Summary of 2002 XJR1300

Page 3: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the xjr1300 (p) 2002. For complete service information procedures it is necessary to use this supple- mentary service manual together with the following manual. Xjr1300 (l) ’99 service manual: 5ea3-ae1...

Page 4: Notice

Note: caution: eas00003 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manu- al. Therefore, anyone who uses this book to perform maintenance and ...

Page 5: How To Use This Manual

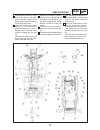

1 2 6 4 5 7 3 8 eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 ...

Page 6: Gen

21 1 3 5 7 9 2 4 8 6 23 24 22 20 18 19 17 16 15 14 13 11 12 10 gen info spec eng carb elec chas chk adj trbl shtg eas00009 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 8 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks an...

Page 7: Contents

Contents specifications general specifications 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance specifications 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . Engine 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

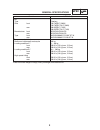

Page 8: Spec

1 spec general specifications specifications general specifications model xjr1300 (p) model code: 5eat/5eaw (eur) 5eau/5eax (for d) 5eav/5eay (for aus) dimensions: overall length overall width overall height seat height wheelbase minimum ground clearance minimum turning radius 2,175 mm 775 mm 1,115 ...

Page 9: Spec

2 spec general specifications model xjr1300 (p) tire: type size front rear manufacturer front rear type front rear tubeless 120/70zr17 (58w)/ 120/70zr17 m/c (58w) 180/55zr17 (73w)/ 180/55zr17 m/c (73w) michelin/dunlop michelin/dunlop macadam90x e/d220f st m macadam90x e/d220 st m tire pressure (cold...

Page 10: Spec

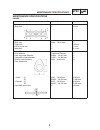

3 spec maintenance specifications maintenance specifications engine model standard limit cylinder head: warp limit !!! 0.2 mm cylinder: bore size taper limit out of round limit wear limit 79.00 ! 79.01 mm !!! !!! !!! !!! 0.05 mm 0.1 mm 79.1 mm camshaft: drive method cam cap inside diameter camshaft ...

Page 11: Spec

4 spec maintenance specifications model standard limit piston: piston to cylinder clearance piston size “d” 0.015 ! 0.040 mm 78.970 ! 78.985 mm 0.15 mm !!! Measuring point “h” piston off-set piston off-set direction piston pin bore inside diameter piston pin outside diameter 5 mm 1 mm in side 18.004...

Page 12: Spec

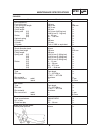

5 spec maintenance specifications tightening torques part to be tightened part name thread size q’ty tightening torque remarks g size y nm m!Kg carburetor joint and carburetor carburetor and air filter joint air induction system pipe joint air induction system band clamp – bolt m4 " 0.7 m4 " 0.7 – m...

Page 13: Spec

6 spec maintenance specifications chassis model standard limit front suspension: front fork travel fork spring free length fitting length collar length spring rate (k1) (k2) stroke (k1) (k2) optional spring oil capacity oil level oil grade 130 mm 308.3 mm 287.3 mm 245 mm 6.4 n/mm (0.65 kg/mm) 10.8 n...

Page 14: Spec

7 spec maintenance specifications tightening torques part to be tightened part name thread size q’ty tightening torque remarks g y nm m!Kg throttle cable and carburetor ignition coil nut nut m6 " 1.0 m6 " 1.0 2 2 4 6.5 0.4 0.65.

Page 15: Spec

8 spec maintenance specifications electrical model standard limit t.C.I.: pickup coil resistance/color t.C.I. Unit model/manufacturer 248 ! 372 Ω/w/r-w/g tndf63/denso (except for d) tndf64/denso (for d) !!! !!! !!! Charging system: type model/manufacturer normal output rotor coil resistance stator c...

Page 16: Spec

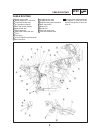

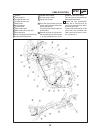

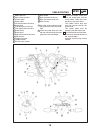

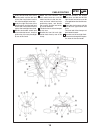

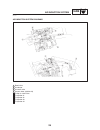

9 a pass the starter motor cable and the negative (–) lead wire of the battery through the inside of the seat rail. 13 #3 high-tension cord 14 #4 high-tension cord 15 engine frame ground lead wire 16 rear stop switch 17 relay assy 18 guide wire 19 fuel tank drain hose 20 fuel tank breather hose 1 st...

