- DL manuals

- YAMADA

- Water Pump

- DP-10BA

- Operation manual

YAMADA DP-10BA Operation manual

Summary of DP-10BA

Page 1

Doc. No. Ndp174u-18 operation manual yamada air-operated double diaphragm pump ndp-5 series dp-10 series ndp-15 series.

Page 3

1 ·introduction thank you for purchasing a yamada diaphragm pump. This product is a positive-displacement pump that transfers fluids by movement of diaphragms driven by compressed air through a unique switching mechanism. The casing that comes in contact with the fluid is made of aluminum, stainless...

Page 4

2 ·warnings and cautions for safe use of this product, be sure to note the following: in this document, warnings and cautions are indicated by symbols. These symbols are for those who will operate this product and for those who will be nearby, for safe operation and for prevention of personal injury...

Page 5

3 warning • when installing this product, be sure to connect a ground wire from the specified position of this product (excluding ndp-5fpt, ndp-15fp□). When this product is installed and operated without the ground wire properly connected, friction between parts, as well as abrasion caused by the fl...

Page 6

4 warning • when pumping a hazardous fluid (hot, flammable, strong acid, etc.) with this product, provide protective measures (install a pit, a protection box, sensors, etc.) in consideration of possible leakage of fluid, and post warning signs at necessary places. Make the warning symbols in [12.Wa...

Page 7

5 table of contents · introduction ················································································ 1 · for safe operation ······································································· 1 · warnings and cautions ·······························································...

Page 8

6 1. Names of parts and materials 1.1 ndp-5 series a: air valve f : pump base b: reset button g: discharge port c: out manifold h: intake port d: out chamber i: lift point e: in manifold j: ground connection point ndp-5fat ndp-5fpt ndp-5fst ndp-5fvt ndp-5fdt type fat fst fpt fvt fdt switching portio...

Page 9

7 1.2 dp-10 series a: air valve f : pump base b: reset button g: discharge port c: out manifold h: intake port d: out chamber i: lift point e: in manifold j: ground connection point dp-10ba□ dp-10bs□ dp-10bp□ dp-10ba□-d dp-10bs□-d •aluminium type([ ]: drum type) type bac [bac-d] ban [ban-d] bat [bat...

Page 10

8 1.3 ndp-15 series a: air valve f : pump base b: reset button g: discharge port c: out manifold h: intake port d: out chamber i: lift point e: in manifold j: ground connection point ndp-15ba□ ndp-15fp□ ndp-15bs□ ndp-15bps ndp-15fvt ndp-15fdt •aluminum type type bac ban bat bah bas bah/t switching p...

Page 11

9 2. Assembly 2.1 installation of accessories 1) first, open the product package and make sure that all the accessories are in order (see [1. Names of parts and materials] ■ list of accessories). 2) attach the air valve and the silencer (nipple) (see the appearance drawings on [1. Names of parts and...

Page 12

10 3. Installation 3.1 method of transport • when lifting the pump using a chain hoist or crane before transporting it, be sure to lift it by the specified lift point (see [1. Names of parts and materials]). Warning • be careful that nobody will pass under the pump when you lift it. It would be very...

Page 13

11 caution • even if you do not use the cushions to secure the pump in place, mount it in such a way that vibration generated by pump operation will be absorbed. • if the pump will be submerged during operation, follow the steps below: *verify the corrosion resistance of each component of the pump, ...

Page 14

12 3.3 connecting the ground wire a) when installing the pump, be sure to connect the ground wire at the specified position. For the specified position for connecting the ground wire, see [1. Names of parts and materials]. (excluding ndp-5fpt, ndp-15fp□). B) also connect ground wires to peripheral e...

Page 15

13 4. Connection 4.1 connecting fluid piping 1) connect a flow valve and a drain valve to the fluid discharge port of the pump. 2) connect a valve for maintenance to the fluid suction intake port of the pump. 3) connect a hose to the valve on the suction-port side and the valve of the discharge-port...

Page 16

14 4.2 connecting air piping warning • before starting work, make sure that the air compressor is shut off. 1) connect an air valve, air filter, regulator and if necessary lubricator (hereinafter called the "peripheral equipment") to hose which connected to compressor. Install air valve on the air i...

