Xlt ovens po box 9090 wichita, kansas 67277 tel: 888-443-2751 fax: 316-943-2769 web site: www.Xltovens.Com xlt oven & avi hood installation & operation manual xd-9010b-ga rev 03 04/07/2011 2000887 this appliance is for professional use by qualified personnel. This appliance must be installed by qual...

2 warning & safety information post in a prominent location instructions to be followed in the event you smell gas. This infor- mation can be obtained by consulting your local gas supplier. For your safety do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or a...

3 for the best results with the xlt oven and avi hood, carefully read this manual and all of the warning labels attached to the products before installing and operating them, and follow the instructions exactly. Keep this manual handy for quick reference. Definitions and symbols a safety instruction...

4 receiving and inspection upon receiving of all goods shipped by a common carrier, check for any exterior damage that may indicate interior damage. If conditions permit, open all crates and do a full inspection for any damage while the delivery driver is still there. If there is damage please note ...

5 warning & safety information..................................................................................................... 2 safety messages ........................................................................................................................... 3 oven description ..........

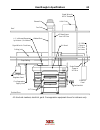

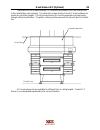

6 oven description 1832b-w 2440b-w 3240b-w 3255b-w 3270b-w 3270sb-w 3855b-w 3870b-w food product is placed on the stainless steel wire conveyor belt on one side of the oven. The conveyor then transports the food through the bake chamber at a user-controlled speed. This provides repeatable and unifor...

7 an easily removable front panel allows the full cleaning of the oven interior. All exposed oven surfaces both exterior and interior are stainless steel. The conveyor is a one piece design and is removed from the side which has the control box. No tools are required for disassembly and cleaning of ...

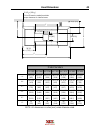

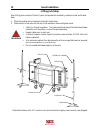

8 oven dimensions m n k l m n k l p n p k l q h j g f b c d * 1 9 .7 7 [5 0 2 ] 1 9 .7 7 [5 0 2 ] 1 7 .5 5 [4 4 6 ] a e 2 0 .8 7 [5 3 0 ] not e : a ll d im e n sio n s in in c h es [ m m ]..

9 triple stack a b c d e f g h j k l m n p q weight 1832 19.41 [493] 32.13 [816] 67.25 [1708] 19.72 [501] 47.23 [1200] n/a* n/a* 39.92 [1014] 14.85 [377] 5.63 [143] 67.69 [1726] 20.66 [525] 16.75 [425] 36.73 [933] 56.72 [1441] 1240 [562] 2440 25.41 [645] 40.13 [1019] 75.25 [1911] 19.72 [501] 53.23 [...

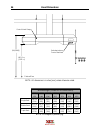

10 gas & electrical connection dimensions - australian & world ovens 8.21 [208] 9.85 [250] 28.19 [716] 29.83 [758] 48.18 [1224] 49.82 [1265] 9.30 [236] 18.91 [480] 23.24 [590] 24.88 [632] 43.23 [1098] 44.87 [1140] 9.30 [236] 18.91 [480] 9.30 [236] 18.91 [480] 23.24 [590] 24.88 [632] note: all dimens...

11 for models 1832, 2440, 3240, 3255 & 3855 25.24 [641] 24.88 [632] 12.35 [314] 18.91 [480] gas & electrical connection dimensions - australian & world ovens 10.21 [259] 9.85 [250] 30.19 [767] 29.83 [758] 50.18 [1275] 49.82 [1265] 12.35 [314] 18.91 [480] 25.24 [641] 24.88 [632] 45.23 [1149] 44.87 [1...

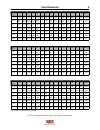

12 oven electrical requirements oven volts amps frequency size 120 vac single double triple 60 hz 1832 6 12 18 2440 6 12 18 3240 6 12 18 3255 6 12 18 3270 12 24 36 3855 6 12 18 3870 12 24 36 standard ovens oven volts amps frequency size 220/230/240 vac single double triple 50 / 60 hz 1832 3 6 9 2440...

