- DL manuals

- XS Scuba

- Diving Instrument

- Airwave Octopus

- Service And Repair Manual

XS Scuba Airwave Octopus Service And Repair Manual

Summary of Airwave Octopus

Page 1

Service & repair manual rev . 06/08 service and repair manual airwave octo pn rg320

Page 2: Contents

Airwave octo 2 airwave octo service and repair manual contents section 1 - introduction warnings, cautions, & notes ................................................................................................................ 3 scheduled service.......................................................

Page 3: Scheduled Service

Service & repair manual 3 copyright ©2008 xs scuba this manual provides factory prescribed procedures for the correct service and repair of the airwave™ second stage regulator. It is not intended to be used as an instructional manual for untrained personnel. The procedures outlined within this manua...

Page 4: Facility Requirements

Airwave octo 4 airwave octo service and repair manual facility requirements "jaws" gripmaster vise ultrasonic cleaner as an authorized xs scuba dealer, your customers expect you to provide top-notch overhaul service, both before and after the sale. Next to airfills and gas blending, it is the single...

Page 5: Specialty Tools

Service & repair manual 5 copyright ©2008 xs scuba specialty tools for the finest tools, fixtures, and supplies that are designed and manufactured specifically for servicing scuba equipment, we recommend one source for all your service facility’s needs. Peter built co., in galion, ohio, is dedicated...

Page 6: Preliminary Inspection

Airwave octo 6 airwave octo service and repair manual preliminary inspection external inspection 1. Closely examine the conical filter to check for any signs that contaminants have entered the system, including sea water, rust, or aluminum oxide. Note: a green discoloration of the filter indicates t...

Page 7

Service & repair manual 7 copyright ©2008 xs scuba intermediate pressure test note: it is not necessary to perform this test unless a problem has been reported that requires diagnostic troubleshooting and repair. When performing routine overhaul service, proceed directly to the following sec- tion, ...

Page 8: Disassembly Procedures

Airwave octo 8 airwave octo service and repair manual disassembly procedures general guidelines ▼ prior to performing any disassembly, check to ensure that the service facility is well equipped with all the tools and parts needed to perform a complete service from start to finish. Do not attempt to ...

Page 9: Second Stage Disassembly

Service & repair manual 9 copyright ©2008 xs scuba second stage disassembly caution: whenever possible, use only plastic or brass o-ring tools for removing o-rings in order to pre- vent damage to the sealing surface. Steel instruments, such as dental picks, can easily damage the sealing surface of a...

Page 10

Airwave octo 10 airwave octo service and repair manual 8. Lift out the diaphragm(4) and thrust washer(3) from the second stage housing. Inspect the diaphragm to ensure that it is supple and free of any pinholes, tears, corrosion, or other damage. If any damage is found, discard it and replace with n...

Page 11

Service & repair manual 11 copyright ©2008 xs scuba fig. 5 – orifice inspection note: the orifice is o-ring sealed, and it will remain inside the air barrel after it has been unthreaded. The following step must be performed to remove the orifice without damaging its polished sealing surface. 18. Whe...

Page 12: General Guidelines

Airwave octo 12 airwave octo service and repair manual general guidelines ▼ refer to the schematic parts list, that highlights automatic re- placement parts which should be discarded and replaced with new during reassembly. These parts are provided in the annual service kit. ▼ before performing any ...

Page 13: Second Stage Reassembly

Service & repair manual 13 copyright ©2008 xs scuba second stage reassembly warning: do not attempt to use any other manu- facturer's part as a substitute for any xs scuba part, regardless of any similarity in shape, size, or appear- ance. Doing so may render the product unsafe, and could result in ...

Page 14

Airwave octo 14 airwave octo service and repair manual 7. Apply a light coat of lubricant to both ends of the poppet spring(4), and place the spring over the small end of the poppet, inside the air barrel. Be careful not to disturb the the orientation of the poppet inside the air barrel. 8. Insert t...

Page 15

Service & repair manual 15 copyright ©2008 xs scuba 15. Install the o-ring(10) onto the head of the adjustable orifice(9) and carefully insert the orifice into the inlet of the air barrel with the polished cone facing in. Using a small wooden or plastic down, press the orifice in so that it rests ag...

Page 16: Final Testing Procedures

Airwave octo 16 airwave octo service and repair manual final testing procedures caution: if the regulator will be used with ean/ nitrox, it is important to pressurize and flow test the regulator using only hydrocarbon-free gas. The regula- tor will otherwise become contaminated with hydrocar- bons i...

Page 17

Service & repair manual 17 copyright ©2008 xs scuba note: correct intermediate pressure for the first stage is between 135-145 psi, with a supply pressure of 2,500 - 3000 psi. 4. Open the supply valve again while monitoring the ip test gauge to ensure that the intermediate pressure does not rise abo...

Page 18

Airwave octo 18 airwave octo service and repair manual slightly counter-clockwise while lightly depressing the purge cover to prevent wear on the seat. Do not adjust any further than is needed to establish a slight leak. 6. Hold the drive of the inline adjustment tool engaged with the orifice. While...

Page 19

Service & repair manual 19 copyright ©2008 xs scuba flowbench testing (optional) the subjective breathing test, combined with the inter- mediate pressure test, will sufficiently verify the regulator's performance in most circumstances. As an additional test, a magnahelic flowbench can be used to ver...

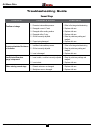

Page 20: Troubleshooting Guide

Airwave octo 20 airwave octo service and repair manual 1. Excessive intermediate pressure. 1. Refer to first stage troubleshooting 2. Damaged or worn lp seat. 2. Replace with new. 3. Damaged orifice sealing surface. 3. Replace with new. 4. Damaged orifice o-ring. 4. Replace with new. 5. Orifice inco...

Page 21: Schematic & Parts List

Service & repair manual 21 copyright ©2008 xs scuba schematic & parts list airwave second stage 1 2 3 4 19 18 17 16 9 10 15 14 11 12 8 13 7 5 6 23 24 25 26 22 21 20 28 29 27 rk2 7.00 - overhaul service kit 1 ....... Rp320-01 1 retaining ring 2 ....... Rp320-02 1 purge cover 3 ....... Rp320-03 1 thru...