- DL manuals

- Xerox

- Printer

- Paser 7400

- Service Manual

Xerox Paser 7400 Service Manual

Summary of Paser 7400

Page 1

Phaser ® 7400 color printer service manual book 2: options.

Page 3: Phaser

Phaser ® 7400 color printer service manual book 2: options warning the following servicing instructions are for use by qualified service personnel only. To avoid personal injury, do not perform any servicing other than that contained in the operating instructions, unless you are qualified to do so. ...

Page 4

1-ii phaser 7400 color printer options service manual copyright © 2005 xerox corporation. All rights reserved. Unpublished rights reserved under the copyright laws of the united states. Contents of this publication may not be reproduced in any form without permission of xerox corporation. Copyright ...

Page 5: Service Terms

Phaser 7400 color printer options service manual iii service terms manual terms various terms are used throughout this manual to either provide additional information on a specific topic or to warn of possible danger present during a procedure or action. Be aware of all symbols and terms when they a...

Page 6

Iv phaser 7400 color printer options service manual symbols marked on the product danger high voltage. Protective ground (earth) symbol. Hot surface on or in the printer. Use caution to avoid personal injury. The surface is hot while the printer is running. After turning off the power, wait 30 minut...

Page 7: Power Safety Precautions

Phaser 7400 color printer options service manual v power safety precautions power source for 115 vac printers, do not apply more than 135 volts rms between the supply conductors or between either supply conductor and ground. For 230 vac printers, do not apply more than 254 volts rms between the supp...

Page 8

Vi phaser 7400 color printer options service manual electrostatic discharge (esd) precautions some semiconductor components, and the respective sub-assemblies that contain them, are vulnerable to damage by electrostatic discharge (esd). These components include integrated circuits (ics), large-scale...

Page 9: Service Safety Summary

Phaser 7400 color printer options service manual vii service safety summary general guidelines for qualified service personnel only: refer also to the preceding power safety precautions. Avoid servicing alone: do not perform internal service or adjustment of this product unless another person capabl...

Page 10

Viii phaser 7400 color printer options service manual servicing electrical components before starting any service procedure, switch off the printer power and unplug the power cord from the wall outlet. If you must service the printer with power applied, be aware of the potential for electrical shock...

Page 11: Regulatory Specifications

Phaser 7400 color printer options service manual ix regulatory specifications xerox has tested this product to electromagnetic emission and immunity standards. These standards are designed to mitigate interference caused or received by this product in a typical office environment. United states (fcc...

Page 12: European Union

X phaser 7400 color printer options service manual european union warning this is a class a product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. Xerox corporation declares, under our sole responsibility, that t...

Page 13: Manual Organization

Phaser 7400 color printer options service manual xi manual organization the xerox phaser 7400 color printer service manual is the primary document used for repairing, maintaining, and troubleshooting the printer. The manual is organized into two books. This volume, book 2, phaser 7400 options includ...

Page 14: Book 1 - Print Engine

Xii phaser 7400 color printer options service manual book 1 - print engine use book 1 as your primary resource for understanding the operational characteristics of the print engine. Book 1 describes printer specifications, theory and includes information important to the diagnosis and repair of prob...

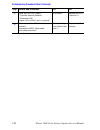

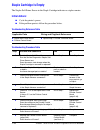

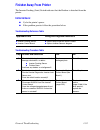

Page 15: 1 General Information

Table of contents xiii contents service terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Iii symbols marked on the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Iv power safety precautions . . . . . . . . . . . . . . . . . . ...

Page 16: 3 General Troubleshooting

Xiv phaser 7400 color printer options service manual sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25 finisher paper path sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27 inverter sensors . . . . . . . . . . . . . . . . ...

Page 17

Table of contents xv clear tray [2][3][4][5][6] riser plate . . . . . . . . . . . . . . . . . . . . . 3-38 out of paper load tray [2][3][4][5][6] with [size][type] . . . . . . 3-39 finisher lower output tray is full, unload paper . . . . . . . . . . . . 3-40 finisher upper output tray is full, unloa...

Page 18: 5 Service Parts Disassembly

Xvi phaser 7400 color printer options service manual no paper in tray [2][3][4][5][6] . . . . . . . . . . . . . . . . . . . . . . . . 3-87 staple cartridge is empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88 punch waste box is full or missing. . . . . . . . . . . . . . . . . . . ...

Page 19

Table of contents xvii upper right cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-37 processing tray assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38 paddle assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43 boards . ....

Page 20

Xviii phaser 7400 color printer options service manual staple/fold clock sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-93 folding home position sensor. . . . . . . . . . . . . . . . . . . . . . . . . . 5-94 folding position sensor . . . . . . . . . . . . . . . . . . . . . . . ...

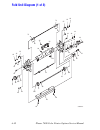

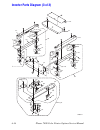

Page 21: 6 Parts List

Table of contents xix 6 parts list using the parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 finisher parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3 finisher unit assembly diagram. . . . . . . . ....

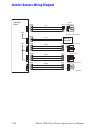

Page 22: 7 Wiring Diagrams

Xx phaser 7400 color printer service manual 7 wiring diagrams plug/jack locator diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 print options plug/jack designators . . . . . . . . . . . . . . . . . . . . . . 7-2 finisher wiring diagrams . . . . . . . . . . . . . . . ...

Page 23: In This Chapter...

1 section general information in this chapter... ■ printer introduction and overview ■ printer configurations ■ printer options ■ specifications.

Page 24

1-2 phaser 7400 color printer options service manual printer introduction and overview the xerox phaser 7400 color printer service manual is the primary document used to repair, maintain, and troubleshoot this printer. For manual updates, service bulletins, knowledge base, etc., see www.Xerox.Com/of...

Page 25: Printer Configurations

General information 1-3 printer configurations the phaser 7400 color printer is available in five configurations. The main differences are standard memory, optional high-capacity feeders, duplexing (2-sided printing) capabilities, networking, finisher capabilities, and internal hard drive. The follo...

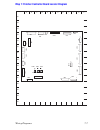

Page 26: Front View

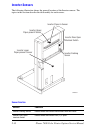

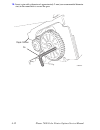

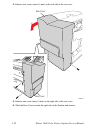

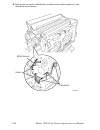

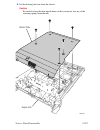

1-4 phaser 7400 color printer options service manual parts of the finisher and paper trays front view rear view s7400-552 s7400-533.

Page 27: Printer Options

General information 1-5 printer options phaser 7400 color printer options include: ■ 1,000-sheet finisher (with hole punch, staple, saddle-stitch, and inverter) ■ 550-sheet feeder (lta) ■ 1650-sheet feeder (hcf) ■ duplex unit finisher the finisher increases the output capacity of the printer by 1,00...

Page 28: Duplex Unit

1-6 phaser 7400 color printer options service manual duplex unit the duplex unit adds two-sided printing. The duplex unit attaches into the left side above tray 2 using two latches. 550-sheet feeder the 550-sheet feeder increases the input capacity of the printer. The feeder attaches below tray 2 wi...

Page 29: 1650-Sheet Feeder

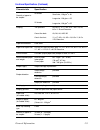

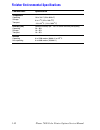

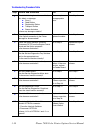

General information 1-7 1650-sheet feeder the 1650-sheet feeder adds three, 550-sheet trays. Control signals reach the sheet feeder by a single connection. The sheet feeder is secured both to the print engine and the 550-sheet feeder. Specifications consumable life specifications finisher electrical...

Page 30

1-8 phaser 7400 color printer options service manual physical dimensions and clearances finisher functional specifications finisher (including stand) value height: 1016 mm (40.0 in.) width: 813 mm (32 in.) depth: 595 mm (23.6in.) weight: approximately 55 kg (122 lb.) finisher only 1650-sheet feeder ...

Page 31

General information 1-9 quantity of paper to be stapled 50 sheets 25 sheets small size, 128 g/m 2 x 48 large size, 128 g/m 2 x 25 large size, 128 g/m 2 x 25 stapling two positions one at the back one in the front a3, b4, 11” x 17”, 8.5” x 14”, 8.5 x 13, a4, 8.5 x 11 r and executive a3, b4, a4, a4r, ...