Page 17: Spec

10 c clamp the throttle cables to the fuel tank rail, on the tank fitting by use of this band. The front end of the band must be directed down- ward. D thread this clamp through the upper hole in the gusset and se- cure the two throttle cables. The front end of the clamp must be di- rected towards t...

Page 18: Spec

11 h bundle the a.C. Generator lead wire, the pickup lead wire, the side stand switch lead wire, the starter motor cable, and the car- buretor heater lead wire (total 5 wires), by use of this clamp. I match the marks of the fuel tank drain hose and fuel tank breather hose, and arrange the two types ...

Page 19: Spec

12 13 flasher relay coupler 14 oil lamp relay coupler 15 igniter unit coupler a pass the wire harness and the starter cable through the holder wire of the gusset. Pass the starter cable under the wire harness. B secure the lead wire branch of the main harness to tension pipe 1, at the immediate rear...

Page 20: Spec

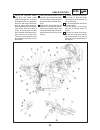

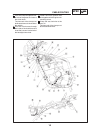

13 d bundle the #1 and #2 high-ten- sion cords using this clamp. Clamp these cords above the #2 head cover mounting bolt. E route the air cleaner drain hose through the right side of the ve- hicle with a clearance above the starter motor. F mount the square fixture of the clutch hose in parallel wit...

Page 21: Spec

14 spec cable routing l pass this clamp through the low- er hole of the gusset and secure the clutch hose. The front end of the clamp must be directed towards the inside of the vehicle. M pass the main harness through the inside of the clutch hose and insert the harness into the left of the headligh...

Page 22: Spec

15 14 starter motor cable 15 thermoswitch 16 starter relay 17 rib of the rear fender 18 seat lock wire 19 positive (+) lead wire of the bat- tery 20 starter relay coupler 21 fuse box 22 negative (–) lead wire coupler of the battery 23 flasher relay 24 oil lamp relay 25 battery band a right horn. Ins...

Page 23: Spec

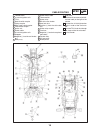

16 h pass the starter cable through the front of the throttle cable. I from left: #1, #2, #3, and #4 high-tension cords. J secure the wire harness and the starter cable, on the harness positioning tape, by use of this band. The front end of the band must be directed downward. The harness must not de...

Page 24: Spec

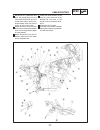

17 p store the wire harness, the tail- light lead wire, and the rear left and right flasher lead wires, into the space between the taillight bracket and the rib of the rear fender. Q the seat lock wire must not ex- tend to the outside of the brack- et. R pass the lead wire leading to the fuse box un...

Page 25: Spec

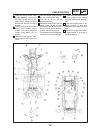

18 16 rear fender 17 rear left flasher lead wire 18 rear right flasher lead wire 19 wire harness a pass the throttle cable through the guide wire of the stay head- light. B insert the meter lead wire and the main switch lead wire into the upper hole of the headlight. 1 meter lead wire 2 main switch ...

Page 26: Spec

19 k the wire harness, the taillight lead wires, and the rear left and right flasher lead wires must be arranged below the rib of the rear fender. L clamp the wire harness and the rear left and right flasher lead wires. The front end of the clamp must be directed forward. M pass the rear left and ri...

Page 27: Chk

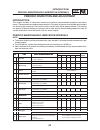

20 chk adj introduction/ periodic maintenance/lubrication intervals note: periodic inspection and adjustment introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more relia...

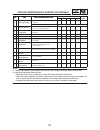

Page 28: Chk

21 note: chk adj periodic maintenance/lubrication intervals no item check or maintenance job odometer reading (" 1,000 km) annual no. Item check or maintenance job 1 10 20 30 40 check 15 * steering bearings ! Check bearing play and steering for roughness. √ √ √ √ √ g g ! Lubricate with lithium-soap-...

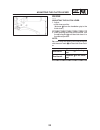

Page 29: Chk

22 adjusting the clutch lever chk adj note: a a engine eas00082 adjusting the clutch lever 1. Adjust: ! Clutch lever position (distance a from the handlebar grip to the clutch lever) a. While pushing the clutch lever forward, turn the adjusting dial 1 until the clutch lever is in the desired positio...

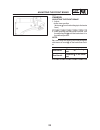

Page 30: Chk

23 adjusting the front brake chk adj note: a a eas00107 chassis adjusting the front brake 1. Adjust: ! Brake lever position (distance a from the throttle grip to the brake lever) a. While pushing the brake lever forward, turn the adjusting dial 1 until the brake lever is in the desired position. Be ...