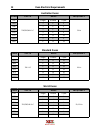

13 inlet pressure oven burner max. Capacity nat gas lp gas size btu/hr kw/hr mj/hr w/c mbar kpa w/c mbar kpa 1832 52,000 15.24 63 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5 2440 65,000 19.05 79 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75-3.5 3240 90,000 26.37 105 6-14 15-35 1.5-3.5 11.5-14 27.5-35 2.75...

14 natural gas (8.75 mbar manifold) lp gas (25 mbar manifold) country symbol i 2h i 2l i 2e i 2e+ i 3b/p i 3+ i 3p germany de x x x austria at x x belgium be x x denmark dk x x spain es x x x finland fi x x france fr x x x x greece gr x ireland ie x x x iceland is italy it x x luxembourg lu norway n...

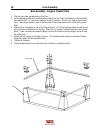

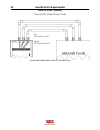

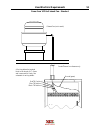

15 the gas supply and the electrical supply are to be provided by the customer prior to instal- lation. The picture shows a typical utility rough-in for a triple stack oven. Preparing the utilities this way allows for an easy third deck addition if a double stack oven is initially installed. All ins...

16 do not use teflon tape on gas line connections as this can possibly cause gas valve malfunction or plugging of orifices from shreds of tape. Use of teflon tape may af- fect warranty. For each oven: electrical service for standard ovens must be 120vac, 20 a, 60 hz single phase circuits with ground...

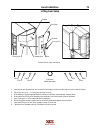

17 oven assembly xlt ovens can easily be moved and stacked with the proper lifting equipment. The use of lifting equipment is highly recommended. Warning & safety information base assembly - triple stack 1. Flip the oven base upside down on the floor. 2. For triple-stack configurations, attach the f...

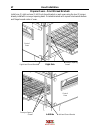

18 oven assembly leg angle leg 1. Flip the oven base upside down on the floor. 2. For single and double-stack configurations, attach the four legs to the bottom of the base with the supplied 3/8" x 1" hex bolts, washers, and lock-washers. Do not fully tighten them at this time. Leave them slightly l...

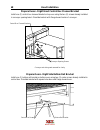

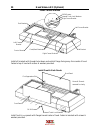

19 prepare the oven for lifting 1. Remove the two conveyor opening flaps and thumbscrews from the oven. Set them aside for reinstallation later. 2. Install the lifting plates in place of the conveyor opening flaps using the same thumbscrews. Oven assembly conveyor opening flap thumb screws conveyor ...

20 lifting jack setup each lifting jack consists of two (2) parts; the pole/winch assembly, and the tripod base. Oven assembly lifting pipe top of oven jack cart bands front of oven 2. Insert the lifting pipe through the oven bake chamber. Make sure the pipe is centered. Make sure that the notch on ...

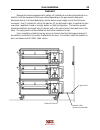

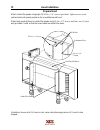

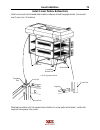

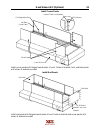

21 base assembly insulation installed oven decks oven assembly 1. Fully insert the lifting jacks into the lifting pipe. 2. Raise the oven high enough to clear the cart or the skid. Failure to engage properly can result in damage, injury, or death from a falling oven. Warning both jacks should be rai...

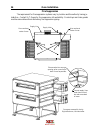

22 8. Reinstall the conveyor opening flaps in each oven deck. A series of holes in the flaps allow adjustment for different heights of food product. 9. Control box heat shields need to be installed on any multi-deck installation. For xx70 models, they are required on both ends. To install, remove th...

23 oven installation physical location & spacing requirements xlt ovens are suitable for installation on either combustible or non-combustible floors, and adjacent to either combustible or non-combustible walls. The motor cover is designed to pro- vide the proper clearance to the back of the oven. T...

