- DL manuals

- Xinje

- Servo Drives

- DS2-45P5-A

- Reference Manual

Xinje DS2-45P5-A Reference Manual

Summary of DS2-45P5-A

Page 1

Wuxi xinje electric co., ltd. Ds2 series 380v servo drive fast reference manual serial no. Sc2309 20120215 1.0

Page 2: ►► Safety Caution

2 ►► safety caution confirmation when receive products do not install any driver which is damaged, lack of accessories or not the same with the model ordered. installation cut off external power supply before installation. wiring cut off external power supply before wiring. Connect ac power su...

Page 3: 2. Model Description

3 however, cannot be turned manually. Is there any damage? Check the overall appearance, and check for damage or scratches that may have occurred during shipping. Are there any loose screws? Check screws for looseness using a screwdriver. Is the motor code the same with the code in driver? Check the...

Page 4: 3. Sections Description

4 base size:180; feedback component: m(photoelectric pulse coder) ; performance specifications: first 3 numbers mean rated torque, last 2 numbers mean rated revolution; for instance:35015:rated torque 35n·m,rated revolution 1500rpm; 48015:rated torque 48n·m,rated revolution 1500rpm; shaft specificat...

Page 5: ►► Installations

5 2)servo drive ►► installations 1. Servomotor ms series servomotors can be installed either horizontally or vertically. The service life of the servomotor can be shortened or unexpected problems might occur if it is installed incorrectly or in an inappropriate location. 1) storage temperature store...

Page 6

6 2) installation site indoor,free of corrosive or explosive gases. Well-ventilated and free of dust and moisture. Ambient temperature of 0° to 50°c. Relative humidity (r.H.) of 20 to 90% with no condensation. Accessible for inspection and cleaning. 3) concentricity please use coupling when connecti...

Page 7: 2. Servo Drive

7 seal the through-shaft section. 6) cable stress make sure that the power lines are free from bends and tension. Be especially careful to wire signal line cables so that they are not subject to stress because the core wires are very thin, measuring only 0.2 to 0.3mm 2 . 2. Servo drive the ds2 serie...

Page 8

8 3)orientation 4)installation follow the procedure below to install multiple servo drives side by side in a control panel. Charge power enter dec inc esc sta sta esc inc dec enter power charge charge power enter dec inc esc sta sta esc inc dec enter power charge servo drive orientation install the ...

Page 9

9 control panel. Environmental conditions in the control panel ambient temperature: 0~50 ℃ humidity: 90%rh or less vibration: 4.9m/s 2 condensation and freezing: none ambient temperature for long-term reliability: 50°c maximum ►► dimensions 1. Servo motor 180 series(units: mm) 180 4- 13.5 200 233 ...

Page 10

10 ms-180st-m27015□□-44p3 262 319 ms-180st-m35015□□-45p5 292 349 ms-180st-m48015□□-47p5 346 403 2. Servo drive(units: mm) ds2-45p5-a sta esc inc dec enter power charge.

Page 11

11 ds2-47p5-a * stored charge do not touch until 10 min. After disconnection * risk of electric shock-dual supply disconnect mains and loadsharing warning ! * do not connect ac power to output terminals of "u v w" before service sta esc 420.0 230.0 160.0 400.0 120.0 217.6 enter charge power.

Page 12: Performance Specification

12 ►► servo drive general specification servo unit ds2 series 380v servo drive encoder incremental encoder (2500 ppr) input power ds2-4□p□-a:3-phase ac380v,50/60hz control mode 3-phase full-wave rectifier control ipm pwm sine-wave current drive using temperature 0~+50 ℃/-20~+85 ℃ humidity below 90% ...

Page 13

13 input signal rs485 p o siti o n c o n tr o l m o d e performance feedforward compensatio n 0~100% (resolution is 1%) positioning finished width 0~250 command unit (resolution is 1 command unit) input signal co m m an d p u lse input pulse type sign+ pulse, cw, ccw mode input pulse state collector...

Page 14

14 bu il t- in fu n cti o n dynamic brake (db) no regeneration built-in regeneration unit, external regenerative resistor over range(ot)protection for p-ot, n-ot action, deceleration stop or inertia stop electronic gear 0.01≤ b/a≤100 protection program error, parameter error, overvoltage, undervolta...

Page 15: ►► Wiring

15 ►► wiring 1. Names and descriptions of main circuit terminal 5.5kw driver: r s t p+ pb p- pe u v w 7.5kw driver: r s t p+ pb p- pe u v w terminal names function r、s、t 3-phase ac 380v±10%(50/60hz) p+、pb regenerative braking resistor connection p+、p- power supply for main circuit pe ground ( co...