Page 32

1-10 phaser 7400 color printer options service manual finisher environmental specifications characteristic specification temperature operating storage transport 10 to 32 o c (50 to 89.6 o f) 0 to 4 o c (32 to 109.4 o f) -10 to 43 o c (-14 to 109.4 o f) humidity (rh) operating storage transport relat...

Page 33: In This Chapter...

2 section theory of operation in this chapter... ■ operational overview ■ finisher overview ■ printer options ■ finishing process summary ■ sensors ■ motors, rollers, solenoids, and clutches ■ detecting jams ■ power supplies.

Page 34

2-2 phaser 7400 color printer options service manual options operational overview the phaser 7400 color printer options package consists of: finisher: ■ punch unit - provides various punch hole (2, 3, and 4 hole) options. ■ staple unit - staples stacked paper for various media type and size. ■ saddl...

Page 35: Finisher Overview

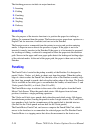

Theory of operation 2-3 finisher overview the finisher increases the output capacity of the printer by 1,000 sheets. Printer output is directed to the finisher by way of the side exit. Depending on the job specifications, as paper enters the finisher it can be inverted, punched, stapled, offset and ...

Page 36: Punch Unit

2-4 phaser 7400 color printer options service manual punch unit the punch unit punches holes in sheets coming from the printer. It provides for 2-hole, 3-hole, and 4-hole punching. The unit installs into the pickup assembly of the finisher. Since the punch unit is not equipped with a paper feeding m...

Page 37: Punch Unit Components

Theory of operation 2-5 the punch unit consists of a die and hole punch (punch blade), which is driven by a a dc motor. The unit attaches to the eccentric cam of the punch shaft. A punch home position sensor detects the home position of the punch shaft to ensure that the punch motor stops exactly at...

Page 38: Staple Unit

2-6 phaser 7400 color printer options service manual staple unit the staple unit receives instructions from the printer through the finisher controller board to initiate staple operation and deliver up to 50 sheets of paper (depending on the paper size) to the finisher staple subassembly. The unit m...

Page 39: Staple Unit Components

Theory of operation 2-7 the slide motor is then driven a specified number of pulses until the stapler reaches the rear standby position at the back of the machine. At this point, the unit enters the standby state. Staple unit components component function staple/fold motor rotates the cam in the app...

Page 40: Saddle Unit

2-8 phaser 7400 color printer options service manual saddle unit the saddle unit stitches (center staples) up to 50 sheets (middle 2-point), then folds the stack in two in the finisher. The finisher controller board receives commands from the printer to control the following operations: a. Paper fee...

Page 41: Paper Fold System

Theory of operation 2-9 paper fold system the paper fold mechanism consists of a guide plate, paper fold rollers, and a paper pushing plate. The staple/fold motor drives the guide plate, paper-fold rollers, and paper-pushing plate. A combination of gears and cams transfer the drive force while the s...

Page 42: Inverter Unit

2-10 phaser 7400 color printer options service manual inverter unit the inverter unit receives paper from the printer and physically inverts the paper for stacking or folding. The inverter is a self-enclosed unit which connects on a common base with the finisher itself. The entire finisher/inverter ...

Page 43: Printer Options

Theory of operation 2-11 printer options duplex unit the duplex unit adds two-sided printing. The duplex unit attaches to the left side above tray 1 using two twist locks. Installation of the duplex unit requires that the exit 2 module also be added to provide reverse drive. Electrical connection to...

Page 44: 1650-Sheet Feeder

2-12 phaser 7400 color printer options service manual 1650-sheet feeder the 1650-sheet feeder combines three, 550-sheet trays. Control signals reach the 1650-sheet feeder through a single connection. The sheet feeder is secured to the print engine or 550-sheet feeder with four screws located under t...

Page 45: Finishing Process Summary

Theory of operation 2-13 finishing process summary the following illustration shows the various printing processes and process decisions that the finishing components handle on command from the printer. Duplex? Y y y y n n n n duplexer processing invert? Punch? Center staple paper inverted folding p...

Page 46: Inverting

2-14 phaser 7400 color printer options service manual the finishing processes include six major functions: 1. Inverting 2. Folding 3. Punching 4. Stacking 5. Stapling 6. Delivery inverting the sole purpose of the inverter function is to position the paper for stacking or folding. On command from the...

Page 47

Theory of operation 2-15 ■ 4-hole type - the punching operation for the first sheet ends when the punch shaft rotates 180 degrees and the punch home position sensor activates. The punching operation for the second sheet ends when the punch shaft rotates 180 degrees in reverse and the punch home posi...

Page 48

2-16 phaser 7400 color printer options service manual ■ 2-hole, 3-hole type - to make two holes, the punching operation for the first sheet ends when the punch shaft rotates 180 degrees (half-circumference) and the punch home position sensor activates. At this time, the 3-hole punch rotates once on ...

Page 49

Theory of operation 2-17 4. When the punching operation ends, the feed motor moves the paper through the rest of the paper path. The finisher punch transfer motor then rotates in reverse to return the slide unit to home. 5. For each sheet that arrives in succession, the punch slide unit returns to i...

Page 50: Folding

2-18 phaser 7400 color printer options service manual folding finisher paper fold rollers and a paper pushing plate are the main assemblies for the paper folding process when creating a booklet. Concurrent with the start of the stack feed roller rotation, the paper pushing plate pushes the middle of...

Page 51: Stacking

Theory of operation 2-19 stacking there are two types of stacking presented to the delivery tray: ■ simple stacking - the unit pulls in the sheet to the processing tray and then delivers it to the delivery tray. S7400-122.

Page 52

2-20 phaser 7400 color printer options service manual ■ job offset - the machine places the sheet into the processing tray. It then moves the sheet to the front or the rear using the aligning plate. When it has deposited a specific number of sheets, it delivers them as a stacked set.) 4th set (direc...

Page 53: Stacking In Booklet Mode

Theory of operation 2-21 when the number of sheets stacked on the processing tray reaches a specified value, the sheets are delivered in stack form. Even if the unit never reaches a specified value, stacked sheets are temporarily delivered when 25 sheets of large-size paper (300 mm or longer) or 50 ...

Page 54

2-22 phaser 7400 color printer options service manual feed amount stack feed roller (upper) stack feed roller (lower) s7400-147.

Page 55: Stapling

Theory of operation 2-23 stapling after stacking and alignment of paper on the processing tray is complete, the finisher controller board moves the stapler for stapling according to the specified stapling position. When the controller specifies rear 1-point stapling, the stapler does not move; it st...

Page 56: Delivery

2-24 phaser 7400 color printer options service manual delivery the finisher unit includes a delivery tray, and the saddle unit includes a bind tray. The bind tray is a fixed unit where all folded paper stacks are delivered. The bind tray includes a bind tray sensor to detect the presence of paper. T...

Page 57: Sensors

Theory of operation 2-25 sensors the finisher/inverter, duplex unit, and paper trays contain sensors of various types that perform a variety of functions. One group of sensors track the progress of the paper along the paper path and detects if a paper jam occurs. Other sensors stop printer activity ...

Page 58: Microswitches

2-26 phaser 7400 color printer options service manual microswitches microswitches are used primarily as paper size sensors and cover interlocks. They are in a normally open state, and close when actuated. A bank of microswitches detect paper size in the universal trays. Microswitches also employ hoo...

Page 59

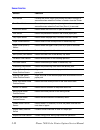

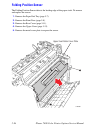

Theory of operation 2-27 finisher paper path sensors the following illustration identifies the various sensors located in the finisher. Error reporting is dependent on these sensors as the paper moves through the paper path. S7400-542 shift lower limit sensor front alignment plate home position sens...

Page 60

2-28 phaser 7400 color printer options service manual sensor function sensor function joint switch prevents the power supply from placing hazardous voltages in accessible areas when the finisher is undocks from the printer. Front door switch prevents the power supply from placing hazardous voltages ...

Page 61

Theory of operation 2-29 note the punch assembly includes up to five light-receiving transistors (photosensor board) mounted over the inlet paper path of the punch unit. The same number of leds are mounted under the path, as well. The front-most sensor (led5, pt5) detects the trailing edge of each s...

Page 62: Inverter Sensors

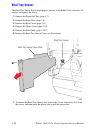

2-30 phaser 7400 color printer options service manual inverter sensors the following illustration shows the general location of the inverter sensors. The topics in this section describe the disassembly for each sensor.. Sensor function sensor function inverter docking sensor detects when the inverte...