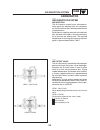

Page 31: Carb

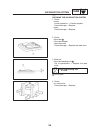

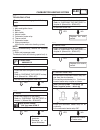

24 view 1. (no flow) view 2. (flow) air induction system carb carburetor eas00507 air induction system air injection the air induction system burns unburned ex- haust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pre...

Page 32: Carb

25 air induction system carb eas00509 air induction system diagrams 1 reed valve 2 air cleaner 3 air cutoff valve 4 vacuum hose (cylinder #3) a to the air cutoff valve b to cylinder #1 c to cylinder #2 d to cylinder #3 e to cylinder #4.

Page 33: Carb

26 air induction system carb eas00510 checking the air induction system 1. Check: ! Hoses loose connection ! Connect properly. Cracks/damage ! Replace. ! Pipes cracks/damage ! Replace. 2. Check: ! Fibre reed 1 ! Fibre reed stopper ! Reed valve seat cracks/damage ! Replace the reed valve. 3. Measure:...

Page 34: Chas

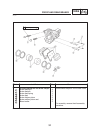

27 chas front and rear brakes order job/part q’ty remarks 1 2 3 4 5 6 7 removing the front brake master cylinder brake fluid brake lever brake switch lead front brake switch union bolt copper washers/brake hose master cylinder bracket master cylinder 1 2 1 1 3/2 1 1 remove the parts in the order lis...

Page 35: Chas

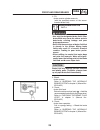

28 chas front and rear brakes warning note: warning caution: note: eas00598 assembling and installing the front brake master cylinder ! Before installation, all internal brake com- ponents should be cleaned and lubricated with clean or new brake fluid. ! Never use solvents on internal brake com- pon...

Page 36: Chas

29 chas front and rear brakes warning caution: 3. Fill: ! Brake master cylinder reservoir (with the specified amount of the recom- mended brake fluid) recommended brake fluid dot 4 ! Use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage an...

Page 37: Chas

30 front and rear brakes chas order job/part q’ty remarks 1 2 3 4 removing the rear brake caliper brake fluid union bolt copper washer brake hose brake caliper 1 2 1 1 remove the parts in the order listed. Drain. For installation, reverse the removal procedure. 40 nm (4.0 m!Kg) 30 nm (3.0 m!Kg) eas0...

Page 38: Chas

31 front and rear brakes chas order job/part q’ty remarks disassembling the rear brake caliper brake pad clip brake pad pin brake pad spring brake pad brake caliper piston brake caliper piston seal bleed screw 4 2 1 2 2 4 2 disassemble the parts in the order listed. For assembly, reverse the disasse...

Page 39: Elec

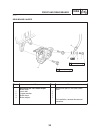

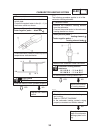

32 2 fuse (main) 3 battery 5 main switch 6 fuse (ignition) 14 neutral switch 51 carburetor heater relay 52 thermo switch 53 carburetor heater carburetor heating system elec electrical carburetor heating system.

Page 40: Elec

33 ! Check the condition of the battery. Refer to “checking the battery” in chapter 3. (manual no.: 5ea3-ae1) eas00738 1. Main, and ignition fuses ! Check the main and ignition fuses for conti- nuity. Refer to “checking the fuses” in chap- ter 3. (manual no.: 5ea3-ae1) ! Are the main and ignition fu...

Page 41: Elec

34 yes no 6. Thermo switch ! Remove the thermo switch from the thermo switch plate. ! Connect the pocket tester to the ( Ω " 1) to the thermo switch as shown. Tester positive probe ! Black tester negative probe ! Black/red replace the thermo switch. ! Check the thermo switch for continuity at the te...

Page 43

Color code b black . . . . . Br brown . . . . Ch chocolate . . . Dg dark green . . . G green . . . . Gy gray . . . L blue . . . . . Lg light green . . . . O orange . . . . Sb sky blue . . . . P pink . . . . . R red . . . . . Y yellow . . . . . B/l black/blue . . . B/r black/red . . B/y black/yellow ...

Page 44

Color code b black . . . . . Br brown . . . . Ch chocolate . . . Dg dark green . . . G green . . . . Gy gray . . . L blue . . . . . Lg light green . . . . O orange . . . . Sb sky blue . . . . P pink . . . . . R red . . . . . Y yellow . . . . . B/l black/blue . . . B/r black/red . . B/y black/yellow ...