Page 16

16 pul+ 3 v1+ +24v for open collector 8 si2 input terminal 2 4 dir- direction input dul- 9 si3 input terminal 3 5 dir+ differential input dir+ 10 +24v +24v for input terminals description of cn1 no. Name description no. Name description 1 nc null 9 bo encoder output b 2 si4 input terminal 4 10 zo en...

Page 17

17 4. I/o signal names and functions 1)input signals item input terminal function digital input si1~si6 multi-functional input terminal pulse input pul-、pul+/v1+ p2-00=0:a-phase pulse;p2-00=2:pulse dir-、dir+/v2+ p2-00=0:b-phase pulse;p2-00=2:pusle direction (sign) 2)output signals class output termi...

Page 18: 6. Communication Port

18 6. Communication port serial port 1(com1) com1 supports rs232, and is often used to connect with pc for debugging. Ds2-45p5-a、ds2-47p5-a 1 5 ( 5-pin port) pin name description 1 txd rs232 send 2 rxd rs232 receive 3 gnd rs232 ground caution:1. Please use the cable provided by xinje company. 2. The...

Page 19

19 7:38400 8:57600 9:115200 p0-04.1 data bits 0 0:8 p0-04.2 stop bits 2 0:2 bits;2:1 bits p0-04.3 parity 2 0~2 0:no parity;1:odd parity;2:even parity modbus station number can be set freely, depending on the following parameter. Parameter number name unit default setting range p0-03 modbus station n...

Page 20

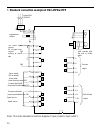

20 7. Standard connection example of ds2-45p5&47p5 note: this is the standard connection diagram of open collector input (+24v). 3.3k Ω 3.3k Ω 3.3k Ω 3.3k Ω 3.3k Ω 3.3k Ω flt m pg r s t u v w pe pul- cn0-1 dir- cn0-4 v1+ cn0-3 cn2 p+ /son cn0-7 /almrs cn0-8 /pot cn0-9 +24v cn0-10 pb +24v cn1-5 cn1-1...

Page 21: 1. Basic Operation

21 ►► using the operation panel 1. Basic operation the operate panel can be used for parameter settings, operating references, and status displays. 5-bit led displays parameter settings, status or alarm. Sta esc inc dec enter power charge the operate panel can display the status, set parameter and r...

Page 22: 2. Running Status Mode

22 display mode: 1. Monitor function u- xx: xx means the number of the monitor function. 2. Auxiliary function fx-xx: the first x means group no., the last two x means the member no. In the group. 3. Parameter setting px-xx: the first x means group no., the last two x means the member no. In the gro...

Page 23

23 ( 2)press the inc or dec key to select the monitor number u-16, and then press and hold enter to enter the monitor mode. ( 3)the value 0 is now displayed, means the driver is in a normal condition. ( 4)press status/esc key to return to the monitoring number switching state. Display contents of mo...

Page 24

24 u-15 feedback command ( 0000~9999)*10000 command u-16 current position (accumulated) ( 0000~9999)*1 encoder pulse u-17 ( 0000~9999)*10000 u-18 current, 1-bit decimal 0.1a u-19 analog input v-ref 0.01v u-20 analog input t-ref 0.01v u-21 i/o signals status u-22 i/o terminals status u-21 displays i/...

Page 25: 4. Auxiliary Function

25 the description of led display please refer to ds2 series servo drive user manual. 4. Auxiliary function use the operate panel to do application in auxiliary function mode. Group no. Content f0-** check system information, display the system code and data f1-** auxiliary run mode, display the aux...

Page 26

26 press status/esc key again to return. 4 different states of jogging: state panel display state panel display idle forward jogging servo on reverse jogging ( 2)trial operation (f1-01) make sure that the motor shaft is not connected to the machine before trial operation! When servo drive is connect...

Page 27

27 about 5 seconds later auto-adjustment is finished, and the panel displays “done” to inform that the function is already finished. Press status/esc key to return. ( 4)speed command offset auto-adjustment (f1-03) select f1-03 and enter speed command offset auto-adjustment function, and the panel di...

Page 28

28 ( 1)press status/esc key to select auxiliary function mode. ( 2)press inc or dec key to set group no. To 2, and press enter to confirm. ( 3)press and hold enter key to display current motor type. ( 4)press inc, dec or enter key to show the motor type and press and hold enter key to confirm. ( 5)r...

Page 29: 5. Parameter Setting

29 5. Parameter setting select or adjust the functions via parameter setting. The following steps show how to change a parameter. The example below shows how to change parameter p3-09 from 2000 to 3000. ( 1)press the status/esc key to select the parameter setting mode. ( 2)at this time the second le...

Page 30: ►► Parameter List

30 ►► parameter list effective time:○ means the parameter can be modified when the servo is off, and effective when servo is on. Parameter:px-xx=×× ×× px-xx. H px-xx.L 1. P0: function selection (address:0000 ~ 00ff) p0- function unit default range effective 00 main mode - 0 0 01 submode 1 0: idle 1:...