Page 63: Duplex Sensors

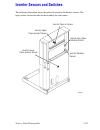

Theory of operation 2-31 duplex sensors the duplex unit receives media diverted to the side exit by the exit gate. The media is detected by the duplex entrance sensor and drawn into the duplex unit. The media is inverted and exits the duplex unit just above registration roller #2. Media moves throug...

Page 64: Optional Tray Sensors

2-32 phaser 7400 color printer options service manual duplex sensors include: ■ duplex entrance sensor detects the leading edge of the media and signals the duplex motor to begin rotation in the forward direction. ■ duplex reverse sensor detects media in the lower portion of the duplex unit and sign...

Page 65: Finisher Motors

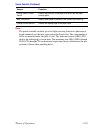

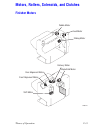

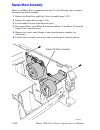

Theory of operation 2-33 motors, rollers, solenoids, and clutches finisher motors [1] s7400-543 paddle motor feed motor sliding motor staple/fold motor shift motor delivery motor rear alignment motor front alignment motor.

Page 66

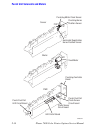

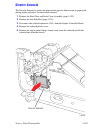

2-34 phaser 7400 color printer options service manual punch unit solenoids and motors sensor m otor pwb pi2p pi1p pi3p m2 m1 [1] [2] [3] [5] [4] s7400-544 punching motor clock sensor punching home position sensor horizontal registration home position sensor feed motor punching controller board punch...

Page 67

Theory of operation 2-35 inverter solenoids and motors the inverter motors move the rollers to move the media throughout the paper path. The feeder clutch, on command from the printer, engages the motors. The inverter solenoids, also on command from the printer, energize the upper and lower paper ro...

Page 68

2-36 phaser 7400 color printer options service manual duplex solenoids, rollers, and motors the duplex unit receives media diverted to the side exit by the exit gate. The media is detected by the duplex entrance sensor and drawn into the duplex unit. The media is inverted and exits the duplex unit j...

Page 69

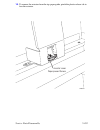

Theory of operation 2-37 optional tray motors, rollers, and clutches the following describes the paper path as it is fed from the optional tray 3. Trays 4 through 6 function in the same manner. Media moves along the paper path as follows: 1. Paper loaded in the tray is detected by the paper size swi...

Page 70

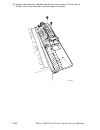

2-38 phaser 7400 color printer options service manual the paper supply and path for the optional trays involve these motors, rollers, and clutches: tray 2 tray 3 registration roller #3 registration roller #2 pick roller feed roller feed-out sensor #3 registration sensor #3 registration sensor #2 reg...

Page 71

Theory of operation 2-39 ■ registration motor this motor drives the registration rollers to pull media from the tray into the paper path. ■ registration clutch this clutch transfers registration motor drive to the registration roller. ■ registration roller this roller aligns the leading edge of the ...

Page 72: Detecting Jams

2-40 phaser 7400 color printer options service manual detecting jams the microprocessor (cpu) on the finisher controller board checks for jams in the finisher and other optional units. The cpu identifies a jam in reference to the presence or absence of paper at a specific sensor. In general, the jam...

Page 73: Finisher/punch Power Supply

Theory of operation 2-41 finisher/punch power supply when the printer is powered on and connected to the finisher, it supplies the finisher controller board with two channels of 24 vdc: one for the motors and clutches, and the other for conversion into 5 vdc in the regulator ic (ic1) of the finisher...

Page 74

2-42 phaser 7400 color printer options service manual finisher power supply protection a circuit breaker (cb1) is available to protect the 24 vdc system that drives the motors against overcurrent conditions. The 24 vdc system drives the feed motor, paddle motor, and delivery motor. Punch unit power ...

Page 75: In This Chapter...

3 section general troubleshooting in this chapter... ■ power on self test (post) ■ service diagnostics ■ error message table ■ troubleshooting the options.

Page 76: Introduction

3-2 phaser 7400 color printer options service manual introduction this section covers the startup, service diagnostics, and power supply operations of the finisher, inverter, duplex unit, and paper tray options to aid in troubleshooting problems. Troubleshooting procedures isolate a problem to a spe...

Page 77: Servicing Instructions

General troubleshooting 3-3 servicing instructions the service checklist below is an overview of the path a service technician should take when servicing the printer and printer optional equipment. Step 1 - identify the problem 1. Verify the reported problem does exist. Verify failure symptoms/behav...

Page 78: Jam Locator

3-4 phaser 7400 color printer options service manual jam locator the following illustrates the door designators that key the jam location error codes and messages. Refer to this diagram when questions arise regarding the area of the jam. Door h door f door j door g door i door c s7400-696.

Page 79: Jam Detection Chart

General troubleshooting 3-5 jam detection chart s7400-563 jam 01 jam 02 jam 03 jam 04 jam 05 jam 07 jam 08 jam 09 jam 10 inverter eject jam inverter feed jam inverter front stack inverter route jam inverter reverse stack area jam.

Page 80: Error Message Summary

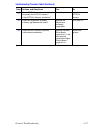

3-6 phaser 7400 color printer options service manual error message summary the error message summary table below lists possible errors, along with the corresponding code, and page reference for the corrective procedure for the finisher, duplex unit, and paper trays. The error column lists the error ...

Page 81

General troubleshooting 3-7 _ close door d 3-34 _ close finisher door f 3-35 _ close finisher door h 3-36 _ close finisher door j 3-37 tray and media errors _ clear tray [3][4][5][6] riser plate 3-38 _ out of paper load tray [3][4][5][6] with [size] [type] 3-39 _ finisher lower output tray is full, ...

Page 82

3-8 phaser 7400 color printer options service manual fatal errors u12 duplex interface failure 3-45 u14 tray 3 interface failure 3-46 u13 tray 4 interface failure 3-46 u16 tray 5 interface failure 3-46 u17 tray 6 interface failure 3-46 u51 inverter unit interface failure 3-47 u34 unsupported duplex ...

Page 83

General troubleshooting 3-9 i97 inverter power supply error. 3-71 221 tray 3 firmware error. Firmware error in tray 3 flash memory. 3-72 222 tray 4 firmware error. Firmware error in tray 4 flash memory. 3-72 223 tray 5 firmware error. Firmware error in tray 5 flash memory. 3-72 224 tray 6 firmware e...

Page 84

3-10 phaser 7400 color printer options service manual _ staple cartridge is empty 3-88 _ punch waste box is full or missing 3-89 _ finisher away from base 3-90 _ finisher away from printer 3-91 error control panel message page.

Page 85

General troubleshooting 3-11 using the troubleshooting procedures 1. Applicable status code(s) lists the error message(s) addressed by each troubleshooting procedure. 2. Applicable parts and wiring and plug/jack references assist you in locating information available for a particular part or procedu...

Page 86: Measurement Techniques

3-12 phaser 7400 color printer options service manual measurement techniques 1. Unless indicated otherwise, the instruction “switch on printer power” means for you to switch on printer power and let the printer proceed through power on self test (post) to a ‘ready’ condition. 2. Conventions used in ...

Page 87: Troubleshooting The Finisher

General troubleshooting 3-13 troubleshooting the finisher jam at door c for tray [3][4][5][6] media reached the feed-out sensor, but did not arrive at the transfer unit entrance sensor on time. This error represents a misfeed jam for media fed from an optional tray. Applicable status codes: code c3:...

Page 88

3-14 phaser 7400 color printer options service manual troubleshooting procedure table step actions and questions yes no 1 check the following for evidence of fault, dirt, debris, or damage: ■ door c ■ feed rollers ■ registration rollers ■ transport rollers ■ sensor actuators is there any damage or d...

Page 89

General troubleshooting 3-15 11 check optry24 harness continuity. Disconnect the optry24 harness. Is the optry24 harness conductive? Go to step 13. Replace the optry24 harness. 12 check the registration assembly. Is there a gap between the rollers? Replace the registration assembly (page 8-84). Go t...

Page 90: Applicable Status Code:

3-16 phaser 7400 color printer options service manual jam at door d open door d to clear media reached duplex reverse sensor, but did not leave the duplex unit on time. This error represents a misfeed jam inside the duplex unit. Applicable status code: code d1: jam at door d initial actions: ■ ensur...

