- DL manuals

- Xray

- Toy

- XB4

- Instruction manual

Xray XB4 Instruction manual

Summary of XB4

Page 2

2 the xray xb4 is a modern, high-competition premium luxury racing 1/10 electric 4wd off-road buggy that is the epitome of high-performance and fine distinctive design. Your xb4 offers highest performance, responsive handling, and traditionally exceptional xray quality, engineering, and design. The ...

Page 3

3 important notes – electrical • insulate any exposed electrical wiring (using heat shrink tubing or electrical tape) to prevent dangerous short circuits. Take maximum care in wiring, connecting and insulating cables. Make sure cables are always connected securely. Check connectors for if they becom...

Page 4

4 arm reamer 3.0mm not included to ensure that you always have access to the most up-to-date version of the set-up book you can download the hudy set-up book from their web site at www.Hudy.Net. By offering this online version instead of including a hardcopy printed version in kits, you will always ...

Page 5

5 xb4 tech tips motor position alternatives shock tower protection please follow the instruction manual and seal the edges of the shock towers with ca to reinforce them and help prevent delamination. Fine sandpaper use fine sandpaper to sand smooth the edges of all graphite parts. Apply ca glue to a...

Page 6

6 bevel gears #364935 graphite (option) #364945 alu (option) #364955 steel (standard) bevel & satelitte gears + pins #304930 + #304980 composite (standard) #335030 + #335080 steel (option) suggested to use with #365114 graphite composite bevel drive gear 14t. 1. Front & rear differential 2x 2x step ...

Page 7

7 differential oil fill differential up to the top of the diff pin. Do not fill the diff to the top of the housing. To ensure you have the same amount of oil from rebuild to rebuild, do the following: ➊ put the diff (without oil) on the scale and check the weight (approximately 9.80g) ➋ slowly pour ...

Page 8

8 2. Rear central transmission graphite grease (hudy #106210) bevel drive gears #365114 graphite (option) #365134 steel (standard) marked “r“ drive shaft cover caps lubricate the drive shaft connecting joint properly so the drive shaft turns freely. In the event that not enough grease is used, the c...

Page 9

9 rear central transmission graphite grease (hudy #106210) ➊ ➋ ➌ ➍ ➎ follow the tech tip on page 5 to protect graphite parts rear diff 8 000 cst detail when installing the gear on the axle, make sure the flat spot of the gear sits on the flat spot of the axle. Note orientation note orientation note ...

Page 10

10 2. Front central transmission graphite grease (hudy #106210) marked “f“ bevel drive gears #365114 graphite (option) #365134 steel (standard) drive shaft collar #365470 composite (standard) #365471-k alu - black (option) #365471-o alu - orange (option) drive shaft cover caps lubricate the drive sh...

Page 11

11 front central transmission ➊ ➋ ➌ ➍ ➎ follow the tech tip on page 5 to protect graphite parts front diff 8 000 cst front block detail important when installing the gear on the axle, make sure the flat spot of the gear sits on the flat spot of the axle. Thread lock note orientation oil oil 940510 b...

Page 12

12 optional 2x for better stability and to make the car easier to drive, optional #362190 and #363190 graphite stiffeners may be used. Using only 4 screws, the graphite stiffener can be installed or removed which would completely change the characteristics of the car. Stiffeners may be used independ...

Page 13

13 toe-in anti-squat roll center track width rear suspension eccentric bushings have two different offsets from the center. Middle position = 0.5° or 0.375mm from center. Outer position = 1° or 0.75mm from center. The xray rear alu lower suspension holders provide great range of adjustment for the r...

Page 14

14 rear suspension anti-roll bar ➊ ➋ ➌ 3x4 3x8 3x3 l=r 2x 1.5mm 4mm l=r 0mm step detail ➌ step check for free movement ➊ detail detail loosen the 3x4 setscrew if the anti-roll bar does not turn freely step ➊ assembly view 901308 sb m3x8 901303 sb m3x3 901304 sb m3x4 902308 sh m3x8.

Page 15

15 optional 2x for better stability and to make the car easier to drive, optional #362190 and #363190 graphite stiffeners may be used. Using only 4 screws, the graphite stiffener can be installed or removed which would completely change the characteristics of the car. Stiffeners may be used independ...

Page 16

16 front suspension kick up roll center track width all possible mounting alternatives of eccentric bushings the tables describe the amounts of adjustment using the center and outside positions of the eccentric bushings. The middle position eccentric bushings allow for finer adjustment increments. T...

Page 17

17 front suspension anti-roll bar l=r 2x 1.5mm 4mm ➊ ➋ ➌ l=r 0mm step detail ➌ step check for free movement ➊ detail detail loosen the 3x4 setscrew if the anti-roll bar does not turn freely step ➊ 3x4 3x3 3x8 901308 sb m3x8 901303 sb m3x3 901304 sb m3x4 902308 sh m3x8 902308 sh m3x8 assembly view.