Page 31: 01Ff)

31 forward rotate 1:from the side view of motor load, cw is forward rotate 06 06.L: stop mode when servo off or alarm. Ds2 series default is inertia stop. Keep the inertia motion after stop. - 2 0~2 ● 06.H: over range (ot) stop mode 0~1: inertia stop. Keep inertia motion after stop. 2: deceleration ...

Page 32: 02Ff)

32 03 reserved 04 the gain of second speed loop 1hz 250 1~5000 √ 05 integral time of second speed loop 0.1ms 10000 1~50000 √ 06 the gain of second position loop 1/s 250 1~2000 √ 07 reserved 08 reserved 09 the gain of position loop feedforward 1% 0 0~100 √ 10 feedforward filter time 0.01ms 0 0~65535 ...

Page 33: 4. P3: Speed Control(0300

33 11 first segment pulse (low bit) 1 0 -9999~ +9999 ○ 12 first segment pulse (high bit) 1 0 -9999~ +9999 ○ 13 first segment speed 0.1rpm 0 0~50000 ○ 14 first segment adjustment time 1ms 0 0~65535 ○ 15 first segment command filter time 0.1ms 0 0~65535 ○ p2-16~p2-90 are 2~16 segments parameter settin...

Page 34: 5. P4: Torque Control(0400

34 09 max speed limit (max speed) rpm different for each type 0~5000 ● 10 speed command input dead area voltage 0.01v 0 0~100 ○ 5. P4: torque control(0400 ~ 04ff) p4- name unit default range effective 00 analog value of rated torque 0.01v 1000 150~3000 ○ 01 torque command filter time 0.01ms 0 0~6553...

Page 35

35 04 near output signal width /near command pulse 50 0~10000 ○ 05 offset pulse limit value 256* command pulse 1000 0~65535 ○ 06 servo off delay time (brake command) 1ms 0 0~500 ○ 07 brake command output speed rpm 100 0~5000 ○ 08 brake command wait time 1ms 500 10~1000 ○ 09 input filter time 5ms 0 0...

Page 36

36 ditto 13 /n-ot reverse drive prohibition ditto - 0004 0000-0016 ● 14 /alm-rst alarm reset ditto - 0002 0000-0016 ● 15 /p-cl forward external torque limit ditto - 0000 0000-0016 ● 16 /n-cl reverse external torque limit ditto - 0000 0000-0016 ● 17 /spd-d internal speed selection ditto - 0000 0000-0...

Page 37

37 25 /chgstp step change signal ditto - 0000 0000-0016 ● 26 reserved 27 reserved 28 /coin positioning finished 0000: not output to the terminal 0001: output positive signal from so1 0002: output positive signal from so2 0003: output positive signal from so3 0011: output negative signal from so1 001...

Page 38: ►► Alarm Information

38 34 /bk brake lock ditto - 0000 0000-0013 ● 35 /warn warn ditto - 0000 0000-0013 ● 36 /near near ditto - 0000 0000-0013 ● 37 /alm alarm ditto - 0002 0000-0013 ● 38 /z encoder z signal ditto - 0000 0000-0013 ● ►► alarm information alarm code description reason solution e-001 program damage program ...

Page 39

39 voltage e-005 regenerative resistor error regenerative resistor is ineffective check the connection of regenerative resistor e-006 module over temperature run with large load for long time reduce the load, and enhance the cooling system, or check if the fan is revolving when motor is on; cool dow...

Page 40: ►►Debug Steps

40 not connected power-off, or replace the damaged encoder e-014 encoder abz wire break encoder wiring error, encoder broken, encoder is not connected check the wiring of encoder, and re-connect the encoder after power-off, or replace the damaged encoder e-015 speed changes too fast (encoder feedbac...

Page 41: ►►Motor Code

41 e) enter f2-00,set the correct motor code. F) after power on again,proceed to current offset auto-adjustment,please refer to auxiliary run mode; g) set f1-01=1, check if the motor can work normally. If yes, enter f1-00. If not, check the cables. H) enter f1-00 and proceed to jog test-running, if ...

Page 42

42 ►► suitable motor code for each servo drive servo drive motor code ds2-20p2-as 1003 ds2-20p4/-a/-as 0004 ds2-20p7/-a/-as 0011(default setting) 0021 ds2-21p5/-a/-b 0031 0032 0042 0044(default setting) ds2-22p3-a 0043 0046(default setting) ds2-23p0-a 0052(default setting) ds2-45p5-a 0150 0151 0152(...

Page 43

43 wuxi xinje electric co., ltd. 4th floor, building 7th, no.100 dicui rd, wuxi, china tel: 86-0510-85134139 fax: 86-0510-85111290 www.Xinje.Com email: cheerfiona@gmail.Com.