- DL manuals

- Xinje

- Servo Drives

- DS2-20P2-AS

- User Manual

Xinje DS2-20P2-AS User Manual

Summary of DS2-20P2-AS

Page 1

Wuxi xinje electric co., ltd. Ds2 series servo drive manual data no.: sc209 20110412 1.0

Page 2

2.

Page 3

1 ►► safety notes confirmation do not use the drivers that are broken, lack of parts or wrong types. installation make sure all the external powers are cut off before install the drivers. wiring please cut off all the powers before wiring. Connect the ac power to the power terminals of driver....

Page 4

2 matched please contact us if there are any problems in these items. 2. Type (1) servo driver ds2 – 2 0p7 – as (2) servo motor ms -80 st - m 02430 a z- 2 0p7 power voltage power-loss brake shaft specs feature code feedback part code sine drive motor base code series name base code: 60, 80, 90; feed...

Page 5

3 shaft spec: a- no bond; b- with bond; power-loss brake: empty- no brake; z- with brake; voltage level: 2-220v; power: 0p2: 0.2kw; 0p4: 0.4kw; 0p7: 0.75kw; 3. Parts introduction (1) servo motor (2) servo driver ds2-20p2-as, ds2-20p4-as, ds2-20p7-as encoder frame flange output shaft.

Page 6

4 pul- pul+ v1+ dir- dir+ v2+ si1 si2 si3 si4 +24v so1 so2 com power light when power on panel buttons for parameter settings panel display display the servo state, parameter, alarm cn2 cn1 cn0 pulse, direction, i/o signal cn1 i/o, analog, position feedback signal cn2 encoder terminal power and moto...

Page 7

5 ►► installation 1. Servo motor ms series servo motors can be installed either horizontally or vertically. The service life of the servo motor can be shortened or unexpected problems might occur if it is installed incorrectly or in an inappropriate location. Follow these installation instructions c...

Page 8

6 (1) storage temperature store the servomotor within -20~+60 ℃ as long as it is stored with the power cable disconnected. (2) installation location free of corrosive or explosive gases. Well-ventilated and free of dust and moisture. Ambient temperature of 0° to 50°c. Relative humidity (r.H.) of 20 ...

Page 9

7 ms series servo motors can be installed either horizontally or vertically. (5) avoid oil and water install a protective cover over the servomotor if it is used in a location that is subject to water or oil mist. Also use a servomotor with an oil seal when needed to seal the through-shaft section. ...

Page 10

8 50°c. Installation near a heating unit minimize heat radiated from the heating unit as well as any temperature rise caused by natural convection so the temperature around the servo drivers does not exceed 50°c. Installation near a source of vibration install a vibration isolator beneath the servo ...

Page 11

9 (4) installation follow the procedure below to install multiple servo drivers side by side in a control panel. Servo drive direction install the servo driver perpendicular to the wall and make the front panel towards operator. Cooling please leave enough space as the above diagram to ensure coolin...

Page 12

10 ambient inside control panel ambient temperature: 0~50 ℃ humidity: 90%rh or less vibration: 4.9m/s 2 condensation and freezing: none ambient temperature for long-term reliability: 50°c maximum ►► dimensions 1. Servo motor 60 series motor installation dimensions unit: mm type la ms-60st-...

Page 13

11 type la normal with brake ms-60st-m01330□□-20p4 146 189.

Page 14

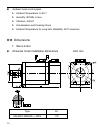

12 80 series motor installation dimensions unit: mm type la normal with brake ms-80st-m02430□□-20p7 150 191.

Page 15

13 ms-90st-m02430□□-20p7 installation dimensions unit: mm type la normal with brake ms-90st-m02430□□-20p7 149 194 2. Servo drive(unit: mm) ds2-20p2-as, ds2-20p4-as, ds2-20p7-as.

Page 16

14 ►► wiring 1. Main circuit.

