. Out of spec. → proceed with the adjustment procedure. Adjustment reference the exposure light ...

Page 61

4-26 section 4 disassembly/assembly/adjustment 5. Xerographic 5.1.5 isil assembly replacement removal 1. Warning: power off the machine and disconnect the power cord. 2. Open the front cover and then the machine. 3. Remove the drum unit and place a black bag over it. ……………………………. (5.1.1) 4. Remove t...

Page 62

4-27 6. Development section 4 disassembly/assembly/adjustment 6.2.1 deve. Unit removal/installation removal 1. Warning: power off the machine and disconnect the power cord. 2. Open the front cover and then the machine. 3. (fig. 1): remove the deve. Unit. Note: • ensure before the work that the deve....

Page 63

4-28 section 4 disassembly/assembly/adjustment 8. Fuser 8.1.1 fuser thermostat replacement 8.1.2 fuser thermistor replacement common procedure removal 1. Warning: power off the machine and disconnect the power cord. Warning fuser surfaces are hot, allow the fuser to cool down before attempting servi...

Page 64

4-29 8. Fuser section 4 disassembly/assembly/adjustment 8.2.1 heater rod replacement note: a. Take great care in handling the heater rod glass tube. It is fragile. B. Do not touch the heater rod glass tube with your bare hand(s). If you touch it, wipe it with drum cleaner. Removal 1. Warning: power ...

Page 65

4-30 section 4 disassembly/assembly/adjustment 8. Fuser 8.2.2 heat roller replacement removal 1. Warning: power off the machine and disconnect the power cord. Warning fuser surfaces are hot, allow the fuser to cool down before attempting service procedure. Fuser lubricant can cause discomfort to eye...

Page 66

4-31 8. Fuser section 4 disassembly/assembly/adjustment 8.2.3 pressure roller replacement removal 1. Warnin: power off the machine and disconnect the power cord. Warning fuser surfaces are hot, allow the fuser to cool down before attempting service procedure. Fuser lubricant can cause discomfort to ...

Page 67

4-32 section 4 disassembly/assembly/adjustment 8. Fuser 8.2.4 contact arc adjustment purpose to obtain the appropriate fusing level. Note: a narrow contact arc would cause improper fusing. Wide contact arc or a great difference in contact arc between front and rear would cause wrinkled or curled cop...

Page 68

4-33 8. Fuser section 4 disassembly/assembly/adjustment 8.3.1 heat roller fingers replacement 8.3.2 pressure roller fingers replacement common procedure removal 1. Warning: power off the machine and disconnect the power cord. Warning fuser surfaces are hot, allow the fuser to cool down before attemp...

Page 69

4-34 section 4 disassembly/assembly/adjustment 8. Fuser installation 1. Perform the installation in the reverse order of removal. Note: • (fig. 7): install the finger with the both ends of the spring under the shaft. (fig. 7) 8.5.1 fuser fan motor assembly replacement removal 1. Warning: power off t...

Page 70

4-35 8. Electrical section 4 disassembly/assembly/adjustment 9.1.2 main pwb replacement removal 1. If the machine is ready, make a copy of table diag. Modes from the succeeding pages. 2. Enter diag. Mode and record the data of chain codes into table diag. Mode. Note: • if there is any unreadable dat...

Page 71

4-36 section 4 disassembly/assembly/adjustment 9. Electrical chain code 20 table ∗ the list below deletes function which do not need recording. Chain code function code setup item min. Value initial value max.Value 1 step change adj 20 1 registration adjustment 16(-4.13mm) 32 64(+4.13mm) 0.2584mm 2....

Page 72

4-37 9. Electrical section 4 disassembly/assembly/adjustment chain 30 code table chain code function code current value component counter 30 1 tray 1 feed counter 4 msi feed counter chain 40 code table chain code function code current value component counter 40 1 e1 jam counter 2 e3 jam counter 5 c1...

Page 73

4-38 section 4 disassembly/assembly/adjustment 9. Electrical 9.1.3 lvps replacement removal 1. Warning: power off the machine and disconnect the power cord. 2. Remove the rear lower cover. 3. (fig. 1): remove lvps. ➀. Disconnect all connectors from lvps. ➁. Remove screws(2). ➂. Remove lvps. (fig. 1)...

Page 74

4-39 10. Covers & frame section 4 disassembly/assembly/adjustment 10.1.1 front gas spring replacement removal 1. Power off the machine and disconnect the power plug. 2. Remove the console assembly. ….... (10.2.1) 3. Open the machine. 4. (fig. 1): remove the main switch cover. ➀. Loosen screw and rem...

