Summary of 2002 TW125

Page 2: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the tw125 2002. For complete service information procedures it is necessary to use this supplementary service manual together with the following manual. Tw125 service manual: 5ek1-ae1 tw125 2002 supple...

Page 3: Notice

Note: warning caution: eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maint...

Page 4: How To Use This Manual

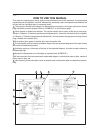

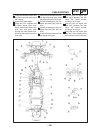

1 2 5 7 6 4 3 8 eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and inspection procedures are laid out with the individual steps in sequential orde...

Page 5: Gen

21 1 3 5 7 9 2 4 8 6 23 24 22 20 18 19 17 15 14 13 11 12 10 gen info spec eng carb elec chas chk adj trbl shtg 16 eas00009 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 9 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks an...

Page 6

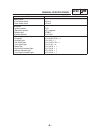

Contents specifications general specifications 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance specifications 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Engine 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

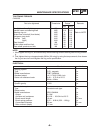

Page 7: Spec

General specifications spec specifications general specifications model tw125 model code: 5rs1, 5rs2 dimensions: overall length overall width overall height seat height wheelbase minimum ground clearance minimum turning radius 2,135 mm , 820 mm 1,120 mm , 820 mm 1,350 mm , 255 mm 2,100 mm carburetor...

Page 8: Spec

General specifications spec model tw125 wheel travel: front wheel travel rear wheel travel 150 mm 150 mm electrical: ignition system generator system battery type battery capacity c.D.I. A.C. Magneto gt6b-3 12 v 6 ah bulb wattage quantity: headlight auxiliary light tail / brake light turn signal lig...

Page 9: Spec

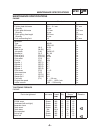

Maintenance specifications spec maintenance specifications engine item standard limit clutch: friction plate thickness quantity clutch plate thickness quantity clutch spring free length quantity push rod bending limit 2.9 x 3.1 mm 5 pcs. 1.6 mm 4 pcs. 34.9 mm 4 pcs. Sss 2.7 mm sss 0.05 mm sss 33.9 m...

Page 10: Spec

Maintenance specifications spec chassis item standard limit front suspension: front fork travel fork spring free length fitting length spring rate (k1) stroke (k1) oil capacity oil level oil grade inner tube vend limit 150 mm 330 mm 325 mm 4.9 n / mm (0.49 kg / mm) 0 x 150 mm 0.259 l (259 cm 3 ) 122...

Page 11: Spec

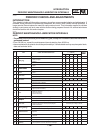

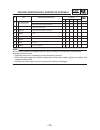

Maintenance specifications spec note: tightening torques chassis part to be tightened thread size tightening torque remarks g nm m skg headlight and headlight stay handle crown and steering shaft steering ring nut brake hose union bolt (front brake) swingarm pivot shaft footrest (left) (right) rear ...

Page 12: Spec

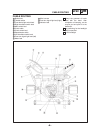

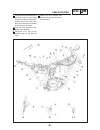

Cable routing spec 12 wire harness 13 front turn signal light lead (right) 14 indicator lead 1 brake hose 2 throttle cables 3 front brake light switch lead 4 right handlebar switch lead 5 main switch lead 6 clutch cable 7 clutch switch lead 8 speedometer cable 9 left handlebar switch lead 10 front t...

Page 13: Spec

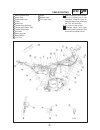

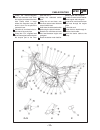

A after clamping the wire harness, point the surplus part to the downward. Clamp the part im- mediately before the junction to the c.D.I. Unit and relay. B cut it to be 10 mm or less. C handlebar switch lead (right) and front brake light switch lead should not be twined around. 1 battery positive le...

Page 14: Spec

Cable routing spec i pass the throttle cables through the engine bracket hole. Point the surplus part to the downward and cut the end. J pass the carburetor heater lead in front of the seat pillar tube so that it is not caught between the side cover flange and seat pillar tube frame. K point the rea...

Page 15: Spec

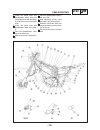

Cable routing spec o clamp the wire harness and diode. Point the surplus part to the downward. L clamp the rear brake switch lead connector and turn signal relay lead with the band and point the surplus part to the inner side, then cut it. Secure the connector at the front part of frame. M push the ...

Page 16: Spec

Cable routing spec a clamp between the positioning belts of resonator hose. Do not pinch the resonator hose. B starter cable, clutch switch lead and main switch lead should not be twined around. C clamp at the point ahead of the part where resonator hose pro- tector is torn. Do not pinch the resonat...