Page 17

15 ds2-20p2-as, ds2-20p4-as, ds2-20p7-as the terminal function of main circuit: terminal function explanation l1/l2/l3 power input of main circuit ac single-phase or 3-phase 200~240v, 50/60hz ground terminal connect to ground terminal of motor p+、pb regeneration brake resistor connect the regenera...

Page 18

16 ds2-20p2-as ds2-20p4-as ds2-20p7-as cn0 cn1(db15) pul- pul+ v1+ dir- dir+ v2+ si1 si2 si3 si4 +24v so1 so2 com 1 5 6 10 11 15 cn0, cn1 terminal ds2-20p2-as ds2-20p4-as ds2-20p7-as cn0 terminals no. Name contents no. Name contents 1 pul- pulse input pul- 8 si2 input terminal 2 2 pul+ difference ...

Page 19

17 pul+ 3 v1+ open collector +24v 10 si4 input terminal 4 4 dir- direction input dir- 11 +24v input terminal +24v 5 dir+ difference input dir+ 12 so1 output terminal 1 6 v2+ open collector +24v 13 so2 output terminal 2 7 si1 input terminal 1 14 com ground of output terminal ds2-20p2-as ds2-20p4-as d...

Page 20

18 output b- input 6 a+ encoder output a+ 14 a rs485 + 7 a- encoder output a- 15 b rs485 - 8 z+ encoder output z+ 4. I/o signals (1) input signal item input terminals function digital input si1~si5 multi-functional input terminals pulse input pul-、pul+ p2-00=0: positive pulse p2-00=2: pulse dir-、dir...

Page 21

19 9 10 15 14 13 12 11 1 2 3 4 5 6 7 8 drive terminal encoder terminal name drive terminal encoder terminal name 60、80、90 series motor 60、80、90 series motor 1 9 a+ 2 4 b+ 3 7 z+ 4 6 u+ 5 11 w+ 6 13 a- 7 14 b- 8 5 z- 9 8 u- 10 15 w- 11 1 shield 12 3 gnd 13 2 5v 14 10 v+ 15 12 v- 6. Communication port...

Page 22

20 ds2-20p2-as、ds2-20p4-as、ds2-20p7-as 1 5 (5-pin port) terminal name explanation 1 txd rs232 send 2 rxd rs232 receive 3 gnd rs232 ground note: please use the cable offered by xinje company. Com2 the com2 position of each type: type port com mode mark ds2-20p2-as ds2-20p4-as ds2-20p7-as a (cn1-14)...

Page 23

21 8:57600 9:115200 p0-04.1 data bit 0 0:8 p0-04.2 stop bit 2 0:2 bits;2:1 bit p0-04.3 parity bit 2 0~2 0:no parity 1:odd parity 2:even parity modbus station no. Can be set through p0-03. Parameter function unit default setting range p0-03 modbus station no. - 1 1~255 note: the above parameters will...

Page 24

22 v2+ /dir- /pul- cn0-6 cn0-4 cn1-7 cn1-6 cn0-14 cn1-4 cn0-13 cn0-12 cn1-3 cn0-9 /p-ot /spd-a reverse prohibited (effective when off) cn0-11 alarm reset (clear the alarm when on) encoder output a0- ao+ com shield layer connects 0v at signal side, be empty at drive side vcc cn0-1 2.2kΩ w v pg m v 3-...

Page 25

23 ►► use the control panel 1. Basic operation the control panel can display the servo status, alarm code, command and set the parameters. Status esc dec enter inc the control panel can display the running status, set the parameters and command. The basic status includes display status, parameter se...

Page 26

24 display mode: monitor mode: u- xx: xx is monitor parameter code auxiliary function mode: fx-xx: the first x is group code; the second x is parameter code in this group. Parameter settings mode px-xx: the first x is group code; the second x is parameter code in this group. Alarm mode e-xxx:xxx is ...