Page 17

15 5. Operation 5.1 method of operation caution • before starting the pump, make sure that all piping is properly connected. • also, before starting the pump, make sure that all the bolts are securely tightened. (refer to the maintenance manual for the bolts that a regulation torque are explained.) ...

Page 18

16 5.3 shutdown • close the air valve of the pump and shut off the supply air. Caution • there is no problem in shutting down the pump with the flow valve closed while air is being supplied; however, if this condition continues for many hours while there is nobody watching the pump, it may continue ...

Page 19

17 6. Method of cleaning warning •before starting operation, make sure that compressed air is not supplied to the pump. •before starting operation, make sure that the pump is not pressurized. 1) remove the hose from the suction side of the pump. 2) close the flow valve on the discharge side, open th...

Page 20

18 7. Daily check • before starting pump operation, be sure to conduct the following check every day. If any irregularity is found, do not start running the pump until the cause of the irregularity has been found and corrective measures have been taken. A) verify the drain flow through the air filte...

Page 21

19 8.4 liquid leakage from exhaust port (silencer) cause action to be taken the diaphragm is damaged. Disassemble and check the pump and replace the diaphragm. The fastening nuts for the center disk are loose. Disassemble and check the pump. Tighten the nuts. 8.5 high air consumption during operatio...

Page 22

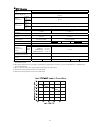

20 10. Main body specification 10.1 main specifications ■ ndp-5 series ndp-5 type fat fst fpt fvt fdt nominal diameter 1/4˝ (6 mm) suction port fluid connection discharge port rc 1/4 supply port rc 1/4 air connection exhaust port rc 3/8 operating air pressure 0.2~0.7 mpa 0.2~0.7 mpa * 1 maximum disc...

Page 23

21 ■ ndp-15 series type ndp-15 ba□ bs□ fp□ bps fvt fdt nominal diameter 1/2˝ (15mm) fluid connection suction port rc 1/2 discharge port air connection supply port rc 1/4 exhaust port rc 3/8 operating air pressure 0.2~0.7 mpa 0.2~0.7 mpa * 1 maximum discharge pressure 0.7 mpa 0.7 mpa * 1 discharge vo...

Page 24

22 10.2 appearance and dimensions 10.2.1 ndp-5 series ■ ndp-5fat ■ ndp-5fst ■ ndp-5fpt/ fvt/ fdt [ ]:fvt.

Page 25: □

23 10.2.2 dp-10 series ■ dp-10ba □ ■ dp-10bs □ ■ dp-10bp □.

Page 26: □

24 ■ dp-10ba □ -d ■ dp-10bs □ -d 10.2.3 ndp-15 series ■ ndp-15ba □.

Page 27: □

25 ■ ndp-15bs □ ■ ndp-15fp □ / bps/ fvt/ fdt caution ▪ due to improvement or modification of products, dimensions may change without notice. Please contact your distributor our regional office for detailed information..

Page 28: □

26 10.3 performance curve 10.3.1 ndp-5 series 10.3.2 dp-10 series ■ ndp-5 series ■ dp-10ba □ /bs □ ■ dp-10ba □ -d/ bs □ -d ■ dp-10bp □ 10.3.3 ndp-15 series ■ ndp-15ba □ / bs □ ■ ndp-15fp □ / bps/ fvt/ fdt.

Page 29

27 note: method of measurement of performance curve measuring instruments and procedure fig.10.1 ▪ conditions a) supplied air pressure: maintaining preset pressure b) liquid pumped: fresh water c) temperature: ambient d) condition of suction: flat suction 0 meter head e) measuring system: system a …...

Page 30

28 11. Limited warranty if an abnormality occurs during normal operation in accordance with the operating instructions and other operating cautions within the warranty period (12 months after date of purchase) that can be attributed to a manufacturing defect, the defective parts of this product will...

Page 31

29 12. Warning symbols beware: high temperature electric shock poison flammable corrosion explosion general warnings, cautions and danger notifications fire strictly prohibited.

Page 32

Manufactured by yamada corporation international department no.1-3, 1-chome, minami- magome, ohta-ku, tokyo, 143-8504, japan phone : +81-(0)3-3777-0241 fax : +81-(0)3-3777-0584 201710 ndp174u.