24 oven installation for australia, if installing with a flexible hose assembly, the assembly must be certified to as/nzs 1869, and be class b or d. For standard ovens, if installing with a flexible gas hose, the installation must comply with either ansi z21.69 or can/cga-6.16 and a disconnect devic...

25 restraint because all ovens are equipped with casters, all installations must be configured with a re- straint to limit the movement of the oven without depending on the gas connector and quick- disconnect device or its associated piping, and the electric power supply cord to limit the oven movem...

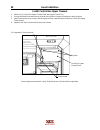

26 fire suppression the requirement for fire suppression systems vary by location and the authority having ju- risdiction. Contact xlt ovens for fire suppression kit availability. Crumb trays and chain guards must be removable without disturbing fire suppression piping. Oven installation aim nozzles...

27 ventilation requirements & guidelines ventilation requirements most gas burning appliances produce co (carbon monoxide), a poison. Co and heat must be vented to the outside. A powered ventilation hood is required to remove these. The hood and hvac installation must meet local building and mechani...

28 ventilation requirements & guidelines oven initial start-up all xlt ovens are test-fired at the factory. Operation is verified, and adjustments are made to ensure proper function. However, field conditions are sometimes different than factory conditions, such as voltage and fuel pressure. These v...

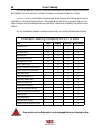

Oven initial start-up checklist - remove & return to xlt ovens date of installation: ______________________________ installed by: xlt installer: ______________________ other: company:____________________ installer: ____________________ phone #: ____________________ oven size: 1832 2440 3240 3255 327...

T op oven mo d el # : _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ ser ial # : _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ t h in c ru st t h ick c ru st p an scr ee n oth er p ro d u ct: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ fro n t b...

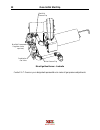

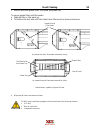

31 oven initial start-up contact xlt ovens or your designated representative to make all gas pressure adjustments. Direct ignition burner combination gas valve low flame bias adjustment (5mm) inlet pressure tap manifold pressure tap manifold pressure adjustment high flame bias screw (brass nut 8mm) ...

32 oven initial start-up contact xlt ovens or your designated representative to make all gas pressure adjustments. Direct ignition burner - australia combination gas valve inlet pressure tap manifold pressure tap manifold pressure regulator (under cap screw).

33 oven operator controls front conveyor speed control back conveyor speed control conveyor speed control temperature control circuit breakers fan & filter models 1832, 2440, 3240, 3255 & 3855 single oven shown, double and triple stack similar oven switch left right front back control panel standard...

34 oven operator controls right side temperature control left side temperature control circuit breakers fan & filter back conveyor speed control oven switch models 3270 & 3870 single oven shown, double and triple stack similar front left right right side control panel standard belt left side control...

35 oven operation this oven is not capable of being safely placed in operation in the event of a power failure. No attempt should be made to operate this oven during power failure. 1. Turn the switch on. The fan(s) will energize, the temperature and conveyor control will light up, and the conveyor w...

36 oven must be cool and the electric cord unplugged before any cleaning is done. Warning oven cleaning as with any appliance, periodic cleaning and maintenance is required. Many factors affect this schedule such as product mix and hours of usage. An example schedule is included. Your xlt oven is co...

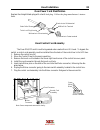

37 oven cleaning 1. Remove and clean crumb trays, product stops, and conveyor opening flaps. 2. Hold the front panel in place while removing the four (4) front panel knobs. Then remove and clean the front panel. Crumb tray product stop conveyor opening flap front panel knob note do not immerse front...

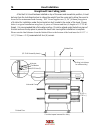

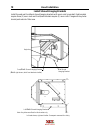

38 oven cleaning 3. To remove and clean the lower finger outer panels and lower finger body assemblies, raise the front of the conveyor and insert two (2) front panel knobs, one (1) each side, as shown. Note prior to the removal of the finger covers, note the location and configuration to ensure pro...

