- DL manuals

- Xnexus

- Welding System

- NXP35

- Operating Manual

Xnexus NXP35 Operating Manual

Summary of NXP35

Page 1

Plasma cutting system model nxp35 november 21, 2005 manual 0-4809 operating manual number the art as art # a-044?? Nexus.

Page 3

Table of contents section 1: general information ................................................................................................ 1-1 1.01 notes, cautions and warnings ...................................................................... 1-1 1.02 important safety precautions ..........

Page 4: Section 1:

November 21, 2005 1-1 general information section 1: general information 1.01 notes, cautions and warnings throughout this manual, notes, cautions, and warn- ings are used to highlight important information. These highlights are categorized as follows: note an operation, procedure, or background in-...

Page 5

General information 1-2 november 21, 2005 electric shock electric shock can injure or kill. The plasma arc pro- cess uses and produces high voltage electrical en- ergy. This electric energy can cause severe or fatal shock to the operator or others in the workplace. • never touch any parts that are e...

Page 6

November 21, 2005 1-3 general information 1.03 publications refer to the following standards or their latest revi- sions for more information: 1. Reducing noise at work guidance on the noise at work regulations 1989 (isbn: 0 7176 1511 1) 2. Coshh - control of substances hazardous to health regu- lat...

Page 7

General information 1-4 november 21, 2005 1.04 statement of warranty for nexus machines limited warranty: leengate welding group limited (the “supplier”), warrants that, subject to the conditions, exclusions and limitations set out in clause 8 of the supplier’s terms and conditions of sale and in th...

Page 8: Section 2:

Introduction 2-1 manual 0-4809 section 2: introduction 2.01 overview plasma is a gas which has been heated to an extremely high temperature and ionized so that it becomes elec- trically conductive. The plasma arc cutting process uses this plasma to transfer an electrical arc to the work- piece. The ...

Page 9

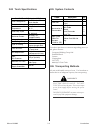

Manual 0-4809 2-2 introduction 2.04 torch specifications torch configuration torch head at 75° to torch handle torch leads length 20 feet ( 6.1 m) ambient temperature 104° f 40° c torch duty cycle 100% @ 60 amps @ 400 scfh maximum current 60 amps, dc, straight polarity voltage (v peak ) 500v arc str...

Page 10: Section 3:

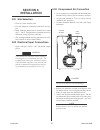

Installation 3-1 manual 0-4809 section 3: installation 3.01 site selection • place in a clean and dry area. • provide adequate ventilation and fresh air sup- ply. • ideal ambient temperature should not exceed 40°c / 104°f. Temperatures exceeding that may diminish cutting capacity or quality. • the c...

Page 11: Section 4:

Operation 4-1 manual 0-4809 section 4: operation 4.01 front control panel overheating indicator ac power indicator air error indicator torch switch latch indicator torch switch latch button air set button air vents work lead connection "on / off" switch art # a-04386 torch connection i o 115vac 230v...

Page 12

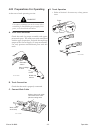

Manual 0-4809 4-2 operation 4.02 preparations for operating at the start of each operating session: warning disconnect primary power at the source before assembling or disassembling power supply, torch parts, or torch and leads assemblies. A. Torch parts selection check the torch for proper assembly...

Page 13

Operation 4-3 manual 0-4809 e. Typical cutting speeds cutting speeds vary according to torch output, the type of material being cut, and operator skill. Speeds shown are typical for this cutting system using air plasma to cut mild steel, with output current at the highest setting and the torch used ...

Page 14: Section 5:

Service 5-1 manual 0-4809 section 5: service 5.01 general maintenance o-rings on the torch require lubrication on a regular basis, depending on how frequently the torch shield cup is disconnected and re-connected. This will allow the o-rings to remain pliable and provide a proper seal. The o-rings w...

Page 15

Manual 0-4809 5-2 service d. Torch will not pilot when torch switch is activated. 1. Gas pressure too high or too low. A. Adjust gas pressure per pressure setting label on power supply. Note it is possible to have enough air pressure to operate the power supply but not enough air flow to operate the...

Page 16

Service 5-3 manual 0-4809 2. Poor work lead connection. A. Check the connection of the work lead to the work piece. Make a clean work cable connection to the work- piece or cutting table work cable and clamp art # a-04389 3. Current sensor or pwm pcb faulty. A. Return to an authorized service center...

Page 17

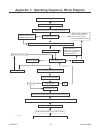

Appendix a-1 manual 0-4809 appendix 1: operating sequence, block diagram primary input power "on" or plugged in green power indicator "on" and fan is running power supply on/off switch "on" no pilot arc air set switch "on" torch tip to work after pilot arc start pilot arc ignition start cutting oper...

Page 18

Manual 0-4809 a-2 appendix appendix 2: torch connection torch switch negative / plasma lead torch head white black orange green pip switch torch leads to power supply adapter disconnect power and air. Lay unit on its side. Remove access plate. Pilot power supply adapter negative / plasma lead art # ...

Page 19

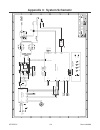

Appendix a-3 manual 0-4809 appendix 3: system schematic n l e4 g3 g2 g t1 c1 c2 g1 cn1 cn2 e2 g4 aaa a cn2 cn1 tb1 cn4 th cn1 cn6 g4 e3 power cn8 e1 e2 g1 hold hold cn9 ou_1 vd_1 ou_2 s/w s/w torch fan nfb ac12 ac18 ac18 cn7 cn5 main e1 g2 r1 temp error no.40271003 g3 e4 e3 igbt air error igbt air c...