Page 91: Jam In Duplex Unit

General troubleshooting 3-17 jam in duplex unit media reached duplex reverse sensor, but did not leave the duplex unit on time. This error represents a misfeed jam inside the duplex unit. Applicable status code: code d2: jam in duplex unit initial actions: ■ cycle printer power. ■ if the problem per...

Page 92: Jam At Duplex Entrance

3-18 phaser 7400 color printer options service manual jam at duplex entrance media reached the fuser exit sensor, but did not reach the duplex entrance sensor on time. This error represents a jam at the duplex entrance or in the exit assembly. Applicable status code: code tc3: jam at duplex entrance...

Page 93

General troubleshooting 3-19 5 check for +24 v to the duplex motors. Disconnect duplex on the motor driver board. Is there +24 v at duplex-6 ground? Go to step 6. Go to step 10. 6 test the fuser motor. Run the service diagnostics fuser motor test. Does the fuser motor function correctly? Go to step ...

Page 94: Jam At Finisher Punch Unit

3-20 phaser 7400 color printer options service manual jam at finisher punch unit media did not clear the finisher entrance sensor on time. This error represents a jam at the finisher entrance. Applicable status code: code fn1: jam at finisher punch initial actions: ■ check for obstructions or debris...

Page 95: Jam At Finisher Door H

General troubleshooting 3-21 jam at finisher door h media reached the finisher entrance sensor, but did not clear the inverter on time. This error represents a jam in the finisher inverter. Applicable status code: code fn2: jam at finisher door h initial actions: ■ check for obstructions or debris i...

Page 96: Applicable Status Code:

3-22 phaser 7400 color printer options service manual jam at finisher upper output tray media remains in the upper output path. This error represents a jam in the finisher. Applicable status code: code fn4: jam at finisher upper output tray initial actions: ■ check for obstructions or debris in the ...

Page 97: Applicable Status Code:

General troubleshooting 3-23 jam at finisher saddle stapler media remains in the buffer area. This error represents a jam in the finisher. Applicable status code: code fn5: jam at finisher saddle stapler initial actions: ■ check for obstructions or debris in the paper path. ■ cycle printer power. ■ ...

Page 98: Applicable Status Code:

3-24 phaser 7400 color printer options service manual jam at finisher upper output tray media remains in the finisher offset rollers. This error represents a jam in the finisher upper output path. Applicable status code: code fn6: jam at finisher upper output tray initial actions: ■ cycle printer po...

Page 99: Jam At Finisher Stapler

General troubleshooting 3-25 jam at finisher stapler media remains in the compiler tray. This error represents a jam in the finisher staple path. Applicable status code: code fn7: jam at finisher stapler initial actions: ■ cycle printer power. ■ if the problem persists, follow the procedure below. T...

Page 100: Jam At Finisher Door G

3-26 phaser 7400 color printer options service manual jam at finisher door g jam detected in the saddle stitch path. Applicable status code: code fn8: jam at finisher door g initial actions: ■ cycle printer power. ■ if the problem persists, follow the procedure below. Troubleshooting reference table...

Page 101: Applicable Status Code:

General troubleshooting 3-27 jam at finisher saddle stapler this error represents a jam in the finisher staple path. Applicable status code: code fn9: jam at finisher saddle stapler initial actions: ■ cycle printer power. ■ if the problem persists, follow the procedure below. Troubleshooting referen...

Page 102: Applicable Status Code:

3-28 phaser 7400 color printer options service manual jam at finisher upper output tray media remains in the compiler tray. This error represents a jam in the finisher eject path. Applicable status code: code fn10: jam at finisher upper output tray initial actions: ■ cycle printer power. ■ if the pr...

Page 103: Jam Inside Finisher

General troubleshooting 3-29 jam inside finisher media remains in the inverter. These errors represent a jam in the inverter path. Applicable status codes: code: in1: media remains in the inverter lower sensor. Code: in2: media remains in the inverter exit sensor. Code: in3: media reached the invert...

Page 104: Jam At Finisher Entrance

3-30 phaser 7400 color printer options service manual jam at finisher entrance media remains in the inverter entrance sensor. This error represents a jam in the printer/finisher interface. Applicable status codes: code in5: media did not reach the inverter entrance sensor following an eject command ...

Page 105: Applicable Status Code:

General troubleshooting 3-31 finisher output tray jammed this error represents a failure of, or an obstruction in the finisher upper output tray’s up or down motion. Applicable status code: code ft: finisher output tray jammed initial actions: ■ cycle printer power. ■ if the problem persists, follow...

Page 106

3-32 phaser 7400 color printer options service manual 5 check for +24 v to the shift motor. Disconnect cn6 from the finisher control board. Is there +24 v cn6-1 cn6-2? Replace the shift motor (page 5-59). Replace the finisher control board. If the error persists, go to step 6. 6 test the shift motor...

Page 107: Initial Actions:

General troubleshooting 3-33 close right door c for tray [3][4][5][6] the door c detect sensor for one of the option trays indicates that door c is open. Initial actions: ■ ensure that the door is free of obstructions and fully closed. ■ verify that the detect sensor actuator molded into the door is...

Page 108: Close Left Door D

3-34 phaser 7400 color printer options service manual close left door d the door d detect sensor on the duplex unit indicates that door d is open. Initial actions: ■ ensure that the door is free of obstructions and fully closed. ■ verify that the detect sensor actuator is not broken. ■ cycle printer...

Page 109: Close Finisher Door F

General troubleshooting 3-35 close finisher door f the door f interlock switch indicates that door f is open. Initial actions: ■ ensure that the door is free of obstructions and fully closed. ■ verify that the actuator is not broken. ■ cycle printer power. ■ if the problem persists, follow the proce...

Page 110: Close Finisher Door H

3-36 phaser 7400 color printer options service manual close finisher door h the upper cover (door h) sensor indicates that door h is open. Initial actions: ■ ensure that the door is free of obstructions and fully closed. ■ verify that the actuator is not broken. ■ cycle printer power. ■ if the probl...

Page 111: Close Finisher Door J

General troubleshooting 3-37 close finisher door j the front cover (door j) sensor indicates that door j is open. Initial actions: ■ ensure that the door is free of obstructions and fully closed. ■ verify that the actuator is not broken. ■ cycle printer power. ■ if the problem persists, follow the p...

Page 112: Initial Actions:

3-38 phaser 7400 color printer options service manual clear tray [2][3][4][5][6] riser plate the lift motor failed to raise the media to the pre-feed position. For a remove paper error, the level sensor indicates pre-feed position or higher before a lift is executed initial actions: ■ remove the tra...

Page 113: Initial Actions:

General troubleshooting 3-39 out of paper load tray [2][3][4][5][6] with [size][type] the tray’s no paper sensor indicates the tray is empty. Initial actions: ■ inspect the tray to ensure that it is free of obstructions, is loaded with supported media, and the guides are adjusted correctly. ■ cycle ...

Page 114: Initial Actions:

3-40 phaser 7400 color printer options service manual finisher lower output tray is full, unload paper initial actions: ■ ensure that the output tray is empty and the actuator is in the correct position. ■ cycle printer power. ■ if the problem persists, follow the procedure below. Troubleshooting re...

Page 115: Initial Actions:

General troubleshooting 3-41 finisher upper output tray is full, unload paper initial actions: ■ ensure that the output tray is empty and the actuator is in the correct position. ■ cycle printer power. ■ if the problem persists, follow the procedure below. Troubleshooting reference table applicable ...

Page 116: [Size][Type]

3-42 phaser 7400 color printer options service manual wrong paper size; load tray [3][4][5][6] with [size][type] tray [3] [4] [5] [6] paper size mismatch error. The paper size switch indicates that the media loaded in the source tray does not match the size specified by the print job. Initial action...

Page 117: [Size][Type]

General troubleshooting 3-43 wrong paper type load tray [3][4][5][6] with [size][type] the media thickness sensor has detected a change in the media type (thickness) in the same tray, or reports a thickness value exceeding the reference. Initial actions: ■ ensure the tray is free of obstructions and...

Page 118: [Size][Type]

3-44 phaser 7400 color printer options service manual paper not available load tray [3][4][5][6] with [size][type] tray [3] [4] [5] [6] paper type mismatch error. The paper size switch indicates that the media loaded in the source tray does not match the size specified by the print job. Initial acti...

