Summary of NXS 150

Page 1

Nxs 150 – dual voltage operating manual.

Page 2

Thank you for purchasing a nexus quality product. This machine is a quality built modern inverter, and uses the latest technology in power electronics. It should give you years of satisfaction, if the safety, operating and maintenance instructions in this manual are complied with fully. In the inter...

Page 3: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 table of contents warranty policy statement ........................................................................................... 5 1. Warranty statement.…………………….……………………………………………………………………...…5 safety................................................

Page 4: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 table of contents setting up ............................................................................................................................. 15 7. Connection to the main supply.................................................................

Page 5: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 warranty policy statement user’s manual 1. Statement of warranty for nexus machines limited warrant : elégante welding group limited (the “supplier”), warrants that, subject to the conditions, exclusions and limitations set out in clause 8 of the suppl...

Page 6: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety the equipment you have just acquired will give you entire satisfaction if you respect the operating and maintenance instructions. Its design, the specification of the components and its manufacture are in accordance with the existing rules, fren...

Page 7: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety if electromagnetic disturbances are detected, then it shall be the responsibility of the user of the arc welding equipment to resolve the situation with the technical assistance of the manufacturer. In some cases this remedial action may be as s...

Page 8: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety adjustments covered in the manufacturer’s instructions. In particular, the spark gaps of arc striking and stabilising devices should be adjusted and maintained according to the manufacturer’s recommendations. 2.2.2.3. Welding cables the welding ...

Page 9: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety 3.2. Working area the use of arc welding implies a strict respect of safety conditions with regard to electric currents (decree dated 14.12.1988). It is necessary to check that no metal piece accessible to the operators and to their assistants c...

Page 10: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety 3.5. Risks of fire and explosion welding can cause risk of fire or explosion. You have to pay attention to fire safety regulation - remove flammable or explosive materials from welding area. - always have sufficient fire fighting equipment - fir...

Page 11: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety opacity gradation numbers and recommended use for arc welding current intensity in amps welding process or connected techniques 0.5 2.5 10 20 40 80 125 175 225 275 350 450 1 5 15 30 60 100 150 200 250 300 400 500 coated electrodes 9 10 11 12 13 ...

Page 12: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 safety 4.2. Risk of internal injuries gases and fumes gases fumes produced during the welding process can be dangerous and hazardous to your health. Arc welding works have to be carried out in suitable ventilated areas. Ventilation must be adequate to ...

Page 13: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 description 5. General characteristics nxs 150 welding machines have been designed as integrated and portable units using the latest techniques in power electronics, based on an inverter process with igbt, which enables the following: - a considerable ...

Page 14: Nxs 150

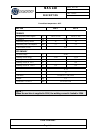

Notice not 083 nxs 150 rev : 00 date : 13/10/05 description for ambient temperature : 40°c nxs 150 110 v 230 v primary single phase power supplie v 110 v (+/- 13%) 230 v (+/- 13%) frequency hz 50/60 maximum primary current a 32 23 maximum power consumption kva 3,7 5,3 power factor (cos Ø) 0,98 secon...

Page 15: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 setting up 7. Connection to the main supply the power source must be connected to a single-phase 230v or 110v - 50 hz/60 hz mains + ground with a tolerance of +/- 13%. It has built-in over voltage protection (if the power supply is 110v) which allows e...

Page 16: Nxs 150

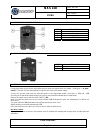

Notice not 083 nxs 150 rev : 00 date : 13/10/05 using 10. Description of the front panel nxs 150 repere designation f1 welding current knob f2 power terminal + f3 warning indicator f4 power on indicator f5 power terminal - 11. Description of the back panel repere designation b1 input cable b2 on/off...

Page 17: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 maintenance 13. Maintenance caution : before opening the unit, disconnect the power source from the mains. Voltages are high and dangerous inside the machine. In spite of their robustness, nexus power sources require some regular maintenance. Once ever...

Page 18: Nxs 150

Notice not 083 nxs 150 rev : 00 date : 13/10/05 maintenance 15. Main pcb ref l93211 connector j1, j5 : 110v / 230v ac main supply, protected against over voltage on main supply connector j2 : protective earth connection connector j3 : connection for 12v dc fan (pin 1 +; pin 2 -) connector j4 : pin 1...

Page 19

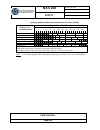

17. Wiring diagram.

Page 20

Leengate welding group ltd redfield road lenton nottingham ng7 2uj 0044 (0) 115 986 7880 nexus reserves the right to make changes without previous notification. Illustrations, descriptions and characteristics are not contractually binding and do not engage the responsibility of the manufacturer..