Page 17: Spec

Cable routing spec tween engine and swingarm. M route the neutral switch lead be- tween engine and swingarm. N route the air vent hose and over flow hose through the engine guide. O to the fuel cock. P route the horn lead through in- side the clutch cable. Q insert the starter cable to the clamp. Si...

Page 18: Spec

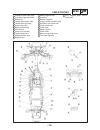

Cable routing spec v place the speedometer cable in the inner side. W after tightening screws, insert the hose in the screw section. X distortion should be within this range toward the traveling direc- tion of vehicle. Y place the brake hose in the outer side. R clamp the brake hose and speedometer ...

Page 19: Spec

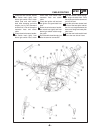

Cable routing spec 24 c.D.I. Magneto leads, neutral switch lead 1 handlebar switch lead (right) 2 front brake light switch lead 3 brake hose 4 throttle cable (return side) 5 throttle cable (pull side) 6 starter motor lead 7 battery positive lead 8 wire harness 9 clamp (wire harness) 10 thermo switch...

Page 20: Spec

Cable routing spec h pass the rear turn signal light lead (right) between the rear frame and license bracket, avoiding to be caught. I pass the rear turn signal light lead (left) between the rear frame and license bracket, avoiding to be caught. J clamp the rear turn signal light lead (left). After ...

Page 21: Spec

Cable routing spec o clamp the handlebar switch lead (left) and clutch switch lead. P after clamping, cut where it is not visible either from the top or the rear. K clamp the thermo switch lead coupler. After clamping, point the surplus part to the inner side. L pass the c.D.I. Magneto lead (2 leads...

Page 22: Chk

Introduction periodic maintenance/lubrication intervals chk adj note: eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable ve...

Page 23: Chk

Periodic maintenance/lubrication intervals chk adj note: no. Item check or maintenance job odometer reading ( 1,000 km) annual check 1 6 12 18 24 check 20 * rear suspension relay arm and connecting s check operation. √ √ √ √ 20 * arm and connecting arm pivoting points s lubricate with lithium-soap-b...

Page 24: Chk

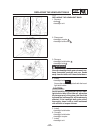

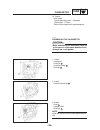

Adjusting the engine idling speed chk adj note: a b engine eas00054 adjusting the engine idling speed prior to adjusting the engine idling speed, the air filter should be clean, and the engine should have adequate compression. 1. Start the engine and let it warm up for several minutes. 2. Install: s...

Page 25: Chk

Adjusting the throttle cable free play chk adj note: note: a b note: eas00058 adjusting the throttle cable free play prior to adjusting the throttle cable free play, the engine idling speed should be adjusted. 1. Check: sthrottle cable free play a out of specification ! Adjust. Throttle cable free p...

Page 26: Chk

Adjusting the throttle cable free play chk adj a b warning direction throttle cable free play is increased. Direction throttle cable free play is decreased. D. Tighten the locknut. After adjusting the throttle cable free play, turn the handlebars to the right and to the left to ensure that this does...

Page 27: Chk

Checking and charging the battery chk adj warning caution: eas00178 electrical system checking and charging the battery batteries generate explosive hydrogen gas and contain electrolyte which is made of poi- sonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures:...

Page 28: Chk

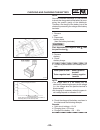

Checking and charging the battery chk adj relationship between the open-circuit voltage and the charging time at 20 _c open-circuit voltage (v) these values vary with the temperature, the condition of the battery plates, and the electrolyte level. 13.0 12.5 12.0 11.5 5 6.5 10 charging time (hours) n...

Page 29: Chk

Checking and charging the battery chk adj charging ambient temperature 20 _c open-circuit voltage (v) check the open-circuit voltage. Time (minutes) ambient temperature 20 _c open-circuit voltage (v) charging condition of the battery (%) warning caution: 5. Charge: sbattery (refer to the appropriate...

Page 30: Chk

Checking and charging the battery chk adj measure the open-circuit voltage prior to charging. Connect a charged and amp meter to the battery and start charging. Make sure that the current is higher than the standard charging current written on the battery. By turning the charging voltage adjust dial...

Page 31: Chk

Checking and charging the battery chk adj measure the open-circuit voltage prior to charging. Connect a charger and amp meter to the battery and start charging. Make sure that the current is higher than the standard charging current written on the battery. Charge the battery until the battery’s char...

Page 32: Chk

Checking and charging the battery chk adj caution: 6. Check: sbattery vent obstruction ! Clean. Damage ! Replace. 7. Install: sbattery 8. Connect: sbattery leads (to the battery terminals) first, connect the positive lead 1 , then the negative lead 2 . 9. Check: sbattery terminals dirt ! Clean with ...