Page 75

4-40 section 4 disassembly/assembly/adjustment 10. Covers & frame 10.2.1 console assembly replacement removal 1. Warning: power off the machine and disconnect the power cord. 2. Open the front cover. 3. (fig. 1): remove the console assembly. ➀. Remove screws(3). ➁. Disconnect p/j’s 417/418. ➂. Remov...

Page 76: Section 5

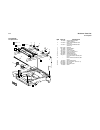

Section 5 parts list.

Page 77

5-1 contents section 5 parts list section 5 parts list preface ……………………………………………..……..… 5-2 pl-1 drive 1.1 main drives(1) ………………………………………... 5-3 1.2 main drives(2) ………………………………………... 5-4 pl-2 paper handling 2.1 paper cassettes assembly …………………..……... 5-5 2.2 multi sheet inserter assembly ………………….…… ...

Page 78

5-2 section 5 parts list preface 5.1 preface 5.1.1 section 5 parts list contains information on xerox 5915 main processor and spare parts. Use this section for applying for replacement spare parts and entering area codes. 5.1.2 plate structure each plate is constructed as follows: ➀ ➂ pl-4 optical ➁...

Page 79

5-3 pl-1 drive section 5 parts list pl-1 drive 1.1 main drive(1) item part no. Description 1 127k 87031 motor assy main (with 2,3) 2 7e 35210 drum gear 3 7e 35200 main motor gear 4 7e 27680 gear helical t36/t41 5 - - shaft (ref only) 6 - - bracket (ref only) 7 7e 41270 gear t18/34 8 7e 41280 gear t2...

Page 80

5-4 section 5 parts list pl-1 drive pl-1 drive 1.2 main drive (2) item part no. Description 1 7e 32461 gear t36 2 - - washer(ref only) 3 7e 30530 gear-spur.T41/35 4 68k 85541 bracket assy (ref only) 5 7e 32961 gear t36 6 7e 28881 gear-t25/16 7 7e 32981 gear t27 8 7e 22910 gear-t37/23 9 - - washer(re...

Page 81

5-5 pl-2 paper handling section 5 parts list pl-2 paper handling 2.1 paper cassette assembly item part no. Description 1 50s 20240 cassette assy 2 38p 50216 guide assy-side 3 9p 50223 spring 4 19p 50218 snubber-r 5 19e 93480 pad-side 6 49p 50212 plate bottom 7 9p 50222 spring-n/f 8 9p 50221 spring-n...

Page 82

5-6 section 5 parts list pl-1 paper handling pl-2 paper handling 2.2 multi sheet inserter assembly item part no. Description 1 22s 50256 msi feeder assy (with 2-5) (see pl2.3) 2 54e 09243 chute-msi ap 220v 3 19s 50212 pad assy retard 4 9e 78271 spring 5 19e 42170 film chute 6 9e 78782 spring n/f msi...

Page 83

5-7 pl-2 paper handling section 5 parts list pl-2 paper handling 2.3 msi upper assembly item part no. Description 1 7k 85620 gear pick up 2 13e 84520 bearing 3 120e 13150 msi actuator 4 107e 06650 msi size sensor 5 13e 84490 bearing 6 22e 84350 roll core 7 120e 09921 actuator n.P 8 107e 06650 sensor...

Page 84

5-8 section 5 parts list pl-1 paper handling pl-2 paper handling 2.4 rh transport cover & paper chute item part no. Description 1 121e 83330 magnet catch 2 63p 50206 tape stopper 3 - - screw(ref only) 4 54e 82040 chute-feed 5 110p 50202 switch-spot miniature 6 - - plate cover(ref only) 7 121e 83312 ...

Page 85

5-9 pl-2 paper handling section 5 parts list pl-2 paper handling 2.5 feeder assembly item part no. Description 1 22s 50260 feeder assy h/m (with 2-21) 2 22k 46310 roller assy-trans 3 13e 84490 bearing 4 59k 03261 roll assy feed 5 - - washer(ref only) 6 7e 41593 gear pick up-feed 7 9e 76810 spring pi...

Page 86

5-10 section 5 parts list pl-2 paper handling pl-2 paper handling 2.6 upper chute assembly item part no. Description 1 54k 08210 upper chute assembly (with 2~12) 2 - - torsion spring 3 - - torsion spring 4 13e 80030 bearing 5 13e 93670 bearing 6 - - hook (ref only) 7 22k 49970 roll assy-regi pinch 8...