39 oven cleaning 5. Raise the front of the upper finger bodies, one at a time, approximately 1” [25 cm], and slide the finger assembly out towards the front. 6. Wipe down and clean all interior and exterior surfaces. Caution do not spray liquid cleaning agents in the slots and holes in the following...

40 oven maintenance the most critical item to be maintained is the filter on the flow path pressure generating fan . The filter is held in place by the stainless steel fan guard/filter mount and can be washed sev- eral times. Regular cleaning of the flow path pressure generating fan filter is import...

41 oven troubleshooting before trouble-shooting the oven; 1. Make sure that the oven is connected to the proper voltage. 2. Check to see that the breaker in the service panel is not disengaged. 3. Check to see that all circuit breakers on the oven are not disengaged. 4. Check to see if the gas suppl...

42 oven troubleshooting proper cooking experimentation is about the only way to determine proper time and temperature settings. While a pizza may look perfectly cooked on the outside, the inside may be undercooked. A ther- mometer is necessary to determine if food items are being properly cooked. Mo...

43 this page intentionally left blank..

44 hood description the avi hood system consists of three (3) major parts, the main canopy, the shrouds, and the variable frequency drive (vfd) exhaust fan controller. The main canopy serves to collect heat and products of combustion and transmits the efflu- ents to the exhaust fan. It houses filter...

45 hood dimensions 13 1/2 [343 ] +1/2 +13 -0 -0 f 12 [305] 12 [305] (24 [610]) b a critical dimension needed to maintain proper clearances for installed ovens c 28 7/8 [733] e d model numbers avi 1832 avi 2440 avi 3240 avi 3255 avi 3270 avi 3855 avi 3870 “a” 34-11/32 [872] 40-11/32 [1025] 48-11/32 [...

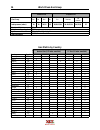

46 hood weight (does not include ovens) avi 1832 avi 2440 avi 3240 avi 3255 avi 3270 avi 3855 avi 3870 single stack 560.39 [254] 644.84 [292] 708.73 [321] 757.05 [343] 790.12 [358] 812.03 [368] 845.32 [383] double stack 513.78 [233] 576.72 [262] 640.25 [290] 681.29 [309] 704.08 [319] 728.01 [330] 75...

47 hood electrical requirements the avi hood system requires two (2) separate electrical inputs and has provision for one (1) optional input. All inputs and input connection points are located on the top of the vfd con- trol box, as well as the connection to the exhaust fan. All optional outputs (fi...

48 vfd control box - standard fuses fire suppression relay (optional) mua damper relays (optional) grounding block terminal block (tb) vfd controller oven/hood interface and power cords connect to bottom of vfd control box electrical supply, mua and fire suppression controls are wired through top of...

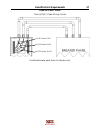

49 top of variable frequency drive (vfd) box power to vfd controller - standard neutral tb position 3 230v 1 phase 10 amp terminal block (tb) hot tb positions 1&2 ground conduit and breaker panel shown for reference only hood electrical requirements.

50 power for ovens - standard three (3) 120v 1 phase 20 amp circuits hot tb positions 7, 9 & 11 neutral tb positions 8, 10 & 12 conduit and breaker panel shown for reference only hood electrical requirements.

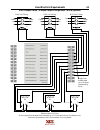

51 hood electrical requirements exhaust fan (not to scale) power from vfd to exhaust fan - standard red tb position 4 blue tb position 5 black tb position 6 ground (green) conduit shown for reference only all wiring below the terminal block to be done by xlt ovens and is removed for clarity. See sch...

52 hood electrical requirements fire alarm relay - standard (optional) t3 t2 t1 l3 l2 l1 oven power out oven power in a1 a2 neutral signal in from fire suppression panel tb position 17 all wiring below the terminal block to be done by xlt ovens and is shown for reference only. See schematic for wiri...