Page 119: Duplex Interface Failure

General troubleshooting 3-45 duplex interface failure error occurs only after the detection of a properly installed and functioning duplex unit. Applicable status code: code u12: communication lost with duplex unit initial actions: ■ reseat the duplex unit ■ cycle the printer's power. ■ if the probl...

Page 120: Applicable Status Codes:

3-46 phaser 7400 color printer options service manual tray [3][4][5][6] interface failure a communications failure has occurred in the option tray interface. Applicable status codes: code u14: tray 3 interface failure code u13: tray 4 interface failure code u16: tray 5 interface failure code u17: tr...

Page 121: Applicable Status Code:

General troubleshooting 3-47 inverter unit interface failure a communication error has occurred in the finisher inverter. Applicable status code: code u51: inverter unit interface failure. Initial actions: ■ reseat the finisher connections. ■ cycle the printer's power. ■ if the problem persists foll...

Page 122: Applicable Status Code:

3-48 phaser 7400 color printer options service manual unsupported duplex unit rom the installed duplex unit does not contain the correct firmware. Applicable status code: code u34: unsupported duplex unit rom initial actions: ■ reseat the duplex unit. ■ cycle the printer's power. ■ if the problem pe...

Page 123: Applicable Status Codes:

General troubleshooting 3-49 unsupported tray [3][4][5][6] rom the printer has detected an incompatible lta or hcf assembly. Applicable status codes: code u35: unsupported tray 3 rom code u36: unsupported tray 4 rom code u37: unsupported tray 5 rom code u38: unsupported tray 6 rom initial actions: ■...

Page 124: Applicable Status Code:

3-50 phaser 7400 color printer options service manual unsupported inverter unit rom the printer has detected an incompatible inverter assembly. Applicable status code: code u50: unsupported inverter rom initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure belo...

Page 125: Applicable Status Code:

General troubleshooting 3-51 unsupported finisher unit rom the printer has detected an incompatible finisher. Applicable status code: code u55: unsupported finisher unit rom initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference ...

Page 126: Applicable Status Code:

3-52 phaser 7400 color printer options service manual finisher fold position sensor failure an error was detected with the fold position sensor. Applicable status code: code f131: fold position sensor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedur...

Page 127: Finisher Paddle Failure

General troubleshooting 3-53 finisher paddle failure an error was detected in the finisher paddle motor. Applicable status code: code f103: paddle motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applica...

Page 128: Applicable Status Code:

3-54 phaser 7400 color printer options service manual finisher stapler swing motor failure the stapler swing home position sensor detected a stapler swing motor error. Applicable status code: code f106: swing motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follo...

Page 129: Applicable Status Code:

General troubleshooting 3-55 finisher stack handling motor failure the delivery belt home position sensor detected a stack handling error. Applicable status code: code f111: stack handling motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure belo...

Page 130: Applicable Status Code:

3-56 phaser 7400 color printer options service manual finisher staple motor failure an error was detected in the staple motor. Applicable status code: code f110: staple motor initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference...

Page 131: Finisher Jog Motor Failure

General troubleshooting 3-57 finisher jog motor failure an error was detected in either the front or rear alignment motor. Applicable status code: code f93: jog motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference...

Page 132: Applicable Status Code:

3-58 phaser 7400 color printer options service manual finisher lift motor failure the paper surface, upper limit, or lift motor clock sensor detected a lift motor error. Applicable status code: code f115: lift motor failure initial actions: ■ check the tray lift mechanism for obstructions or damage....

Page 133

General troubleshooting 3-59 5 check all pins of the inverter interface cable for continuity. Disconnect cn1 and cn2 from the finisher control board and the opposite end from the inverter. Is the cable conductive? Replace the inverter power supply (page 5-56). Replace the cable. Troubleshooting proc...

Page 134: Finisher Exit Failure

3-60 phaser 7400 color printer options service manual finisher exit failure the delivery belt home position sensor detected a delivery motor error. Applicable status code: code f116: delivery motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure b...

Page 135: Applicable Status Code:

General troubleshooting 3-61 finisher punch backup ram failure an error was detected in the punch unit’s backup ram. Applicable status code: code f138: punch unit’s backup ram failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting ...

Page 136: Applicable Status Code:

3-62 phaser 7400 color printer options service manual finisher punch communications failure an communications error occurred with the punch unit. Applicable status code: code f132: punch unit communications failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the pr...

Page 137: Applicable Status Code:

General troubleshooting 3-63 finisher punch unit transfer motor failure an error was detected in the punch transfer motor. Applicable status code: code f181: punch transfer motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooti...

Page 138: Applicable Status Code:

3-64 phaser 7400 color printer options service manual finisher punch motor failure an error was detected in the punch motor. Applicable status code: code f134: punch motor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting refe...

Page 139: Applicable Status Code:

General troubleshooting 3-65 finisher backup ram failure an error was detected in the finisher’s backup ram. Applicable status code: code f137: finisher’s backup ram failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference ...

Page 140: Applicable Status Code:

3-66 phaser 7400 color printer options service manual finisher punch dust sensor failure an error was detected in the punch waste sensor. Applicable status code: code f139: punch waste sensor failure initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. ...

Page 141

General troubleshooting 3-67 6 replace the finisher control board (page 5-46). Does the error still occur? Replace the engine control board (see book 1). Complete. Troubleshooting procedure table (continued) step actions and questions yes no.

Page 142: Applicable Status Code:

3-68 phaser 7400 color printer options service manual printer error - contact service; report fault [n] the following procedures apply to codes associated with the printer error message. Finisher punch unit counter at end of life the punch count indicates that punch unit has reached its end of life....

Page 143: Applicable Status Code:

General troubleshooting 3-69 finisher staple unit counter at end of life applicable status code: code f142: staple unit at end of life initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts wiring and plug/...

Page 144: Finisher Interface Error

3-70 phaser 7400 color printer options service manual finisher interface error applicable status code: code f186: finisher serial communications error. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts...

Page 145: Applicable Status Code:

General troubleshooting 3-71 inverter power supply failure applicable status code: code i97: inverter hardware error initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts wiring and plug/jack references ■ ...

Page 146: Applicable Status Codes:

3-72 phaser 7400 color printer options service manual tray [3][4][5][6] firmware error applicable status codes: code 221: software error in tray 3 flash memory. Code 222: software error in tray 4 flash memory. Code 223: software error in tray 5 flash memory. Code 224: software error in tray 6 flash ...

Page 147: Applicable Status Code:

General troubleshooting 3-73 duplex unit firmware error applicable status code: code 225: a firmware error with the duplex unit. Initial actions: ■ reseat the duplex unit ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable par...

Page 148: Applicable Status Code:

3-74 phaser 7400 color printer options service manual finisher inverter firmware error applicable status code: code 227: a software error with the inverter’s flash memory. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference ta...

Page 149: Applicable Status Codes:

General troubleshooting 3-75 tray [3][4][5][6] flash memory failure applicable status codes: code 242: hardware error in tray 3 flash memory. Code 243: hardware error in tray 4 flash memory. Code 244: hardware error in tray 5 flash memory. Code 245: hardware error in tray 6 flash memory. Initial act...

Page 150: Applicable Status Code:

3-76 phaser 7400 color printer options service manual duplex unit flash memory failure applicable status code: code 246: hardware failure with duplex unit flash memory. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table...

Page 151: Applicable Status Code:

General troubleshooting 3-77 finisher inverter flash memory failure applicable status code: code 225: hardware failure with inverter flash memory. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts wiri...

Page 152: Applicable Status Codes:

3-78 phaser 7400 color printer options service manual tray [3][4][5][6] lift motor failure applicable status codes: code 911: the tray 3 lift motor is not rotating. Code 912: the tray 4 lift motor is not rotating. Code 913: the tray 5 lift motor is not rotating. Code 914: the tray 6 lift motor is no...

Page 153

General troubleshooting 3-79 4 check for +24 v at optry24. 1. Close the interlock switches. 2. Disconnect optry24. Is there +24 v at optry24-1 and -2 ground? Replace the affected option control board. Go to step 5. 5 check all pins on the optry24 harness for continuity. Disconnect the optry24 harnes...

Page 154: Duplex Unit Fan Failure

3-80 phaser 7400 color printer options service manual duplex unit fan failure the duplex fan rotation signal indicates the duplex fan has stopped rotating. Applicable status code: code 918: the duplex fan has failed. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the ...