Page 87

5-11 pl-2 paper handling section 5 parts list pl-2 paper handling 2.7 registration chute assembly item part no. Description 1 54k 16331 registration low chute assy (with 2-15) 2 7e 32360 gear-t27 3 7e 32940 gear-t18 4 13e 80030 bearing 5 7e 32930 gear-18 6 13e 84520 bearing 7 12k 93160 link-stud 8 9...

Page 88

5-12 section 5 parts list pl-2 paper transport pl-3 paper transport 3.1 vacuum transport assembly item part no. Description 1 20k 94292 wheel assy(with 5-13) 2 6e 47160 shaft wheel 3 13e 84130 bearing 4 49e 40130 brkt stopper 5 - - wheel shaft (p/o item 1) 6 - - wheel weight (p/o item 1) 7 - - space...

Page 89

5-13 pl-2 optical section 5 parts list pl-4 optical 4.1 optical assembly item part no. Description 1 90s 50209 glass assy platen 2 15p 50249 plate glass 3 - - screw(ref only) 4 57k 90521 seal glass 5 127s 50224 fan assy opt 6 55k 20881 shield assy optic 7 53e 91530 filter-right 8 14p 61844 platen sp...

Page 90

5-14 section 5 parts list pl-4 optical pl-4 optical 4.2 optical drive item part no. Description 1 12e 93380 rear carriage cable (cable scan in) 2 41s 50210 half rate carriage assy (see pl4.3) 3 41s 50211 full rate carriage assy (see pl4.3) 4 413w 77559 bearing 5 113e 16680 holder cable 6 9p 20224 sp...

Page 91

5-15 pl-2 optical section 5 parts list pl-4 optical 4.3 full rate & half rate carriage item part no. Description 1 41s 50211 full rate carriage assy (with 2-7) 2 48e 20972 cover contact in 3 108k 90710 fuse assy exp 4 9e 65820 spring fuse 5 162k 12611 cable assy 6 122p 50201 lamp halogen 7 62e 93400...

Page 92

5-16 section 5 parts list pl-4 optical pl-4 optical 4.4 mirror carriage item part no. Description 1 - - no.4 mirror assy (ref only) 2 35e 30190 seal 3 9e 65650 spring no. 4 hsg 4 - - shaft (ref only) 5 9e 65360 spring extension 6 - - angle plate (ref only) 7 9e 65610 spring 8 6e 57190 shaft cam 9 20...

Page 93

5-17 pl-4 optical section 5 parts list pl-4 optical 4.5 lens carriage item part no. Description 1 - - sensor bracket(ref only) 2 127k 84530 lens motor assy 3 - - sensor bracket(ref only) 4 107e 06650 lens sensor 5 - - lens carriage shield(ref only) 6 9e 65630 spring extension 7 41k 93880 lens carria...

Page 94

5-18 section 5 parts list pl-5 xerographic pl-5 xerographic 5.1 xero module assembly item part no. Description 1 125k 92513 corotron assy-cc(with 2-8) 2 55e 27511 shield-cc 3 118k 91572 rear insulator block 4 55k 18323 rear arc shield 5 9e 65900 wire spring 6 117k 19220 corotron wire 7 118e 12000 fr...

Page 95

5-19 pl-5 xerogaphic section 5 parts list pl-5 xerographic 5.2 tc/dtc corotron item part no. Description 1 125s 50201 transfer & detach corotron assy (with 2-10 13-14) 2 55e 27650 rear arc shield 3 55e 29550 front arc shield 4 - - voltage label 5 32e 05740 dtc guide 6 9e 65900 wire spring 7 117k 192...

Page 96

5-20 section 5 parts list pl-6 development pl-6 development 6.1 deve mechanism item part no. Description 1 1k 49781 deve rail assy (with 2-5) 2 1k 51861 rail assy 3 - - plate front (ref only) 4 - - plate rear (ref only) 5 9e 65630 spring 6 68k 11652 bracket support assy 7 - - roll(p/o item 6) 8 - - ...

Page 97

5-21 pl-6 development section 5 parts list pl-6 development 6.2 deve assembly item part no. Description 1 48s 50267 deve assy (with 2 21) 2 - - screw (p/o item 1) 3 48k 49550 upper deve cover(p/o item 1) 4 - - label (p/o item 1) 5 9e 65870 spring comprassion 6 3e 36350 cartridge stopper (p/o item 1)...