53 hood electrical requirements mua damper relays - single output configuration - standard (optional) a1 a2 mua unit relay (shown for reference only) supply from breaker panel (up to 10amps - determined by mua) power in power out neutral r3 r2 r1 relays located in vfd box all wiring below the termin...

54 hood electrical requirements mua damper relays - multiple output configuration - standard (optional) supply from breaker panel (up to 10 amps - determined by mua) power in a1 mua unit 3 relay power out neutral a2 power in a1 power out neutral a2 power in a1 power out neutral a2 mua unit 1 relay m...

55 vfd control box - world oven/hood interface and power cords connect to bottom of vfd control box wiring removed for clarity. See schematic for wiring details. Terminal block (tb) electrical supply, mua and fire suppression controls are wired through top of vfd control box terminal block (tb) fuse...

56 power to vfd controller - world hood electrical requirements top of variable frequency drive (vfd) box 230v 1 phase 10 amp terminal block (tb) hot tb positions 1&2 ground conduit and breaker panel shown for reference only terminal block (tb).

57 power for ovens - world hood electrical requirements three (3) 230v 1 phase 20 amp circuits hot tb positions 7 &8 conduit and breaker panel shown for reference only hot tb positions 9 &10 hot tb positions 10 & 11.

58 hood electrical requirements power from vfd to exhaust fan - world red tb position 4 blue tb position 5 black tb position 6 ground (green) conduit shown for reference only exhaust fan (not to scale).

59 hood electrical requirements fire alarm relay - world (optional) fire alarm switch to tb position 14 120vac supply to tb position 13 conduit, breaker panel and fire suppression panel shown for reference only. B a b b a b a b a signal in from fire suppression panel tb positions 13 & 14 all wiring ...

60 hood electrical requirements a1 a2 mua unit relay power in power out supply from breaker panel (up to 10 amps determined by mua) mua damper relays - single output configuration - world (optional) relays located in vfd box r4 r3 r2 all wiring below the terminal block to be done by xlt ovens and is...

61 hood electrical requirements mua damper relays - multiple output configuration - world (optional) power in a1 mua unit 3 relay power out a2 power in a1 power out a2 power in a1 power out a2 mua unit 1 relay mua unit 2 relay supply from breaker panel (up to 10 amps determined by mua) r4 r3 r2 rela...

62 hood electrical requirements without vfd controller grounding block terminal block (tb) electrical is wired through top of control box oven/hood interface cords connect to bottom of control box wiring removed for clarity. See schematic for wiring details..

63 ground hot tb position 11 neutral tb position 12 ground hot tb positions 11 & 12 hood electrical requirements without vfd controller standard without vfd controller world some wiring removed for clarity. See schematic for wiring details. Some wiring removed for clarity. See schematic for wiring d...

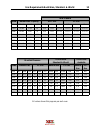

64 exhaust flow rates (min. Recommended) avi 1832 avi 2440 avi 3240 avi 3255 avi 3270 avi 3855 avi 3870 single 246 [6.97] 313 [8.86] 402 [11.38] 402 [11.38] 469 [13.28] 402 [11.38] 469 [13.28] double stack 506 [14.33] 644 [18.24] 828 [23.45] 828 [23.45] 966 [27.35] 828 [23.45] 966 [27.35] triple sta...

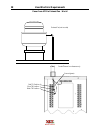

65 hood rough-in specifications exhaust fan roof ceiling joist drop ceiling fire suppression regulator panel finished floor electrical panel welded duct avi hood xlt ovens gas manifold hvac unit fan curb 1/2” all-thread supported by unistrut (4 locations) all structural members, electrical, gas & fi...

66 hood installation purchaser’s responsibility it is the responsibility of the purchaser: thoroughly review the floor plans and specifications. The exact location of the oven must be determined before installing the hood. To unload, uncrate, assemble, and install the hood to it’s intended location....