Page 155: Applicable Status Code:

General troubleshooting 3-81 +24v not available to the duplex unit abnormal current indicates that +24 v is not being supplied to the duplex unit. Applicable status code: code 225: duplex unit is not receiving +24 v. Initial actions: ■ reseat the duplex unit. ■ cycle the printer's power. ■ if the pr...

Page 156

3-82 phaser 7400 color printer options service manual 5 check the lvps +24 v output. 1. Close the interlock switches. 2. Disconnect cn2. Is there +24 v at cn2-1 and ground? Go to step 6. Replace the lvps (see book 1). 6 check all pins of the drv1 harness for continuity. Disconnect the drv1 ribbon ca...

Page 157: Applicable Status Codes:

General troubleshooting 3-83 +24 v not available to tray [3][4][5][6] voltage detection indicates that +24 v is not available to the indicated option tray. Applicable status codes: code 924: tray 3 not receiving +24 v code 925: tray 4 not receiving +24 v code 926: tray 5 not receiving +24 v code 927...

Page 158: Applicable Status Code:

3-84 phaser 7400 color printer options service manual duplex unit clock frequency error the clock frequency for the duplex unit control board cpu is inaccurate. Applicable status code: code 931: the duplex unit’s cpu clock frequency is inaccurate. Initial actions: ■ reseat the duplex unit. ■ cycle t...

Page 159: Applicable Status Code:

General troubleshooting 3-85 finisher inverter clock frequency error the clock frequency for the inverter control board cpu is inaccurate. Applicable status code: code 932: the inverter’s cpu clock frequency is inaccurate. Initial actions: ■ cycle the printer's power. ■ if the problem persists follo...

Page 160: Applicable Status Codes:

3-86 phaser 7400 color printer options service manual tray [3][4][5][6] feeder board clock frequency error the clock frequency on the indicated feeder board is inaccurate. Applicable status codes: code 933: tray 3 feeder board cpu clock frequency is inaccurate. Code 934: tray 4 feeder board cpu cloc...

Page 161: Initial Actions:

General troubleshooting 3-87 no paper in tray [2][3][4][5][6] the no paper sensor indicates that the named tray is empty. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts wiring and plug/jack referenc...

Page 162: Staple Cartridge Is Empty

3-88 phaser 7400 color printer options service manual staple cartridge is empty the stapler self-prime sensor in the staple cartridge indicates no staples remain. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table appli...

Page 163: Initial Actions:

General troubleshooting 3-89 punch waste box is full or missing the punch box sensor indicates the punch box is full or not installed in the finisher. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts ...

Page 164: Finisher Away From Base

3-90 phaser 7400 color printer options service manual finisher away from base the finisher switch indicates that the finisher is detached from the inverter. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable ...

Page 165: Initial Actions:

General troubleshooting 3-91 finisher away from printer the inverter docking (joint) switch indicates that the finisher is detached from the printer. Initial actions: ■ cycle the printer's power. ■ if the problem persists follow the procedure below. Troubleshooting reference table applicable parts w...

Page 166

3-92 phaser 7400 color printer options service manual.

Page 167: In This Chapter...

4 section adjustments and calibrations in this chapter... ■ punch unit adjustments ■ staple unit adjustments ■ saddle unit adjustments.

Page 168: Punch Unit Adjustments

4-2 phaser 7400 color printer options service manual punch unit adjustments registering punch holes perform the following steps to identify the type of punch unit and associated number of punch holes. The punch controller board uses this switching information to identify and register the finisher ty...

Page 169

Adjustments and calibrations 4-3 3. Press switch sw1002 on the punch controller board to select the appropriate number of punch holes. Each press on sw1002 moves the selection through the following (repeatedly from top to bottom). 4. Press switch sw1003 on the punch controller board twice. The press...

Page 170

4-4 phaser 7400 color printer options service manual adjusting sensor output after sensor replacement perform the following steps whenever you replace the punch controller board, horizontal registration sensor (photosensor board/led board), or waste full sensor (waste full photosensor board/waste fu...

Page 171

Adjustments and calibrations 4-5 adjusting sensor output after ee-prom replacement to adjust the sensor output after replacing the ee-prom, use the following steps: 1. Turn off the phaser 7400 color printer. 2. Locate dip switches sw1001, sw1002, and sw1003 and leds led1001, led1002, and led1003 on ...

Page 172: Stapler Unit Adjustments

4-6 phaser 7400 color printer options service manual stapler unit adjustments adjusting the saddle stitch double stapling position to adjust the stapling position for middle 2-point stapling, you must match it with the folding position. If you have replaced the finisher controller board, you must tr...

Page 173: Adjusting The Stapler Phase

Adjustments and calibrations 4-7 3. Press switches psw1 or psw2 on the finisher controller board as necessary to move the stapling position to the proper location (pressing the switch once moves the stapling position about 0.14 mm): ■ to move the stapling position in the "-" direction, press switch ...

Page 174

4-8 phaser 7400 color printer options service manual 4. Remove the e-ring to detach the side cover of the staple clincher. 5. Remove the two e-rings to remove the staple jam releasing gear, timing belt, and relay gear 1. Remove the spacer and spring at the back of the staple jam releasing gear. Gear...

Page 175

Adjustments and calibrations 4-9 6. Remove the screw to remove the belt tensioner from its mounting post (also remove the spring). 7. Remove the timing belt. Timing belt belt tensioner staple jam releasing gear relay gear 1 s7400-204.

Page 176

4-10 phaser 7400 color printer options service manual 8. Remove the e-ring to remove the staple position check gear. E-ring staple position check gear timing belt s7400-205.

Page 177

Adjustments and calibrations 4-11 9. Turn the gear to align the round hole in the staple driver gear with the round hole at the back. Gear staple driver gear hole s7400-206 staple clincher staple driver.

Page 178

4-12 phaser 7400 color printer options service manual 10. Insert a pin with a diameter of approximately 2 mm (use recommended diameter size) in the round hole to secure the gear. Pin staple clincher s7400-207.

Page 179

Adjustments and calibrations 4-13 11. Turn the gear to align the round hole in the staple clincher cam with the round hole at the back. Gear staple clincher cam hole staple clincher s7400-208.

Page 180

4-14 phaser 7400 color printer options service manual 12. Insert a pin with a diameter of approximately 2 mm (use of a 2 mm allen wrench as recommended) in the round hole to secure the gear. 13. With the gears and cam fixed, install the timing belt on the gears. Pin s7400-209 staple clincher cam gea...

Page 181

Adjustments and calibrations 4-15 14. Mount the staple position check gear so that the blue mark on the staple position check gear is aligned with the round hole in the frame. Reinstall the e-ring on the gear. Caution it is necessary to mount the gear at the correct position. The position where the ...

Page 182

4-16 phaser 7400 color printer options service manual 16. Assemble the spring, spacer, staple jam releasing gear, timing belt, and relay gear. Secure them with the e-ring. 17. Replace the front cover and two knobs and reinstall the stapler unit. Staple jam releasing gear e-ring relay gear spring spa...

Page 183: Saddle Unit Adjustments

Adjustments and calibrations 4-17 saddle unit adjustments adjusting the folding position if you replace the finisher controller board, you must match the folding position to the stapling position. Perform the following steps: 1. Locate dip switch sw1 on the finisher controller board. 2. Set sw1 on t...

Page 184

4-18 phaser 7400 color printer options service manual 4. After adjusting the folding position, set all bits of sw1 on the finisher controller board to off (this action will ensure that the switch will no longer affect the settings). 5. Enter the booklet mode of the printer and check whether the fold...

Page 185

Adjustments and calibrations 4-19 2. With the paper fold rollers and saddle cam positioned as shown in the proceeding figure, mount gears as shown in the following figure. Align the mark (either one of the two marks) on the saddle cam drive gear with the mark on the relay gear. The relay gear is loc...

Page 186

4-20 phaser 7400 color printer options service manual.

Page 187: In This Chapter...

5 section service parts disassembly in this chapter... ■ general notes on disassembly ■ overview ■ finisher disassembly ■ inverter disassembly ■ duplex unit disassembly ■ optional paper tray disassembly.

Page 188: Overview

5-2 phaser 7400 color printer options service manual overview this section contains the removal and replacement procedures for selected parts of the printer options package according to the field replaceable units (frus) parts list. Not all replacement procedures are included in this service manual....