Page 98

5-22 section 5 parts list pl-8 fuser pl-8 fuser 8.1 inlet chute & temperature control item part no. Description 1 48k 75880 fuser cover (with 2) 2 - - caution label 3 130k 85732 fuser sensor assy (with 4 6,10) 4 - - sensor bracket(ref only) 5 - - harness (ref only) 6 130p 08241 fuser thermostat 7 54...

Page 99

5-23 pl-8 fuser section 5 parts list pl-8 fuser 8.2 heat roller item part no. Description 1 22p 50261 heat roller 2 59s 50200 pressure roller 3 13p 61059 bearing 4 49e 40170 front heater rod support 5 28e 93121 heat roller ring 6 5j 90590 collar 7 13e 82160 bearing 8 7e 34910 gear-48t 9 49e 40190 re...

Page 100

5-24 section 5 parts list pl-8 fuser pl-8 fuser 8.3 paper exit item part no description 1 120k 91080 exit switch actuator assy 2 9e 65940 spring 3 19e 22120 heat roller finger 19e 92740 heat roller finger (alt) 4 - - shaft (ref only) 5 110k 91880 exit switch assy 6 22k 39321 exit pinch roller assy 7...

Page 101

5-25 pl-8 fuser section 5 parts list pl-8 fuser 8.4 upper frame & receiving tray item part no. Description 1 126s 50225 fuser assembly 2 50p 50247 exit tray assy 2 1 aq.

Page 102

5-26 section 5 parts list pl-8 fuser pl-8 fuser 8.5 fuser fan motor & ozone filter item part no. Description 1 127k 84431 fuser fan motor 2 53e 91510 ozone filter 3 54e 08552 duct (ref only) 4 122k 92080 erase lamp.

Page 103

5-27 pl-9 electrical section 5 parts list pl-9 electrical 9.1 rear side (1) item part no. Description 1 - - pwb support 2 140s 50182 main pwb 3 140s 50191 ac drive pwb 4 48p 50261 ac drive pwb cover 5 110p 50203 tray 1 switch 6 105s 50209 lvps 7 - - screw 8 - - power cord (220v).

Page 104

5-28 section 5 parts list pl-9 electrical pl-9 electrical 9.2 rear side (2) item part no. Description 1 113s 50217 charge corotron holder 2 113s 50218 tc/tdc corotron holder 3 105s 50210 hvps 4 48p 50273 hvps cover 5 26p 62407 screw 2 1 4 5 aq aq aq 3.

Page 105

5-29 pl-10 frame & cover section 5 parts list pl-10 frame & cover 10.1 gas spring & latch lever item part no. Description 1 9p 50208 rear gas spring kit (with 2) 2 - - stopper (p/o item 1) 3 9p 50209 front gas spring kit 4 26e 82620 tapping screw 5 1p 50264 right frame 6 - - tapping screw (ref only)...

Page 106

5-30 section 5 parts list pl-10 frame & cover pl-10 frame & cover 10.2 console & top, platen cover item part no. Description 1 48s 50214 platen cover (with 2,3) 2 36k 90941 counter balance (p/o item 1) 3 26e 46630 tapping screw 4 4k 92320 platen cushion 5 26p 50221 screw 6 302p 50329 right blind cov...

Page 107

5-31 pl-10 frame & cover section 5 parts list pl-10 frame & cover 10.3 front & left hand item part no. Description 1 48p 50294 front cover 2 63e 93100 stopper tape 3 112w 27659 screw del m3 × 8 4 26e 46630 tapping screw 5 3e 35414 hinge 6 110p 50208 main power switch 7 96p 50345 lebel deve 8 48p 014...

Page 108

5-32 section 5 parts list pl-10 frame & cover pl-10 frame & cover 10.4 rear & right hand cover item part no description 1 48p 50238 rear lower cover 2 302p 50322 rear connecter cover 3 - - date plate (ref only) 4 26e 93961 screw del m4 × 8 5 26e 14060 tapping screw 6 48p 50251 rear upper cover 7 53p...

Page 109

5-33 the w number parts section 5 parts list part no description a 102w 27651 screw b 102w 28251 screw c 112w 27651 screw d 112w 27659 screw del sems e 112w 27851 screw f 112w 27859 screw (m3 × 8) g 112w 28451 screw h 112w 29751 screw washer i 112w 36259 screw-del sems j 113w 15651 screw k 113w 1585...