Page 27

25 the status contents code contents code contents standby servo is off (motor has no electricity) run servo enable (motor has electricity) forward prohibit p-ot on reverse prohibit n-ot on 3. Monitor status the monitor status can show the command, i/o signal status, servo internal status. The monit...

Page 28

26 (4) press status/esc to return the contents of monitor code: code contents unit u-00 motor real speed rpm u-01 input speed command rpm u-02 internal torque command % u-03 rotate angle (physical angle) 0.1° u-04 rotate angle (electricity angle) 0.1° u-05 bus voltage v u-06 module temperature 0.1℃ ...

Page 29

27 u-19 analog input v-ref 0.01v u-20 analog input t-ref 0.01v u-21 i/o signal status u-22 i/o terminal status u-21 can show the i/o signal status. The following is the i/o status. Fig 1 fig 2 in fig 1, input status is shown in led4 and led5; output status is shown in led1 and led2. Fig 2 is the led...

Page 30

28 4. Auxiliary function the control panel can performance some applications in auxiliary function. Function code contents f0-** system information f1-** auxiliary function, show auxiliary command and result f2-** motor code f3-** alarm information f4-00 reset to default settings f5-00 external comm...

Page 31

29 dec for reverse jog. Press status/esc to exit. 4 statuses when jogging: status display status display idle forward enable reverse (2)test run(f1-01) make sure the motor doesn’t connect to the machine before test running! please enter test run if servo connects to non-original encoder line and pow...

Page 32

30 press enter to perform the function, it will show ref_o. It will show done in 1 second when the auto-tune is successful. Press status/esc to exit. (5)torque command offset auto-tune choose f1-04 to enter this function. It will show ref_o. Press enter to run this function, it will show ref_o and b...

Page 33

31 (4) keep press enter to show the information. Please refer to ds2 servo manual for detailed alarm information. Set to default value the following are the steps of set to default value. The operations must be done when servo is off. (1) press status/esc to enter auxiliary function. (2) press inc o...

Page 34

32 (4) it will show the value in p3-09. The lowest bit will blink; press enter to left shift the bit. Press inc, dec or enter to change the value to 3000. Keep press enter to confirm. Repeat step2 to step4 to change the value. (5) press status/esc to exit. 6. Alarm it will show alarm code when servo...

Page 35

33 3: speed (terminal command) 4: speed (analog) 5: position (internal) 6: position (pulse) 7: speed (pulse) 02 sub-mode 2 0~7 ditto - 0 0~7 ○ 03 modbus station no. Of com2 - 1 1~255 ● 04 parameters of com2 - n.2206 n.0000 ~ n.2209 ● 05 rotation direction 0: look at load side, counterclockwise is fo...

Page 36

34 07 t-ref distribution 0: undefined. 1: t-ref is external torque limit input. 2: undefined. 3: p-cl, n-cl is on, t-ref is external torque limit input. - 0 0~3 ○ 08 v-ref distribution 0: undefined. 1: v-ref external speed limit input. - 0 0、1 ○ 2. Control parameter p1(address: 0100 ~ 01ff) p1- name...

Page 37

35 3. Position control parameter p2(address: 0200 ~ 02ff) p2 - function unit default value range effective time 00 command pulse mode 1: ab phase pulse (90° phase, 4-time) 2: sign and pulses - 2 1、2 ● 01 position command filter 0: first order filter 1: smooth filter - 0 0、1 ● 02 electronic gear rati...

Page 38

36 15 first segment command filter time 0.1ms 0 0~65535 ○ p2-16~p2-90 are 2~16 segment parameters, p2-91~p2-93 are reserved. 94 the times pass z phase signal after leaving the limit switch times 2 1~65535 ○ 95 the speed close to the proximity switch 0.1rpm 600 0~50000 ○ 96 the speed leave the proxim...