Page 33: Chk

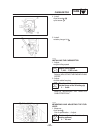

Replacing the headlight bulb chk adj warning caution: eas00182 replacing the headlight bulb 1. Remove: sbolts 1 sheadlight unit 2. Disconnect: sheadlight coupler 1 sheadlight bulb cover 2 3. Remove: sheadlight bulb holder 1 sheadlight bulb 2 since the headlight bulb gets extremely hot, keep flammabl...

Page 34: Chk

Adjusting the headlight beam chk adj a b a b eas00184 adjusting the headlight beam 1. Adjust: sheadlight beam (vertically) a. Turn the adjusting screw 1 in direction a or b . Direction ! Headlight beam is raised. Direction ! Headlight beam is lowered. 2. Adjust: sheadlight beam (horizontally) a. Tur...

Page 35: Eng

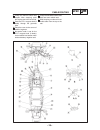

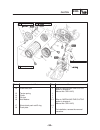

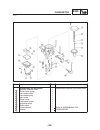

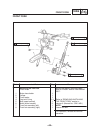

Clutch eng order job / part q’ty remarks 1 2 3 4 5 6 7 8 9 10 11 removing the clutch clutch springs pressure plate friction plates clutch plates nut / lock washer clutch boss thrust washer clutch housing ball long clutch push rod push lever screw / gasket 4 1 5 4 1 / 1 1 1 1 1 1 1 / 1 remove the par...

Page 36: Eng

Order job / part q’ty remarks 12 13 14 15 16 17 18 push lever axle torsion spring circlip oil seal nut / washer short clutch push rod / o-ring push plate 1 1 1 1 1 / 1 1 / 1 1 refer to “installing the clutch” section in chapter 4. (manual no.: 5ek1-ae1) refer to “installing the clutch” section in ch...

Page 37: Eng

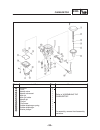

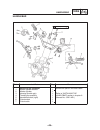

Carburetor eng order job / part q’ty remarks 1 2 3 4 removing the carburetor side cover seat fuel tank heater unit lead starter cable carburetor joint clamp screw air filter joint clamp screw carburetor assembly throttle cables 1 1 1 2 remove the parts in order listed. S disconnect the connector fro...

Page 38: Eng

Order job / part q’ty remarks disassembly the carburetor vacuum chamber cover piston valve spring jet needle holder jet needle spring jet needle piston valve carburetor heater adjusting screw drain screw float chamber gasket 1 1 1 1 1 1 1 1 1 1 1 disassemble the parts in the order listed. Refer to “...

Page 39: Eng

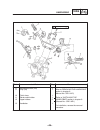

Carburetor eng order job / part q’ty remarks float pin float needle valve needle valve seat main jet main jet holder needle jet pilot jet pilot screw rubber diaphragm spring rubber diaphragm starter plunger 1 1 1 1 1 1 1 1 1 1 1 1 for assembly, reverse the disassembly procedure. Refer to “assembling...

Page 40: Carb

Carburetor carb eas00485 checking the carburetor 1. Check: scarburetor body sfloat chamber sjet housing cracks / damage ! Replace. 2. Check: sfuel passages obstruction ! Clean. A. Wash the carburetor in a petroleum-based solvent. Do not use any caustic carburetor cleaning solution. B. Blow out all o...

Page 41: Carb

Carburetor carb 8. Check: spiston valve 1 damage / scratches / wear ! Replace. Srubber diaphragm 2 cracks / tears ! Replace. 9. Check: svacuum chamber cover 1 spiston valve spring 2 sjet needle holder 3 sjet needle spring 4 cracks / damage ! Replace. 10. Check: sjet needle kit 1 sneedle jet 2 smain ...

Page 42: Carb

Carburetor carb caution: note: 13. Check: sfuel hoses cracks / damage / wear ! Replace. Obstruction ! Clean. Blow out the hoses with compressed air. Eas00487 assembling the carburetor sbefor assembling the carburetor, wash all of the parts in a petroleum-based solvent. Salways use a new gasket. 1. I...

Page 43: Carb

Carburetor carb 4. Install: sfloat chamber 1 spilot screw 2 5. Install: sstarter plunger kit 1 eas00492 installing the carburetor 1. Adjust: sengine idling speed engine idling speed 1,450 x 1,650 r/min refer to “adjusting the engine idling speed” 2. Adjust: sthrottle cable free play throttle cable f...

Page 44: Carb

Carburetor carb a. Stand the motorcycle on a level surface. B. Place the motorcycle on a suitable stand to ensure that the motorcycle is standing straight up. C. Install the fuel level gauge 1 to the fuel drain pipe 2 . Fuel level gauge 90890-01312 d. Loosen the fuel drain screw 3 . E. Hold the fuel...