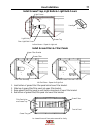

67 prepare ovens—front shroud brackets hood installation install one (1) right and one (1) left front shroud bracket on each oven using the two (2) screws already installed in conveyor opening bezel. Orientate brackets with square hole towards bottom and flange toward center of oven. Right side conv...

68 hood installation prepare ovens - right hand control box closeout bracket control box closeout bracket conveyor opening screws conveyor and chain guard removed for clarity install one (1) control box closeout bracket on top oven using the two (2) screws already installed in conveyor opening bezel...

69 hood installation prepare ovens - left side back shroud brackets for models 1832, 2440, 3240, 3255 & 3855 conveyor opening screws left back shroud bracket install one (1) left back shroud bracket for each oven. The bottom oven will receive the bracket with a square hole, orientate this bracket wi...

70 hood installation prepare ovens - left hand control box closeout bracket control box closeout bracket conveyor opening screws conveyor removed for clarity install one (1) control box closeout bracket on top oven using the two (2) screws already installed in conveyor opening bezel. Orientate brack...

71 hood installation prepare ovens - control box side closeout right hand control box side closeout install right hand control box side closeout using screws already installed on control boxes, at loca- tions shown with arrows. Upper flange of closeout to face front of oven. (double stack shown, bra...

72 hood installation prepare hood attach inside filler panels using eight (8) 10-24 x 1/4” screws (provided). Tighten screws in ad- justment slots with panels pushed as far as possible toward hood. Attach back panel stiffener to inside filler panels using 10-24 x 1/2” screws and nuts, two (2) each e...

73 hood installation lifting gear setup threaded rod end beam saddle lifting hook bracket nuts locking pin 1. Insert end of each threaded rod into the small holes located on bracket so that ends are to the inside of bracket. 2. Thread nuts about 1/2” (12.7mm) onto threaded rod ends. 3. Slide saddle ...

74 hood installation lifting jack setup each lifting jack consists of three (3) parts; the pole/winch assembly, extension tube, and tripod base. Check for smooth operation. The cable should not be pinched and should pass smoothly over the pulley on top of the pole assembly. Inspect cable prior to ea...

75 1. Fully insert the lifting jacks into the lifting gear assemblies attached to each end of the hood. 2. Raise the hood high enough to clear the cart or skid. Failure to engage properly can result in damage, injury, or death from a falling hood. Warning both jacks should be raised in unison, other...

76 hood installation hang hood from ceiling joists after the avi hood has been installed on top of the ovens and moved into position, it must be hung from the building structure to relieve the weight from the ovens and to allow the ovens to be moved for maintenance and cleaning. Xlt ovens supplies t...

77 install grease trays, light bulbs & light bulb covers hood installation grease tray light bulb clear light bulb cover light fixture grease tray handle left end shown - repeat for right end install grease filters & filler panels 1. Insert bottom of grease filter filler panel behind lower filter br...

78 hood installation end shroud hanging bracket front/ back shroud hanging bracket ( back right shown, both front brackets similar) left end shown, right end similar. Some parts removed for clarity install shroud hanging brackets install the end and front/back shroud hanging brackets with acorn nuts...

79 hood installation install corner posts & bottom rails slide tabs on bottom rails into square holes in bottom of corner posts and brackets. Install with cage nuts facing away from ovens. Install corner post onto threaded stud located in between shroud hanging brackets. Secure with one (1) acorn nu...

80 install control box upper closeout hood installation thumb screws keyholes some components removed for clarity. Right side shown, left side similar if applicable. Fire suppression piping (optional) 1. Install one (1) control box upper closeout panel above upper control box. 2. Line up shoulder bo...

81 front front shroud panels (with crumb tray doors) size specific shroud panel hood installation line up shoulder bolts with keyholes in bracket. Allow panel to drop into place. Secure bottom of shroud panel to bottom rail with two (2) thumb screws. Keyhole shoulder bolt open crumb tray doors locat...