Page 39

37 speed) for each motor 10 speed command input dead area voltage 0.01v 0 0~100 ○ 5. Torque control p4(address: 0400 ~ 04ff) p4- name unit default value range effective time 00 analog value of rated torque 0.01v 1000 150~3000 ○ 01 torque command filter time 0.01ms 0 0~65535 ○ 02 forward torque limit...

Page 40

38 pulse 01 zero clamp speed /zclamp rpm 10 0~300 ○ 02 rotation checking speed /tgon rpm 20 1~1000 ○ 03 co-speed checking signal width /v-cmp rpm 10 1~250 ○ 04 near output signal width /near command pulse 50 0~10000 ○ 05 deviation pulse limit 256 command pulses 1000 0~65535 ○ 06 servo off delay time...

Page 41

39 0006:input positive signal to terminal si6 0010:signals are valid 0011:input negative signal to terminal si1 0012:input negative signal to terminal si2 0013:input negative signal to terminal si3 0014:input negative signal to terminal si4 0015:input negative signal to terminal si5 0016:input negat...

Page 42

40 19 /spd-b internal speed choice, ditto - ※1 ※3 ● 20 /c-sel control mode choice, ditto - ※1 ※3 ● 21 /zclamp zero clamp, ditto - ※1 ※3 ● 22 /inhibit pulse command prohibition, ditto ※1 ※3 ● 23 /g-sel gain switching, ditto - ※1 ※3 ● 24 /clr clear pulse offset, ditto - ※1 ※3 ● 25 /chgstp change step ...

Page 43

41 ditto 30 /tgon rotation checking, ditto - ※2 ※4 ● 31 /s-rdy ready, ditto - ※2 ※4 ● 32 /clt torque limit, ditto - ※2 ※4 ● 33 /vlt speed limit checking, ditto - ※2 ※4 ● 34 /bk brake interlock, ditto - ※2 ※4 ● 35 /warn warn, ditto - ※2 ※4 ● 36 /near near, ditto - ※2 ※4 ● 37 /alm alarm, ditto - ※2 ※4...

Page 44

42 ds2-20p2-as ds2-20p4-as ds2-20p7-as /s-on /alm-rst /p-ot /n-ot /spd-a table 3: output signal distributions output terminal parameters servo drive range p5-28~p5-38 ds2-20p2-as ds2-20p4-as ds2-20p7-as n.0000~n.0003 n.0010~n.0013 the range is different as the output terminals of servo drive. Table ...

Page 45

43 damage parameter self-test contact us e-003 bus overvoltage grid voltage is too high or not connect to regenerative resistor, regenerative resistor is broken or value to large check the grid and regenerative e-004 bus under voltage grid voltage is too low check the grid e-005 regenerative resisto...

Page 46

44 broken motor e-012 motor uvw current error current collection circuit is error check motor wiring, change servo drive e-013 encoder uvw open circuit not connect encoder, encoder wiring is error or damaged check encoder wiring, re-connect it after power off, change the encoder e-014 encoder abz op...

Page 47

45 ►► general debug steps (a) make sure there is no obvious damage on the product before power on. (b) connect servo drive and motor. Please note the power terminal uvw and the servo drive terminal uvw must one-to-one connect. Otherwise, the servo motor will be blocked or run too fast. (c) power on,...

Page 49

►► motor code motor type power kw torque nm speed rpm current a overload times motor code ms-60st-m006 30-20p2 0.2 0.637 3000 1.8 3 1003 ms-60st-m013 30-20p4 0.4 1.27 3000 2.5 3 0004 ms-80st-m024 30-20p7 0.75 2.39 3000 3.0 3 0011 ms-90st-m024 30-20p7 0.75 2.4 3000 3.0 3 0021 ►► motor code servo driv...

Page 50

Xinje electronic co., ltd. 4th floor building 7,originality industry park, liyuan development zone, wuxi city, jiangsu province 214072 tel: 86-510-85134136 fax: 86-510-85111290