Page 45: Chas

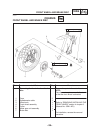

Front wheel and brake disc chas order job / part q’ty remarks 1 2 3 4 5 6 7 removing the front wheel and brake disc caps speedometer cable wheel axle front wheel assembly collar meter gear unit assembly brake disc 2 1 1 1 1 1 1 remove the parts in the order listed. Place the motorcycle on a suitable...

Page 46: Chas

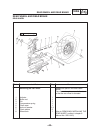

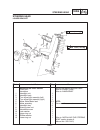

Order job / part q’ty remarks 1 2 3 4 5 6 7 8 removing the rear wheel adjuster brake rod pin compression spring chain case axle nut / washer chain pullers wheel axle 1 1 1 1 1 1 / 1 2 1 remove the parts in the order listed. Place the motorcycle on a suitable stand so that the rear wheel is elevated....

Page 47: Chas

Order job / part q’ty remarks 9 10 rear wheel assembly collar 1 2 refer to “removing / installing the rear wheel” section in chapter 6. (manual no.: 5ek1-ae1) for installation, reverse the removal procedure. 90 nm (9.0 m skg) rear wheel and rear brake chas –41–.

Page 48: Chas

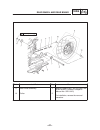

Order job / part q’ty remarks 1 2 3 removing the rear brake and rear wheel sprocket shoe plate nuts driven sprocket 1 6 1 remove the parts in the order listed. For installation, reverse the removal procedure. Refer to “assemblyng the rear wheel” section in chapter 6. (manual no.: 5ek1-ae1) 43 nm (4....

Page 49: Chas

Order job / part q’ty remarks disassembling the rear wheel bearing spacer oil seal bearing 1 1 1 1 disassemble the parts in the order listed. For assembly, reverse the disassembly procedure. 1 2 3 4 rear wheel and rear brake chas –43–.

Page 50: Chas

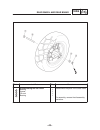

Order job / part q’ty remarks 1 2 3 4 5 6 7 8 removing the front fork front wheel brake hose holder caliper front fender cap bolt / o-ring bolt (upper bracket) bolts (under bracket) front fork assembly (left) front fork assembly (right) 1 1 1 1 / 1 1 2 1 1 remove the parts in the order listed. Refer...

Page 51: Chas

Order job / part q’ty remarks 1 2 3 4 5 6 7 removing the handlebar master cylinder bracket master cylinder housing (throttle grip) throttle grip assembly handlebar switch (right) clutch switch clutch cable 1 1 1 1 1 1 1 remove the parts in the order listed. Refer to “installing the handlebar” sectio...

Page 52: Chas

Order job / part q’ty remarks 8 9 10 11 12 13 handlebar switch (left) grip (left) clutch lever starter cable holder upper holders handlebar 1 1 1 1 2 1 refer to “removing the handlebar” section in chapter 6. (manual no.: 5ek1-ae1) for installation, reverse the removal procedure. Refer to “installing...

Page 53: Chas

Order job / part q’ty remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 removing the lower bracket front fork handlebar headlight unit headlight body turn signal light assembly (left) turn signal light assembly (right) meter cable / meter lead meter assembly headlight stay steering stem nut handlebar crown lock...

Page 54: Chas

Steering head chas order job / part q’ty remarks 14 15 16 17 18 19 20 ball race ccver lower bracket ball race (upper) ball ball ball race (center) ball race (lower) 1 1 1 22 19 1 1 for installation, reverse the removal procedure. Refer to “installing the steering” section in chapter 6. (manual no.: ...

Page 55: Elec

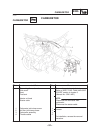

Ignition system elec 1 c.D.I. Magneto 2 neutral switch 4 battery 6 fuse 10 engine stop switch 11 main switch 13 diode 14 c.D.I. Unit 15 ignition coil 16 spark plug 22 neutral relay 24 reed switch eas00734 electrlcal system ignition system circuit diagram –49–.

Page 56: Elec

Ignition system elec no yes s make the speedometer indicate s check the continuity or open circuit status. S if it counts 4 cycles of continuity and open actions per speedometer rotation, the result is acceptable. S is the reed switch ok? Replace the reed switch. S remove the meter assembly. S conne...

Page 57

Color code b black . . . . . . . . . Br brown . . . . . . . . . Ch chocolate . . . . . . . . Dg dark green . . . . . . . . G green . . . . . . . . . L blue . . . . . . . . . . O orange . . . . . . . . . 1 c.D.I. Magneto 2 neutral switch 3 rectifier / regulator 4 battery 5 starter relay 6 fuse 7 star...