Page 18

18 drive shaft collar #365470 composite (standard) #365471-k alu - black (option) #365471-o alu - orange (option) rear uprights #363350 composite (standard) #363351 alu (option) 4. Rear transmission 30 2665 composite ball joint 4.9mm - closed with hole (4) 36 2610 adj. Turnbuckle m3 l/r 50 mm - spri...

Page 19

19 camber roll center wheelbase rear transmission do not overtighten 33.5 mm 2x 2x 2x 2x l=r l=r l=r l=r l=r l=r when using outside position on the hub, use only outside position on the arm. When using inside position on the hub, use only inside position on the arm. Check for free movement ensure th...

Page 20

20 caster roll-center drive shaft collar #365470 composite (standard) #365471-k alu - black (option) #365471-o alu - orange (option) 4. Front transmission 30 2665 composite ball joint 4.9mm - closed with hole (4) 30 3122 alu shim 3x6x1.0mm (10) 36 2210 composite c-hub 9° deg. Right 36 2211 composite...

Page 21

21 roll center camber ➊ 1:1 front transmission 34 mm 2x 2x 2x 2x l=r l=r l=r l=r right thread left thread 9mm 20mm 10mm thread 10mm thread 8mm thread 8mm thread do not overtighten l=r check for free movement if the c-hub does not move freely, use a hudy arm reamer to resize the hole. Arm reamer (hud...

Page 22

22 4. Front & rear assembly bag 36 1182 composite rear lower brace 36 1291 composite chassis brace front 36 1292 composite chassis brace rear 36 1320 body mount, battery mount - v2 & wing shim (2) 90 2312 hex screw sh m3x12 (10) 90 2314 hex screw sh m3x14 (10) 90 2316 hex screw sh m3x16 (10) 903310 ...

Page 23

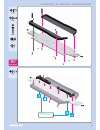

23 chassis flex setting 4. Front & rear assembly front & rear assembly 903308 sfh m3x8 903310 sfh m3x10 903310 sfh m3x10 903314 sfh m3x14 3x14 3x8 3x10 960030 n m3 961032 s 3.2 screws for multi-flex™ setting. For more details see page 45..

Page 24

24 902314 sh m3x14 902312 sh m3x12 902314 sh m3x14 902316 sh m3x16 903310 sfh m3x10 903310 sfh m3x10 4. Front & rear assembly optional to raise the rear differential and rear suspension use these two optional parts together. #361262 composite rear chassis plate #361181 graphite rear lower brace 2.0m...

Page 25

25 servo saver 970100 o 10x1.5 steering plate #362571 composite (standard) #362573 alu (option) 4. Front & rear assembly bag 5. Steering 2mm initial preload setting cleaner thread lock 30 2665 composite ball joint 4.9mm - closed with hole (4) 30 3125 alu shim 3x6x3.0mm (10) 33 2540 alu servo saver a...

Page 26

26 ackermann bump steer toe-in 903310 sfh m3x10 940508 bb 5x8x2.5 steering initial position right thread left thread conical shim 3x6x2 left thread 32mm right thread check for free movement note orientation adjustment block towards outside note orientation adjustment block towards outside note orien...

Page 27

27 901304 sb m3x4 bag 6. Slipper clutch assembly ➊ ➋ ➌ ➍ ➊ ➋ ➌ ➍ detail note orientation cutaway view 36 1163 graphite front upper deck 2.0mm 36 1164 graphite rear upper deck 2.0mm 36 1165 graphite center upper deck 2.0mm 36 1184 graphite rear upper brace 2.0mm 36 1320 body mount, battery mount - v2...

Page 28

28 903310 sfh m3x10 903310 sfh m3x10 902318 sh m3x18 slipper clutch assembly 941015 bb 10x15x4 tighten gently note orientation bearing oil (hudy #106230) oil oil note orientation.

Page 29

29 slipper clutch assembly slipper clutch adjustment the slipper clutch can be adjusted by loosening the set-screw and then, while keeping the tool inside of the set-screw, rotating the spur gear by hand as indicated in the drawing. To tighten: rotate the spur gear in the counterclockwise (ccw) dire...

Page 30

30 shock damping shock pistons ➊ ➊ ➋ ➋ ➌ ➌ 7. Shock absorbers rear springs #368273 progressive - 2 stripes (option) #368284 linear - 1 dot (option) #368285 linear - 2 dots (standard) #368286 linear - 3 dots (option) pistons detail there are two different thickness shims, use them as shown. Use the s...

Page 31

31 shock oil gently push the shock shaft completely into the shock body. Excess oil will flow through the hole in the shock cap. Keep the shock shaft pushed in the shock body and insert the screw into the shock cap. The rebound will be at approximately 0% tighten fully 1~1.5 mm detail 4x 4x 1mm 2mm ...

Page 32

32 fill the shock body with shock oil up to the top. Make sure to use same viscosity shock oil as is in the shock. ➋ orient the filled shock vertically for several minutes with the shock shaft fully extended. The remaining air bubbles will release. Gently place the shock cap assembly onto the filled...