Page 110: Section 6

Section 6 general.

Page 111

6-1 contents section 6 general section 6 general 6.1 xerox 5915 specifications 6.1.1 product code ………………………..………..…… 6-2 6.1.2 dimensions ………………………………………... 6-2 6.1.3 space required for installation …………..……….. 6-3 6.1.4 levels… ………………………..…………………. 6-3 6.1.5 electrical specification …………………...……..… ...

Page 112

6-2 section 6 general 6.1 specification 6.1 xerox 5915 specifications 6.1.1 product code model m/c no product code 5915 (220v) sea transport 350100001x g3l 5915 (220v) air transport 350500001x g4l x: check digit 6.1.2 dimensions xerox 5915 (unit: mm) width (mm) depth (mm) height (mm) weight (kg) 591...

Page 113

6-3 6.1 specification section 6 general 6.1.3 space required for installation xerox 5915 (unit: mm) 6.1.4 levels • front & rear directions: moves freely for less than 5mm. • horizontal directions: moves freely for less than 10mm. 6.1.5 electrical specifications • frequency …… 50hz/60hz ± 0.5% (all m...

Page 114

6-4 section 6 general 6.1 specification 6.1.11 time required for changing magnification ratio • a ratio can be changed in less than 6 seconds within the magnification of 70-141%. (less than 9 seconds for 61% → 163% or 163% → 61%) 6.1.12 copy speed fcot: xerox 5915-6.7sec(a4lef,using the no.1 tray) f...

Page 115

6-5 6.1 specification section 6 general 6.1.20 copy quality -- : not specified mag. Test chart copy quality item ratio test chart checked copy density (%) at normal light dark i.D (density) density uniformity 100 499t247(a3) 0.7 gray over 1.08 tolerance less than 0.2 -- -- -- -- low contrast (light ...

Page 116

6-6 section 6 general 6.2 tools and consumables for servicing 6.2 tools and consumables for servicing 6.2.1 tools no. Tool no. Tool name 1 499t225 test pattern(cam-ii) 2 499t7002 test pattern case 3 499t247 test pattern (a3):10 4 499t248 test pattern (b4):10 5 499t301 mini driver(-) 6 499t355 screw ...

Page 117

6-7 6.5 installation/removeal section 6 general 6.5 installation/removal 6.5.1 installation xerox 5915 installation procedure note: to comply iec 950, iec 950 brackets (yj-68) is required as mandatory. See procedure no 9. 1. Introduction • tick (v) the ”check column of the table below as you proceed...

Page 118

6-8 section 6 general 6.5 installation/ removal 6.5.2 removal removal as described in this manual applies to field clearance activity only perform the removal procedure in the reverse order of installation. Customer service engineers should check the final destination of the machine prior to field c...

Page 119

6-9 6.6 program setting section 6 general 6.6 program setting 6.6.1 entering the program mode press the program button as “ready to copy” is on display. Note: inapplicable in the interrupt mode. 6.6.2 entering the program number and setup value. • if you enter an inappropriate program number or setu...

Page 120

6-10 section 6 general 6.6 program setting 6.6.6 setting start mode the start mode can be set and changed as required. Procedure 1. Press custom presets. Note custom presets is cleared if no button is pressed within 60 seconds. 2. Enter 86, using the numeric keyboard and the start mode is set. 3. Pr...

Page 121

6-11 6.6 program setting section 6 general 6.6.7 setting single-password mode to prevent the machine from being incorrectly used, the machine administrator can exercise control by setting a password after turning the machine on. Procedure 1.Press custom presets. Note •••• custom presets is cleared i...

Page 122

6-12 section 6 general 6.6 program setting 6.6.8 changing passwords this function enables the machine administrator or the account users to modify passwords. Procedure 1. Modifying passwords under single-password mode (1). Turn the machine power switch on, and the information presenting state id is ...

Page 123: Section 7

Section 7 wiring data.

Page 124

7-1 contents section 7 wiring data section 7 wiring data • plug/jack list ……………………………………….………7-2 • connector configuration …………………………………. 7-5.

Page 125

7-2 section 7 wiring data plug jack list plug/jack list how to read the plug/jack list: fig …………………… • indicates a figure or bsd where the respective plug/jack are shown. Number of pins ……. • indicates the number of pins, which does not necessarily match with the number of wires. Destination ………… • ...

