Summary of 2002 YFA1

Page 1

Yfa1 ( p ) supplementary service manual 3fa-ae1 2002.

Page 3: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and new data for the yfa1(p) 2002. For complete information on service procedures, it is necessary to use this sup- plementary service manual together with the following manual. Yfa1w service manual: 3fa-me1 yfa1(p...

Page 4: Notice

Eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on y...

Page 5: How to Use This Manual

How to use this manual construction of this manual this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1: this is a chapter with its symbol on the upper right of each page. 2nd title 2: this title appears on the upper of each page on the left o...

Page 6: Illustrated Symbols

Eb003000 illustrated symbols illustrated symbols 1 to 9 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 carburetion 6 drive train 7 chassis 8 electrical 9 troubleshooting illustrat...

Page 7: Contents

Contents general information ..............................................................................1 machine identification ....................................................................1 model label .....................................................................................1...

Page 9: Gen

– 1 – gen info machine identification general information machine identification model label the model label 1 is affixed to the frame. This information will be needed to order spare parts..

Page 10: Spec

– 2 – spec general specifications specifications general specifications model yfa1 (p) 2002 model code number 3fay (cdn, europe and oceania) engine: engine type air-cooled 4-stroke, sohc cylinder arrangement forward-inclined single cylinder displacement 124 cm 3 bore × stroke 49 × 66 mm (1.93 × 2.60...

Page 11: Spec

– 3 – spec maintenance specifications maintenance specifications engine model yfa1 (p) 2002 cylinder: bore size 48.99 ~ 49.03 mm (1.9287 ~ 1.9303 in) measuring point “ * ” 45 mm (1.77 in) camshaft: drive method chain drive (left) cam dimensions intake “a” 26.169 ~ 26.269 mm (1.0303 ~ 1.0342 in) “b” ...

Page 12: Spec

– 4 – spec maintenance specifications inside diameter (valve guide) intake 5.000 ~ 5.012 mm (0.197 in) exhaust 5.000 ~ 5.012 mm (0.197 in) stem-to-guide clearance intake 0.010 ~ 0.037 mm (0.004 ~ 0.0014 in) exhaust 0.025 ~ 0.052 mm (0.0010 ~ 0.0020 in) stem runout limit 0.01 mm (0.0004 in) valve sea...

Page 13: Spec

– 5 – spec maintenance specifications chassis side clearance top ring 0.03 ~ 0.07 mm (0.0012 ~ 0.0027 in) second ring 0.02 ~ 0.06 mm (0.0008 ~ 0.0024 in) carburetor: i.D. Mark 3fa02 main jet (m.J.) #82.5 main air jet (m.A.J.) ø1.3 jet needle (j.N.) 4h36-3 needle jet (n.J.) n-6 cutaway (c.A.) 2.5 pil...

Page 14: Spec

– 6 – spec maintenance specifications electrical drive chain: type/manufacturer 520v6/daido number of links 74 links chain slack 30 mm (1.18 in) 10-link length limit 150.1 mm (5.909 in) brake lever: free play front brake 5 ~ 8 mm (0.20 ~ 0.31 in) at lever pivot. Rear brake 5 ~ 8 mm (0.20 ~ 0.31 in) ...

Page 15: Spec

– 7 – spec maintenance specifications rectifier/regulator: model/manufacturer ehu–01tr31/matsushita regulator type semi conductor short circuit type no load regulated voltage (dc) 14.0 ~ 15.0 v no load regulated voltage (ac) 13.0 ~ 14.0 v rectifier capacity (dc) 8.0 a rectifier capacity (ac) 8.0 a w...

Page 16: Spec

– 8 – spec cable routing 1 throttle cable 2 band 3 breather hose 4 rear brake switch lead 5 rear brake cable 6 front brake cable 7 front brake switch lead cable routing.

Page 17: Spec

– 9 – spec 1 front brake cable 2 band 3 rear brake cable 4 rear brake switch lead 5 cdi unit 6 wire harness 7 main switch 8 front brake switch lead È pass leads in front of the brake cable and con- nect them inside the headlight body. É pass the inlet and outlet hoses between the brake cables. Ê cla...

Page 18: Spec

– 10 – spec 1 throttle cable 2 rectifier/regulator 3 starting motor 4 cdi magneto lead 5 clamp 6 ignition coil È fasten the wire harness, starting motor lead and transmission case breather hose to the frame with a plastic band. Cable routing.

Page 19: Spec

– 11 – spec 1 taillight 2 reverse relay 3 starting circuit cut-off relay 4 fuse holder 5 starter relay 6 wire harness 7 breather hose (transmission case) 8 neutral switch lead 9 select lever switch 0 overflow hose a battery breather hose b band c battery negative lead d reverse switch lead È hold th...

Page 20: Spec

– 12 – spec 1 inlet hose 2 outlet hose 3 fuel hose 4 breather hose (crankcase) 5 overflow hose 6 guide 7 rear brake cable 8 front brake cable (left) 9 front brake cable (right) 0 cdi unit a band È pass the breather hose through the hole of han- dlebar cover and then between the steering col- umn and...

Page 21: Spec

– 13 – spec 1 cdi unit 2 band 3 starter cable 4 wire harness 5 breather hose (transmission case) 6 ignition coil 7 battery positive lead 8 battery negative lead 9 breather hose (crankcase) 0 throttle cable a fuse holder b starting circuit cut-off relay c reverse relay È pass the breather hose betwee...

Page 22: Chk

– 14 – chk adj introduction/ periodic maintenance/lubrication intervals eb300000 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more r...

Page 23: Chk

– 15 – chk adj adjusting the front brake chassis adjusting the front brake 1.Check: ● front brake lever free play a out of specification → adjust. 2.Adjust: ● front brake lever free play *********************************************** ● loosen the locknut 1. ● turn the adjuster 2 in or out until the...

Page 24: Chas

– 16 – chas steering system chassis steering system 1 handlebar holder (upper) 2 handlebar holder (lower) 3 steering column 4 cable joint 5 cable joint bracket 6 collar 7 steering bracket 8 oil seal 9 steering bracket 0 steering knuckle a tie-rod.

Page 25: Elec

– 17 – – + elec checking the switch electrical checking the switch checking the switch use a pocket tester to check the terminals for continuity. If the continuity is faulty at any point, replace the switch. Note: ● set the pocket tester to “0” before starting the test. ● the pocket tester should be...

Page 26: Elec

– 18 – – + elec signal system eb806000 signal system circuit diagram off lo hi ru n off off push on off w /l w /r w /l w /r g /w r /b g /y o o b b w y r r br y /r r /b br l r /w w y /r r bw yr wb ry /r w /lw /r w /rw /l rb r br l r /wb y /r r /b lb r br /w y /r r /b br g /y yb g /yb r by b (gra y) y...

Page 27: Elec

– 19 – – + elec signal system checking the signal system 1.If the tail/brake light fails to come on: continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. No continuity replace the bulb and/or bulb socket. Continuity 2.Brake light switches refer to “checking the switch...

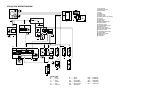

Page 29: Yfa1(P) 2002 Wiring Diagram

Yfa1(p) 2002 wiring diagram off lo hi run off off push on off w/l w/r w/l w/r g/w r/b g/y o o b b w y r r br y/r r/b br l r/w w y/r r b w y r w b r y/r w/l w/r w/r w/l r br br l r/w b y/r r/b l br b r/w y/r r/b br g/y y b g/y br b y b (gray) y br (gray) (red) (gray) b b b w/r w/l g/w r/b b o g/y r/w...