Page 189: Fastener Types

Service parts disassembly 5-3 notations in the disassembly text ■ the notation “(item x)” points to a numbered callout in the illustration corresponding to the you disassembly procedure being performed. ■ the notation “plx.X.X” indicates that this component is listed in the fru parts list. ■ bold ar...

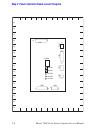

Page 190: Standard Orientation

5-4 phaser 7400 color printer options service manual standard orientation when needed the orientation of the option is called out in the procedure for locating parts, refer to the orientation graphic for locating the right, left, front and back sides of the printer. S7400-339 left front back right.

Page 191: Finisher Disassembly

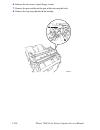

Service parts disassembly 5-5 finisher disassembly the finisher disassembly is presented in the following categories: ■ base unit and inverter ■ tray and covers ■ subassemblies ■ field replaceable units removing inverter base unit from finisher 1. Release the hook attaching the finisher to the base ...

Page 192

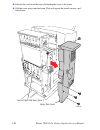

5-6 phaser 7400 color printer options service manual undocking inverter from printer 1. Slide out the bar on the bottom of the finisher base unit. 2. Remove two screws (metal, 6 mm) holding the inverter to the printer. 3. Remove guide pins. 4. Slide inverter away from the printer. S7400-528.

Page 193: Trays and Covers

Service parts disassembly 5-7 trays and covers paper exit tray 1. Remove four screws (metal, 6 mm) and detach the paper exit tray. S7400-527 paper tray.

Page 194: Front Door (Door J)

5-8 phaser 7400 color printer options service manual front door (door j) 1. Open the front door. 2. Remove two screws (metal, 6 mm). 3. While squeezing the plastic hooks, remove the fold jam release knob. 4. Press the release latch and slide the finisher away from the finisher base unit. Fold jam re...

Page 195

Service parts disassembly 5-9 5. To detach the front door, remove four screws (metal, 6 mm), pull the right side of the cover away from the finisher, and then slide the cover to the left (moving the guide tab out of the slot on the cover). S7400-161 front door.

Page 196: Right Side Door (Door G)

5-10 phaser 7400 color printer options service manual right side door (door g) for diagnostic purposes, you may be instructed to open or close the right side door on the finisher. The illustration below identifies the location of the right side door (door g). S7400-719 finisher right side door (door...

Page 197: Rear Cover

Service parts disassembly 5-11 rear cover 1. Remove the paper exit tray (page 5-7). 2. Press the release latch and slide the finisher away from the base. 3. Detach the cable from the finisher to the inverter (at the rear of the finisher). S7400-697.

Page 198

5-12 phaser 7400 color printer options service manual 4. Remove two screws (metal, 6 mm) on the left side of the rear cover. 5. Remove one screw (metal, 6 mm) on the right side of the rear cover. 6. Slide the rear cover towards the right side of the finisher and remove. Rear cover s7400-162 rear cov...

Page 199: Upper Cover (Door H)

Service parts disassembly 5-13 upper cover (door h) 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Open the upper cover and turn the stopper strap retainer clip counter-clockwise, then remove the strap from the cover. 4. Remove the screw (metal, 6 mm) and detach t...

Page 200

5-14 phaser 7400 color printer options service manual 5. Detach the upper cover. Processing tray rear cover upper cover s7400-164.

Page 201

Service parts disassembly 5-15 processing tray upper cover 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the upper cover. (page 5-13). 4. Disconnect the top end of the cable from the connector and free the cable from the harness. 5. Remove the single screw...

Page 202

5-16 phaser 7400 color printer options service manual 6. While lifting the processing tray upper cover, disconnect the other end of the cable from the connector underneath the tray. Replacement note when replacing or reconnecting the connector, be sure the connection is firm and secure. Otherwise, y...

Page 203: Inverter Front Covers

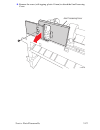

Service parts disassembly 5-17 inverter front covers 1. Remove the inverter and base unit from the finisher (page 5-5). 2. Press the release latch and slide the finisher away from the printer. 3. Remove two screws (metal flange, 10 mm) holding the lower front cover to the chassis. 4. Remove the lowe...

Page 204

5-18 phaser 7400 color printer options service manual 5. Remove two screws (metal flange, 10 mm) from the left side and two screws from the right side of the upper front cover. 6. Remove one screw (metal flange, 10 mm) from the bottom of the upper front cover. 7. Carefully move the finisher release ...

Page 205: Inverter Rear Covers

Service parts disassembly 5-19 inverter rear covers 1. Remove the inverter and base unit from the finisher (page 5-5). 2. Press the release latch and slide the finisher away from the printer. 3. Remove two screws (metal flange, 10 mm) holding the lower rear cover to the chassis. 4. Remove the lower ...

Page 206

5-20 phaser 7400 color printer options service manual 8. Release the cover from the four tabs holding the cover to the frame. 9. Pull the cover away from the frame. This will expose the boards, motors, and clutch units. Upper rear cover s7400-490 inverter right side door (door i).

Page 207

Service parts disassembly 5-21 inverter left side door (door f) for diagnostic purposes, you may be instructed to open or close the left side door on the inverter. The illustration below identifies the location of the inverter left side door (door f). S7400-718 inverter left side door (door f).

Page 208

5-22 phaser 7400 color printer options service manual inverter right side door (door i) for diagnostic purposes, you may be instructed to open or close the right side door on the inverter. The illustration below identifies the location of the right side door (door i). Upper rear cover s7400-490 inve...

Page 209: Inverter Top Cover

Service parts disassembly 5-23 inverter top cover 1. Remove the inverter and base unit from the finisher (page 5-5). 2. Remove the inverter front covers (page 5-17). 3. Remove the inverter rear covers (page 5-19). 4. Remove two black screws (self-tapping, 6 mm) on each side of the cover. 5. Lift the...

Page 210: Units

5-24 phaser 7400 color printer options service manual units punch unit the steps in this procedure show you how to remove the punch unit. 1. Remove the paper exit tray (page 5-7). 2. Remove the front door (page 5-8). 3. Remove the rear cover (page 5-11). 4. Remove the waste case box. 5. Remove the t...

Page 211

Service parts disassembly 5-25 6. Remove the screw (self-tapping, plastic 10 mm) to detach the jam processing cover. Jam processing cover s7400-256.

Page 212

5-26 phaser 7400 color printer options service manual 7. Disconnect the connector. And remove the harness from the harness guide. 8. Remove the screw (metal flange, 6 mm) and sensor support plate. 9. From the left side view, disconnect the sensor connector. Connector harness guide s7400-257 connecto...

Page 213

Service parts disassembly 5-27 10. Remove one screw (metal flange, 6 mm) and washer. 11. Disconnect the connector (from the underside of the unit) and then the assembly. Remove the two screws (self-tapping, plastic 10 mm) to detach the base cover. Base cover connector s7400-259.

Page 214

5-28 phaser 7400 color printer options service manual 12. Remove the three screws (metal flange, 6 mm) to remove the upper transmission sensor unit and the lower transmission sensor. 13. Remove the punch unit from the finisher punch transfer motor assembly. Upper transmission sensor unit lower trans...

Page 215: Staple Unit

Service parts disassembly 5-29 staple unit 1. Open the front door to gain access to the staple unit. 2. Slide out the staple unit while pressing the stopper. Note do not remove the stapler frame shaft. If removed, the position where the staple driver (lower unit of the stapler) inserts the staple th...

Page 216: Staple/fold Drive Unit

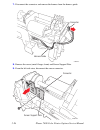

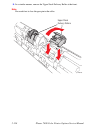

5-30 phaser 7400 color printer options service manual staple/fold drive unit note the references indicate the connector on the finisher controller board. 1. Remove the front door (page 5-8) and slide out the stapler unit to the front. 2. Remove the rear cover (page 5-11). 3. Remove the screw (metal ...

Page 217

Service parts disassembly 5-31 6. Disconnect the cable connector (to cn10) behind the punch unit. 7. Slide the finisher away from the inverter and then free the harness. 8. Free the harness from the edge saddle and disconnect the two connectors (to cn18). 9. Remove the two screws (metal flange, 6 mm...

Page 218

5-32 phaser 7400 color printer options service manual 10. Disconnect the connector to cn8 and the connector to cn6, and free the harness from the edge saddle. Cn71 staple/fold motor staple/fold clock sensor edge saddle cn52 s7400-229.