Page 33

33 8. Final assembly 10 7871 hudy self-adhesive foam strip (2) 30 2665 composite ball joint 4.9mm - closed with hole (4) 30 6301 antenna mount - thin 30 9402 body clip for 6mm body post (4) 35 2610 adj. Turnbuckle m3 l/r 45 mm - spring steel™ (2) 35 6200 brake/throttle arms & steering servo arms - s...

Page 34

34 902316 sh m3x16 902312 sh m3x12 ➋ ➊ ➍ ➊ ➌ ➌ ➋ ➍ final assembly right thread left thread servo link adjust servo link to fit your servo. Left thread 26mm right thread 6mm thread 6mm thread 6mm thread short note orientation long from servo 6mm thread 902308 sh m3x8 l=r l=r initial position initial ...

Page 35

35 final assembly short long remove front & center upper-deck 903310 sfh m3x10 903310 sfh m3x10 903308 sfh m3x8 902310 sh m3x10 double-sided tape (not included) receiver (not included) feed the receiver wire into the antenna tube note: in case the antenna tube does not hold the antenna properly, app...

Page 36

36 lipo battery packs (not included) 902312 sh m3x12 962030 shim 3x6x0.3 adjust the motor so the pinion meshes with the spur gear properly. Make sure the gear mesh is not too tight. There should be a small amount of play between the teeth of the pinion gear and the spur gear. ➊ adjust gear mesh ➋ ti...

Page 37

37 assembly back front & center upper-deck ➍ before cutting and making holes on the body, put the unpainted body on the chassis to confirm the mounting position and location for holes and cutouts. Before cutting and making holes on the wing, put the unpainted wing on the wing holders to confirm the ...

Page 38

38 960240 n m4 final assembly 903308 sfh m3x8 rear wide wheel front narrow wheel final assembly view optional wing shim #293561 alu rear wing shim silver (option) #293561-o alu rear wing shim orange (option).

Page 39

39 36 1166 graphite front upper deck 2.0mm - short 36 1167 graphite rear upper deck 2.0mm - long 36 5424 central drive shaft 85mm - hudy spring steel™ 36 5425 central drive shaft 95mm - hudy spring steel™ 36 6114 composite battery strap - long 90 3308 hex screw sfh m3x8 (10) 90 3310 hex screw sfh m3...

Page 40

40 980210 p 2x10 980210 p 2x10 902310 sh m3x10 902310 sh m3x10 page 8 / step 1 page 10 / step 1 page 9 / step 2 page 11 / step 2 graphite grease (hudy #106210) ➊ ➋ ➌ ➍ note orientation - diff gear on opposite side rearward motor position graphite grease (hudy #106210) central drive shaft (85mm) - sh...

Page 41

41 page 23 / step 1 page 26 / step 1 page 26 / step 2 sh 3x10 sh 3x10 903308 sfh m3x8 903310 sfh m3x10 960030 n m3 961032 s 3.2 902310 sh m3x10 903310 sfh m3x10 303125 shim 3x6x3 sfh 3x10 sfh 3x10 rearward motor position 3x10 3x10 3x8 3x8 3x10 3x10 bag note orientation posts in different positions u...

Page 42

42 page 28 / step 1 page 28 / step 2 page 28 / step 3 903310 sfh m3x10 902318 sh m3x18 tighten gently 941015 bb 10x15x4 rearward motor position 903310 sfh m3x10 note orientation - slipper clutch direction is reversed bearing oil (hudy #106230) oil oil note orientation - stand in different location n...

Page 43

43 page 29 / step 3 page 34 / step 4 page 35 / step 1 3x10 3x10 3x8 903310 sfh m3x10 bag bag rearward motor position 902308 sh m3x8 902310 sh m3x10 short note orientation long from servo 902308 sh m3x8 long short note orientation.

Page 44

44 page 35 / step 3 page 35 / step 2 page 36 / step 2 902312 sh m3x12 rearward motor position ➊ loosen the screw ➋ insert motor into the bulkhead ➋ ➊ 903310 sfh m3x10 double-sided tape (not included) receiver (not included) feed the receiver wire into the antenna tube note: in case the antenna tube ...

Page 45

45 final assembly view multi-flex™ you can adjust the chassis flex by adding or removing the screws in the center of the chassis. The less screws used the softer the chassis flex will be. The more screws used the stiffer the chassis flex will be. Less screws = soft flex setting more screws = stiffer...

Page 46

46 recommended products • use #106230 hudy bearing oil to lubricate the bearings. Suspension & drivetrain maintenance • check suspension for free movement during building and operation, and especially after running and if you have crashed the car. If the suspension does not move freely, use the appr...

Page 47

47 #107717 gauge #107717 gauge gearing pinion cst cst track size tight open track traction high low track surface smooth medium medium medium bumpy track type hard packed blue groove carpet yes no yes no ball diff gear diff gear diff slipper ball diff gear diff steel composite steel composite grass ...

Page 48

48 É/i>8À>ÞÊ É/i>8À>ÞÊ É/i>8À>ÞÊ É8À>Þ,>v} ɳ/i>8À>Þ, rc america, 2030 century center blvd #15, irving, tx 75062, usa phone: 214-744-2400, fax: 214-744-2401, xray@rcamerica.Com.