Page 126

7-3 plug jack list section 7 wiring data p/j no. Fig. No. Number of pins destination 114 bsd5 3 tray1 no paper sensor 116 9,4 3 feed regi. Sensor 117 9,4 2 fuser exit sensor 118 bsd7 2 fuser thermistor 122 bsd7 3 toner empty sensor 200 5,8 10 isil 202 5 2 erase lamp 203 2 counter ↔ main pwb 204 3 ma...

Page 127

7-4 section 7 wiring data plug jack list p/j no. Fig. No. Number of pins destination t59 3,2, bsd2 bsd6 tray1 switch t60 up chute assy ground wire t61 up chute assy ground wire t62 3 6 bsd6 right cover switch t63 3 6 bsd3 bsd6 right cover switch t64 bsd1 bsd2 front cover intlk switch t65 bsd1 front ...

Page 128

7-5 connector configuration section 7 wiring data top view (fig.1) top view (fig.2) rear view ( fig.3) main motor main pwb.

Page 129

7-6 section 7 wiring data connector configuration top view (fig.4) a a details (main sw) terminal no wire color wire color terminal no t13 brn 2 5 blu t14 t11 brn 1 4 blu t12 front view (fig. 5).

Page 130

7-7 connector configuration section 7 wiring data r/h view a-a details top view (fig. 6) (fig. 7).

Page 131

7-8 section 7 wiring data connector configuration top view (fig. 8) base frame top view (fig.9).

Page 132: Section 9

Section 9 bsd (block schematic diagram).

Page 133

9-1 contents section 9 bsd (block schematic diagram) section 9 bsd (block schematic diagram) 9.1 symbol/signal nomenclature 9.1.1 symbols ……………………………………………. 9-2 9.1.2 signal nomenclature ……………………………… 9-2 9.2 bsd 1. Standby power ……………………………...…… 9-3 2. Mode selection, machine run control start print...

Page 134

9-2 section 9 bsd (block schematic diagram) 9.1 symbol/signal nomenclature 9.1 symbol/signal nomenclature 9.1.1 symbols following symbols are used in bsds. • test data this symbol on a bsd indicates that test data must always be referred to check existence of the signal. • note instructs to refer to...

Page 135

9-3 1.1 standby power section 9 bsd (block schematic diagram).

Page 136

9-4 section 9 bsd (block schematic diagram) 1.1 standby power.

Page 137

9-5 1.1 standby power section 9 bsd (block schematic diagram).

Page 138

9-6 section 9 bsd (block schematic diagram) 2. Mode selection, machine run control,start print power.

Page 139

9-7 3.1 optics section 9 bsd (block schematic diagram).

Page 140

9-8 section 9 bsd (block schematic diagram) 3.2 optics u2-1 lamp carriage fail - standby lamp carriage fails to activate optical registration sensor for 6.5 sec during standby. U2-2 lamp carriage fail - position case 1: optical registration sensor fails to turn on within 0.65 sec at lamp carriage in...

Page 141

9-9 4. Paper supplying and transportation section 9 bsd (block schematic diagram).

Page 142

9-10 section 9 bsd (block schematic diagram) 4.2 paper supplying and transportation c1-2 tray 1 misfeed jam feed sensor fails to turn on within 2.7 sec after feed was initiated. C9-3 msi misfeed jam registration gate sensor fails to turn on within 2.3 seconds after initiation of feed. E1-2 regi-gate...

Page 143

9-11 5. Xerographics, copy transportation and fusing section 9 bsd (block schematic diagram).

Page 144

9-12 section 9 bsd (block schematic diagram) 5.2 xeroxgraphics, copy transportation and fusing u4-1 fuser thermistor open fail electrical discontinuation of fuser thermistor or faulty fuser thermistor circuit. U4-2 fuser warm up fail fuser is not ready 1 minute after power on or front interlock swit...

Page 145

9-13 5.3 xeroxgraphics, copy transportation and fusing section 9 bsd (block schematic diagram) test data no. Signal name measurement point measurement method reference value 1 zero cross signal j410-9 ⊕ com measure in standby mode. (close front cover) +0.5vdc 2 erase lamp on(l) +24vdc j403-5 ⊕ com e...

Page 146: Xerox

Xerox the document company xerox 5915 service manual 1st edition •••• this service manual covers the following models: electrostatic copier xerox 5915 manufactured by shanghai xerox. •••• related materials no related materials are issued other than this service manual. •••• confidentiality • this se...