Page 219

Service parts disassembly 5-33 11. Remove the five screws (metal, 10 mm), lift to free two hooks (one on each side, and remove the unit. S7400-230 staple/fold drive unit.

Page 220: Saddle Unit

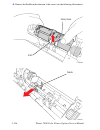

5-34 phaser 7400 color printer options service manual saddle unit 1. Remove the paper exit tray (page 5-7). 2. Remove the front door (page 5-8). 3. Remove the rear cover (page 5-11). 4. Open the jam removal cover (door i) and remove two screws (metal, 10mm) and the right stay. 5. Turn the fold jam r...

Page 221

Service parts disassembly 5-35 7. Remove the stop ring and detach the timing belt. 8. Disconnect the two connectors. Stop ring timing belt connectors s7400-216.

Page 222

5-36 phaser 7400 color printer options service manual 9. Remove the three screws (metal, 10mm) and slide out the stapler unit slightly to the front and remove the saddle unit. Stapler unit saddle unit s7400-217.

Page 223: Assemblies

Service parts disassembly 5-37 assemblies upper right cover assembly 1. Remove the front door (page 5-8). 2. Remove the rear cover (page 5-11). 3. Remove two screws (metal, 6 mm) at the front and two screws at the rear of the assembly. 4. Detach the assembly and lift up to remove. Upper right cover ...

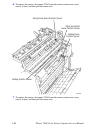

Page 224: Processing Tray Assembly

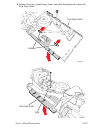

5-38 phaser 7400 color printer options service manual processing tray assembly 1. Remove the processing tray upper cover (page 5-15). 2. Remove the upper right cover assembly (page 5-37). 3. Remove the side guide (page 5-107). 4. Remove the two screws (metal, 10 mm) and disconnect the following four...

Page 225

Service parts disassembly 5-39 5. Pull the processing stopper base to the front and free the hooks at the front and rear of the processing stopper. Hook processing stopper hook processing stopper processing stopper base s7400-219.

Page 226

5-40 phaser 7400 color printer options service manual 6. Release the two hooks of the harness retainer, remove three connectors and detach the motor harness. Motor harness hooks connectors s7400-220

Page 227

Service parts disassembly 5-41 7. Remove the stop ring and detach the timing belt. Caution a free-floating pin is inserted in the gear shaft that can easily fall into the chassis. Be careful when loosening or removing the belt from the gear. 8. Disconnect the connector and free the harness from the ...

Page 228

5-42 phaser 7400 color printer options service manual 9. Remove the two screws (metal flange, 6 mm), slide the processing tray assembly to the rear, then lift it to detach. Caution note the inset in the illustration below to find two screws on the chassis side holding the tray to the unit. You must ...

Page 229: Paddle Assembly

Service parts disassembly 5-43 paddle assembly 1. Remove the processing tray assembly (page 5-38). 2. Place the assembly as shown. Caution be sure to take care not to damage the aligning plates. Aligning plates paddle assembly s7400-223.

Page 230

5-44 phaser 7400 color printer options service manual 3. Detach the timing belt and remove the two screws (metal flange, 6 mm). Timing belt s7400-224.

Page 231

Service parts disassembly 5-45 4. Separate the processing tray assembly and the paddle assembly as shown. Paddle assembly s7400-225 processing tray assembly.

Page 232: Boards

5-46 phaser 7400 color printer options service manual boards finisher controller board 1. Remove the rear cover (page 5-11). 2. Disconnect the 17 connectors and remove the screw (metal flange, 6 mm). 3. Free the board retainer and detach the finisher controller board. Finisher controller board board...

Page 233: Home Position Board

Service parts disassembly 5-47 home position board 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Open the front door and turn the knob on the stapler slide in the direction of the arrow to slide the stapler to the front-most posi...

Page 234

5-48 phaser 7400 color printer options service manual 8. Turn the knob on the stapler side in the direction of the arrow so that the fixing screw (metal, 10 mm) of the slide home position board is in view through the round hole. 9. Remove the fixing screw (metal, 10mm). Slide home position pcb fixin...

Page 235

Service parts disassembly 5-49 10. Disconnect the connector. 11. Remove the flexible cable retainer. 12. Free the lock of the connector in the direction of the arrow, and then detach the flexible cable. 13. Detach the board. Slide home position pcb connector connector lock flexible cable flexible ca...

Page 236: Punch Control Board

5-50 phaser 7400 color printer options service manual punch control board 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Remove the two screws (metal flange, 6 mm). 5. Disconnect the five connectors to remove the punch control boa...

Page 237: Photo Sensor Board

Service parts disassembly 5-51 photo sensor board 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Remove the punch motor assembly (page 5-46). 5. Remove the screw (metal flange, 6 mm). 6. Remove the harness from the harness guide o...

Page 238

5-52 phaser 7400 color printer options service manual 7. Disconnect the connector to remove the photosensor board. Photosensor board connector s7400-264.

Page 239: Punch Led Board

Service parts disassembly 5-53 punch led board 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Remove the waste case box. 5. Disconnect the connector. 6. Remove the harness from the harness guide. 7. Remove the metal screw (metal f...

Page 240: Waste Full Led Board

5-54 phaser 7400 color printer options service manual waste full led board 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Remove the screw (metal flange, 6 mm). 5. Disconnect the connector to remove the board. Connector waste-full...

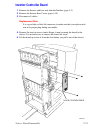

Page 241: Inverter Controller Board

Service parts disassembly 5-55 inverter controller board 1. Remove the inverter and base unit from the finisher (page 5-5). 2. Remove the inverter rear covers (page 5-19). 3. Disconnect all cables. Replacement note it is a good idea to label all connectors to make sure that you replace each one in i...

Page 242

5-56 phaser 7400 color printer options service manual inverter power supply board 1. Remove the inverter and base unit from the finisher (page 5-5). 2. Remove the inverter rear covers (page 5-19). 3. Remove the inverter controller board (page 5-55). 4. Disconnect all cables. Replacement note it is a...

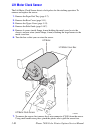

Page 243: Punch Motor

Service parts disassembly 5-57 motors, clutches, and solenoids punch motor 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Disconnect the connector j002 on the punch motor. 5. Remove the two metal screws (metal flange, 6 mm) securi...

Page 244

5-58 phaser 7400 color printer options service manual finisher punch transfer motor 1. Remove the rear cover (page 5-11). 2. Remove the front door (page 5-8). 3. Remove the upper cover (page 5-13). 4. Disconnect connector to the motor. 5. Remove the harness from the harness guide. 6. To remove the f...

Page 245: Lift Motor

Service parts disassembly 5-59 lift motor 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the upper cover (page 5-13). 4. Remove the side guide (page 5-107). 5. Remove three screws (metal, 6 mm) from the lift motor cover box. 6. Disconnect connector cn 70 fr...

Page 246: Staple/fold Motor

5-60 phaser 7400 color printer options service manual staple/fold motor 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the staple/fold drive unit (page 5-30). 4. Disconnect connector cn71 from the motor. 5. Face the drive unit toward you and remove two scre...

Page 247: Slide Motor

Service parts disassembly 5-61 slide motor 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the staple unit (page 5-29). 4. With the staple unit facing you, disconnect connector cn72 from the motor. 5. Slide the belt off of the motor gear. 6. Remove two screw...

Page 248: Feed Motor

5-62 phaser 7400 color printer options service manual feed motor 1. Remove the front door(page 5-8). 2. Remove the rear cover (page 5-11). 3. Remove the punch unit (page 5-50). 4. Open the harness retainer and disconnect the cable from connector cn56. 5. Remove two small screws (metal flange, 6 mm) ...

Page 249: Paddle Motor

Service parts disassembly 5-63 paddle motor 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the upper cover (page 5-13). 4. Disconnect connector cn57 from motor wiring. 5. To remove the motor, remove two screws (metal, 6 mm), and list the unit free from the ...

Page 250: Delivery Motor

5-64 phaser 7400 color printer options service manual delivery motor 1. Remove the paper exit tray (page 5-7). 2. Remove the rear cover (page 5-11). 3. Remove the side guide (page 5-107). 4. Refer to the illustration below to locate the delivery motor. 5. Slide the belt off of the motor gear. 6. To ...

Page 251