82 hood installation install back shroud panel back shroud panel back for models 1832, 2440, 3240, 3255 & 3855 bottom rail thumb screw bottom outside of back shroud panel top inside of back shroud panel keyhole shoulder bolt line up shoulder bolts with keyholes in bracket. Allow panel to drop into p...

83 hood installation oven power cord modification twist-lock plug housing strain relief screws #6 blue fork terminal hood control cord assembly the oven on/off switch must be bypassed when used with an avi hood. To bypass the switch, a control cord assembly must be installed from the back of the con...

84 hood installation connect oven power and controls to hood after appropriate connections have been made, the oven power and control cords must be connected to the vfd box located on the right back corner of the avi hood. All vfd boxes are outfitted with three (3) power outlets and three (3) contro...

85 1. Set f001 (main profile parameters). This will set the output frequency for the exhaust fan. A. Press & hold the function key until d001 displays. B. Use the up / down arrows to reach the f001. C. Press the function key one time. D. With all of the switches in the off position the display shoul...

86 hood operator controls the control switches are located on the front of the hood. 1. Turn the light switch on. 2. Turn the desired oven switch on. Refer to the oven start-up section for instructions on how to adjust temperature and conveyor speed. The oven(s), exhaust fan, and make-up air unit wi...

Avi hood model #: ______________________________________ serial #: _______________________________________ hood hung prior to oven installation: yes no height from bottom of hood to finished floor: _________ hood hung to local & state codes: yes no switches face front of ovens: yes no vfd box cover ...

This page intentionally left blank..

89 drop ceiling finished floor installed valance kit hood valance kit (optional) the valance kit size is determined by avi hood size and distance from the finished floor to the installed drop ceiling height. The valance kit screws directly to the avi hood and does not require any structural support....

90 install all brackets with through holes down and vertical flange facing away from center of hood. Fasten to top of hood with screws & washers provided. Front of hood 10-24 screws internal tooth lock washers right corner bracket end bracket front/back brackets end bracket right corner bracket left...

91 install corner panels hood valance kit (optional) internal tooth lock washers 10-24 screws corner panels left back corner panel fire suppression slot front of hood install corner panels with flanges toward center of hood. Fasten to brackets, front, and back panels with screws & washers provided. ...

92 hood cleaning 1. Remove and wipe clean front and end shroud panels. 2. Remove and clean product take-off shelves (if installed) and crumb trays. Caution shroud panels can weight up to 60 lbs [27 kg]. Use caution when lifting. Example maintenance & cleaning schedule for avi hoods task daily weekly...

93 hood cleaning 3. Remove and clean grease filters, filler panel and grease tray. To remove grease filters and filler panels. A. Slide the filter or filler panel up. B. Tilt bottom into duct area until filter clears lower filter mount as shown and remove. As viewed from end. Some parts removed for ...

94 for service and spare parts in australia, please contact your xlt australian distributor: j. L. Lennard food equipment pty ltd. Service hotline: 1800 777 440 spare parts hotline: (during office hours 8:00 am – 4:30 pm, mon-fri) 1800 777 144 after hours service: 1800 077 081 for service and spare ...

95 oven schematic 1832, 2440, 3240, 3255 & 3855 - square burner - standard.

96 oven schematic 1832, 2440, 3240, 3255 & 3855 - square burner - world.

97 oven schematic 1832, 2440, 3240, 3255 & 3855 - round burner - australia.

98 oven schematic 3270 & 3870 - square burner - standard - rh control box.

99 3270 & 3870 - square burner - standard - lh control box oven schematic.

100 oven schematic 3270 & 3870 - square burner - world - rh control box.

101 oven schematic 3270 & 3870 - square burner - world - lh control box.

102 3270 & 3870 - round burner - australia - lh control box oven schematic.

103 oven schematic 3270 & 3870 - round burner - australia - rh control box.

104 hood schematic - standard.

105 hood schematic - world.

106 hood schematic - without vfd controller.